Long-service-life split type valve seat

A split type and valve seat technology, which is applied in variable capacity pump components, liquid fuel engines, parts of pumping devices for elastic fluids, etc., can solve the problems of frequent replacement, aggravated valve bodies and valve seats, Problems such as short service life of the valve seat can achieve the effect of reducing production cost, prolonging service life and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

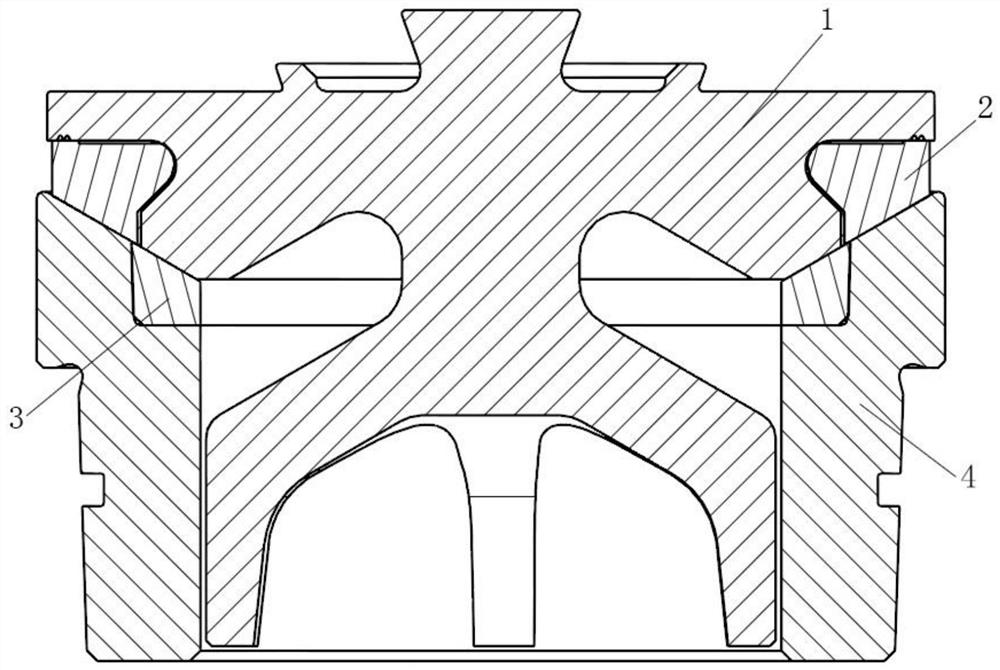

[0036] Such as figure 1 As shown, a long-life split valve seat includes a bushing 3 and a base 4, the bushing 3 is embedded in the outlet end of the base 4, and the bushing 3 is used in conjunction with the valve body 1, so The bushing 3 is tungsten carbide alloy. Further preferably, the tungsten carbide alloy includes nickel-based tungsten carbide or cobalt-based tungsten carbide. The bushing 3 is a cylindrical structure, the base 4 is a T-shaped structure, and the base 4 includes a cylindrical head and a circular frustum tail connected sequentially from top to bottom, and the diameter of the upper bottom surface of the circular frustum tail is larger than Bottom diameter. The diameter of the head of the cylinder is greater than the diameter of the upper bottom surface of the tail of the frustum of a cone. A first through hole is provided in the bushing 3, and the first through hole includes a first circular truncated through hole 5 and a first cylindrical through hole 6 c...

