Patents

Literature

30results about How to "Use long-acting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

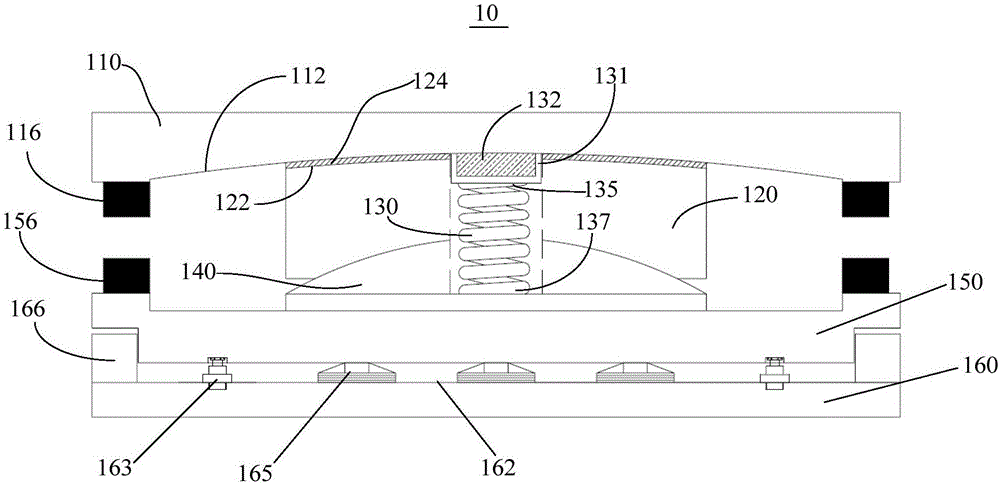

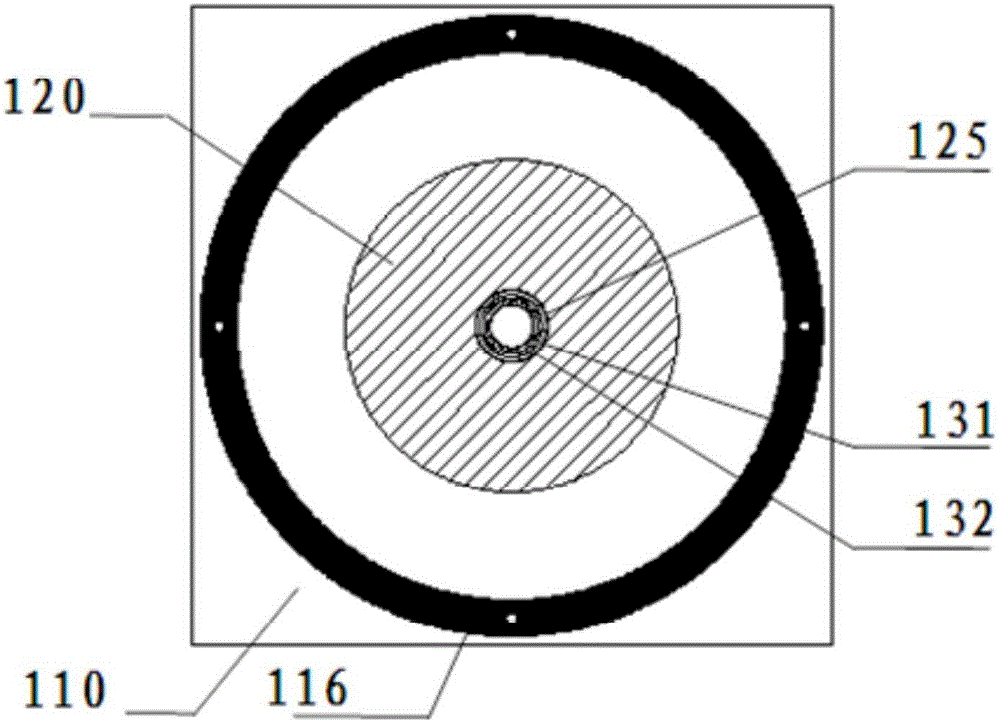

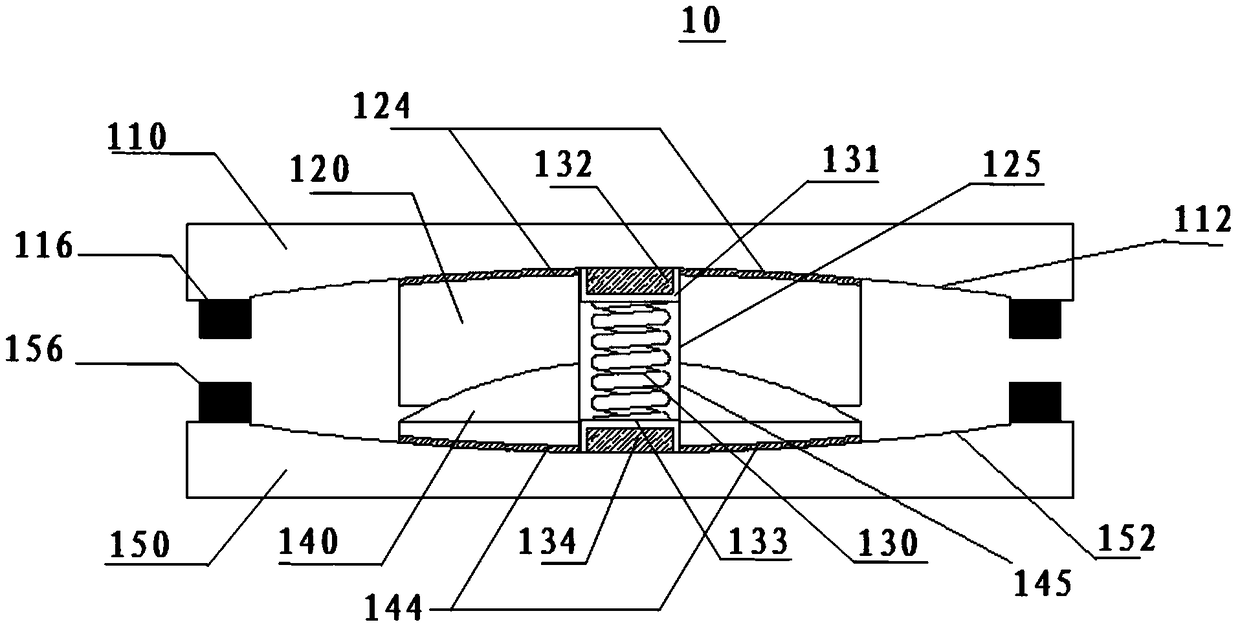

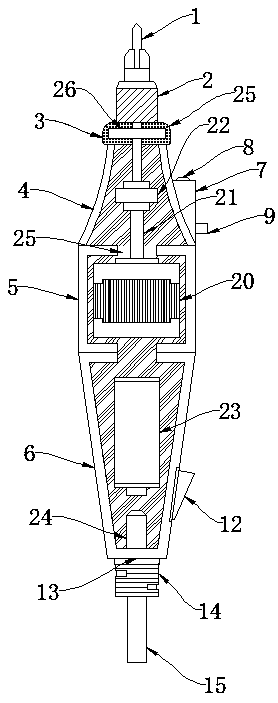

Three-dimensional shock insulation supporting seat

ActiveCN106381934AImprove stabilityAchieve consumptionProtective buildings/sheltersShock proofingElastic componentEngineering

The invention provides a three-dimensional shock insulation supporting seat which realizes consumption of seismic energy by rubbing a first friction hook face with a first rubbing piece arranged at the first end of a first elastic component. As the elastic component can continuously supply stable pressure for the first rubbing piece, the three-dimensional shock insulation supporting seat has relatively high stability, and can be used effectively for a long time.

Owner:TSINGHUA UNIV

Preparing method of odor removal bead with core-shell structure and function of absorbing water

InactiveCN110292650AUse long-actingImprove deodorization efficiencyDeodrantsStructure and functionCore shell

The invention relates to the field of odor removal, in particular to a preparing method of an odor removal bead with a core-shell structure and the function of absorbing water. The core-shell structure is involved and comprises an outer layer and an inner core covered with the outer layer, and the bead is mainly prepared by steps of preparation of a clathrate compound, preparation of the inner core, preparation of the outer layer and drying granulation. The material which forms a micropore structure when swelling in the presence of water restores the original shape when losing water, the innercore is slow-release particles formed by the clathrate compound containing camphor essential oil, eucalyptus essential oil or yucca schidigera plant essential oil and other natural odor removal materials, high-molecular water-absorbing capsule walls of the outer layer swell in the presence of water, then micropores in the high-molecular capsule walls are opened, thus water enters the micropores and is in contact with the inner core, the inner core releases odor removal substances in the presence of water, and then the odor removal substances are slowly released through the micropores; when the adsorbed water molecules reach the saturation value, along with water loss, the odor removal bead is gradually shrunk day by day until the bead restores the original size, after water is re-added into the bead, the original odor removal function can be restored, the bead can be repeatedly used multiple times, and the safe, long-acting and lasting odor removal effects are achieved.

