Rectification tower capable of rapidly heating and vaporizing material

A rectifying tower and fast technology, applied in the field of rectification, can solve the problems of difficult to achieve high vacuum of materials, inability to achieve high vacuum of materials, and reduced thickness of heating liquid layer, etc. The effect of a small dwell time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

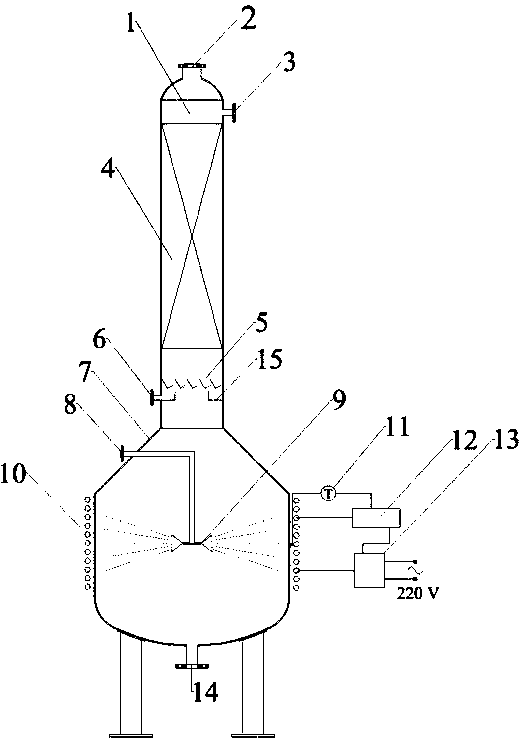

[0019] Embodiment 1: Control figure 1

[0020] A rectification tower that can realize rapid temperature rise and vaporization of materials includes a rectification tower body 1 , a tower bottom heating kettle 7 arranged below the distillation tower body 1 , and an atomizer 9 arranged inside the tower bottom heating kettle 7 . The rectification column body 1 is provided with a tower top gas rise port 2, a tower top return port 3, a packing 4, a louver liquid collecting plate 5, a ring plate 15 and a ring plate discharge port 6 from top to bottom, and the packing 4, the louver set The liquid plate 5 and the ring plate 15 are arranged inside the rectification tower body 1 , and the ring plate outlet 6 is arranged on the lower side wall of the rectification tower body 1 . The ring plate 15 is composed of a circular ring plate and a gas riser connected to the circular ring plate, and the circular ring plate is fixedly connected to the inner wall of the rectification column body 1;...

Embodiment 2

[0027] Embodiment 2 adopts the glycerol distillation of the device of the present invention

[0028] The rectifying tower of the present invention is connected with a tower top condenser, a feed pump and a liquid storage tank. The rectification raw material is a crude product with a glycerol content of 85% (other components are heavy components with high boiling points). When the rectification runs continuously and stably, the rectification raw material is preheated to 100°C, and the wall temperature of the bottom heating tank 7 is 200°C. The pressure is 500Pa, the reflux ratio is 0.1, and the still liquid is collected from the outlet 14 at the bottom of the still. The purity of the glycerin product at the top of the tower is 98%, and the yield is 95%.

Embodiment 3

[0029] Embodiment 3 Adopt the distillation of the trimethylolpropane fatty acid ester of device of the present invention

[0030] The rectifying tower of the present invention is connected with a tower top condenser, a feed pump and a liquid storage tank. The raw material for rectification is the crude product with 80% content of trimethylolpropane fatty acid methyl ester (other components are mainly heavy components with high boiling point). The wall surface temperature is 300°C, under the operating pressure of 100Pa, the reflux ratio is 0.1, the still liquid is collected from the discharge port 14 at the bottom of the still, the purity of the trimethylolpropane fatty acid methyl ester product at the top of the tower is 90%, and the yield is 92% .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com