Double-efficient energy-saving and water-saving rectifying system and process for methanol

A double-effect distillation and water-saving system technology, which is applied in the chemical industry, sustainable manufacturing/processing, and preparation of organic compounds, can solve the problems of increasing the load of the recovery tower, waste, and high energy consumption, and achieve economic benefits. The effect of saving extraction water and reducing rectification energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

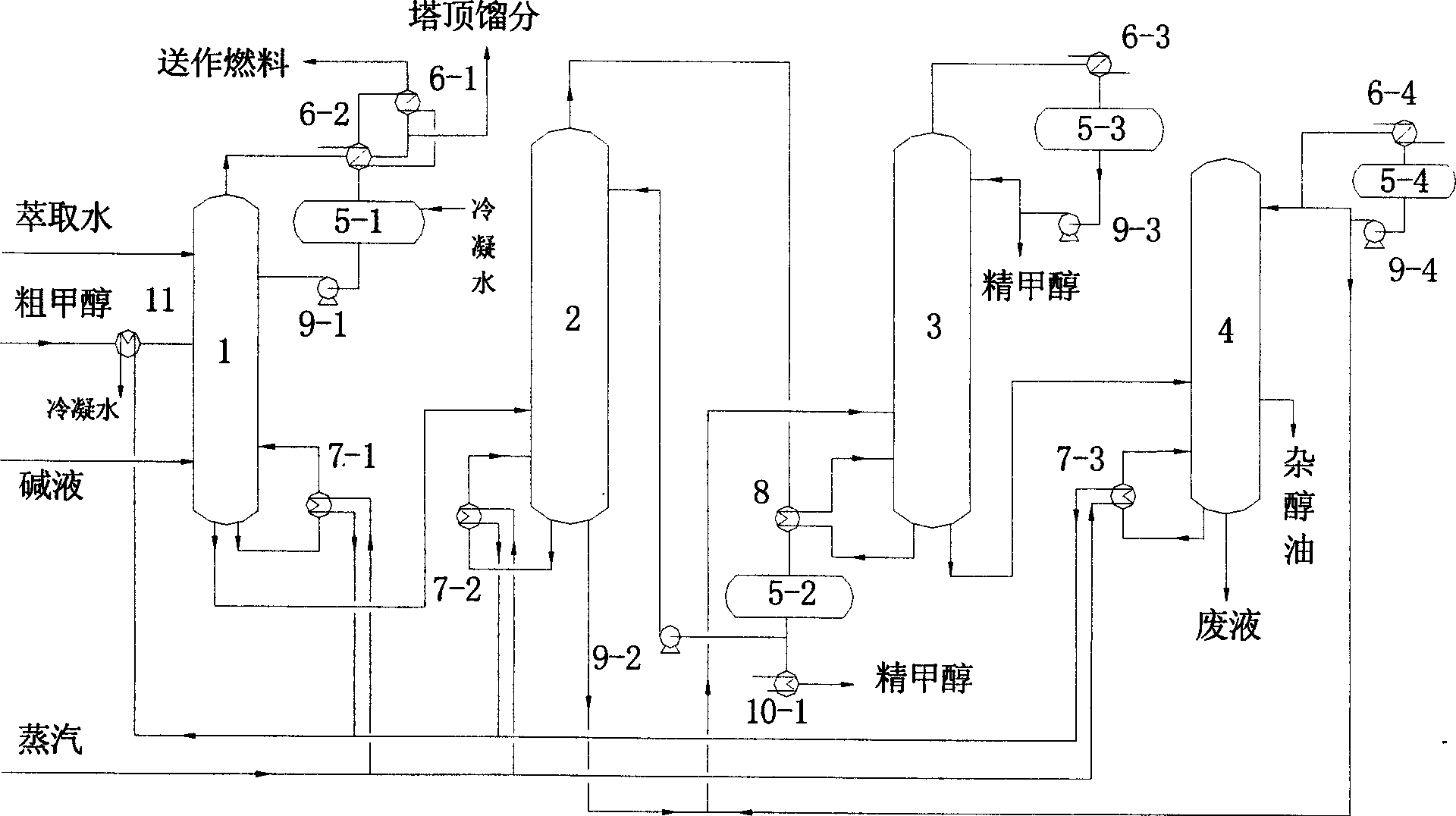

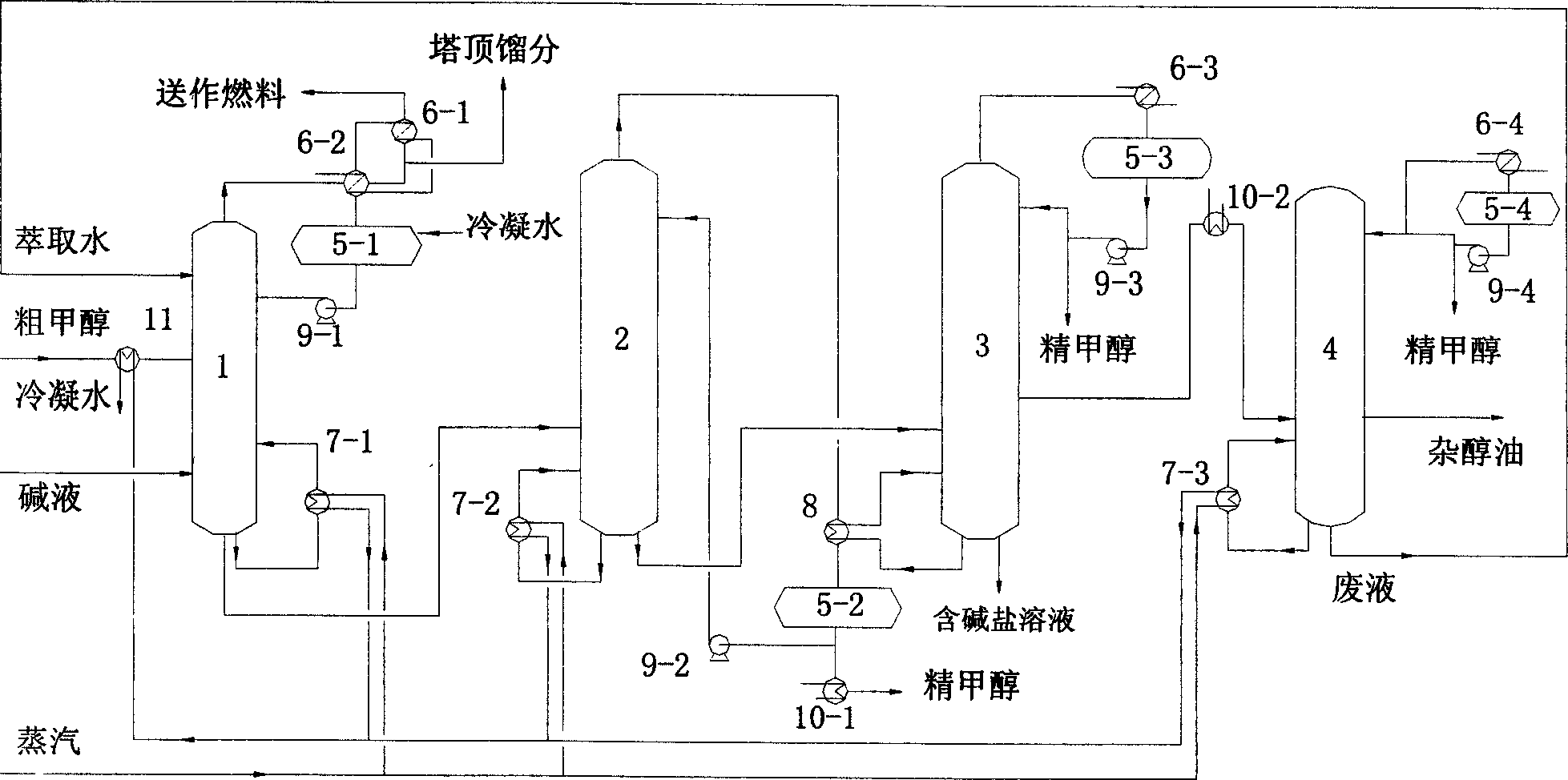

[0023] The energy-saving main equipment of the methanol double-effect rectification of the present invention is the same as the ordinary double-effect rectification equipment, specifically including: crude methanol preheater, pre-rectification tower, post-rectification methanol heater, pressurized tower, atmospheric tower, reboiler device, condensing reboiler and methanol recovery tower, etc. Among them, the difference between each device and the existing device connection method is:

[0024] 1) The side line production pipe of the atmospheric tower is connected to the cooler, and the cooler is then connected to the feed port of the recovery tower;

[0025] 2) The bottom of the atmospheric tower is connected to the extraction pipe of the alkali-containing salt solution;

[0026] 3) The side line of the recovery tower is connected to the fusel oil recovery pipe;

[0027] 4) The waste liquid discharge pipe at the bottom of the tower is connected with the extraction water pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com