Owner:GUANGZHOU JIANISI ANTIBIOSIS MATERIAL CO LTD

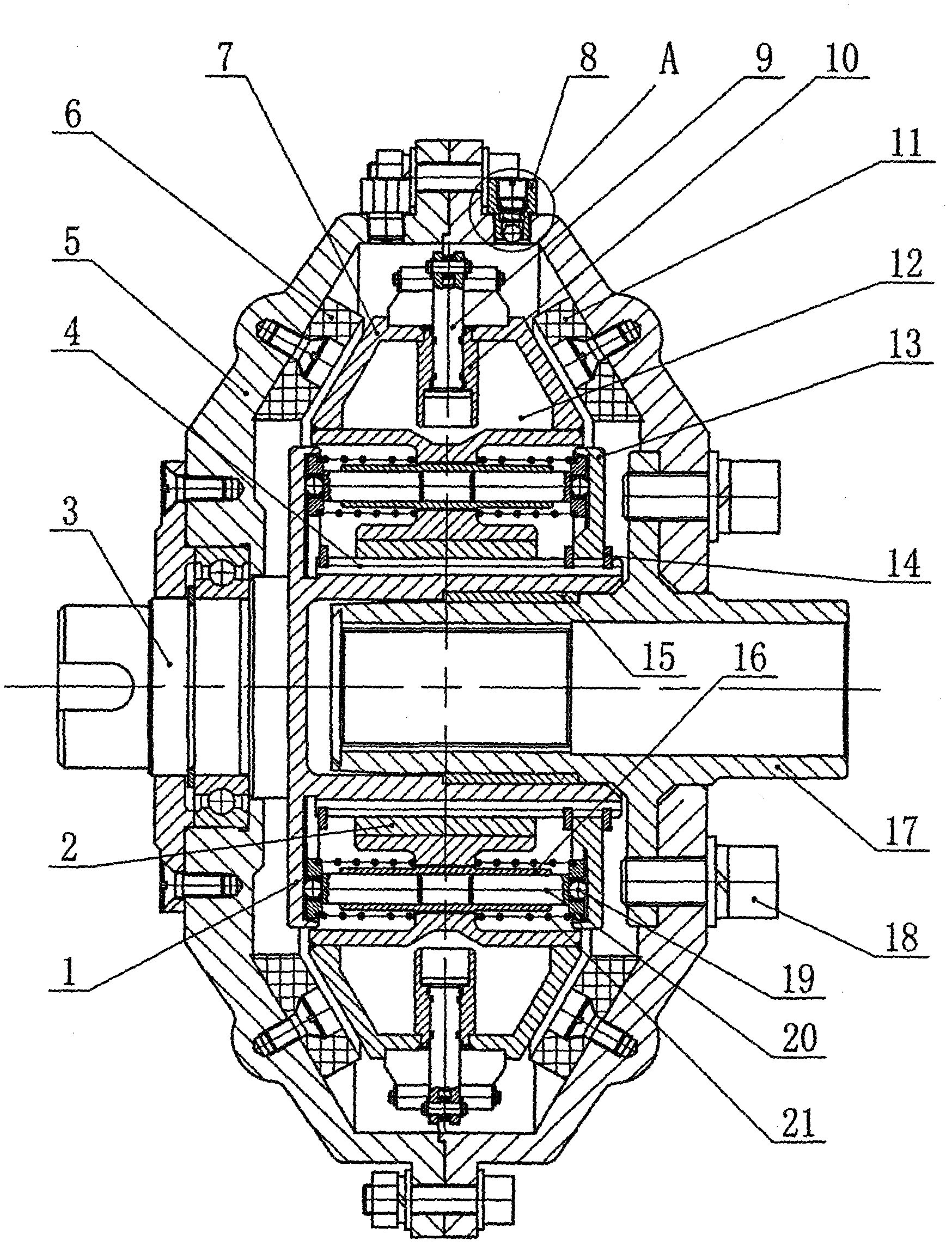

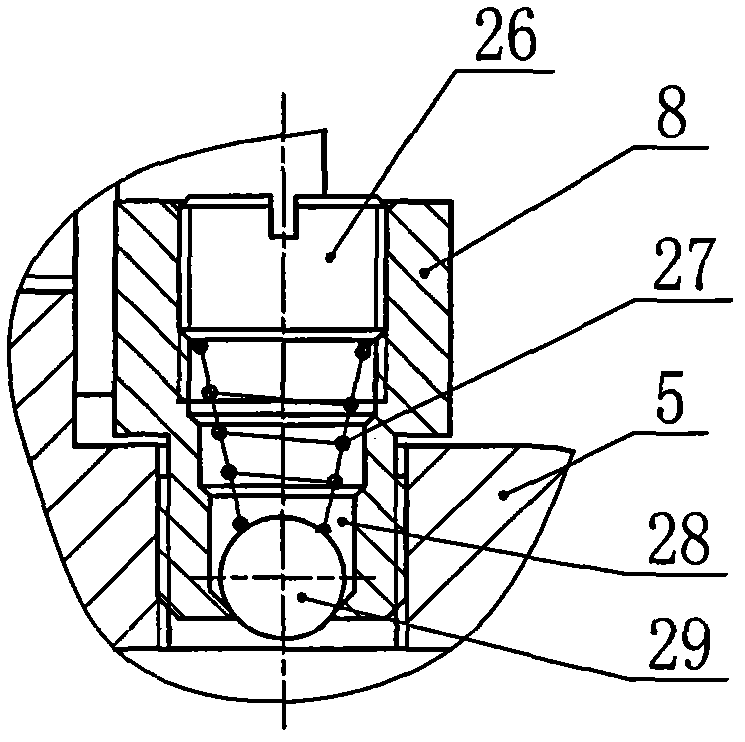

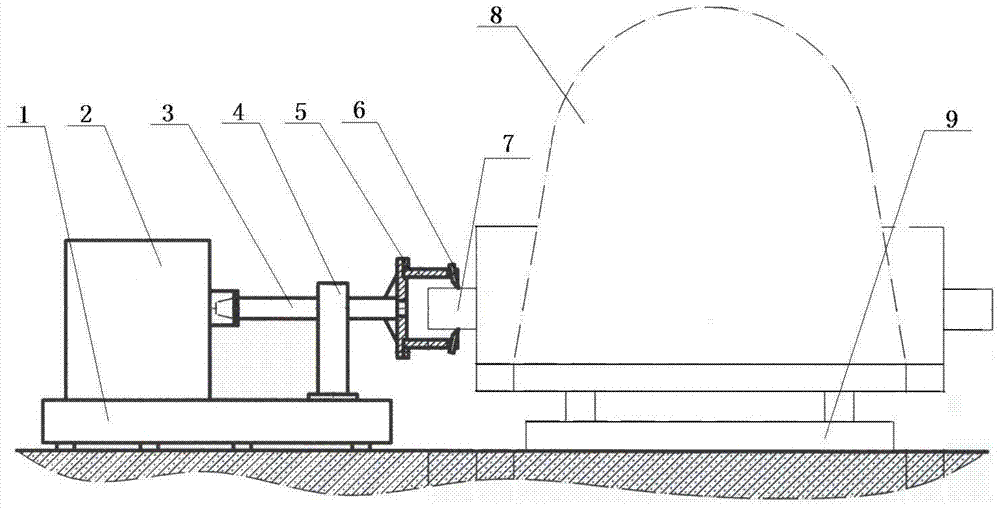

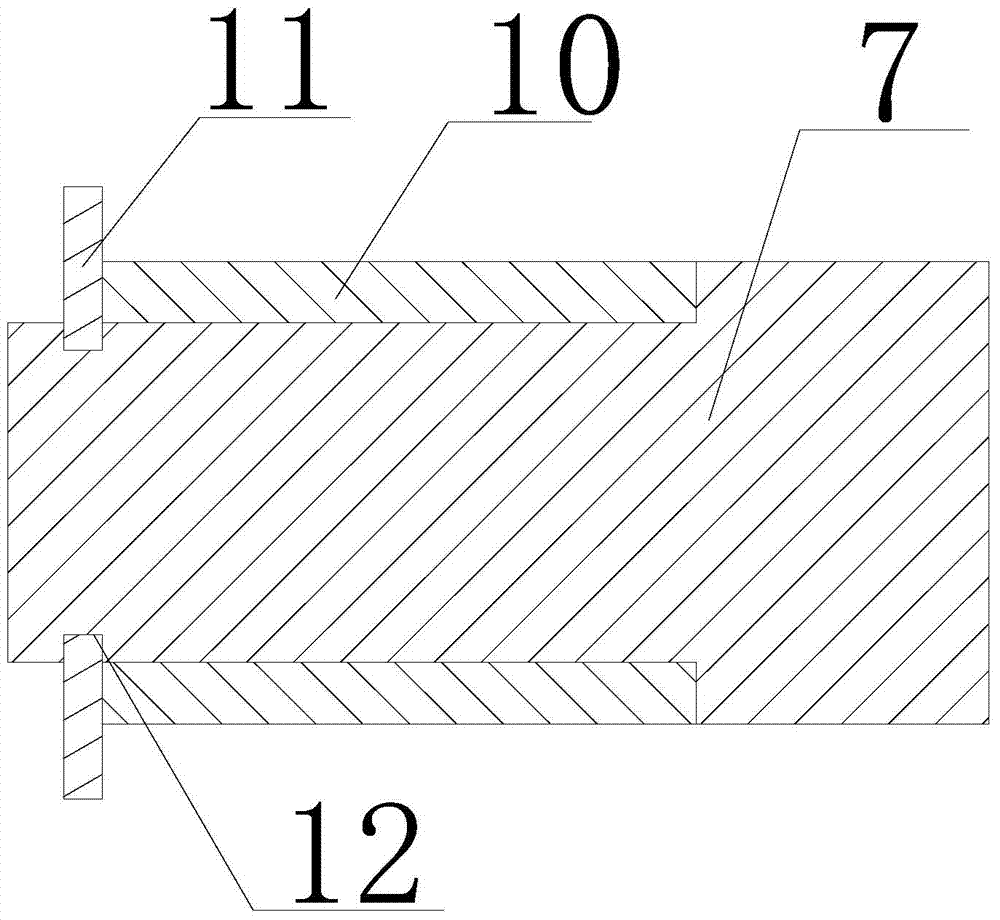

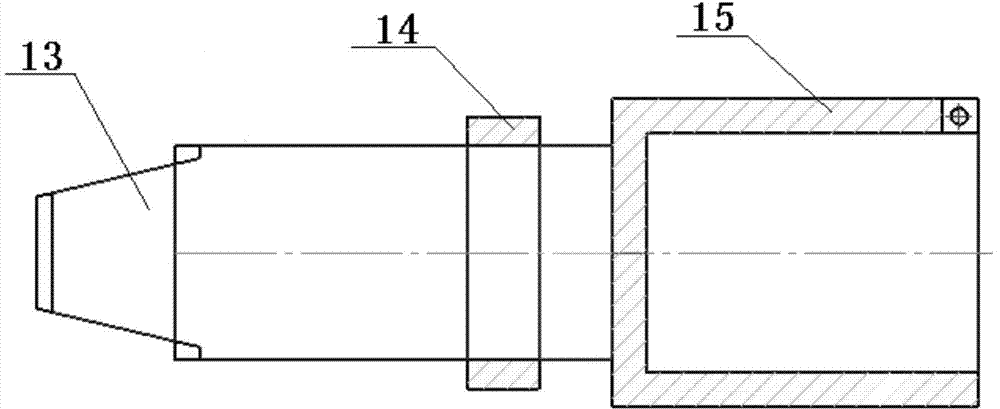

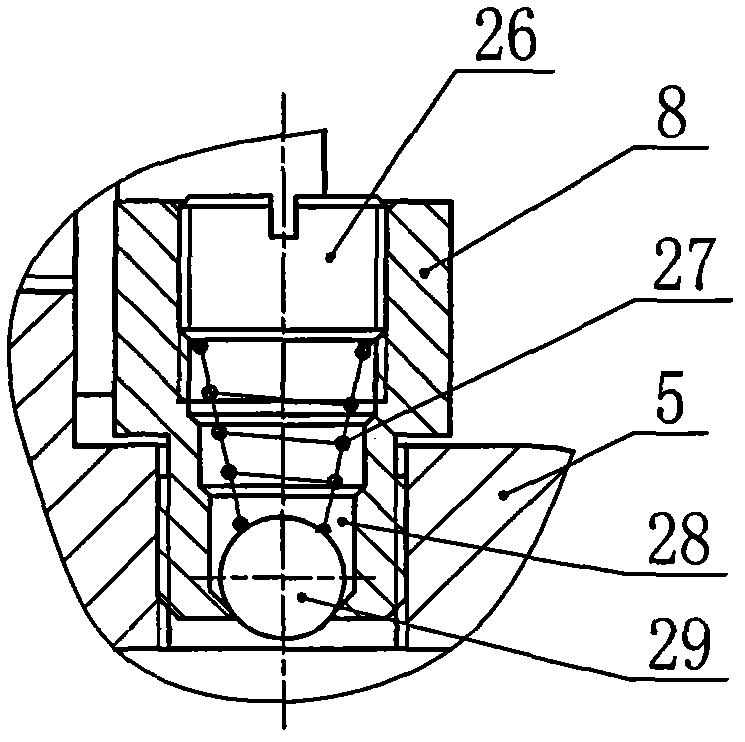

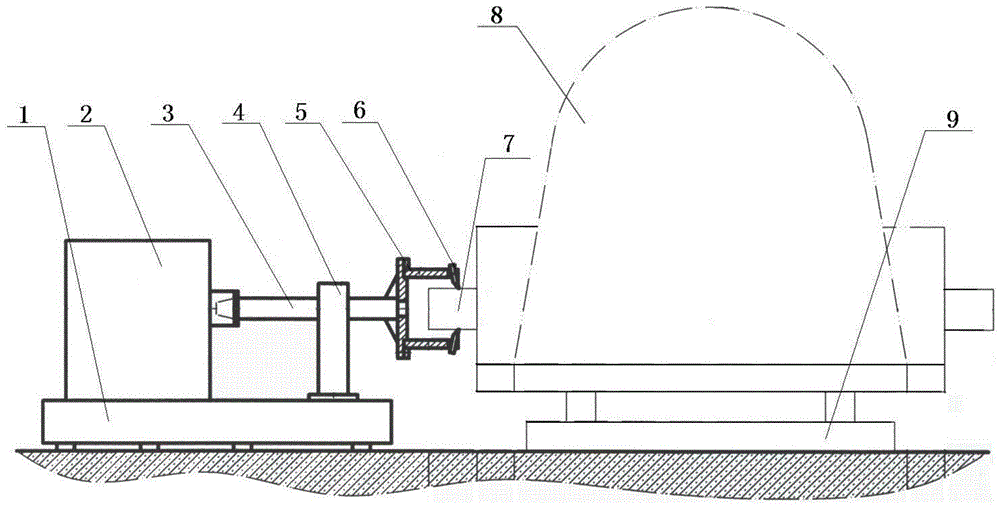

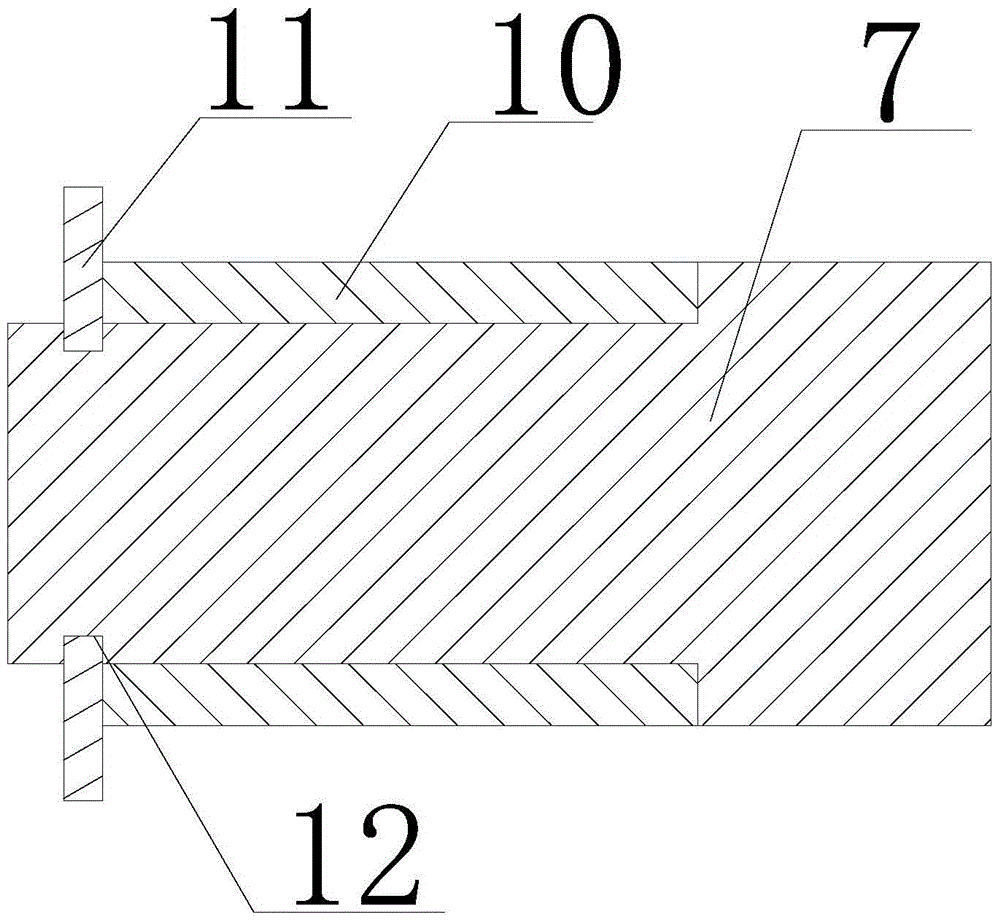

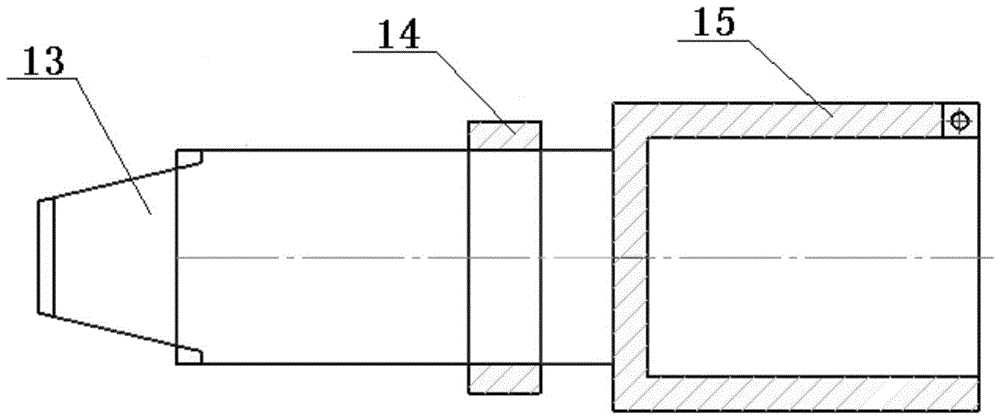

Friction-type coupler

InactiveCN102252047ANo excessive wear and tearAchieve power transmissionSlip couplingFriction clutchesDrive shaftEngineering

The invention relates to a friction-type coupler which comprises a main transmission shaft (3), a friction plate (7), a clutch shell (5), an inner spline connecting sleeve (17) and a device, wherein the device positions the friction plate (7) in axial direction and is subjected to axial spring pressure; when the coupler is started, a friction block (25) is in contact friction with the radial inner surface of the clutch shell (5) under the action of centrifugal force to control the friction between the friction plate (7) and friction rings (6 and11) at the inner side surface of the clutch shell, and power transfer is realized; in overload, the friction plate and the friction rings have friction to cause temperature rise, liquid in an enclosed cavity (12) of the friction plate has temperature rise and expands to force the fraction plate to separate from the friction rings, and then a motor is separated from the load. The