Method for producing scrape cutter blade

A production method and cutting edge shearing technology, applied in the field of tool manufacturing and processing, can solve the problems of insignificant effect, reduced tool life, poor toughness, etc., so as to improve reliability and service life, reduce impact load, and reduce shearing. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

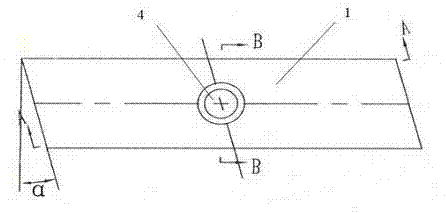

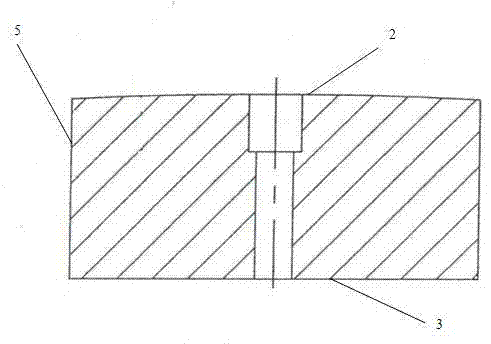

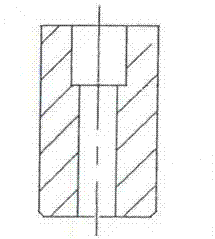

Image

Examples

Embodiment 1

[0034] When producing edge scraping scissors, first select H13 (4Cr5MoSiV1) steel as the raw material; then cut the steel material selected above, and cut out a parallelepiped blank from the steel; then forge, the initial forging temperature is 1119 ° C, and the final forging The forging temperature is 850°C; the blank is preheated in the furnace at 500°C, and the temperature is raised after 3 hours, and the temperature is raised to 850°C at a heating rate of 49°C per hour, and the temperature is kept for 10 minutes to ensure uniform burn-through, then heated to 1119°C, and kept for 60 minutes Forged. Then heat-treat the forged material; use quenching temperature of 1000°C, then oil cooling, tempering twice at 260°C, oil cooling again, hardness HRC=53. Finally, use lathes and milling machines to process the top surface, side surface and bottom surface of the workpiece, so that the outer diameter of the workpiece = the outer diameter of the finished product + 25 ± 2mm; use the ...

Embodiment 2

[0038]When producing edge scraping scissors, first select H13 (4Cr5MoSiV1) steel as the raw material; then cut the steel material selected above, and cut out a parallelepiped blank from the steel; then forge, the initial forging temperature is 1119 ° C, and the final forging The forging temperature is 850°C; the blank is preheated in the furnace at 520°C, and the temperature is raised after 3 hours, and the temperature is raised to 850°C at a heating rate of 49°C per hour, and the temperature is kept for 10 minutes to ensure uniform burn-through, then heated to 1119°C, and kept for 60 minutes Forged. Then heat-treat the forged material; use quenching temperature of 980°C, then oil cooling, tempering twice at 255°C, oil cooling again, hardness HRC=54. Finally, use lathes and milling machines to process the top surface, side surface and bottom surface of the workpiece, so that the outer diameter of the workpiece = the outer diameter of the finished product + 25 ± 2mm; use the dr...

Embodiment 3

[0041] When producing edge scraping scissors, first select H13 (4Cr5MoSiV1) steel as the raw material; then cut the steel material selected above, and cut out a parallelepiped blank from the steel; then forge, the initial forging temperature is 1119 ° C, and the final forging The forging temperature is 850°C; the blank is preheated in the furnace at 499°C, the temperature is raised after 3 hours, and the temperature is raised to 850°C at a heating rate of 49°C per hour, and the temperature is kept for 10 minutes to ensure uniform burn-through, then heated to 1119°C, and kept for 60 minutes Forged. Then heat-treat the forged material; use a quenching temperature of 980°C, then oil-cool, temper three times at 265°C, and oil-cool again, with a hardness of HRC=55. Finally, use lathes and milling machines to process the top surface, side surface and bottom surface of the workpiece, so that the outer diameter of the workpiece = the outer diameter of the finished product + 25 ± 2mm; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com