Continuously variable transmissions and methods therefor

a technology of transmission and continuous variable, applied in the direction of friction gearing, gear lubrication/cooling, gearing, etc., can solve the problem that technology has generally been unable to overcome technical and economic hurdles to gain a wider adoption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

” one will understand how the features of the system and methods provide several advantages over traditional systems and methods.

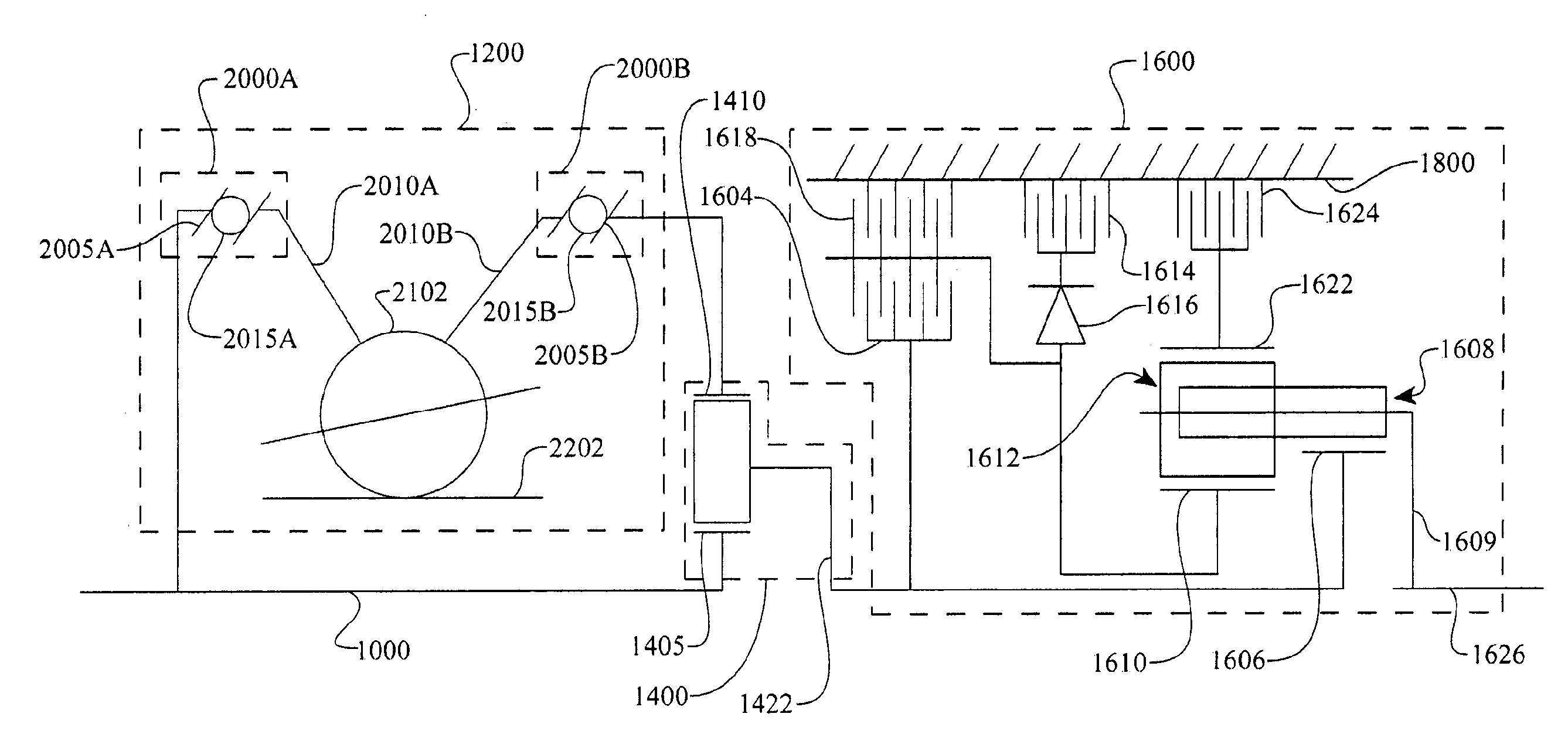

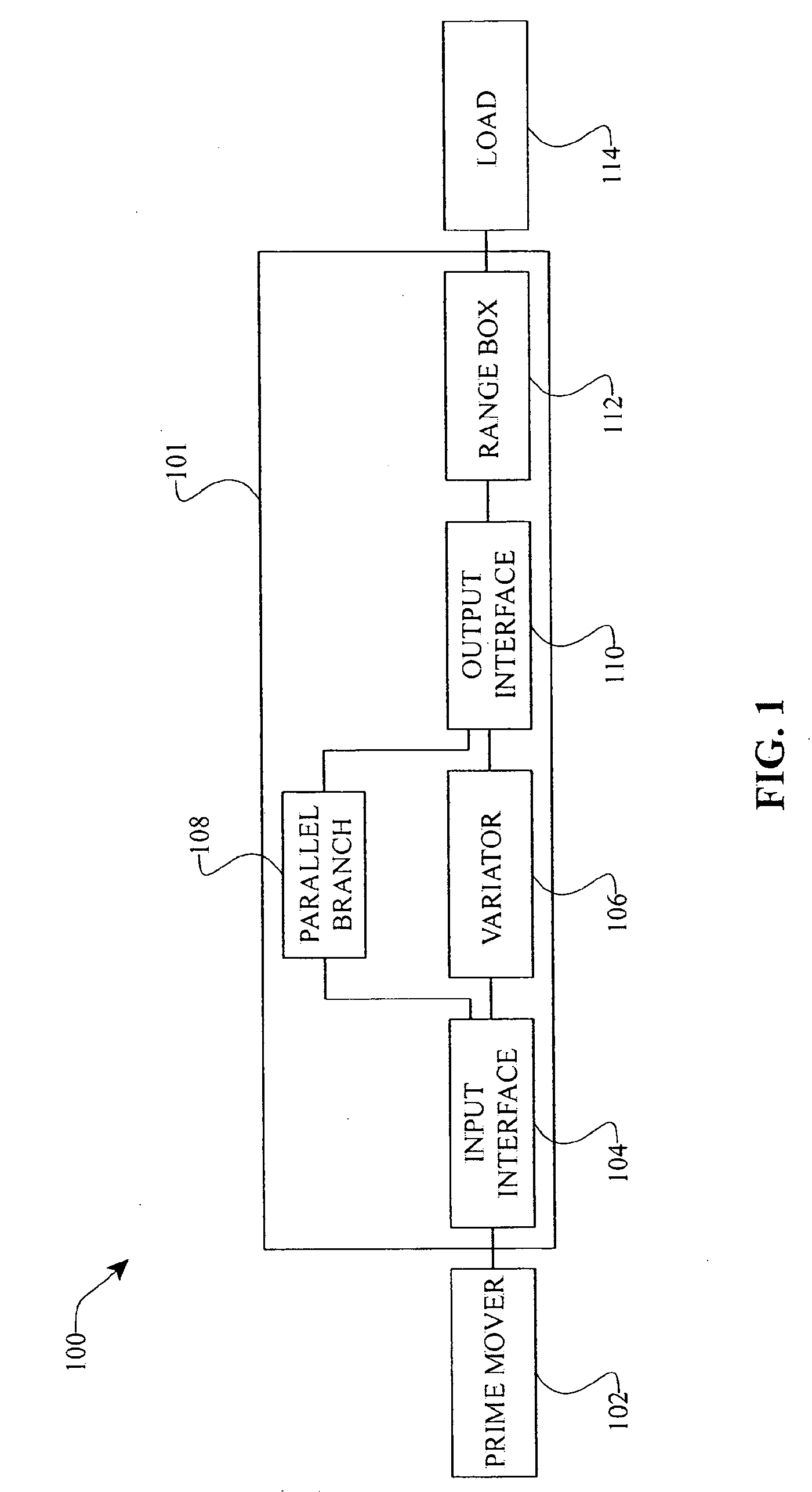

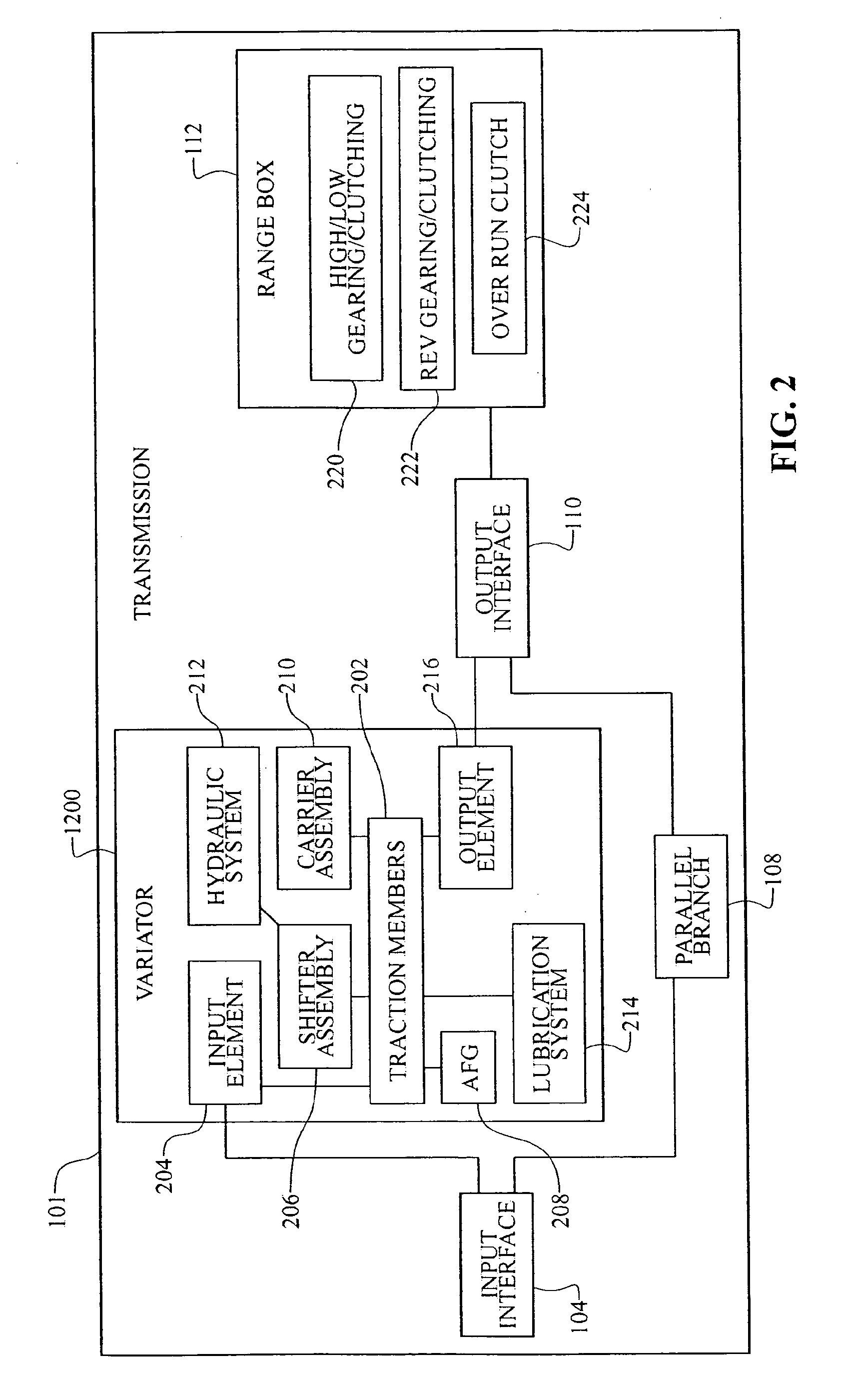

[0008]One aspect of the invention relates to a drive having a prime mover and a transmission coupled to the prime mover. In one embodiment the transmission has a continuously variable unit (CVU), an input interface coupled to the prime mover and to the CVU, and an output interface coupled to the CVU. The drive also has a parallel branch for mechanical power transmission. The parallel branch can be coupled to the input interface and to the output interface.

[0009]Another aspect of the invention addresses a transmission having a main shaft, an input load cam, an input traction ring, and a first set of load cam rollers positioned between the input load cam and the input traction ring. In one embodiment, the transmission has a number of traction planets in contact with the input traction ring, and the transmission has a traction sun in contact with the traction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com