friction-type coupler has the advantages of light weight, stable connection, sensitive power transfer, great contact friction force and long-acting effect in use, and the surface temperature of the coupler can be controlled; the over-temperature safety hazard is eliminated thoroughly, and the couple is especially suitable for occasions with the high temperature safety requirement.

Owner:XUZHOU ZHIDIAN ELECTROMECHANICAL EQUIP

Large slag ladle repairing technology

ActiveCN103567698AExtended service lifeReduce manufacturing costMetal working apparatusSlag% diameter reduction

The invention discloses a large slag ladle repairing technology. The large slag ladle repairing technology is characterized in that a hanger shaft of a slag ladle is milled through a machining device in a manner that a cutter rotates while the workpiece stays still, so that the diameter of the hanger shaft is reduced; the hanger shaft with the reduced diameter is then sleeved by a shaft sleeve, and the outer diameter of the shaft sleeve is identical to the diameter of the hanger shaft before the diameter reduction. The large slag ladle repairing technology disclosed by the invention has the advantages that the diameter of the worn-out hanger shaft of the slag ladle is reduced to 270 mm through machining, and the hanger shaft is then sleeved by the shaft sleeve with a diameter of 300 mm, so that the slag ladle can be reused after repair, which greatly prolongs the service life of the slag ladle and saves the production cost.

