Oil-free air compressor for rail vehicles with air ventilation

a rail vehicle and air compressor technology, applied in the direction of machines/engines, liquid fuel engines, positive displacement liquid engines, etc., can solve the problems of increased maintenance and disposal expenditures, high heat development, oil fouling of pneumatically operated brake units on rail vehicles,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]For purposes of the description hereinafter, spatial orientation terms, as used, shall relate to the referenced embodiment as it is oriented in the accompanying drawing figures or otherwise described in the following detailed description. However, it is to be understood that the embodiments described hereinafter may assume many alternative variations and configurations. It is also to be understood that the specific components, devices, and features illustrated in the accompanying drawing figures and described herein are simply exemplary and should not be considered as limiting.

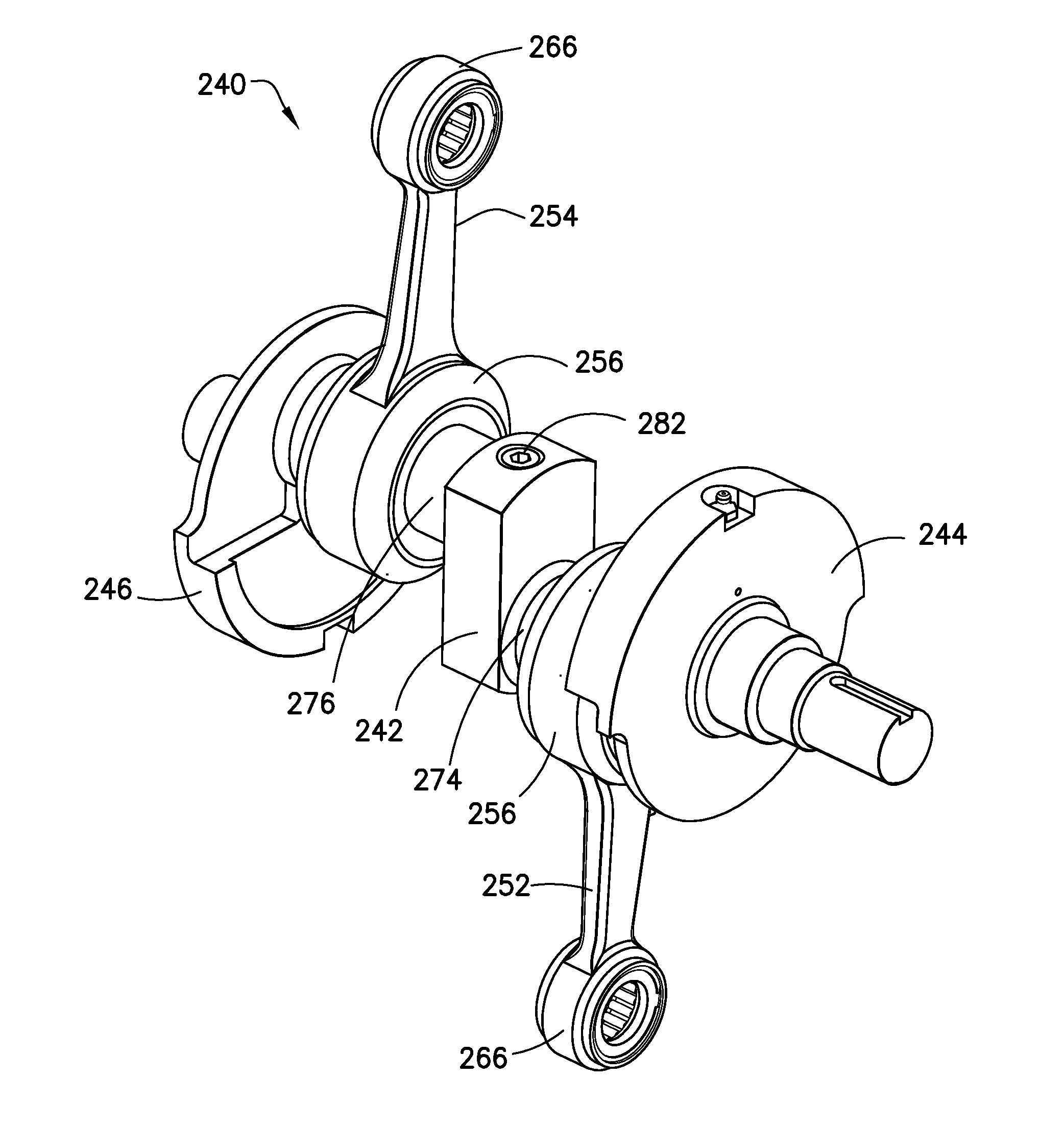

