Method for preparing nano fiber reinforcement toughening resin base composite material

A technology of nanofibers and composite materials, applied in fiber processing, filament/thread forming, textiles and papermaking, etc., can solve the problems of poor interfacial compatibility of nanofiber-reinforced resin-based composite materials, and achieve easy popularization and application and improve electrical conductivity and heat conduction, the effect of improving the interface performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

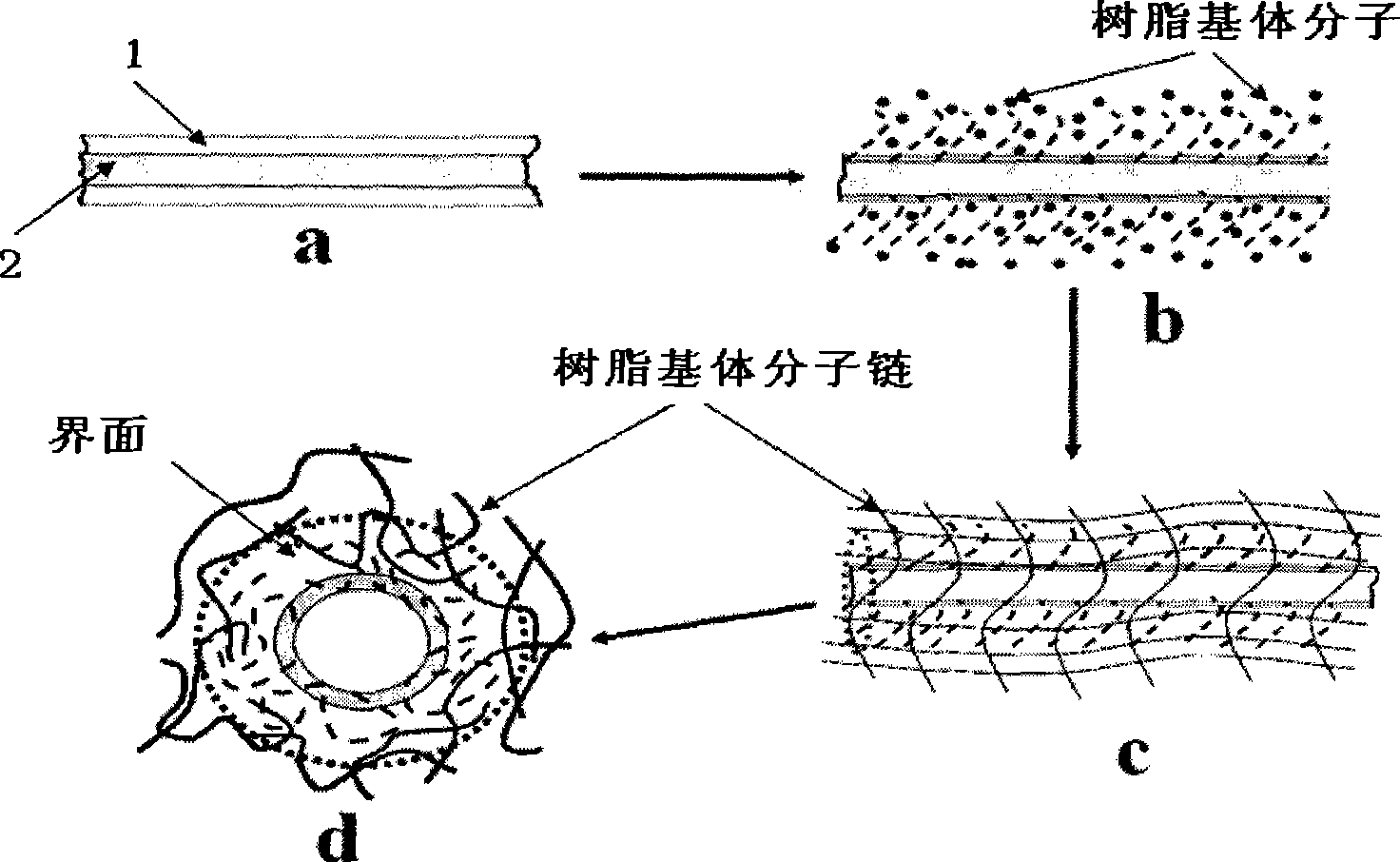

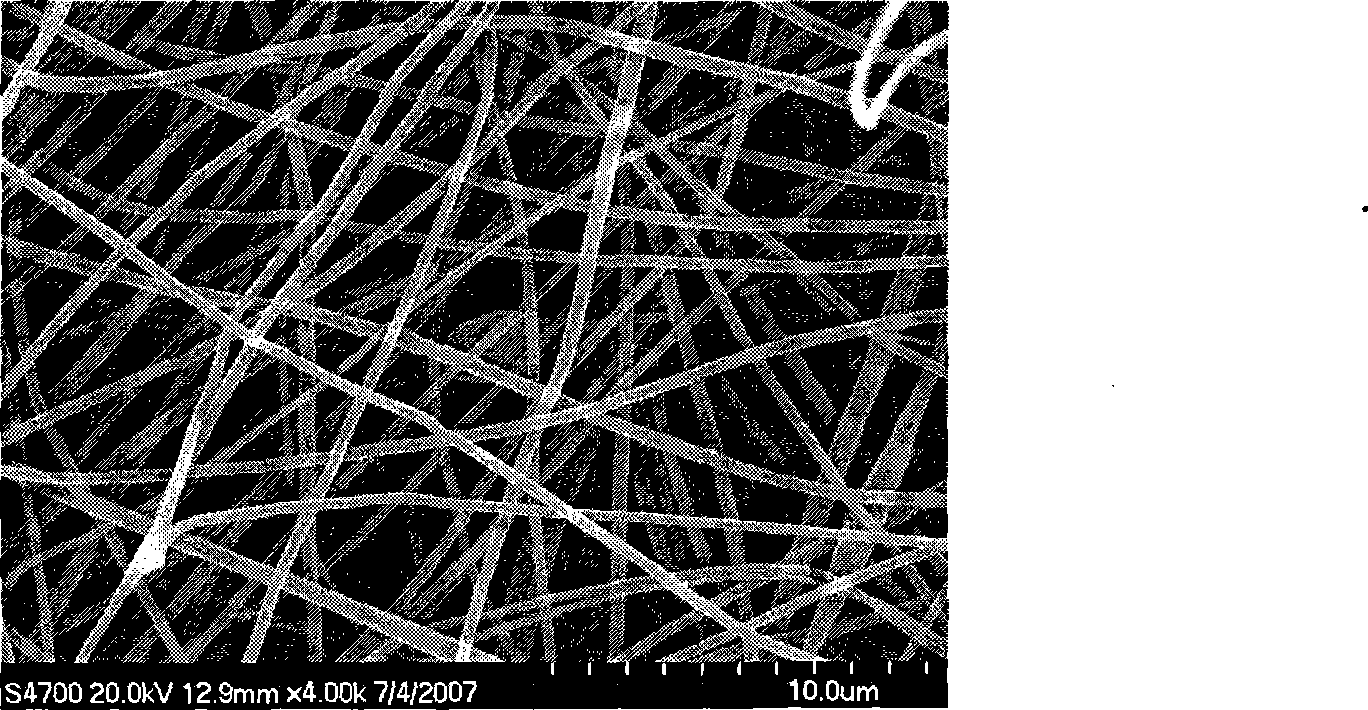

[0027] Example 1: Polymethyl methacrylate (PMMA) and polyacrylonitrile (PAN) were selected to prepare shell-core structure PMMA / PAN nanofibers. PMMA is Korean Atofina V020 (molecular weight 50000g / mol), and PAN is selected from British Courtaulds Ltd company (molecular weight 100000g / mol). 1.2g PAN is dissolved in dimethylformamide (DMF) of 10ml, and the viscosity is 598.4mPa. s, 1.2g PMMA is dissolved in 10ml of DMF, the viscosity is 100mPa.s. The two solutions are fully stirred and mixed. The viscosity of the mixed solution is 306.5mPa.s. It is used for electrospinning, and the spun silk is a shell-core structure nanofiber. PAN is located in the core structure, and PMMA is located in the shell structure, such as figure 2 shown.

Embodiment 2

[0028] Example 2: The raw materials are the same as in Example 1, 1.6g PAN is dissolved in 10ml of DMF with a viscosity of 718.4mPa.s, 0.8gPMMA is dissolved in 10ml of DMF with a viscosity of 48.6mPa.s. The two solutions are fully stirred and mixed. The viscosity of the mixed solution is 356.5mPa.s. It is used for electrospinning, and the spun silk is a shell-core structure nanofiber. PAN is located in the core structure and PMMA is located in the shell structure.

Embodiment 3

[0029] Example 3: The raw materials are the same as in Example 1, 1.8g PAN is dissolved in 10ml of DMF with a viscosity of 816.4mPa.s, 0.6gPMMA is dissolved in 10ml of DMF with a viscosity of 35.6mPa.s. The two solutions are fully stirred and mixed. The viscosity of the mixed solution is 412.5mPa.s. It is used for electrospinning, and the spun silk is a shell-core structure nanofiber. PAN is located in the core structure and PMMA is located in the shell structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com