Cable lubricant

A dry lubricant, stranded wire technology, used in lubricating compositions, textile cables, coatings, etc., can solve the problems of deterioration of lubrication effect, accelerated wear of traction mechanism, pollution of mechanical parts, etc., to reduce direct contact and reduce friction. wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

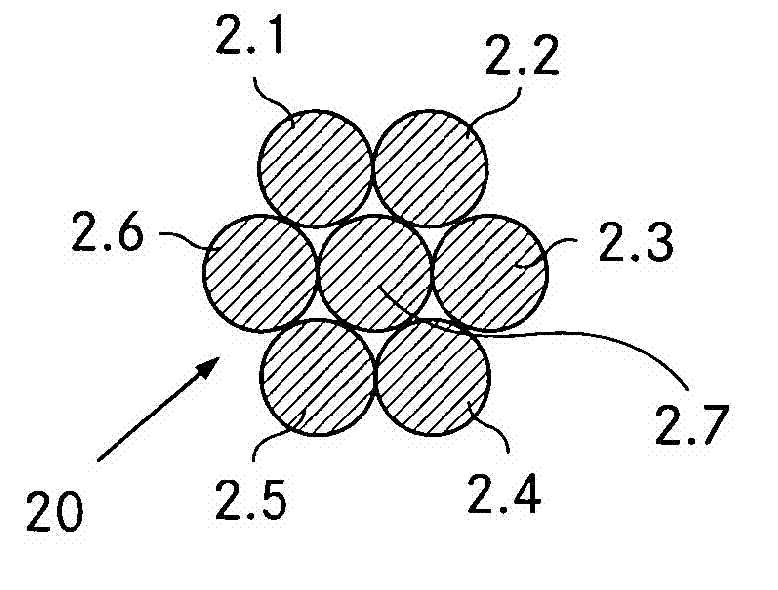

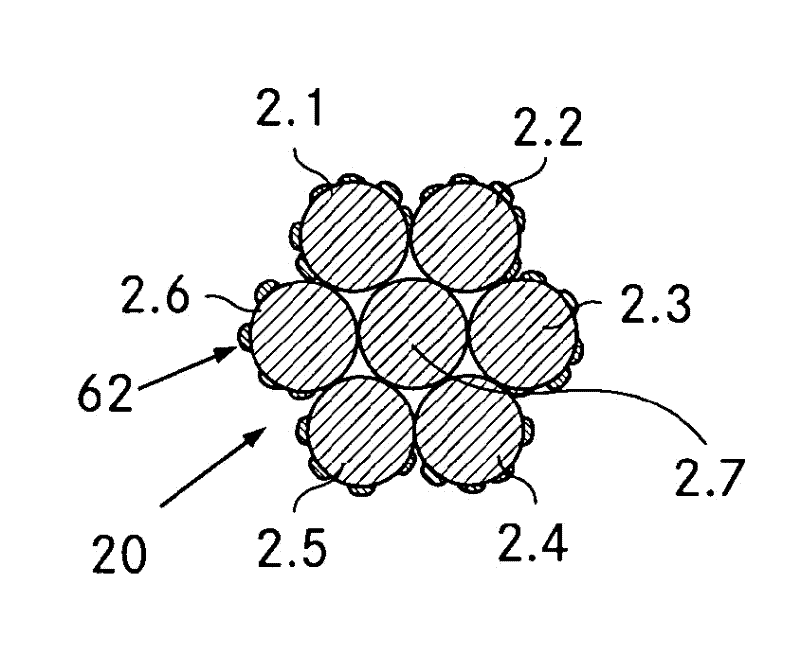

[0079] figure 1 A first production line 100 for individual elements of the painting traction mechanism according to the invention is shown. This first production line 100 has a rotatable uncoiler 101, shown at figure 1 The left-hand side of , from which a total of 7 individual elements in the form of 7 wires 1.1, 1.2, . . . 1.7 are spatially separated. These 7 wires 1.1, 1.2, . In the forming tool 105, the seven wires 1.1, 1.2, . The crawler drive 106 downstream of the forming tool 105 pulls the first strand 10 . 1 out of the forming tool 105 . Furthermore, arranged downstream of the crawler drive 106 is a take-up roller 107 on which the first litz wire 10.1 is wound.

[0080] A spraying device is arranged in a fixed position in the region between the rotatable uncoiler 101 and the forming tool 105 above the seven wires 1.1, 1.2, . form. Spray gun 104 produces a widened and conical jet 51 of molten or fluidized dry lubricant 50 . The jet 51 consists of droplets of fluid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com