A coating-encapsulated thin-film solar cell and its forming method

A technology of solar cells and thin films, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems of ethylene-tetrafluoroethylene copolymer films without heat sealing performance, poor component compatibility, and high technical requirements, and achieve fast and effective Encapsulation process, good product performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

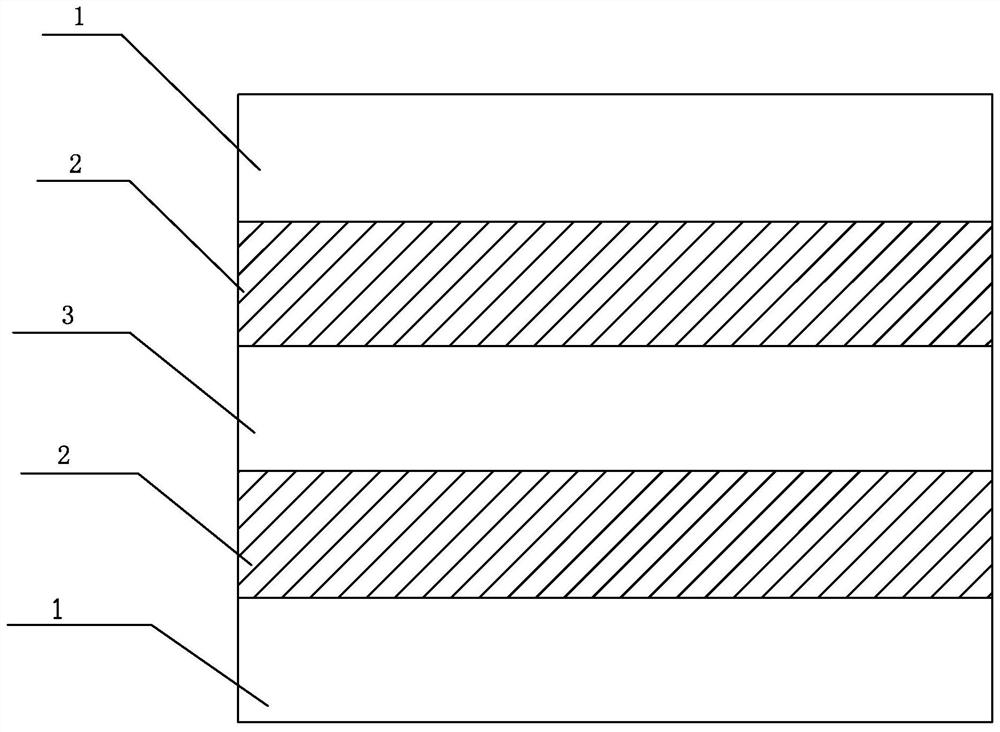

Image

Examples

Embodiment 1

[0030] A method for forming a thin-film solar cell encapsulated by a paint, comprising the following steps:

[0031] (1) Spray the mixed powder of ETFE and PTFE (the mass ratio of ETFE and PTFE is 99:1) on the polycrystalline silicon thin film solar cell by electrostatic spraying process, and then put it into an oven at 250°C for plasticization to obtain astigmatism on the surface layers of solar cells;

[0032] (2) Spray ETFE powder on the solar cell with a light-scattering layer obtained in step (1) by electrostatic spraying process, then bake at 250° C. and cool to obtain a coating-encapsulated thin-film solar cell.

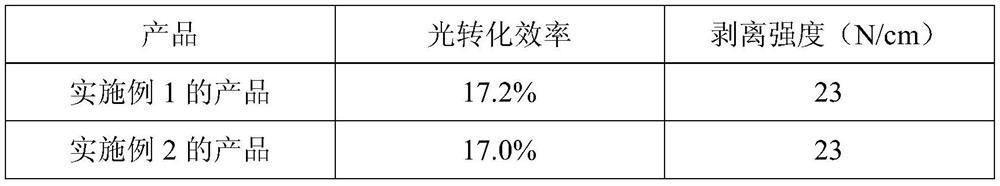

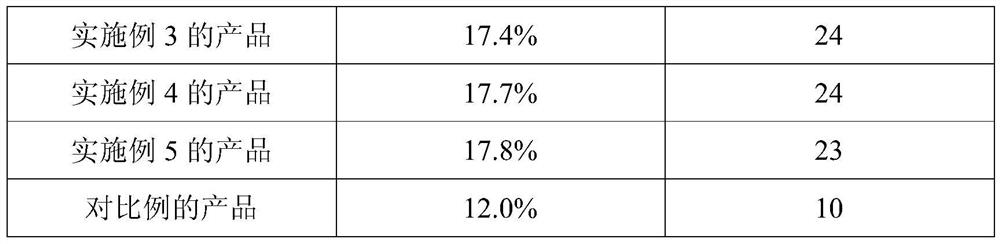

[0033] Results: The thickness of the encapsulation layer of the prepared coating-encapsulated thin-film solar cell product is 50 microns, and the thickness of the scattering layer is 10 microns. The properties are shown in Table 1.

Embodiment 2

[0035] A method for forming a thin-film solar cell encapsulated by a paint, comprising the following steps:

[0036] (1) Spray the mixed powder of ETFE and FEP (the mass ratio of ETFE and FEP is 95:5) on the polysilicon thin film solar cell by electrostatic spraying process, and then put it into an oven at 270°C for plasticization to obtain a surface with Solar cells in the light-scattering layer;

[0037] (2) The ETFE powder is sprayed on the solar cell with a light-scattering layer obtained in step (1) by an electrostatic spraying process, and then baked at 270° C. and then cooled to obtain a coating-encapsulated thin-film solar cell.

[0038] Results: The thickness of the encapsulation layer of the prepared coating-encapsulated thin-film solar cell product was 80 microns, and the thickness of the scattering layer was 20 microns. The properties are shown in Table 1.

Embodiment 3

[0040] A method for forming a thin-film solar cell encapsulated by a paint, comprising the following steps:

[0041] (1) The mixed powder of ETFE and FEP (the mass ratio of ETFE and FEP is 90:10) is sprayed on polycrystalline silicon thin film solar cells by electrostatic spraying process, and then put into an oven at 300°C for plasticization to obtain astigmatism on the surface layers of solar cells;

[0042] (2) Spray ETFE powder on the solar cell with a light-scattering layer on the surface obtained in step (1) by using an electrostatic spraying process, then bake at 300° C. and cool to obtain a coating-encapsulated thin-film solar cell.

[0043] Results: The thickness of the encapsulation layer of the prepared coating-encapsulated thin-film solar cell product is 100 microns, and the thickness of the scattering layer is 30 microns. The properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com