Capacitive flexible pressure sensor and preparation method thereof

A pressure sensor and capacitive technology, applied in the field of capacitive flexible pressure sensor and its preparation, can solve the problems of difficult and large-area production, complexity, and complicated production process, and achieve the effects of good air permeability, high sensitivity, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

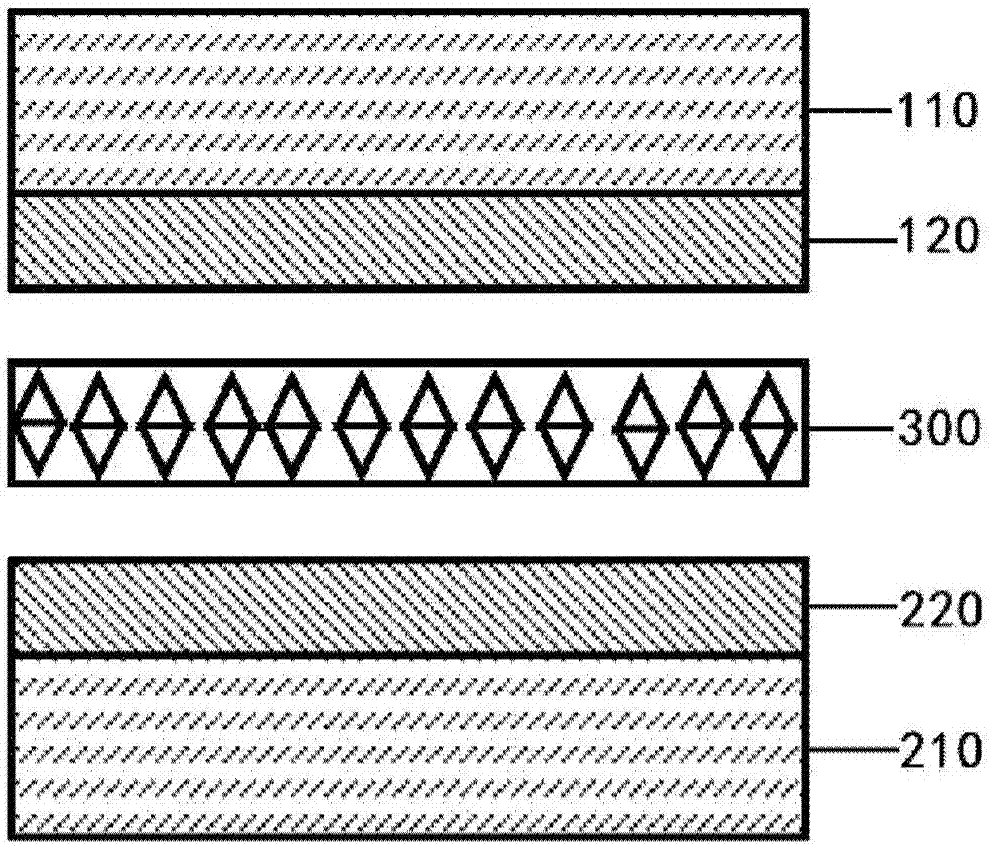

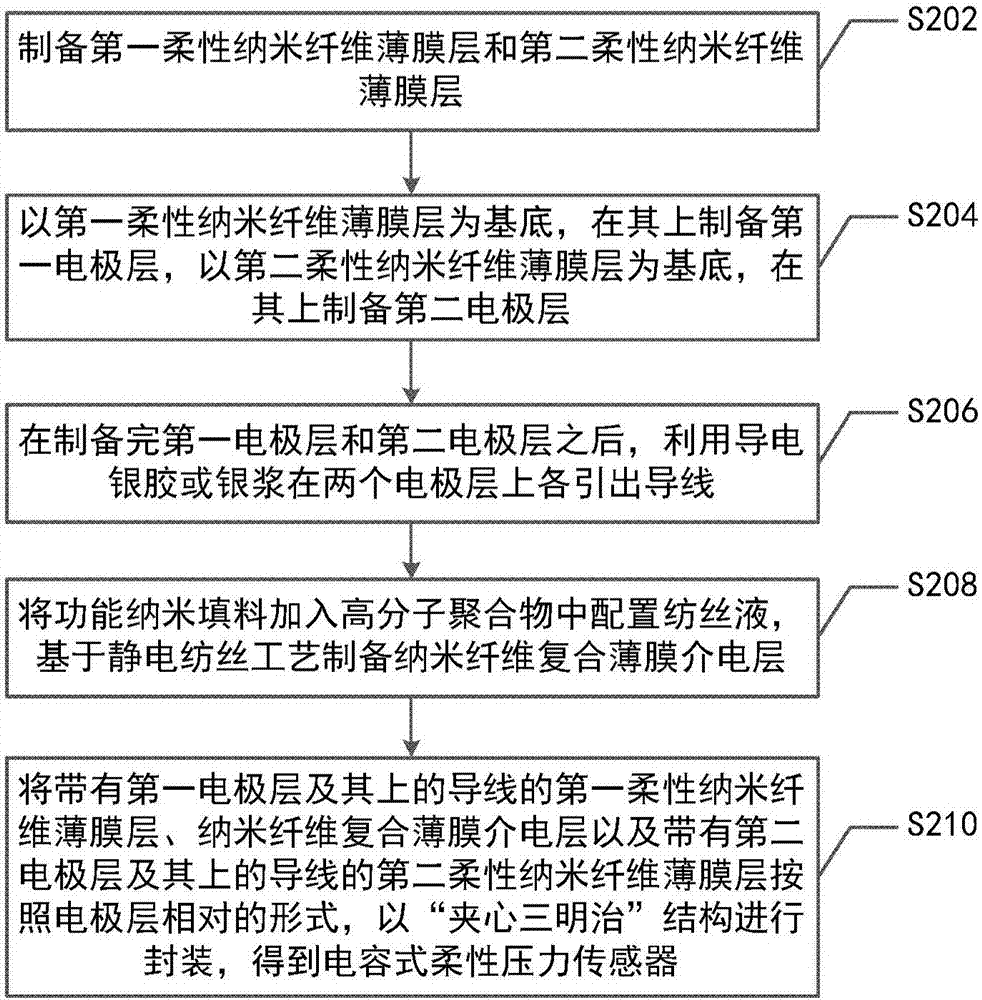

[0052] figure 2 It is a flowchart of a method for preparing a capacitive flexible pressure sensor according to an embodiment of the present disclosure. Such as figure 2 As shown, the preparation method of the disclosed capacitive flexible pressure sensor includes:

