Oil-free refrigerant circulation technology for air-conditioning and refrigeration system

a technology of which is applied in the field of oil-free refrigerant circulation technology for air-conditioning and refrigeration system, can solve the problems of high energy efficiency of compressors, and achieve the effect of reducing maintenance costs and increasing energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

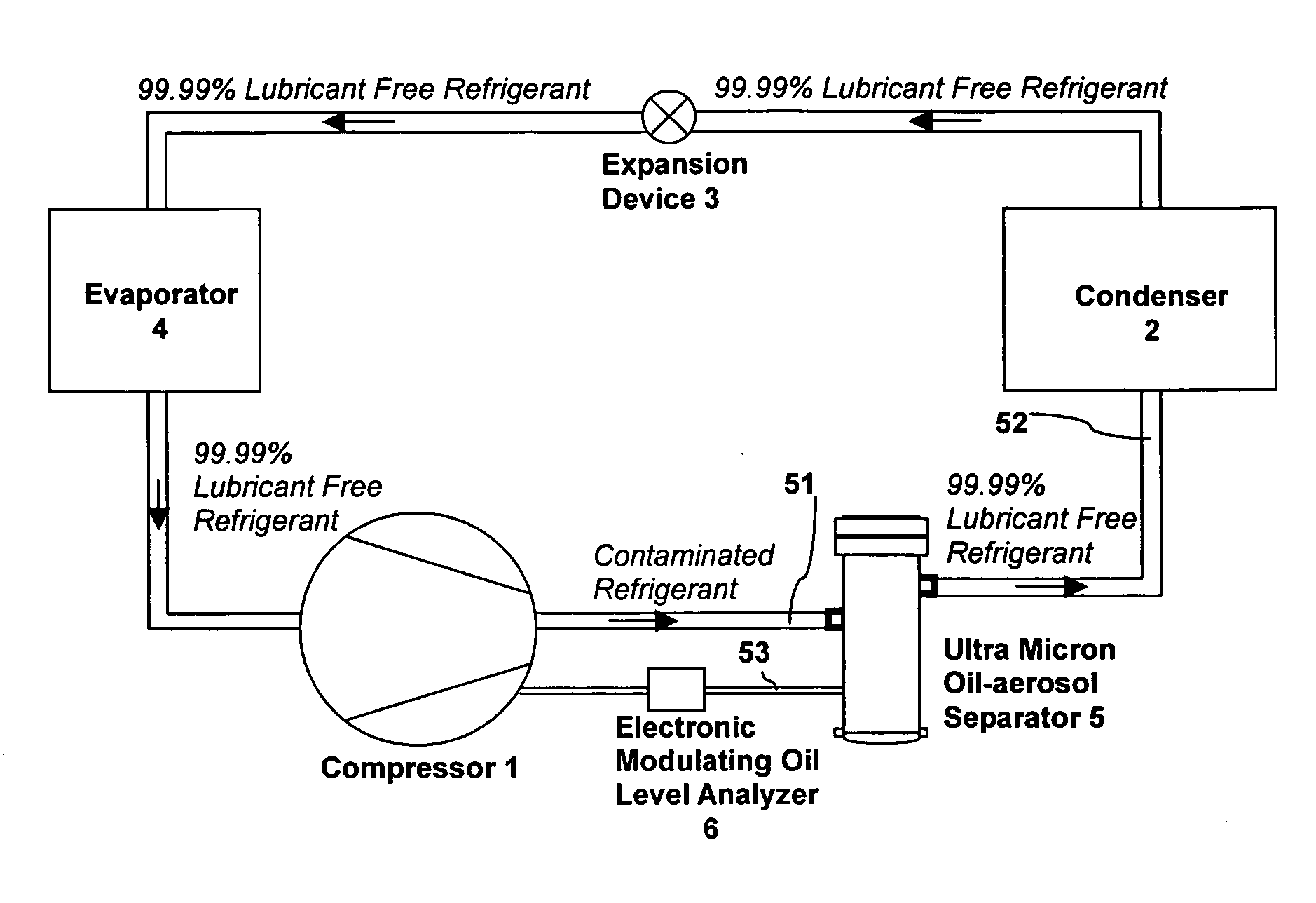

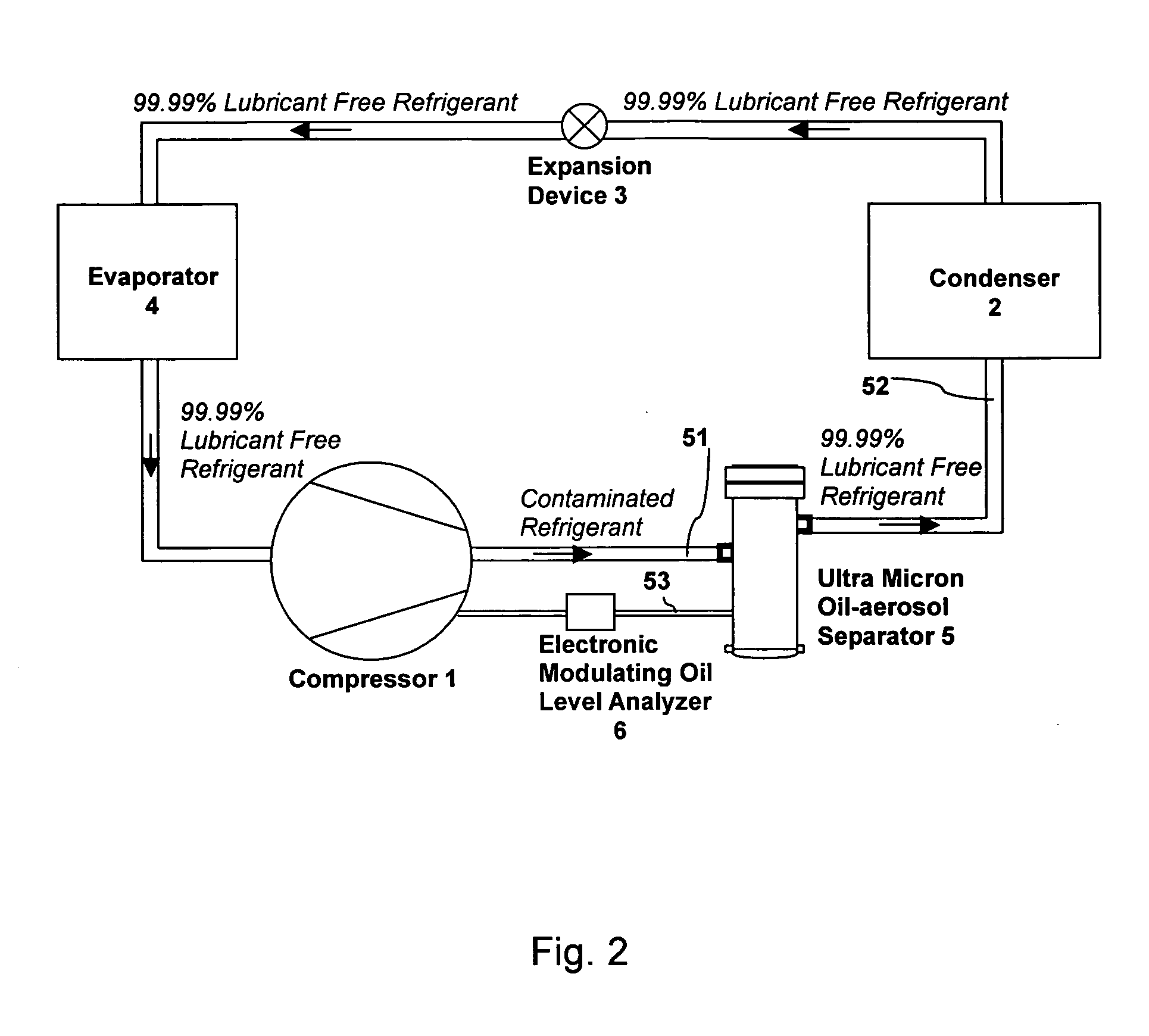

[0066] Referring to FIG. 2, which shows schematically the oil-free refrigerant circulation system according to the present invention, the compressor 1 drives the contaminated refrigerant to the ultra micron oil-aerosol separator 5 through pipe 51, and then the ultra micron oil-aerosol separator 5 will collect 100% of the oil aerosol to be fed back via pipe 53 to the compressor 1 through the electronic modulating oil level analyzer 6. The 99.99% oil-vapor free (OVF) refrigerant vapor will first be de-superheated and then enter the condenser 2 through pipe 52 for condensation. The liquid refrigerant will then passes through the expansion device 3 and enter the evaporator 4 for evaporation by absorbing surrounding heat. The evaporated refrigerant vapor will then be sucked back into compressor 1.

[0067]FIG. 3 shows schematically the structure of ultra micron oil-aerosol separator according to the present invention. The compressor 1 will drive the contaminated refrigerant to the ultra mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com