Owner:SICHUAN DAZHOU IRON & STEEL GROUP

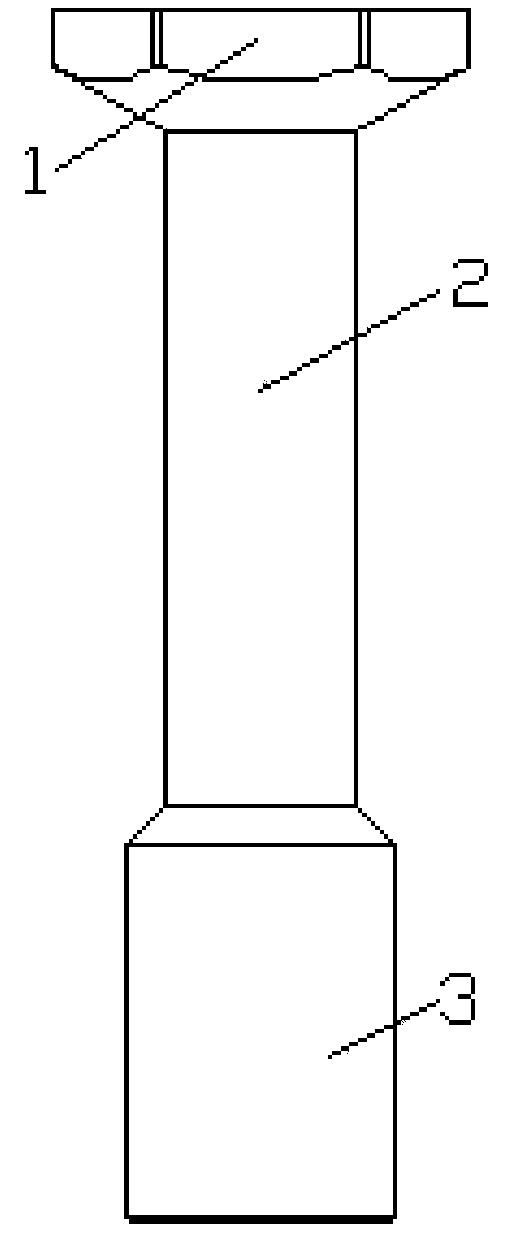

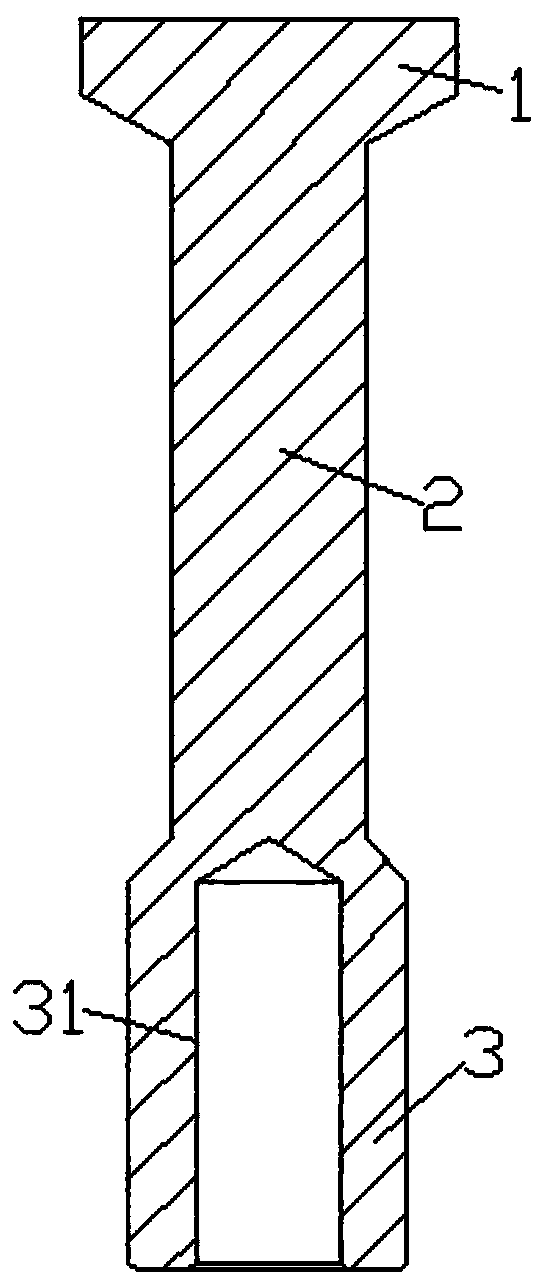

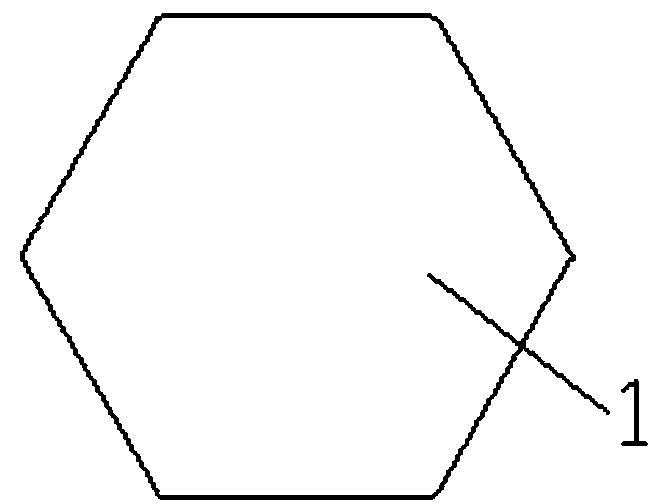

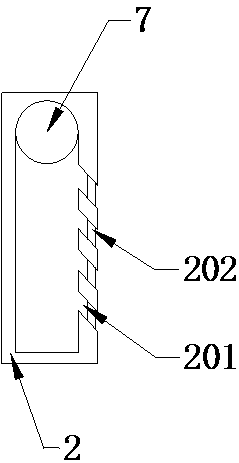

Stainless steel pre-buried sleeve

InactiveCN109296085AReduce usageUse long-actingBuilding constructionsPull forceAgricultural engineering

The invention discloses a stainless steel pre-buried sleeve, which comprises an anti-pulling device, a connecting rod and an inner threaded sleeve. The anti-pulling device is fixedly mounted at the upper end of the connecting rod, and the lower end of the connecting rod is fixedly connected with the inner threaded sleeve; and the circumcircle diameter ratio of the anti-pulling device to the connecting rod to the inner threaded sleeve is (0.5 to 3) to 1 to (0.15 to 2.35). The anti-pulling device is of a regular polygon structure, after the stainless steel pre-buried sleeve is buried in concrete, pulling force can be borne through the anti-pulling device in a specific shape, maximization of the axial pulling force borne by the stainless steel pre-buried sleeve is ensured, and thus operatingstability is further guaranteed; and meanwhile, overall rotation can be effectively prevented through the regular polygon structure, and thus overall loosening caused by rotating can be avoided.

Owner:江苏远兴集团建设有限公司 +1

Anti-rust protective film for building steel stamping part

InactiveCN108250815AWith high strength and wear resistanceStrong adhesionAnti-corrosive paintsTectorial membraneSuccinic acid

The invention discloses an anti-rust protective film for a building steel stamping part. The anti-rust protective film is prepared from the following raw materials in parts by weight: 40-75 parts of chlorosulfonated polyethylene, 20-35 parts of polyamino resin, 12-18 parts of ethyl silicate, 5-10 parts of sulfur dioxide, 2-8 parts of toughening resin, 5-15 parts of styrene-acrylic emulsion, 3-9 parts of dodecenyl succinic acid, 4-9 parts of aluminum powder, 2-4 parts of superfine palm wax micro powder, 3-7 parts of zinc sulfate and 6-10 parts of sepiolite powder. The protective film has the advantages of being high in strength, wear resistance and adhesive force, good in isolation performance and weather resistance, resistant to impact and the like, the stamping part can be repeatedly usedafter being subjected to one-time treatment, and the purposes of long-acting use, rust prevention and corrosion prevention and steel saving are achieved.

