A cable drag chain moving device for curve power supply and its working method

A technology of mobile devices and driving devices, which is applied in the direction of hoses, pipe supports, pipes, etc., can solve the problems that drag chains are not widely used and lack of research, and achieve the effect of reliable support and reliable power supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

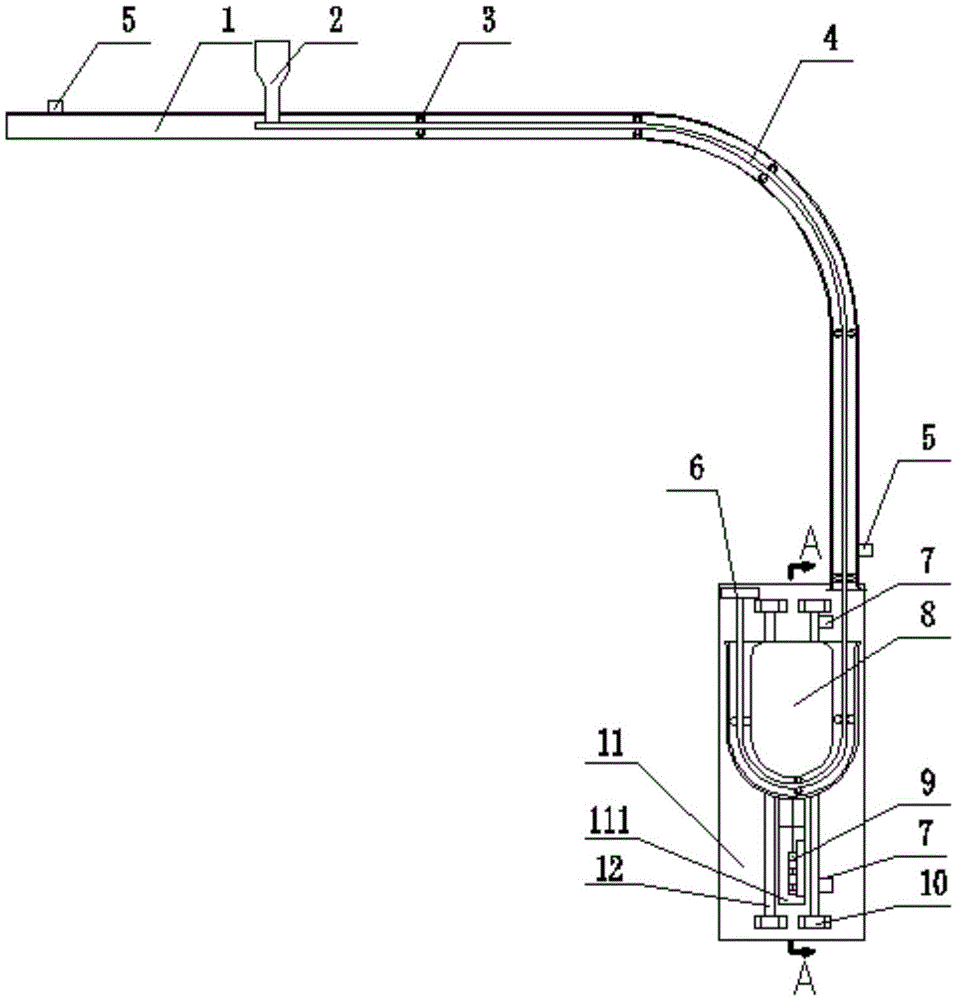

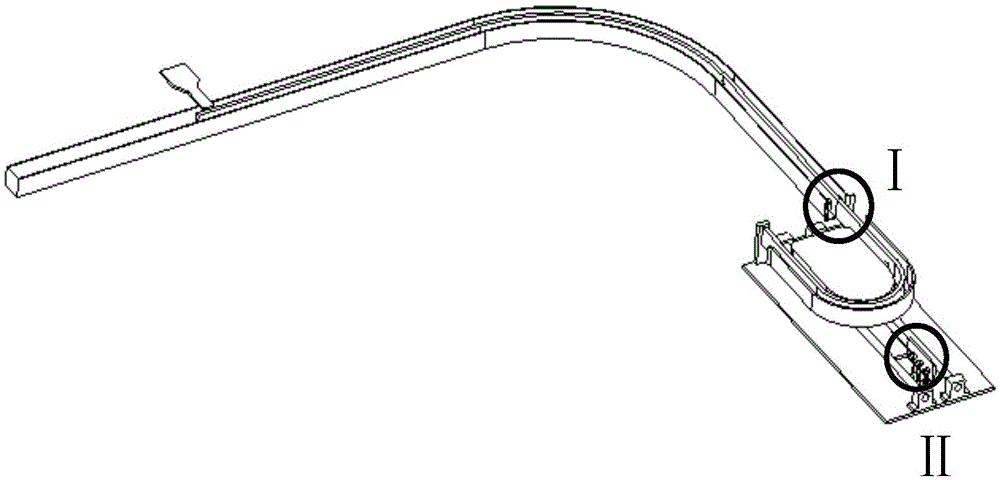

[0044] Such as Figure 1 ~ Figure 3 As shown, a drag chain moving device for curve power supply mainly includes: guide groove 1, connecting frame 2, roller 3, drag chain 4, limit block 7, moving frame 8, moving frame driving device 9, limit Switch 5, optical axis 12, slide block 13 etc., cable towline moving device is installed on the substrate such as wall or column by support.

