Drill bits and other downhole tools with hardfacing having tungsten carbide pellets and other hard materials

a technology of tungsten carbide pellets and drill bits, which is applied in earth drilling, cutting machines, coatings, etc., can solve the problems of high cost and difficulty in machining hard materials, erosion and/or wear resistance materials, and achieve the effect of improving performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

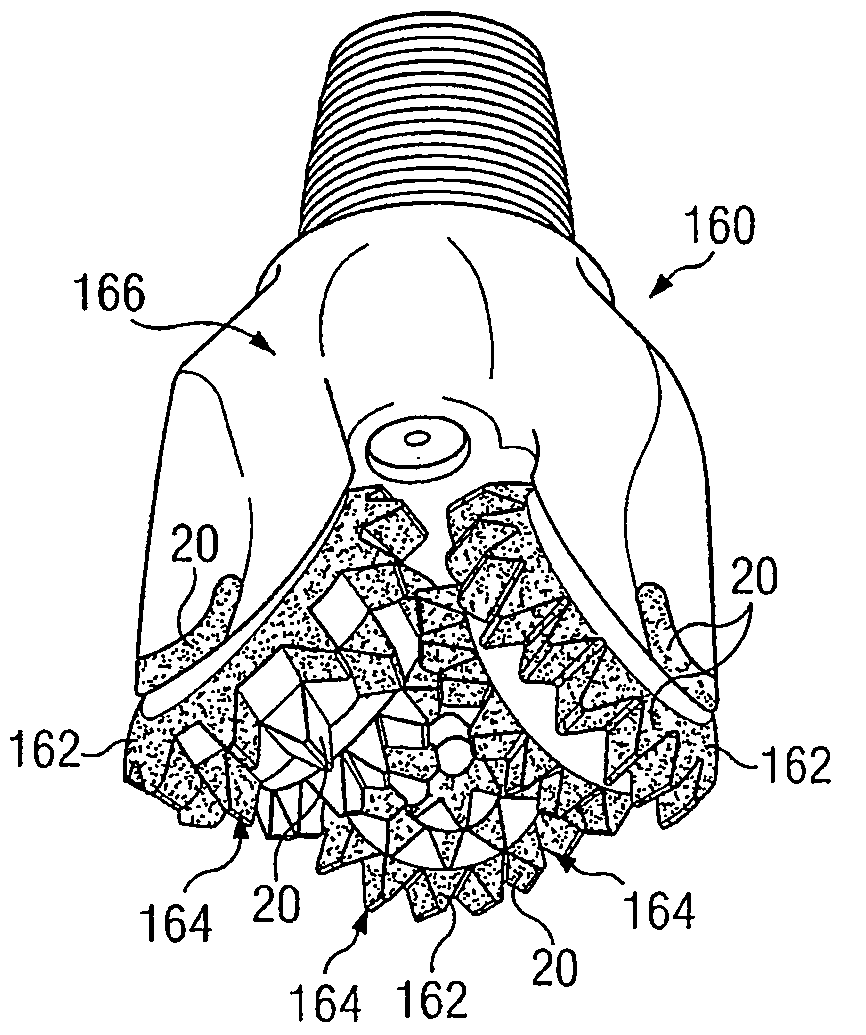

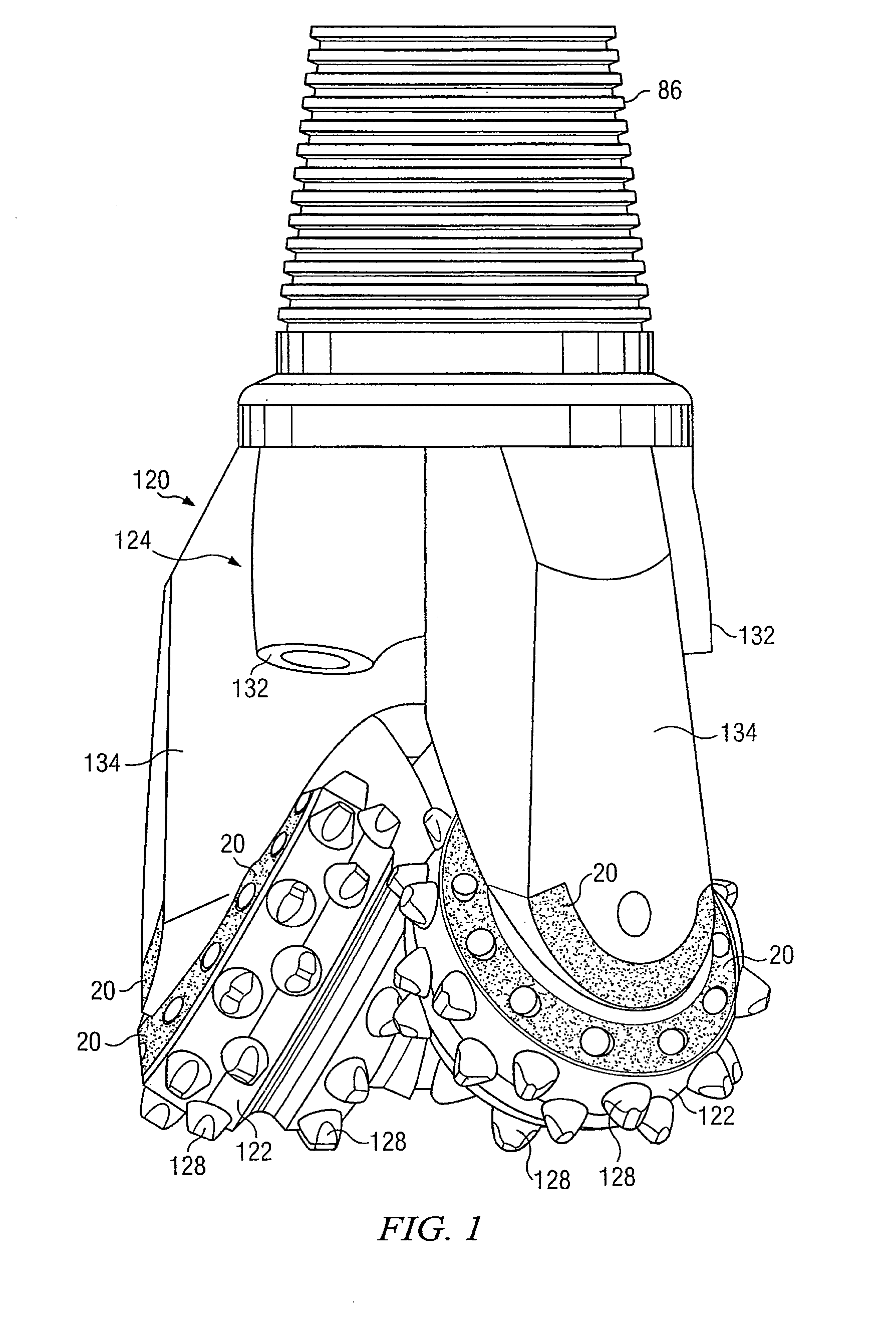