Owner:红安县弘志物资贸易有限公司

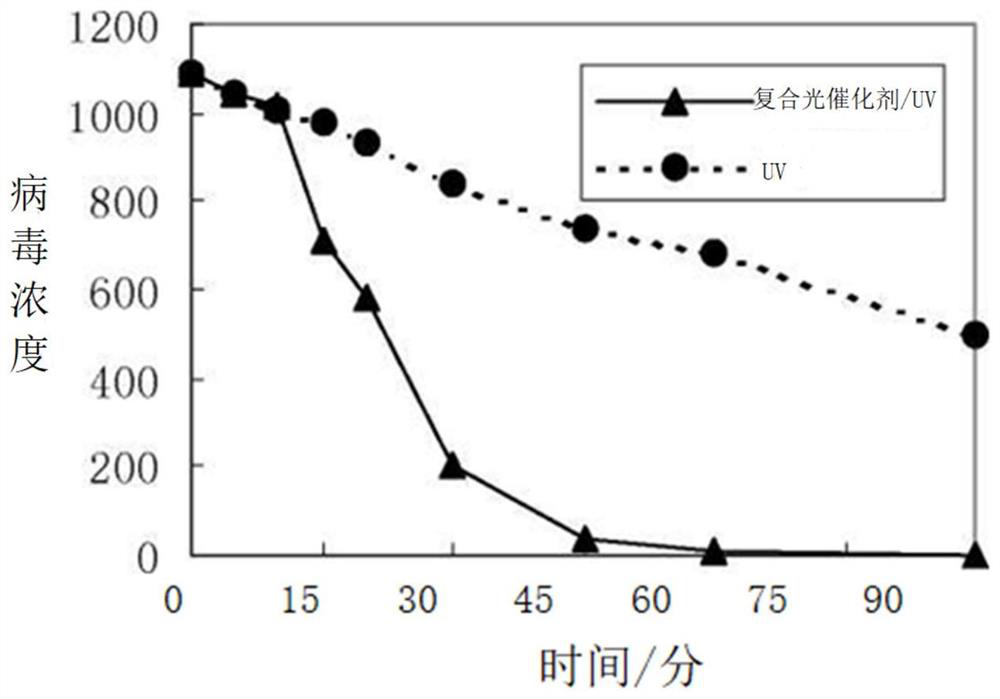

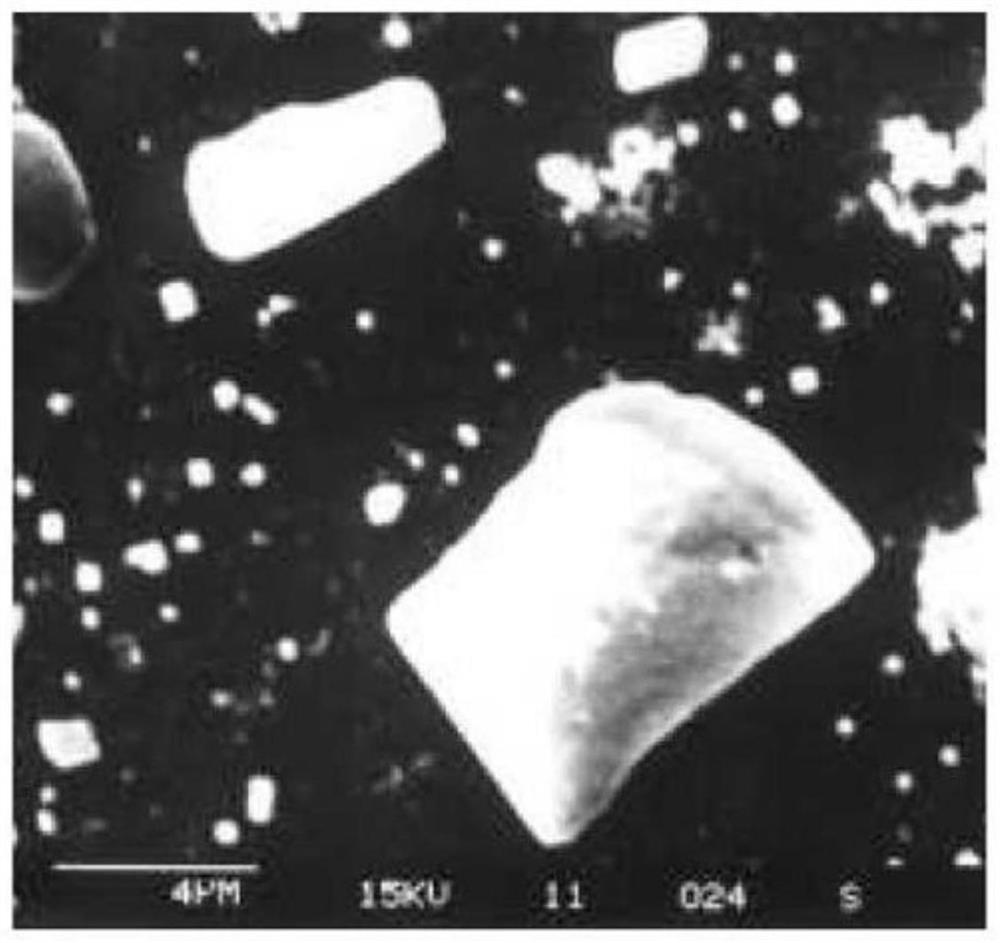

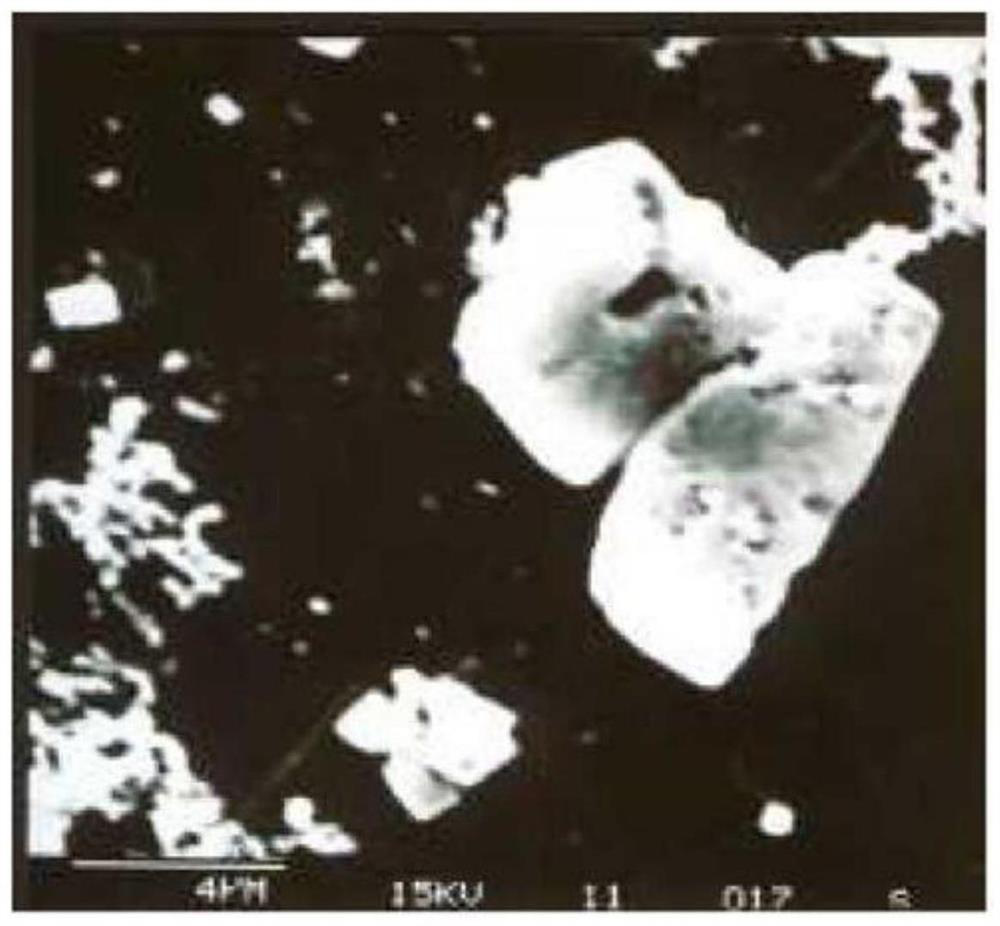

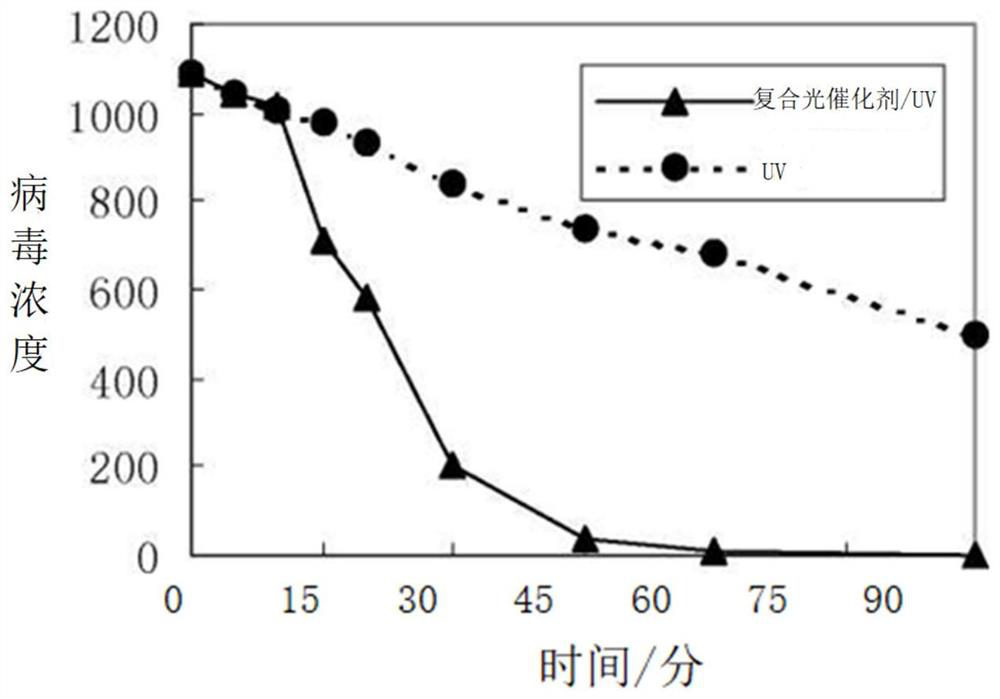

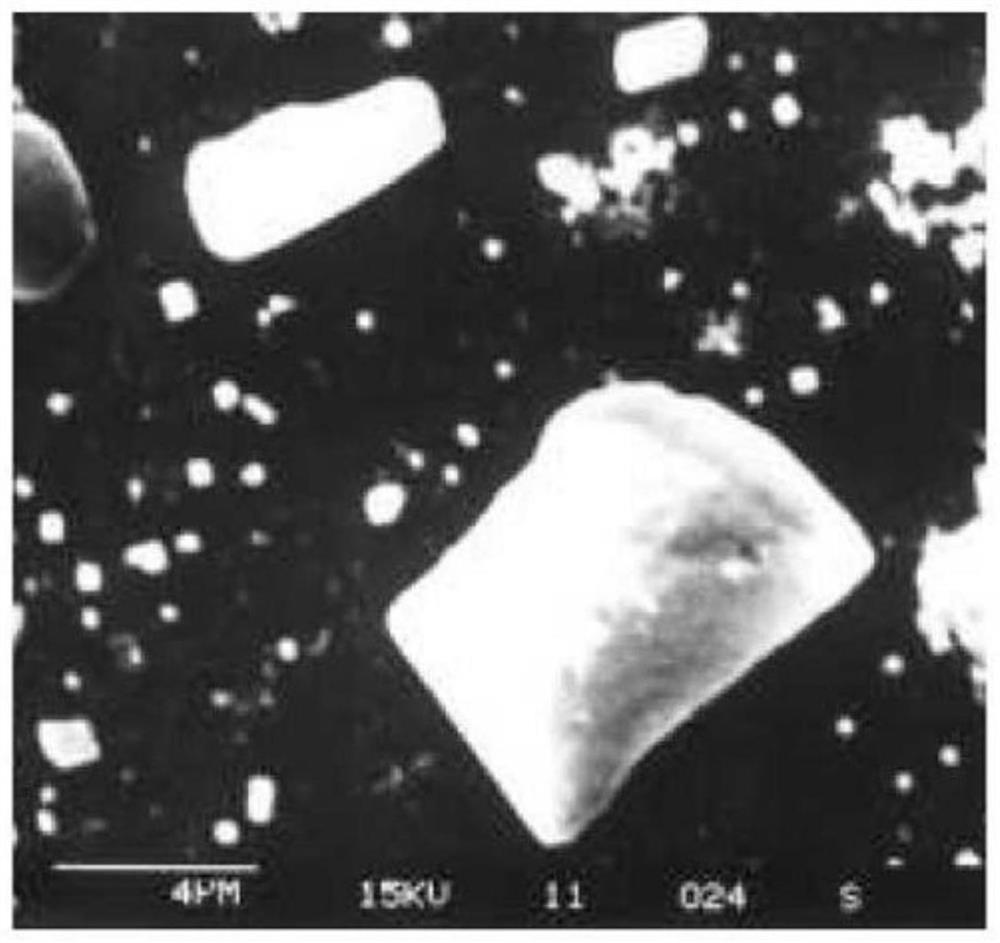

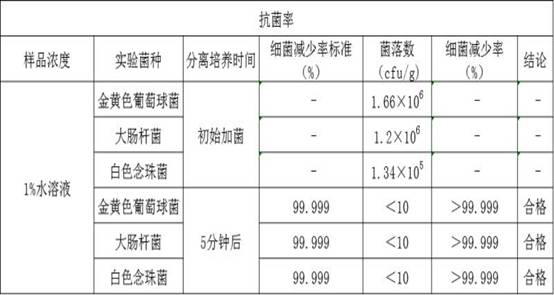

Sterilization and disinfection mask adopting photocatalysis apatite wrapping technology

ActiveCN112914173ASterilization hasAntibacterialProtective garmentSpecial outerwear garmentsPhoto catalysisSilver Nano

The invention belongs to the technical field of masks, and relates to a sterilization and disinfection mask adopting a photocatalysis apatite wrapping technology. The sterilization and disinfection mask comprises a sterilization and disinfection outer layer and a textile fabric inner layer contacting with a human face; the sterilization and disinfection outer layer comprises base layer cloth; the surface of the base layer cloth is coated with an apatite-nanometer titanium dioxide composite photocatalyst; and the base cloth is composed of nano-silver fibers, bamboo charcoal fibers and photocatalytic fibers. According to the mask, the outer layer of the mask is coated with the composite photocatalyst which is made of titanium dioxide and apatite and serves as a main sterilization and disinfection action object, the photocatalysis, sterilization and disinfection efficiency of titanium dioxide is integrally improved, and the mask has a long-acting use effect.

