Method for removing oil-containing drill cuttings and oil component in oil polluted soil

A technology polluted by oil and oil components, applied in the restoration of contaminated soil, etc., can solve problems such as limited processing capacity, low safety, soil pollution, etc., achieve great economic and environmental advantages, increase economic benefits, and reduce solvents The effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

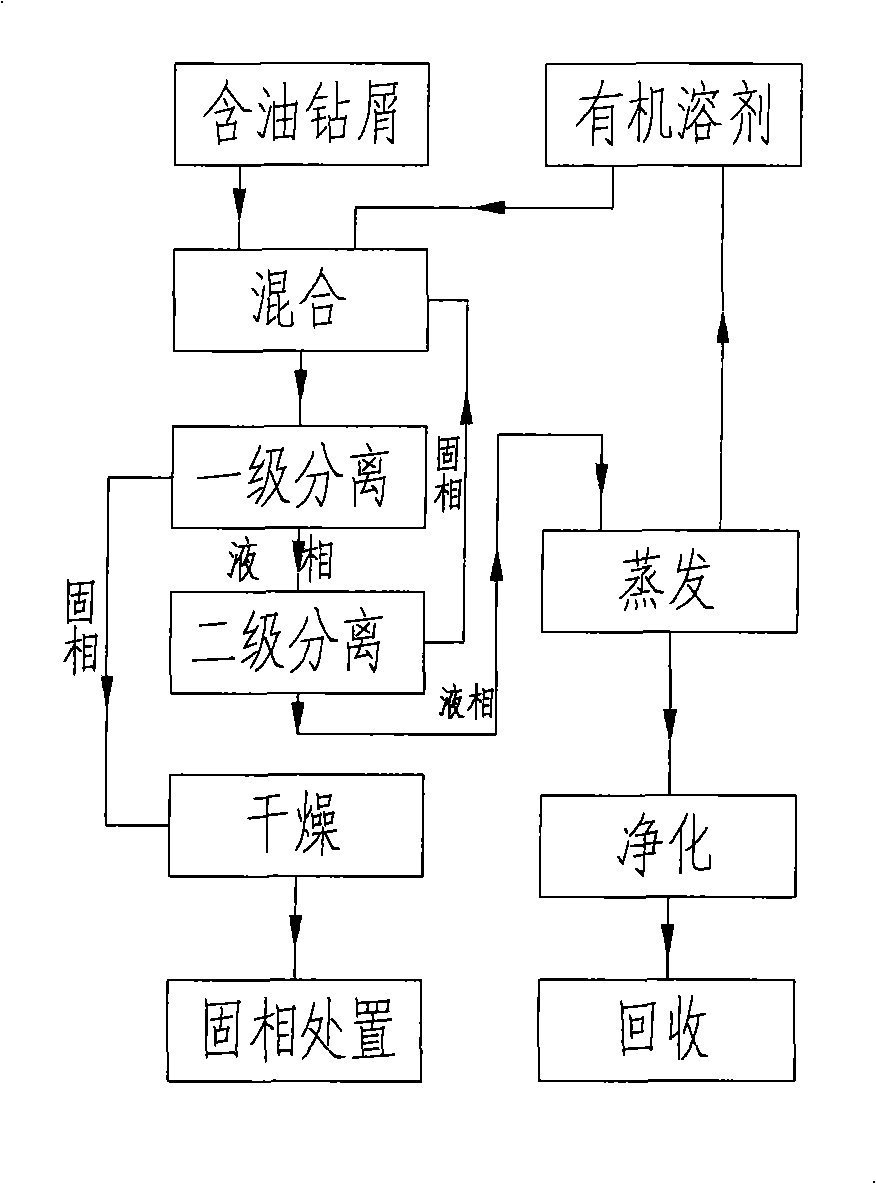

Embodiment 1

[0019] Solvent oil and oily drilling cuttings are mixed in a mixer at a weight ratio of 0.5, thereby forming a mixture of a solid phase and a liquid phase composed of organic solvent and oil; the mixture is sent to a filter dryer for a First-level solid-liquid separation to obtain first-level solid-phase materials and first-level liquid-phase materials; the first-level liquid-phase materials are sent to a centrifuge for second-level solid-liquid separation to obtain second-level solid-phase materials and second-level liquid phase materials ; sending the first-level solid-phase material into a dryer for drying and landfill; sending the second-level solid-phase material back to the mixer to form a new solid-liquid mixture; The grade liquid phase material is sent to the solvent evaporator, and at a temperature of 85°C and a pressure of 0.1Mpa, the solvent oil is separated and sent to the mixer for recycling; the solvent oil separated by the evaporator is Drilling fluid oil base i...

Embodiment 2

[0021] Ethyl acetate and oily cuttings are mixed in a mixer in a weight ratio of 1 to form a mixture of a solid phase and a liquid phase consisting of organic solvent and oil; said mixture is sent to a filter dryer for First-level solid-liquid separation to obtain a first-level solid phase material and a first-level liquid phase material; sending the first-level liquid phase material into a centrifuge for second-level solid-liquid separation to obtain a second-level solid-phase material and a second-level liquid phase material; sending the first-level solid-phase material into a dryer for drying and landfill; sending the second-level solid-phase material back to the mixer to form a new solid-liquid mixture; The secondary liquid phase material is sent to the solvent evaporator, and at a temperature of 90°C and a pressure of 0.1Mpa, the ethyl acetate is separated and then sent to the mixer for recycling; it will be separated by the evaporator Purify and decolorize the oil base o...

Embodiment 3

[0023] Butyl acetate and n-hexane and oil-contaminated soil are mixed in a mixer in a weight ratio of 2, thereby forming a mixture of a solid phase and a liquid phase composed of an organic solvent and oil; sending the mixture to into the filter dryer for primary solid-liquid separation to obtain primary solid phase materials and primary liquid phase materials; send the primary liquid phase materials to a centrifuge for secondary solid-liquid separation to obtain secondary solid phase materials and the secondary liquid phase material; the primary solid phase material is sent to a drier for drying and landfill; the secondary solid phase material is sent back to the mixer to form a new solid-liquid mixture ; The secondary liquid phase material is sent into a solvent evaporator, and at a temperature of 90°C and a pressure of 0.1Mpa, the described n-hexane is separated, and at a temperature of 93°C and a pressure of 0.1Mpa, the The above-mentioned butyl acetate is separated, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com