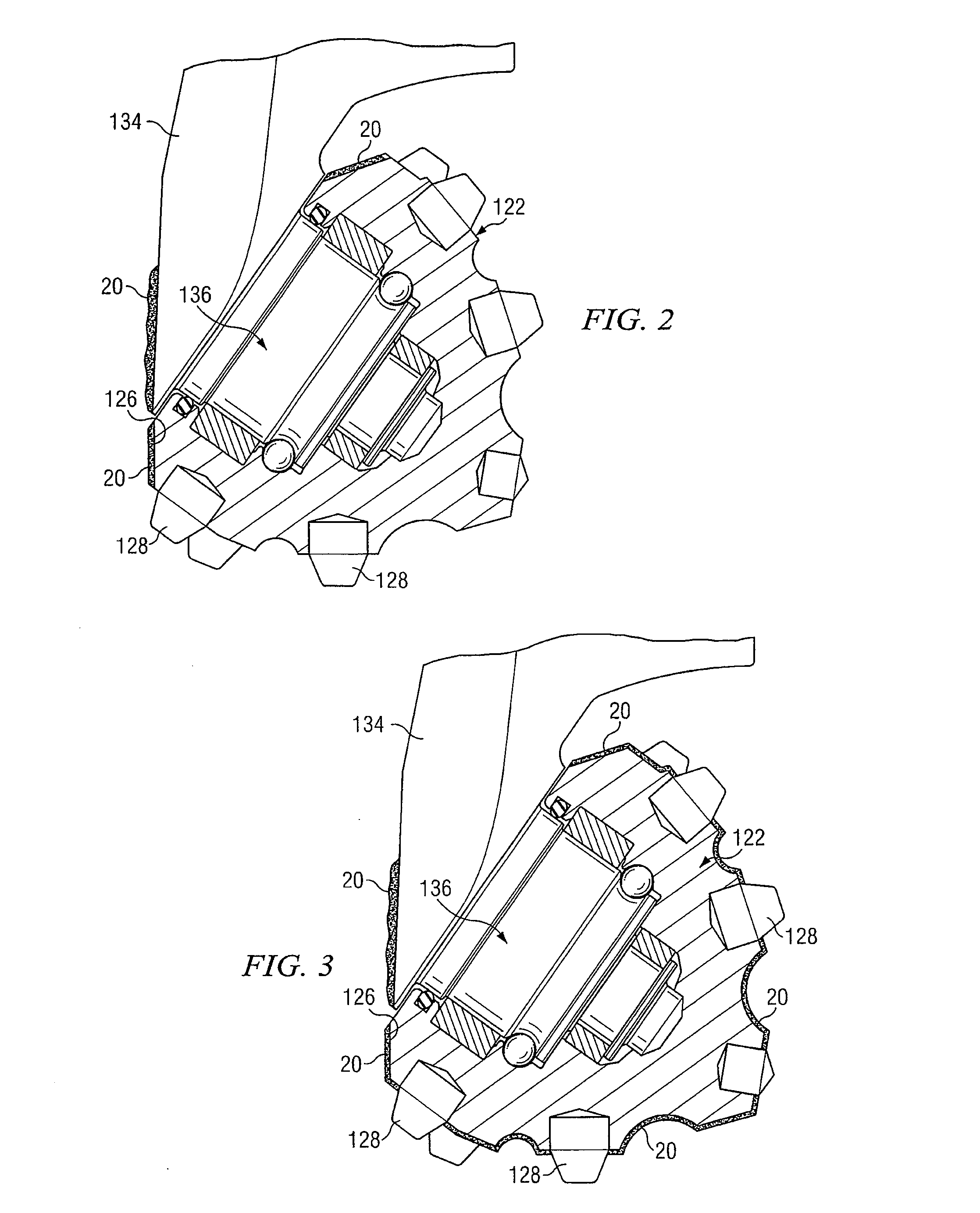

[0029]The preferred embodiments and their advantages may be best understood by referring in more detail to

[0030]FIGS. 1-11 of the drawings, in which like numerals refer to like parts.

[0031]The terms “matrix deposit,”“metallic matrix deposit” and / or “hardfacing” may refer to a layer of hard, abrasion, erosion and / or wear resistant material disposed on a working surface and / or substrate to protect the working surface and / or substrate from abrasion, erosion and / or wear. A matrix deposit may also sometimes be referred to as “metallic alloy material” or as a “deposit matrix.” Various binders and / or binding materials such as cobalt, nickel, copper, iron and alloys thereof may be used to form a matrix deposit with hard, abrasion resistant materials and / or particles dispersed therein and bonded thereto. For example, various types of tungsten carbide particles having an optimum weight percentage of binder or binding material may be included as part of a matrix deposit or layer of hardfacing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com