Nanofiber membrane and preparation method thereof, nanofiber composite and preparation method thereof

A technology of nanofiber membranes and nanomaterials, applied in the fields of its preparation, nanofiber composite materials, and nanofiber membranes, can solve the problems of low porosity, limited ability to purify toxic gases, complex manufacturing process, etc., and achieve a good effect of purifying air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention also provides a kind of preparation method of nanofiber membrane, comprises the following steps:

[0044] A) mixing a polymer and a nanomaterial to obtain a mixture, the nanomaterial comprising a photocatalyst and an adsorbent;

[0045] B) spinning the mixture to obtain a nanofibrous membrane.

[0046] When the spinning method adopts electrospinning, the present invention preferably prepares nanofibrous membrane according to the following steps:

[0047] dissolving the polymer and the nanomaterial in a solvent to obtain a mixture;

[0048] The mixture was electrospun to obtain a nanofibrous membrane.

[0049] In the present invention, the polymer is preferably first dried to obtain a first dried polymer, and the first dried polymer and nanomaterials are dissolved in a solvent to obtain a mixture. In the present invention, the first drying temperature is preferably 60-160°C, more preferably 70-155°C, most preferably 80-150°C; the first drying tim...

Embodiment 1

[0092] Dry the PVDF powder and PVDF-HFP powder in a vacuum drying oven at 100°C for 12 hours, then cool to room temperature, and put them into a desiccator for later use.

[0093] Weigh 120g dry PVDF powder and dissolve it in the mixed solvent of 880g acetone and DMF, stir at room temperature for 12h to obtain a transparent PVDF spinning solution; disperse 6g nano activated carbon in the obtained PVDF spinning solution, and mix the obtained mixed solution After the ultrasonic dispersion is uniform, the PVDF spinning solution is obtained and set aside.

[0094] Take by weighing 120g dry PVDF-HFP powder and be dissolved in 880g DMF and acetone mixed solvent, stir 12h at room temperature, obtain PVDF-HFP spinning solution, disperse 5g nano titanium dioxide in the PVDF-HFP spinning solution that obtains, will get After ultrasonic dispersion of the mixed solution for 6 hours, the PVDF-HFP spinning solution was obtained and set aside.

