A preparation method of dopamine surface functionalized expandable graphite flame retardant epoxy resin

A technology of epoxy resin preparation and surface functionalization, applied in the field of flame retardant preparation and polymer material modification, can solve problems such as poor interface compatibility and uneven dispersion, and achieve improved dispersion, strong controllability, The effect of ideal interface combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Preparation of epoxy resin

[0032] a Weigh 187.5g of epoxy resin and add it to a beaker, and stir for 10min at a speed of 500r / min in a constant temperature water bath at 60°C;

[0033] b Take by weighing 62.5g curing agent and join in above-mentioned epoxy resin, continue to stir 10min at room temperature, then put into vacuum oven and carry out vacuum defoaming treatment, carry out injection molding after defoaming finishes;

[0034] c Pre-cure the injected mold at room temperature for 12 hours. After the pre-curing is completed, put it into an electric blast drying oven with a temperature set at 120°C for high-temperature curing for 4 hours. After the high-temperature curing is completed, cool to room temperature to obtain epoxy resin (EP) Test splines.

[0035] According to the GB / T 2406.2-2009 method, the oxygen index of the prepared epoxy resin was 20.4%.

[0036] According to GB / T 2408-2008, the prepared epoxy resin was tested for its vertical combustion r...

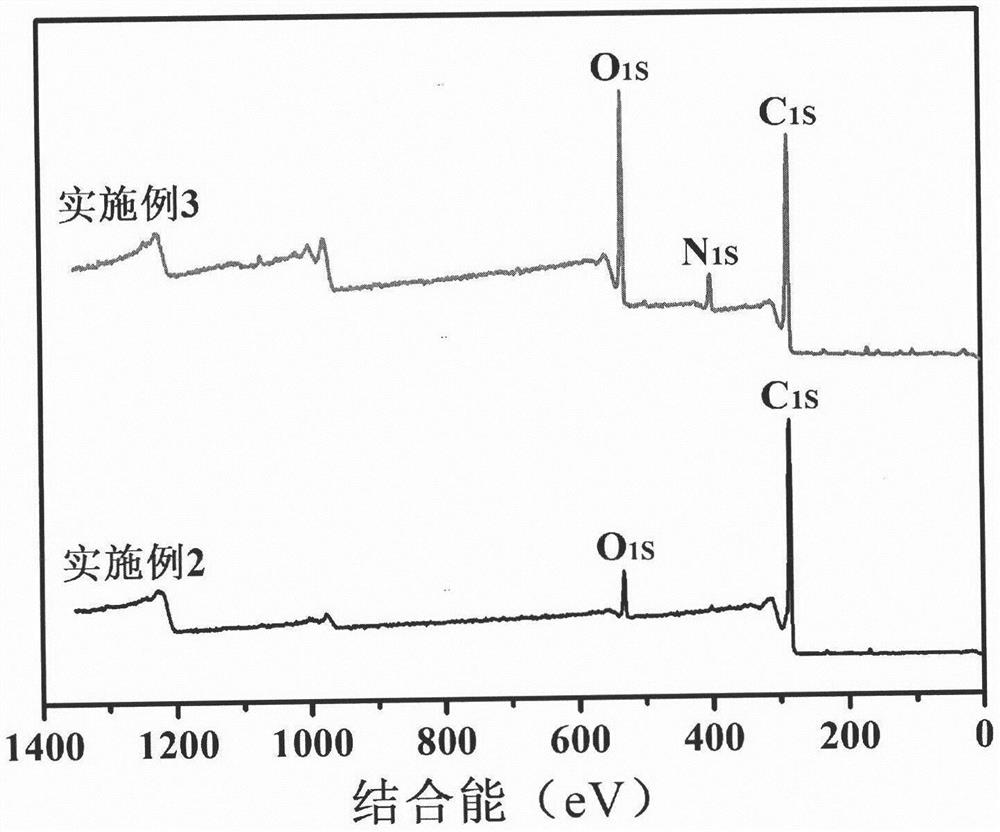

Embodiment 2

[0038] (1) Preparation of expandable graphite flame retardant epoxy resin composites

[0039]a Weigh 25g of expandable graphite and add it to 168.75g of epoxy resin, stir at a speed of 500r / min for 10min in a constant temperature water bath at 60°C and mix evenly;

[0040] b Take by weighing 56.25g curing agent and join in above-mentioned epoxy resin, continue to stir 10min at room temperature, then put into vacuum oven and carry out vacuum defoaming treatment, carry out injection molding after defoaming finishes;

[0041] c. Pre-cure the injected mold at room temperature. After the pre-curing is completed, put it into an electric blast drying oven with a temperature set at 120°C for high-temperature curing. After the high-temperature curing is completed, cool to room temperature to obtain an expandable graphite flame-retardant Epoxy composite (EG / EP) test strips.

[0042] The oxygen index of the prepared expandable graphite flame-retardant epoxy resin composite material was ...

Embodiment 3

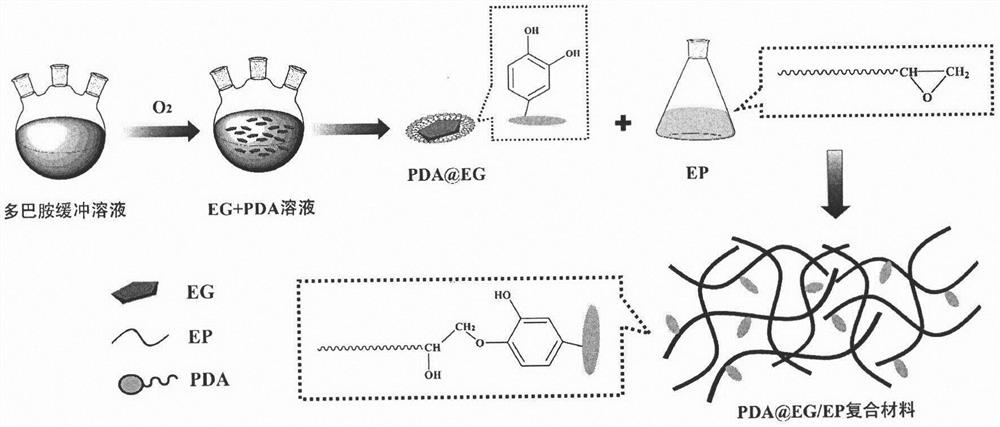

[0045] (1) Surface functionalization of expandable graphite

[0046] a Weigh 1.21 g of tris(hydroxymethyl)aminomethane (Tris) at room temperature, dissolve it in 1 L of deionized water, then add concentrated hydrochloric acid solution to adjust the pH of the buffer to 8.5;

[0047] b Weigh 2g of dopamine hydrochloride and dissolve it in the buffer solution configured above to obtain a dopamine buffer solution with a concentration of 2mg / mL;

[0048] c take 30g of expandable graphite and put it into the dopamine buffer solution of the above-mentioned configuration, place it in a magnetic stirring device and stir for 24h;

[0049] d After the stirring is completed, perform suction filtration, wash with distilled water until colorless, and dry in an electric blast drying oven at 60°C to obtain dopamine surface-functionalized expandable graphite (PDA@EG).

[0050] (2) Preparation of dopamine surface functionalized expandable graphite flame retardant epoxy resin composites

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com