Friction-type coupler

A coupling and friction-type technology, applied in the field of friction-type couplings, can solve the problems of lag in the rotation of the connecting plate, insufficient contact friction, and insensitive power transmission, and achieve sensitive power transmission, large contact friction, and elimination of over-temperature. The effect of security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described below in conjunction with the accompanying drawings and embodiments.

[0013] The "existing friction clutch" mentioned below refers to the "friction clutch" with application number 02241064.3 described in the Background Art section.

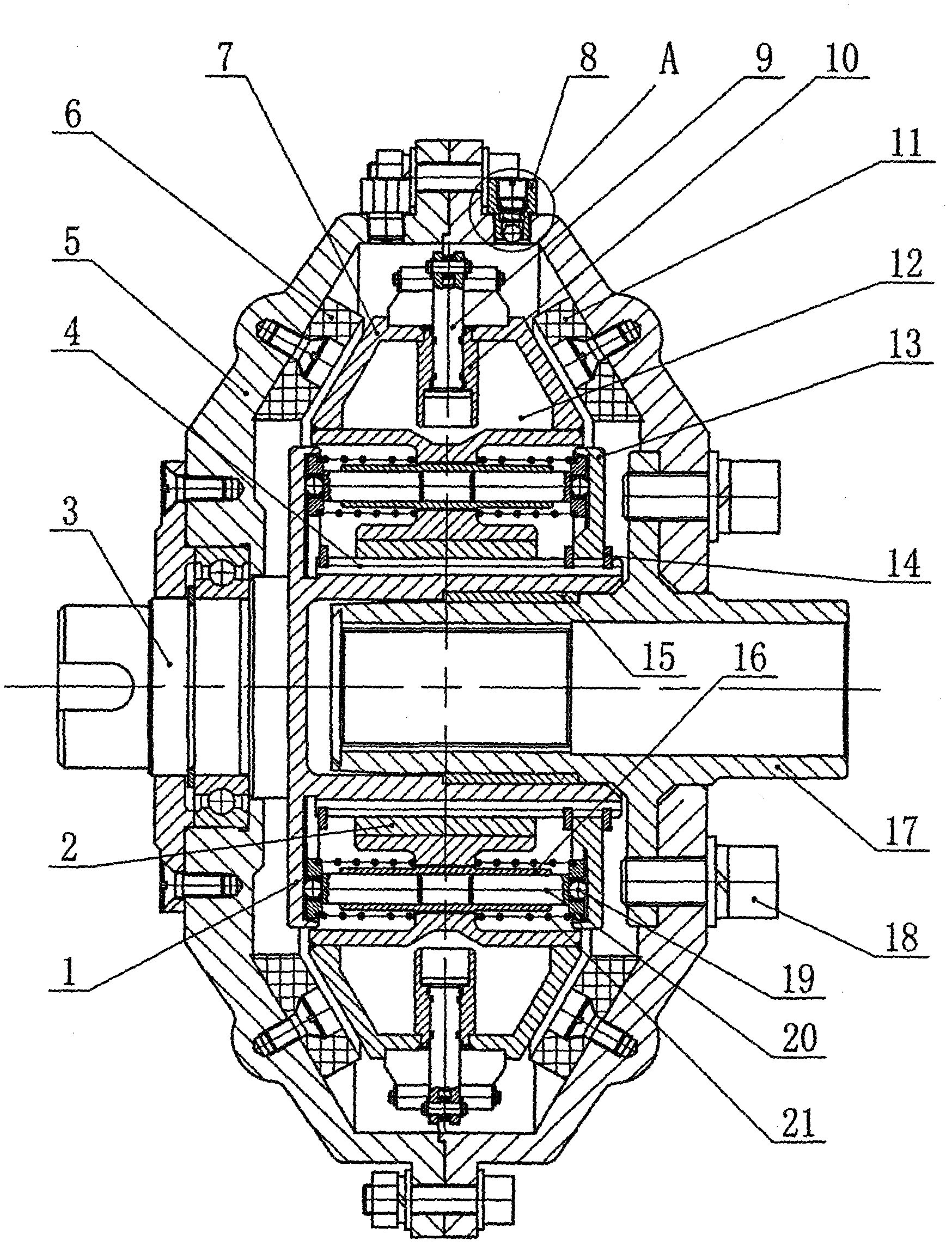

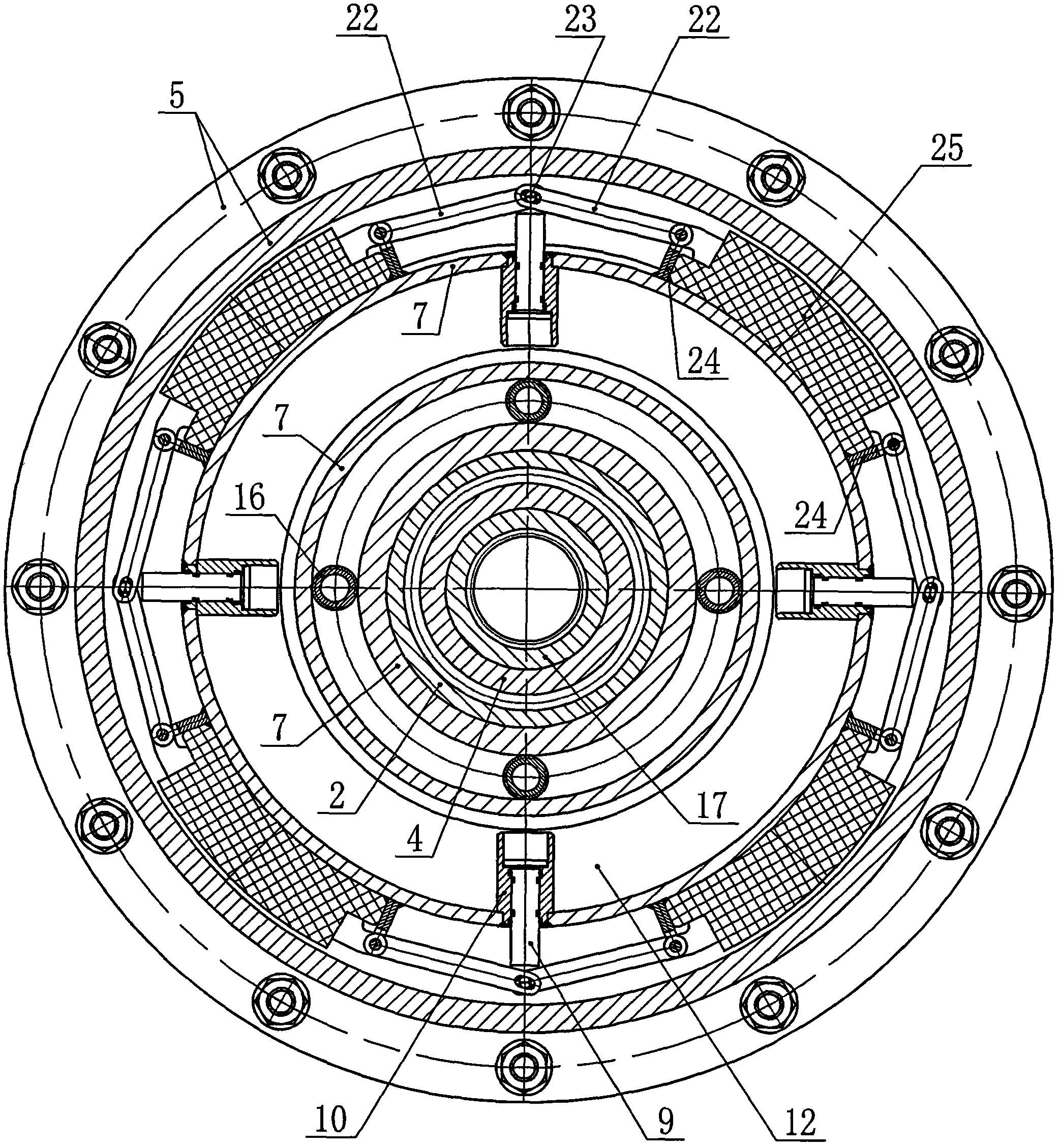

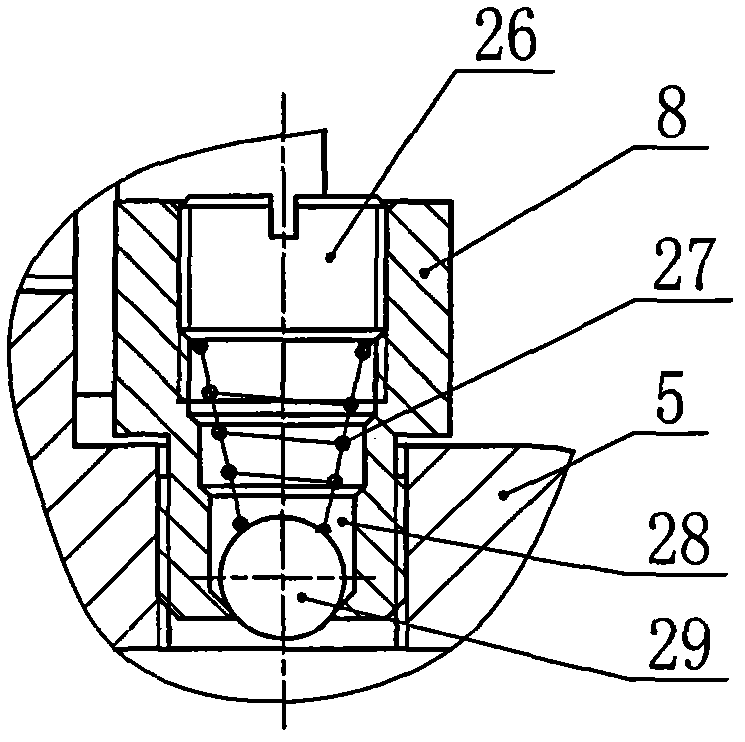

[0014] Such as figure 1 , figure 2 As shown, the friction coupler of the present invention includes a main transmission shaft 3, a friction disc 7, a clutch housing 5, an inner spline connection sleeve 17, a device for axially positioning the friction disc 7 and receiving axial spring pressure; The inner helical gear 2 cooperates with the helical gear 4 at one end of the main transmission shaft 3, the outer circumference of the friction disc 7 is a double inclined plane, and the friction rings 6 and 11 are fixed on the clutch housing 5 with countersunk screws or high temperature resistant glue. On the inner side, the bevel angles of the left and right bevels of the friction disc 7 are equal to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com