Commercial vehicle mudguard support assembly test stand and endurance test method

A fender bracket and test bench technology, which is applied in vehicle testing, mechanical component testing, machine/structural component testing, etc., can solve the problem of not testing the durability performance test bench of a commercial vehicle fender bracket assembly , Affect the product development process, poor repeatability and other issues, to shorten the product development cycle, accelerate the product development process, and facilitate processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

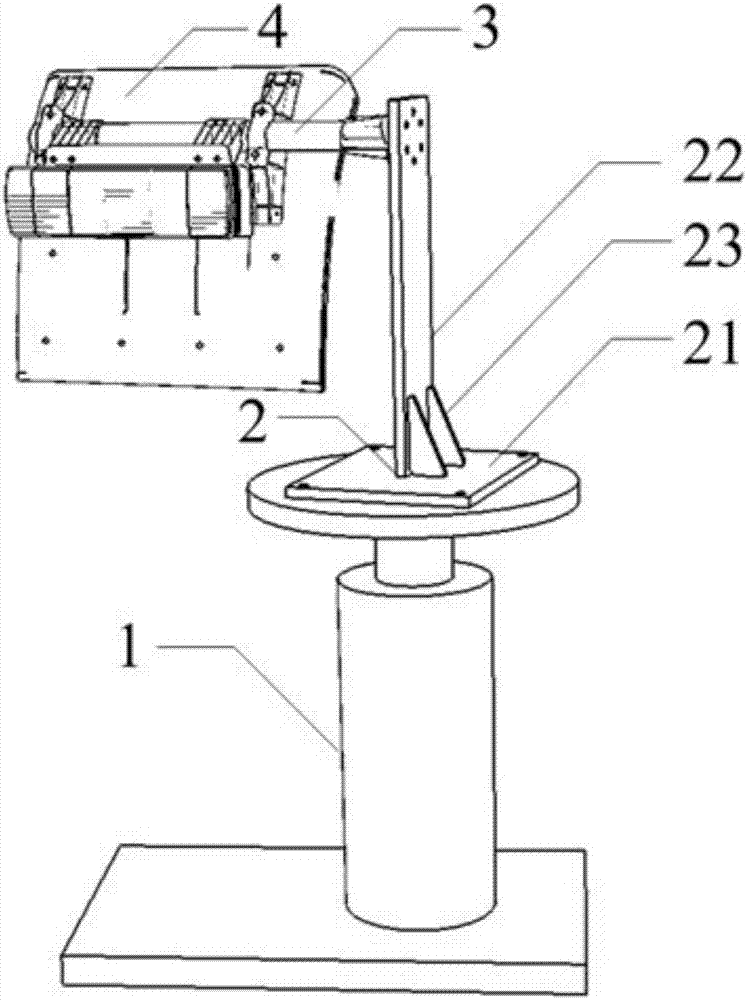

[0038] Such as figure 1 As described above, the present invention provides a commercial vehicle fender bracket assembly test bench, including a linear actuator 1, a connecting fixture 2, a fender bracket 3 and a fender assembly 4; wherein, the connecting fixture 2 It includes a fixture bottom plate 21, a support connecting vertical plate 22 and a reinforcing rib 23. Four holes are opened at the four corners of the fixture bottom plate 21, which correspond to the holes on the top disk of the linear actuator system, and are used for the bottom plate to interact with the linear actuator. The top disk of the actuator system is connected; the upper end of the bracket connection vertical plate 22 is perforated according to the size parameter of the connection hole position between the fender bracket 3 and the vehicle frame, and is used for the fixed connection between the fender bracket 3 and the bracket connection vertical plate 22; The reinforcing rib 23 is welded at the connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com