[0045] The drag chain 4 is mounted on the side of the guide groove 1, and rollers 3 are installed at equal intervals on the side contacting the guide groove 1; the shape of the guide groove 1 is basically the same as the running track curve of the mobile device; one end of the drag chain 4 is connected to the power supply bracket 6 connection, the other end is fixed on the connecting frame 2 of the mobile device, and limit switches 5 are installed at the two limit positions of the mobile device's operating stroke;

[0046] The movable frame 8 is processed with an arc-shaped groove supporting the dra...

Embodiment 2

[0058] Another embodiment of the present invention is to use a motor-driven moving frame instead of the above-mentioned moving frame driven by the counterweight and the pulley block. In this way, the driving force of the mobile frame in the reciprocating operation process is provided by the motor carried by itself. In addition, limit switches are also installed at the two travel positions of the moving frame to control the operation and stop of the driving motor of the moving frame.

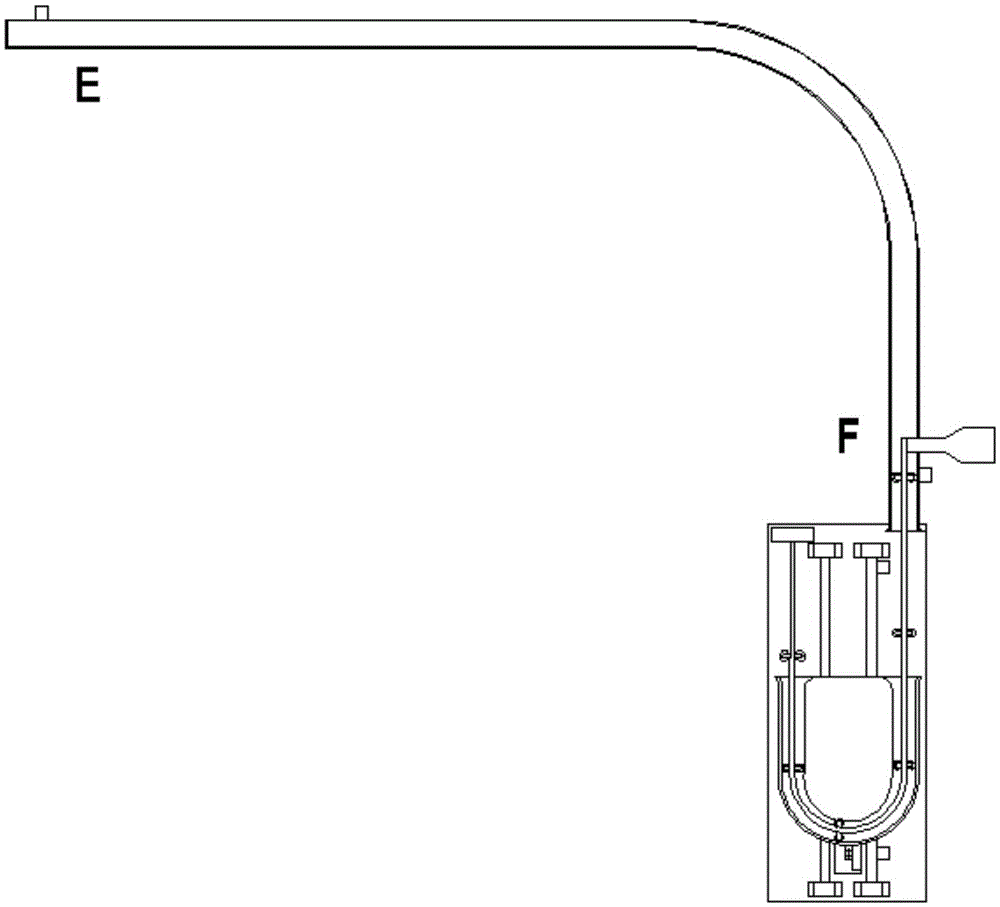

[0059] In this way, it is only necessary to set the moving speed of the mobile frame to be consistent with the running speed of the mobile device during operation, especially when the mobile device is running from E to F, the requirements for the running speed of the two are relatively high. The motor can be cleared after the equipment runs a stroke to prevent accumulated errors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com