Owner:张斌翔

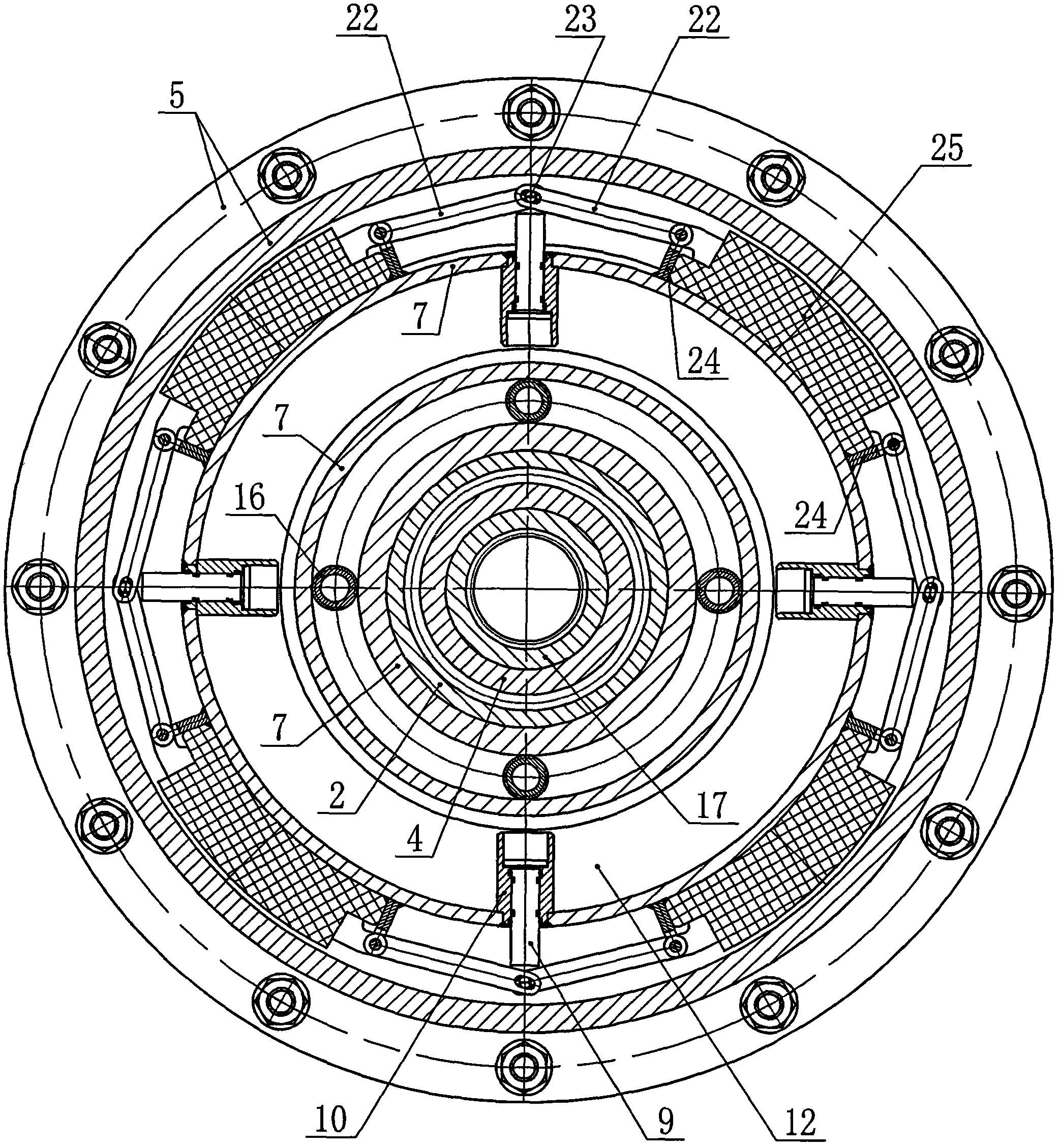

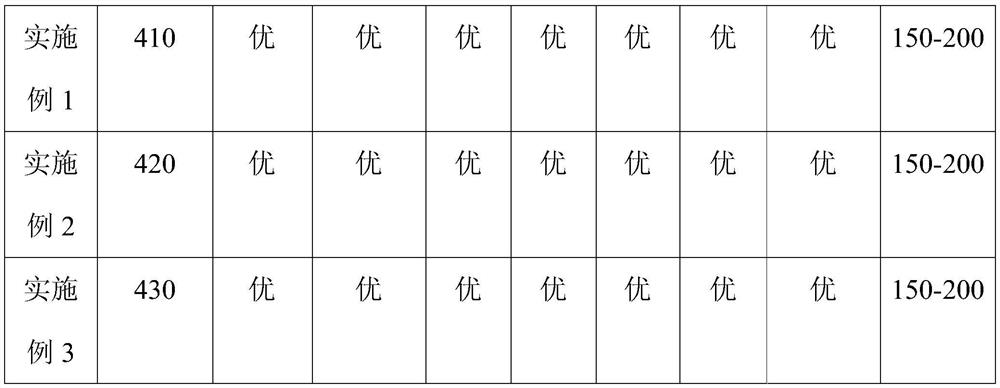

