Tea Garden Tea Picking Institution Test Bench

A technology for test benches and tea gardens, applied to picking machines, harvesters, agricultural machinery and implements, etc., can solve the problems of cumbersome cutting, high stubble unevenness, and low integrity rate, and achieve stable operation, precise and adjustable movement speed, Realize the effect required by the experimental research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

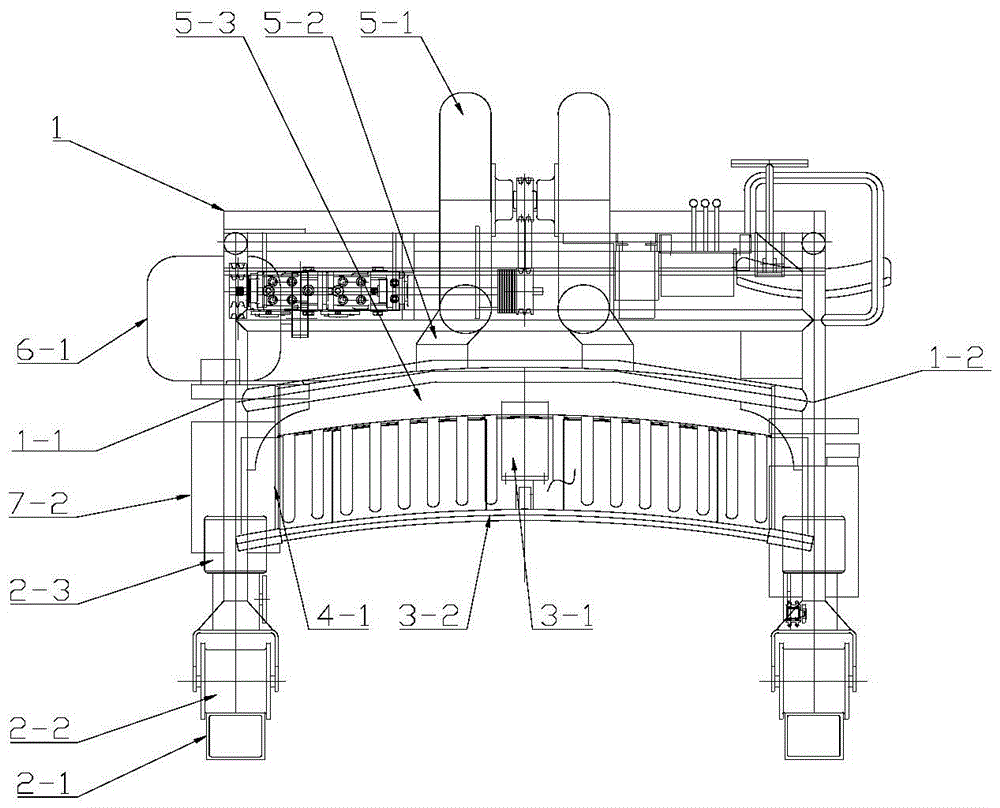

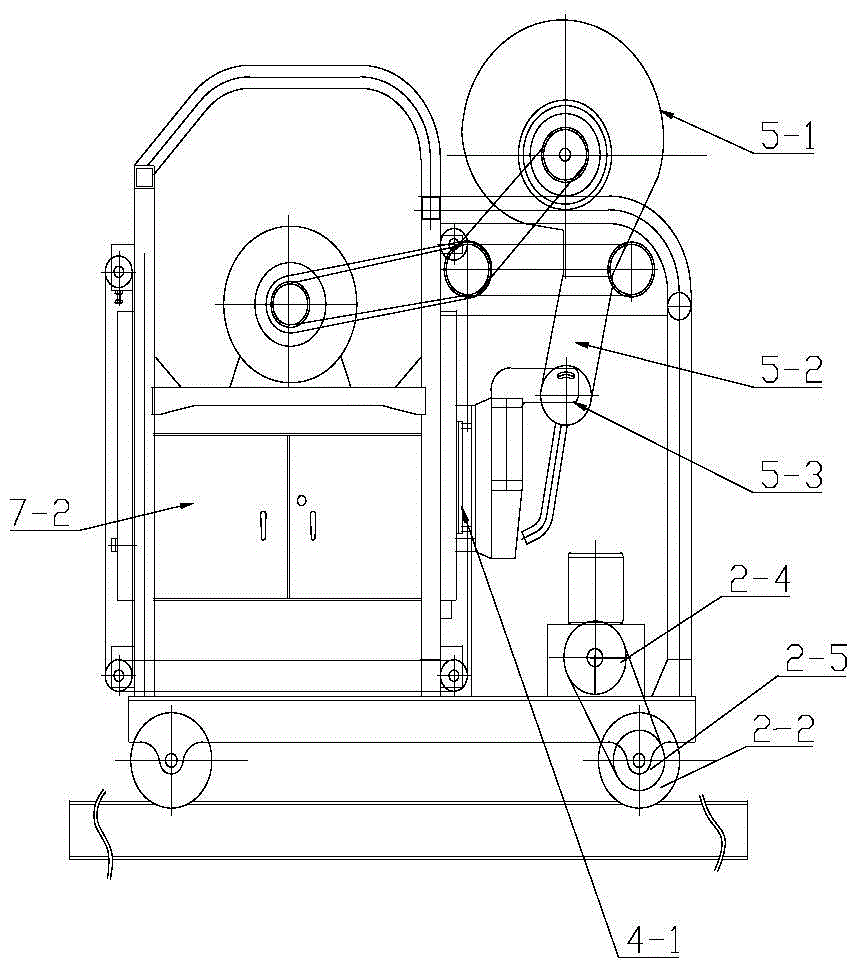

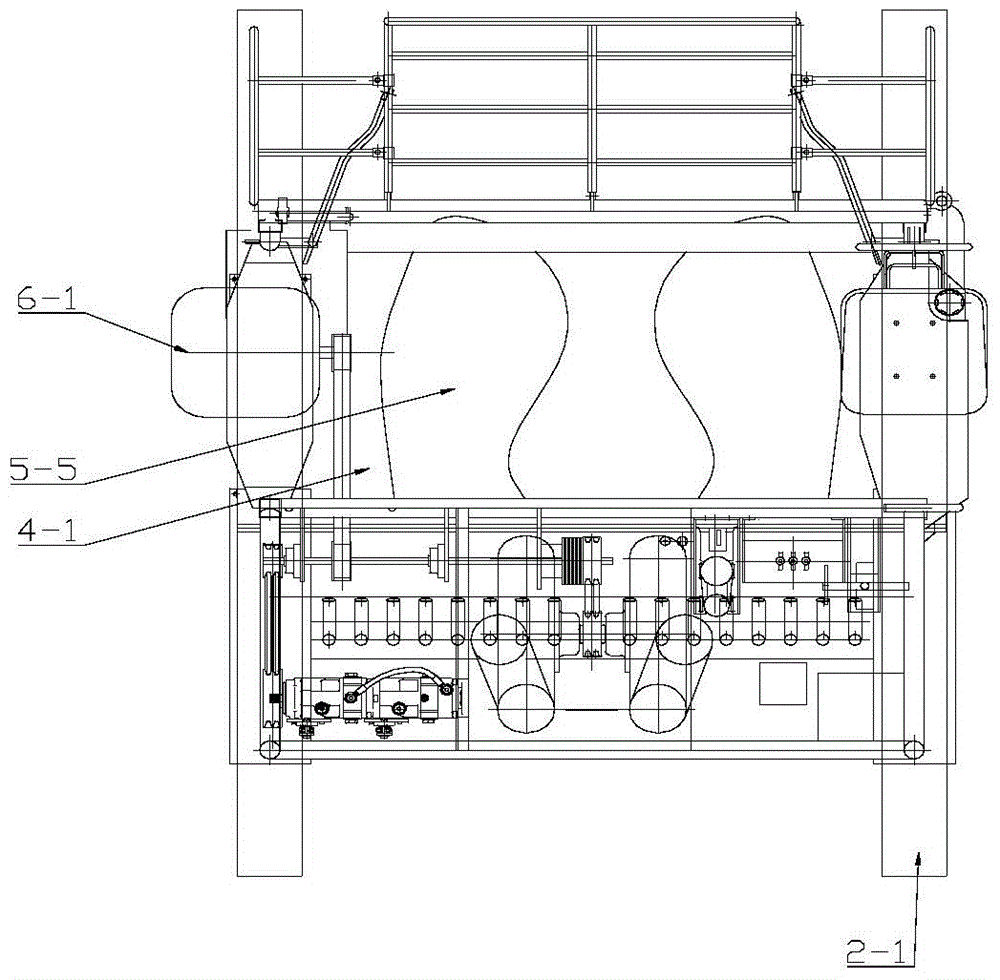

[0019] The tea garden tea-picking mechanism test bench of present embodiment, as figure 1 , figure 2 with image 3 As shown, it includes a door-shaped frame 1 as a whole, a power source (not shown in the figure) and a traveling mechanism that drives the frame to move horizontally; The left and right columns 1-1 and 1-2 on both sides of the tea row in the middle are fixed with horizontal beams at the tops of the left and right columns 1-1 and 1-2; the left and right columns 1-1 and 1-2 There is a lifting frame 4-1 and a lifting mechanism that drives the lifting frame to move up and down along the column. The front end of the lifting frame 4-1 in the forward direction when it is in use is provided with an installation interface for installing the tea picking mechanism 3. There is a power output interface for driving the tea-picking mechanism 3-2, and the lifting frame 4-1 is also provided with a leaf-collecting net bag 5-5 for collecting the tea leaves picked by the tea-picki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com