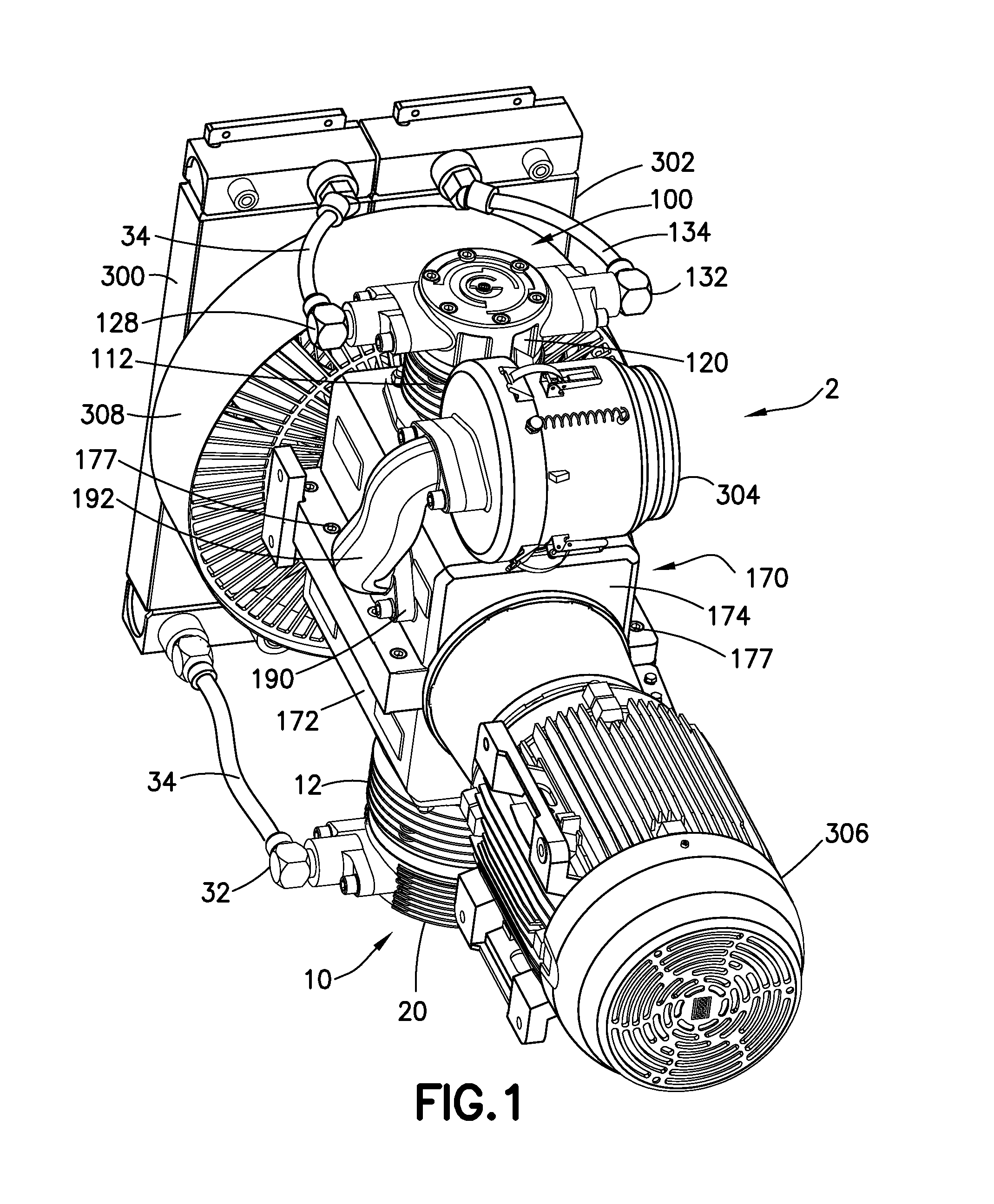

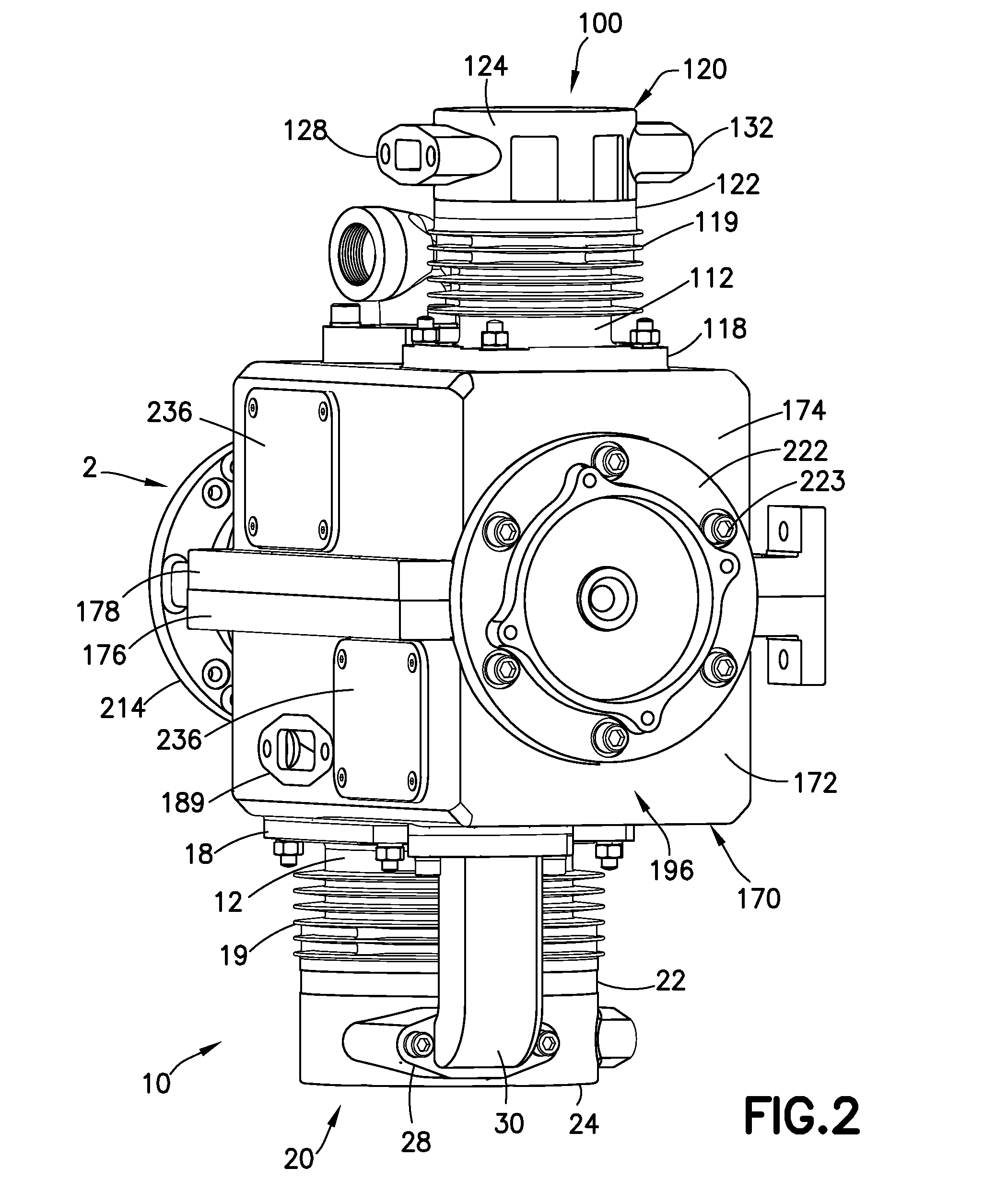

[0035]Referring to FIGS. 1-6, an air compressor 2 according to one embodiment is shown. As shown, the air compressor 2 is a multi-cylinder air compressor 2 comprising at least a first piston-cylinder 10 and a second piston-cylinder 100. The respective first and second piston-cylinders 10, 100 (hereinafter referred to as “first piston cylinder 10” and “second piston cylinder 100”) are supported by a compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com