Electric bridge driving system and vehicle

A drive system and electric bridge technology, applied in the field of vehicles, can solve the problems of large transmission ratio, complex structure, low cost of electric bridge drive system, etc., and achieve the effect of reducing costs and improving transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

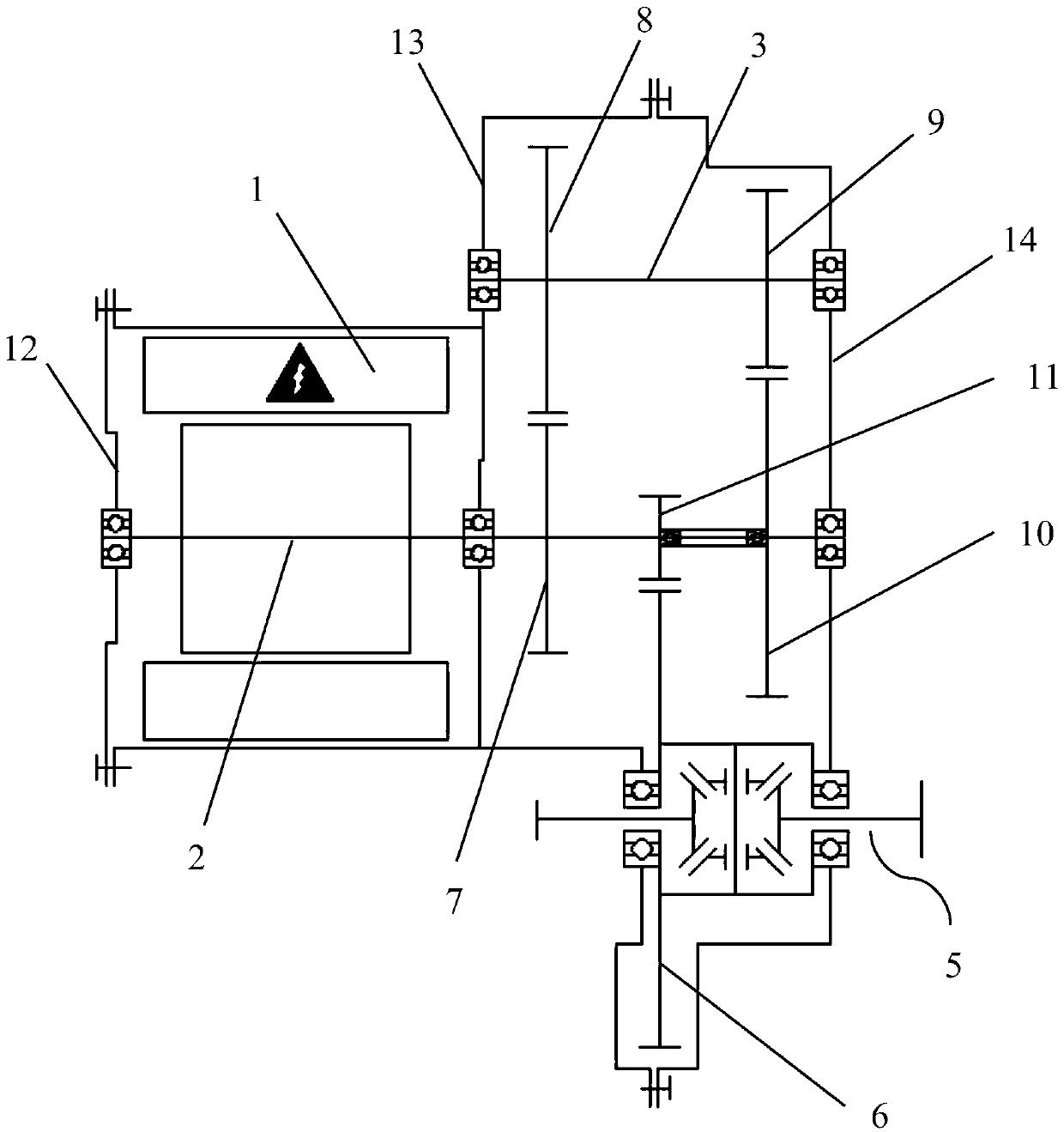

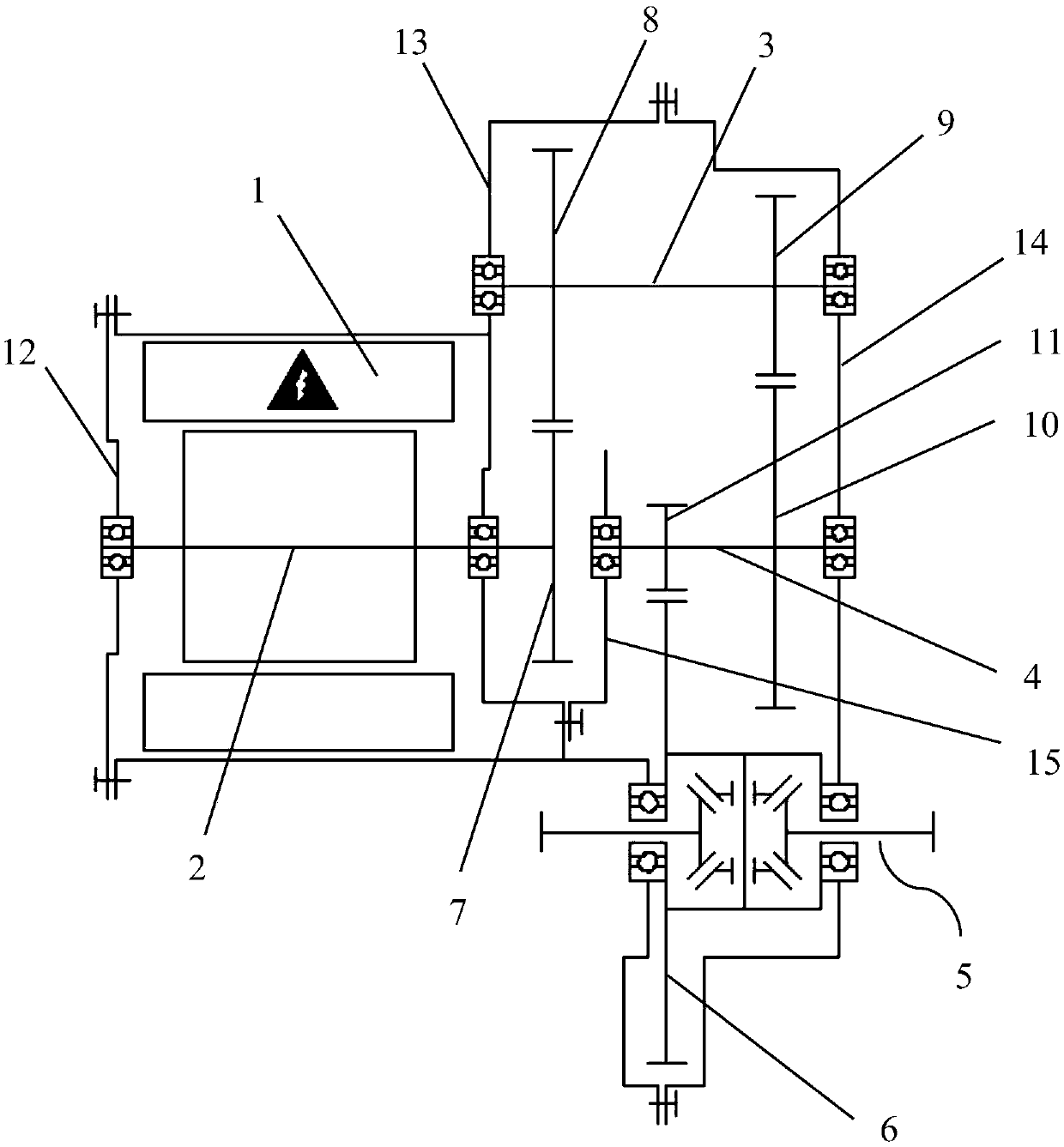

[0020] figure 1 A schematic structural diagram of the bridge drive system according to the first preferred embodiment of the present invention is shown. The bridge drive system is a single-speed drive system for pure electric vehicles or hybrid vehicles. The bridge drive system includes a motor 1 , a transmission, a differential 5 and a system housing surrounding the bridge drive system. The transmission can transmit the power of the motor 1 to the differential 5, and then distribute it to the wheels of the vehicle to drive the vehicle.

[0021] As shown in the figure, the motor 1 is, for example, an inner rotor motor, and has a motor shaft 2 arranged on the same rotation axis as the motor shaft 2, which is connected to the rotor. The differential 5 is an ordinary gear differential, and has a driven gear 6 . The two half shafts of the differential 5 are arranged offset from the motor shaft of the electric machine. The transmission has a motor shaft 2 , an intermediate shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com