Embodiment 2

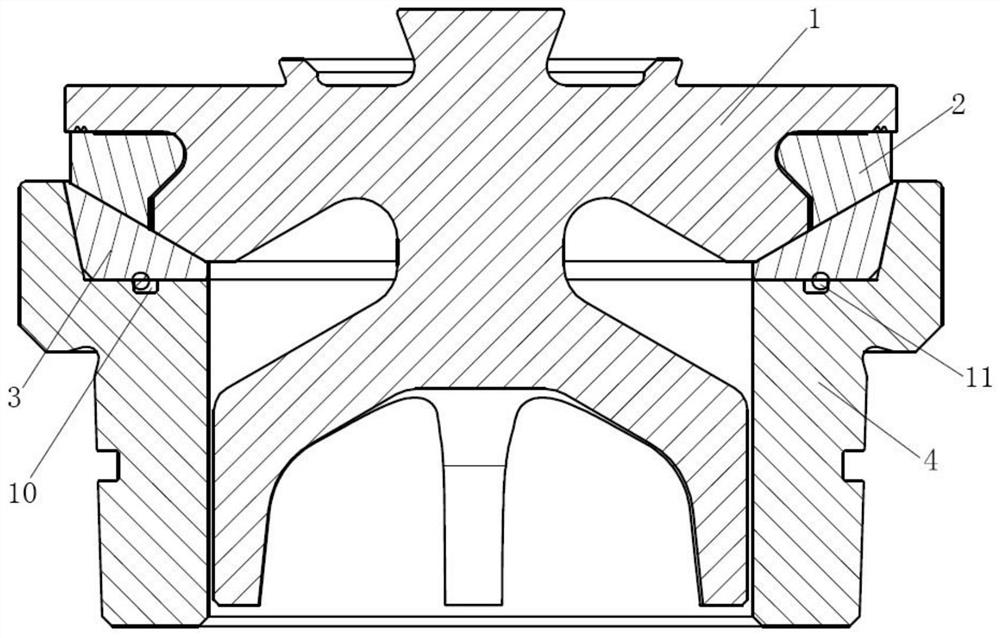

[0038] Such as figure 2 As shown, a long-life split valve seat, the difference from embodiment 1 is that the bushing 3 is a circular platform structure, and the diameter of the upper bottom surface of the first circular platform through hole 5 of the bushing 3 is the same as that of the valve rubber 2 The maximum outer diameter is the same. The bushing 3 is assembled with the base 4 by a pressing method. The second through hole includes a bushing insertion hole 8 and a second cylindrical through hole 9 connected sequentially from top to bottom, the bushing insertion hole 8 is in the shape of a cone, and the diameter of the upper bottom surface of the bushing insertion hole 8 greater than the bottom diameter. The diameter of the lower bottom surface of the bushing insertion hole 8 is larger than the diameter of the second cylinder through hole 9 . The base 4 is also provided with an annular groove 10 on the platform formed by the bush insertion hole 8 and the second cylinde...

Embodiment 3

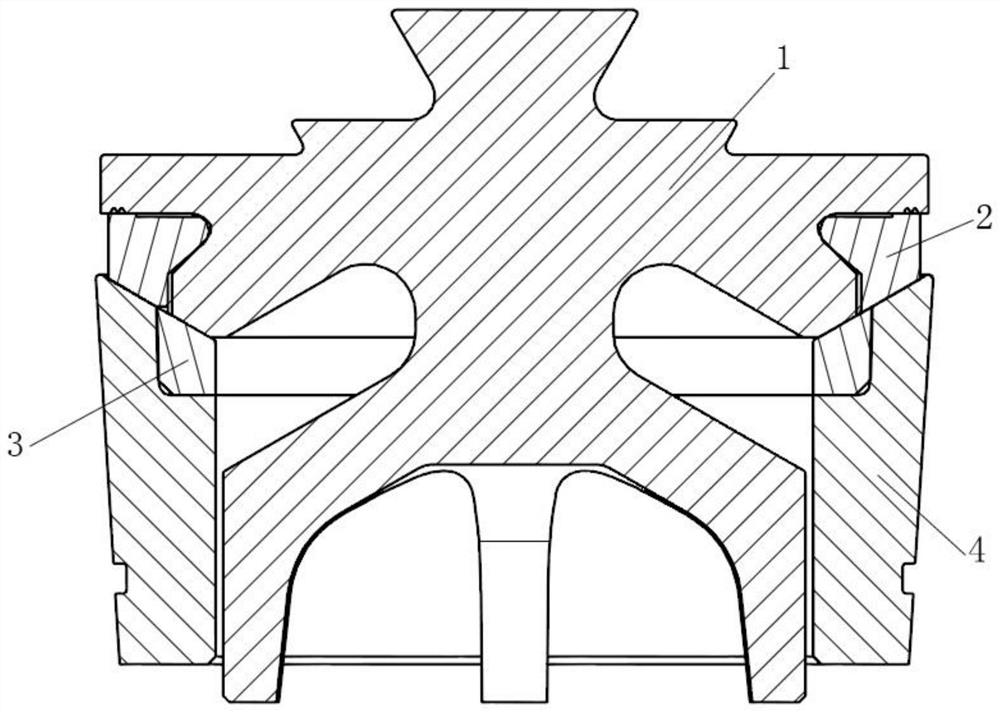

[0040] Such as image 3 As shown, a long-life split-type valve seat is different from Embodiment 1 in that the base 4 is a truncated circular structure, and the diameter of the upper bottom surface of the base is larger than the diameter of the lower bottom surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com