Polyimide nanofiber membrane with surface coated with nano titanium dioxide and preparation method for polyimide nanofiber membrane

A nano-titanium dioxide, nano-fiber membrane technology, applied in fiber processing, fiber chemical characteristics, spinning solution preparation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

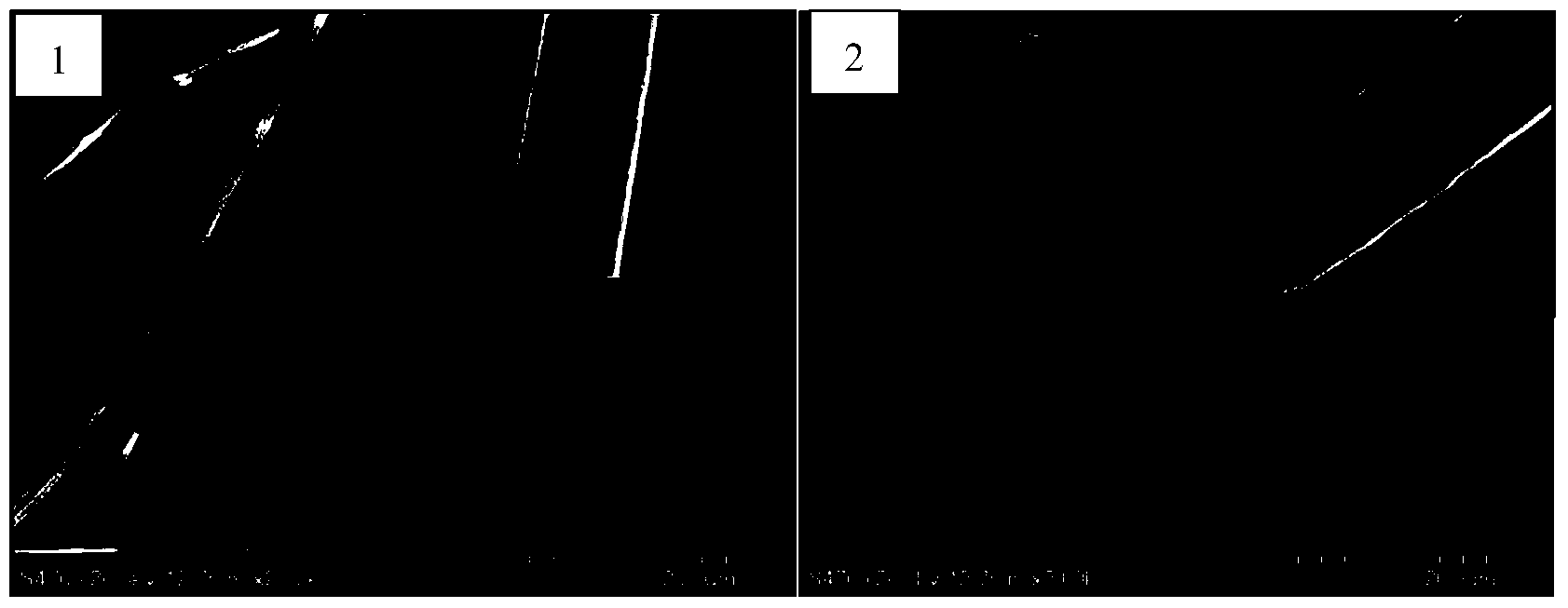

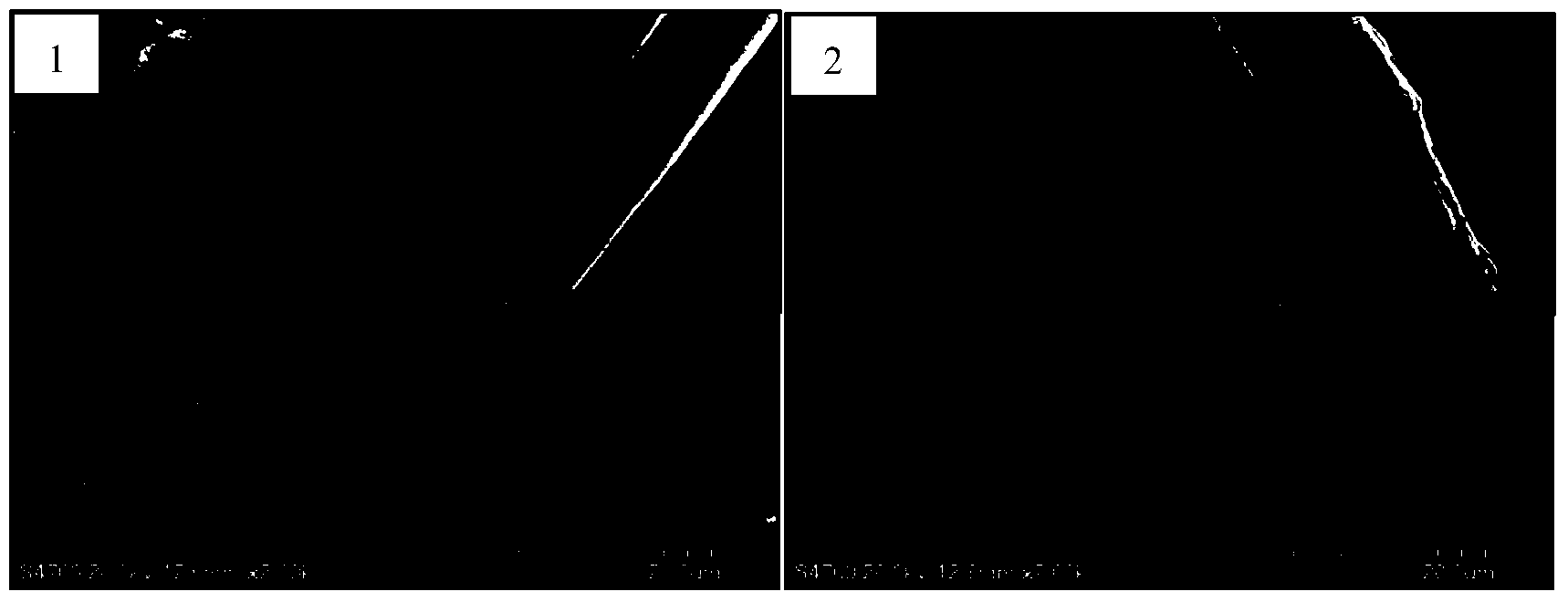

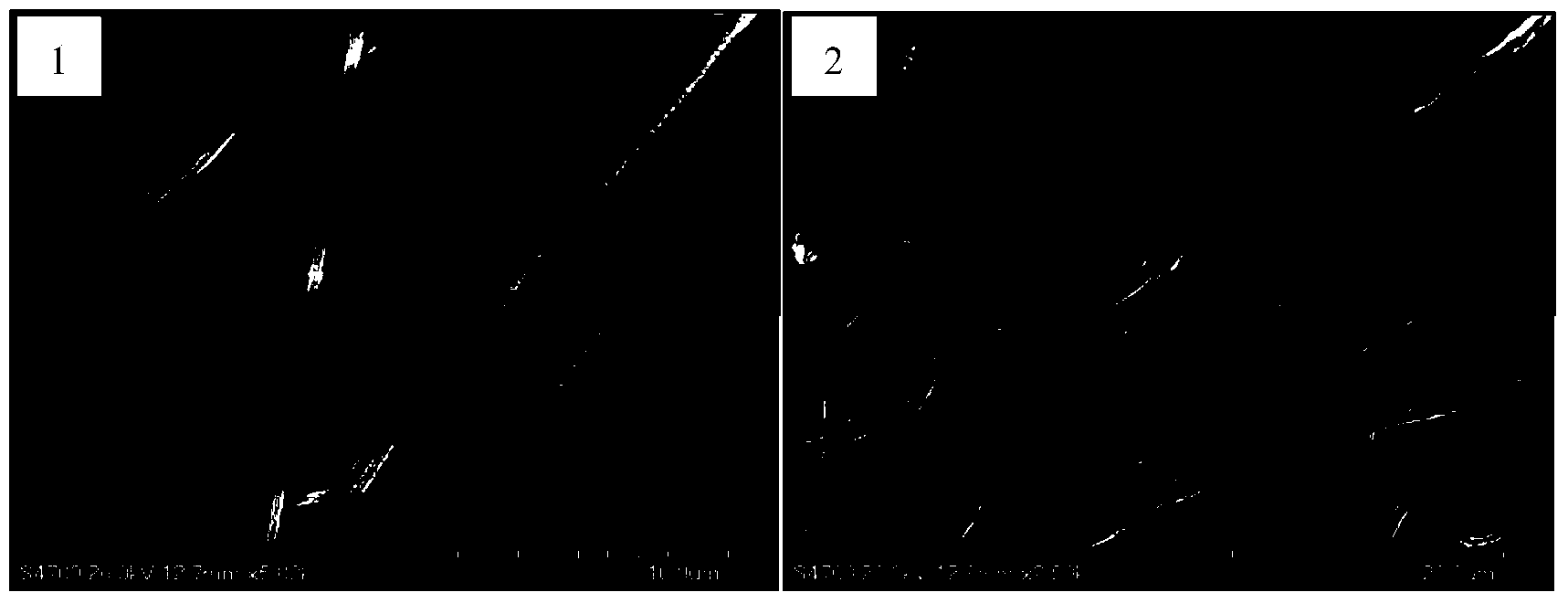

Image

Examples

Embodiment 1

[0033] Preparation of PMDA / ODA system polyamic acid nanofiber membrane soaked in titanium dioxide sol diluted 3 times, dried, and thermal imidization to obtain polyimide and titanium dioxide composite nanofiber membrane. (1) Weigh 2.0g of pyromellitic dianhydride (PMDA) and 1.8g of 4,4`-diaminodiphenyl ether (ODA) with a molar ratio of 1:1, and dissolve all ODA in 30ml of N,N ‐Dimethylformamide (DMF) solvent, stirring mechanically, after ODA is completely dissolved in DMF, under the condition of ice-water bath, add PMDA step by step, after obtaining a polyamic acid solution with moderate viscosity, stir mechanically for 2 hours, then put The polyamic acid solution was put into a 20ml