[0053] Step S202: preparing a first flexible nanofiber film layer and a second flexible nanofiber film layer based on an electrospinning process;

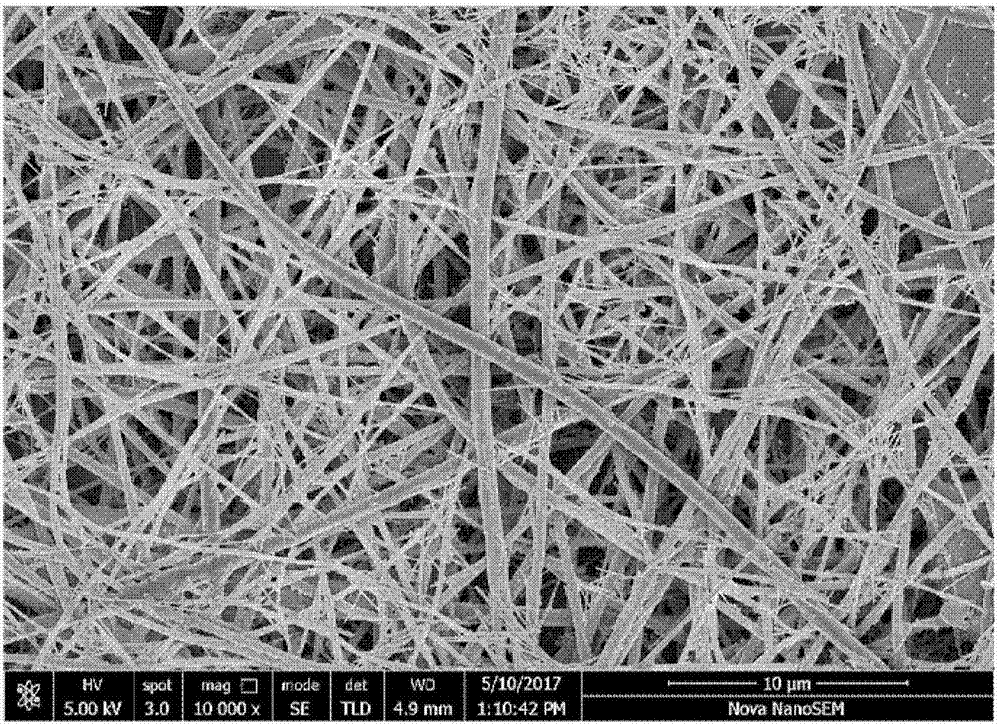

[0054] The method for preparing the first flexible nanofiber film layer and the second flexible nanofiber film layer is as follows: configure the electrospinning solution; use the spinning device and the configured electrospinning solution to spin to obtain the flexible nanofiber film layer; The obtained flexible nanofiber film layer is dried, and the spinning solvent is volatilized to obtain the first flexible nanofiber film layer and the second flexible nanofiber film layer.

[0055] This embodiment is illustrated by taking the preparation of the first flexible n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com