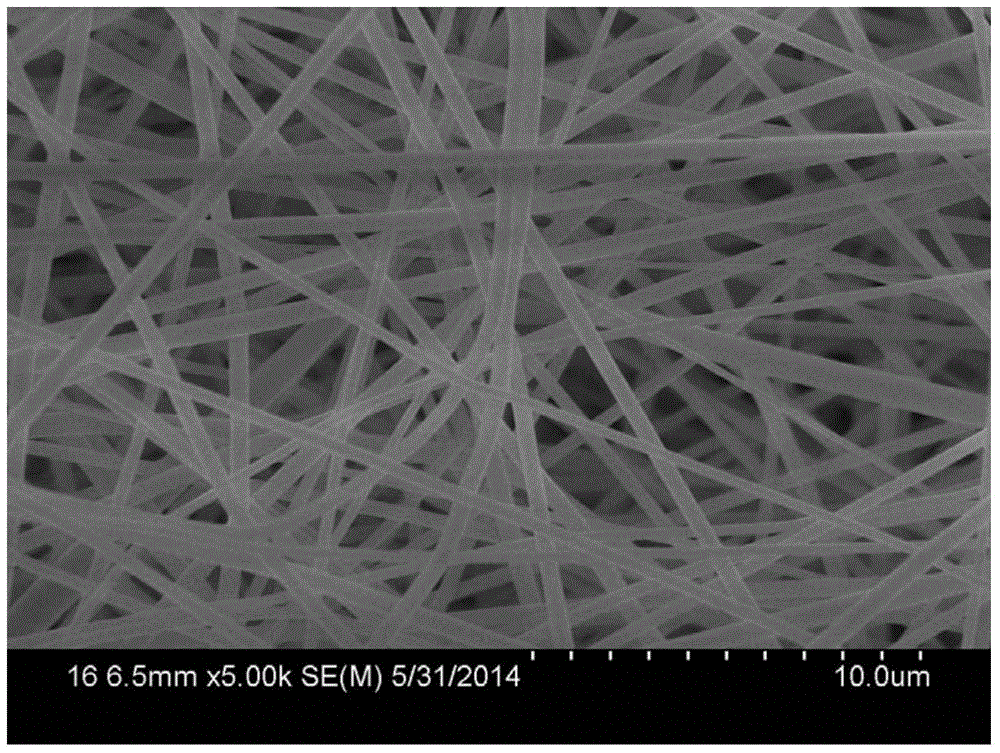

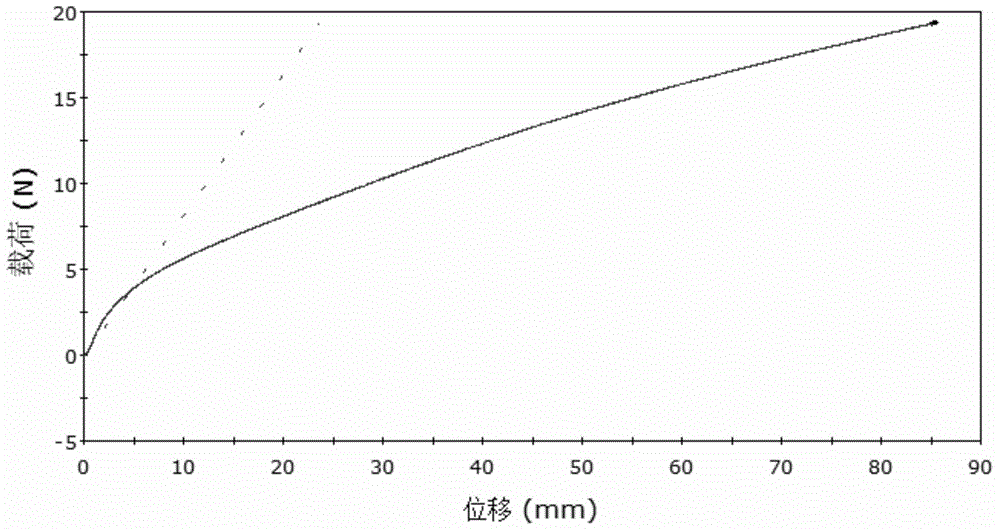

[0095] The viscosities of the obtained PVDF s...

Embodiment 2

[0109] Put the PET powder and PVDF powder in a vacuum drying oven at 100°C for 12 hours, cool to room temperature, and put them in a desiccator for later use.

[0110] Weigh 150g of dry PET powder and dissolve it in a mixed solvent of 850 trifluoroacetic acid and dichloromethane, stir at room temperature for 12h to obtain a transparent PET spinning solution, add 10g of nano-aluminum hydroxide, 9g of nano-activated carbon, and disperse evenly , put it aside for later use;

[0111] Weigh 120g of dry PVDF powder and dissolve it in 880g of DMF and acetone mixed solvent, stir at room temperature for 12h to obtain a PVDF spinning solution, add 6g of nano titanium dioxide, disperse evenly, and let it stand for later use.

[0112] The measured solution viscosities of PET spinning solution and PVDF spinning solution are 2.8Pa·s and 3.1Pa·s respectively.

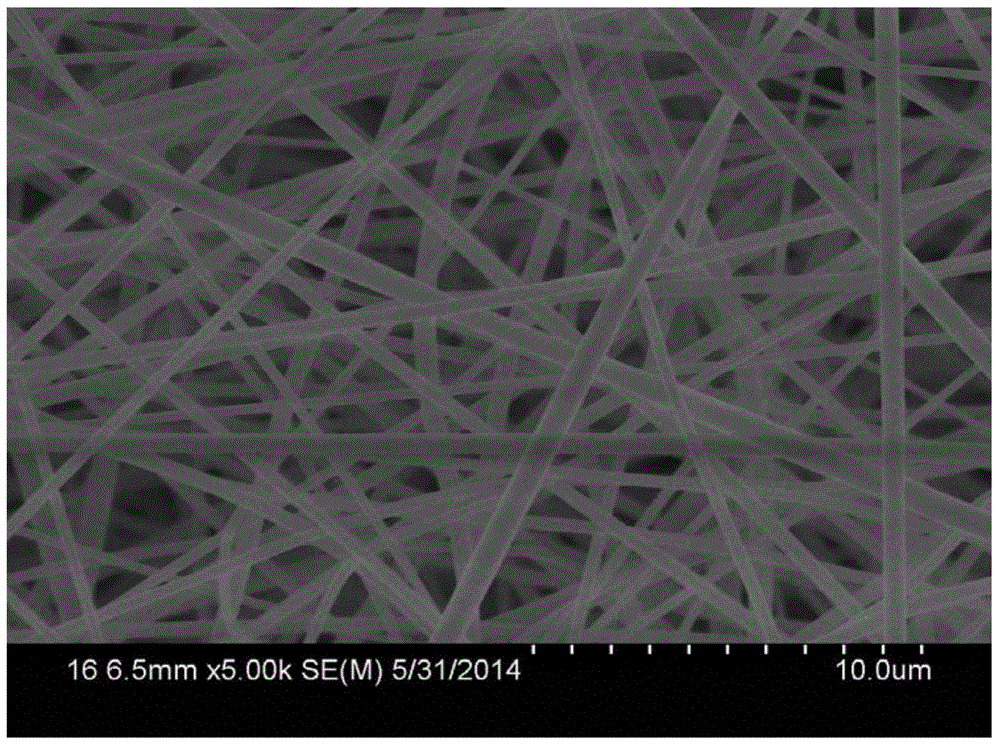

[0113] At a room temperature of 25°C and a relative air humidity of about 30%, the PET spinning solution is mixed and cross-spun th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com