syringe, and the polyamic acid nanofiber film was prepared by electrospinning technology. The specific parameters of the electrospinning machine were spinning voltage: 15.34kV; spinning temperature: room temperature; spinning humidity: 30 %; Syringe needle diameter: No. 12; Receiving roller speed:...

Embodiment 2

[0035] Preparation of PMDA / 6FDA / ODA system polyamic acid nanofiber membrane soaked in 1-fold diluted titanium dioxide sol, dried, and thermal imidization to obtain polyimide and titanium dioxide composite nanofiber membrane. (1) Weigh 1.0g of pyromellitic dianhydride (PMDA), 2.1g of 4,4`-(hexafluoroethylene propylene) diphthalic anhydride (6FDA), 4,4` -Diaminodiphenyl ether (ODA) 1.9g, dissolve all ODA in 30ml of N,N‐dimethylformamide (DMF) solvent, stir mechanically, wait until ODA is completely dissolved in DMF, under the condition of ice water bath , first add 6FDA step by step, then add PMDA step by step, after obtaining a polyamic acid solution with moderate viscosity, after mechanical stirring for 2 hours, put the polyamic acid solution into a 20ml syringe, and use electrospinning technology to prepare polyamic acid Nanofiber membrane, electrospinning machine specific parameters are spinning voltage: 16.78kV; spinning temperature: room temperature; spinning humidity: 33%...

Embodiment 3

[0037] Preparation of 6FDA / ODA system polyamic acid nanofiber membrane soaked in 0-fold diluted titanium dioxide sol, dried, and thermal imidization to obtain a composite nanofiber membrane of polyimide and titanium dioxide. (1) Weigh 3.4g of 4,4`-(hexafluoroethylenepropylene) diphthalic anhydride (6FDA) and 1.5g of 4,4`-diaminodiphenyl ether (ODA) with a molar ratio of 1:1, and mix the ODA Dissolve all in 30ml of N,N‐dimethylformamide (DMF) solvent, stir mechanically, after ODA is completely dissolved in DMF, add 6FDA step by step under the condition of ice-water bath to obtain polyamic acid solution with moderate viscosity Finally, after mechanical stirring for 2 hours, the polyamic acid solution was put into a 20ml syringe, and the polyamic acid nanofiber film was prepared by electrospinning technology. The specific parameters of the electrospinning machine were spinning voltage: 17.62kV; spinning temperature : Room temperature; Spinning humidity: 35%; Syringe needle diamet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com