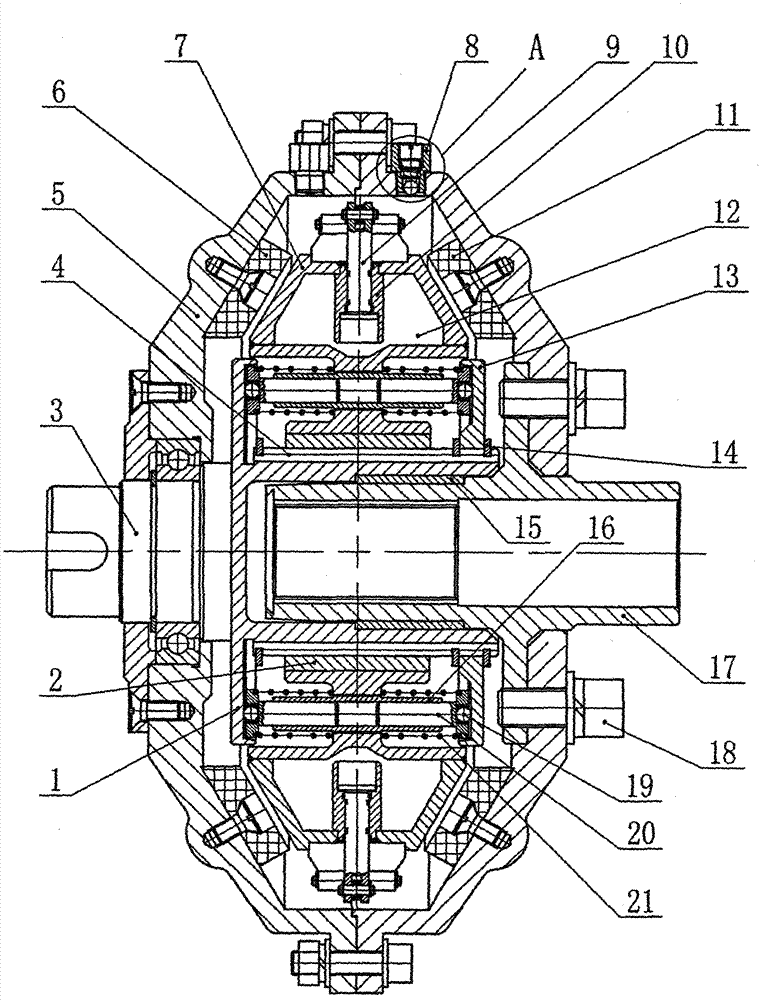

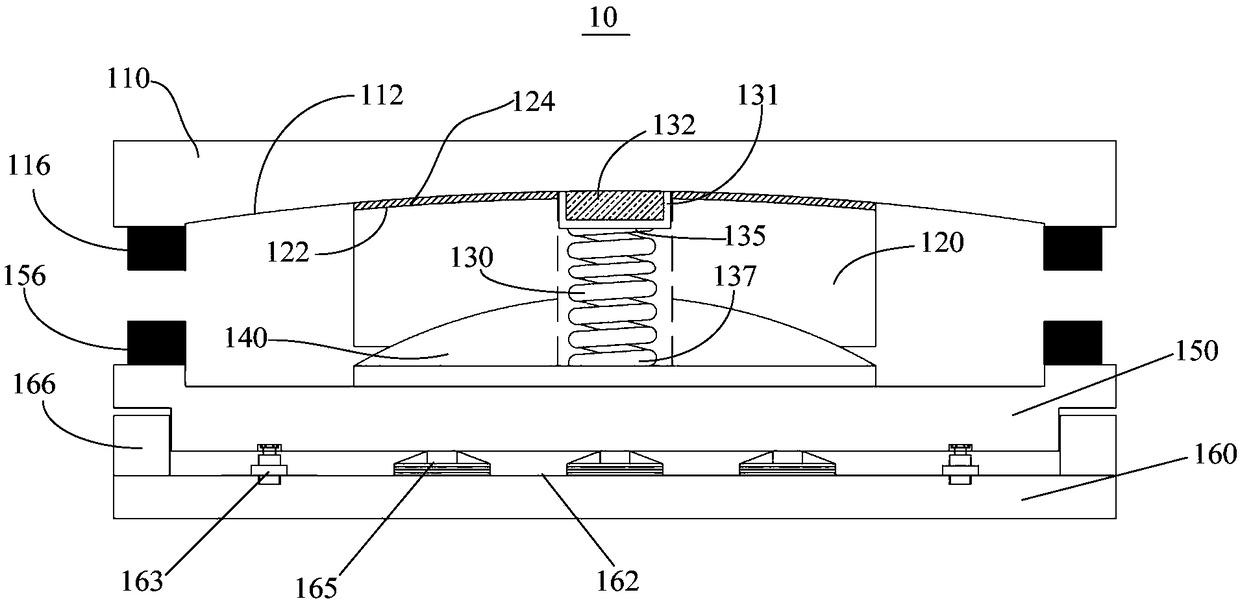

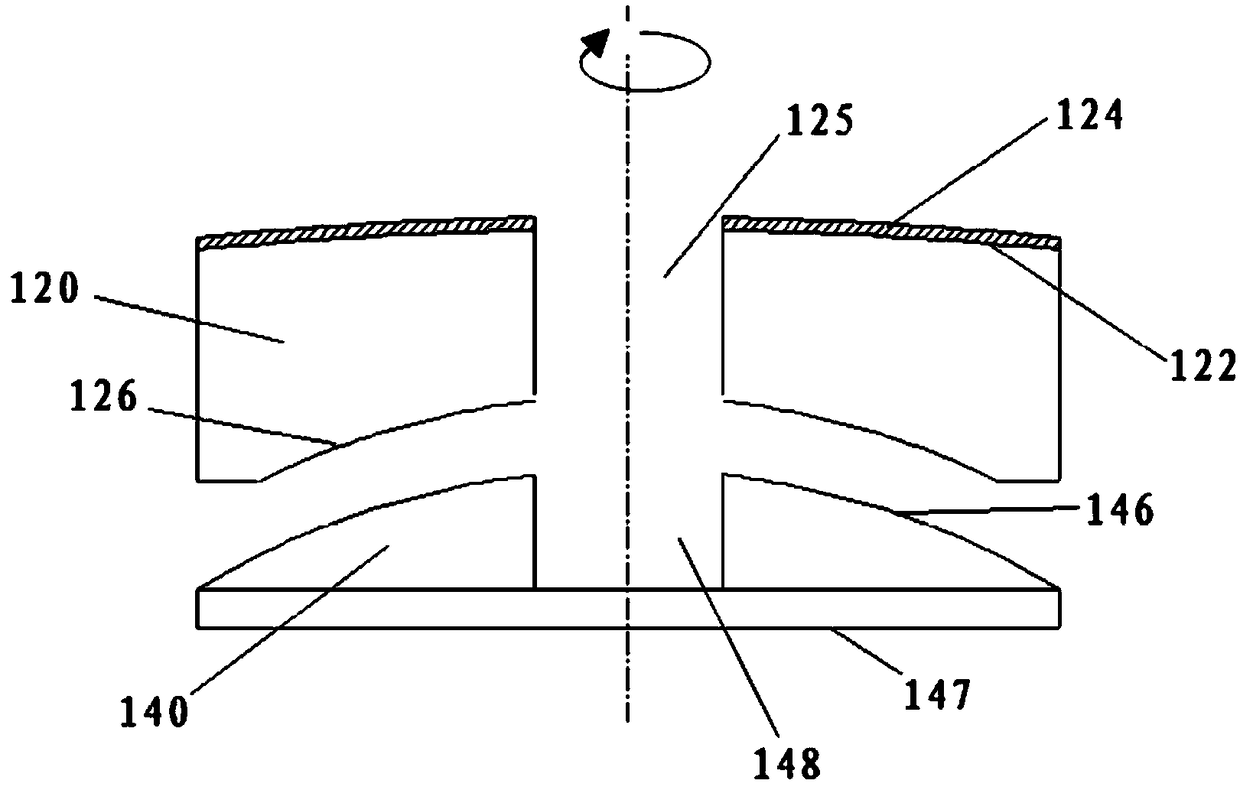

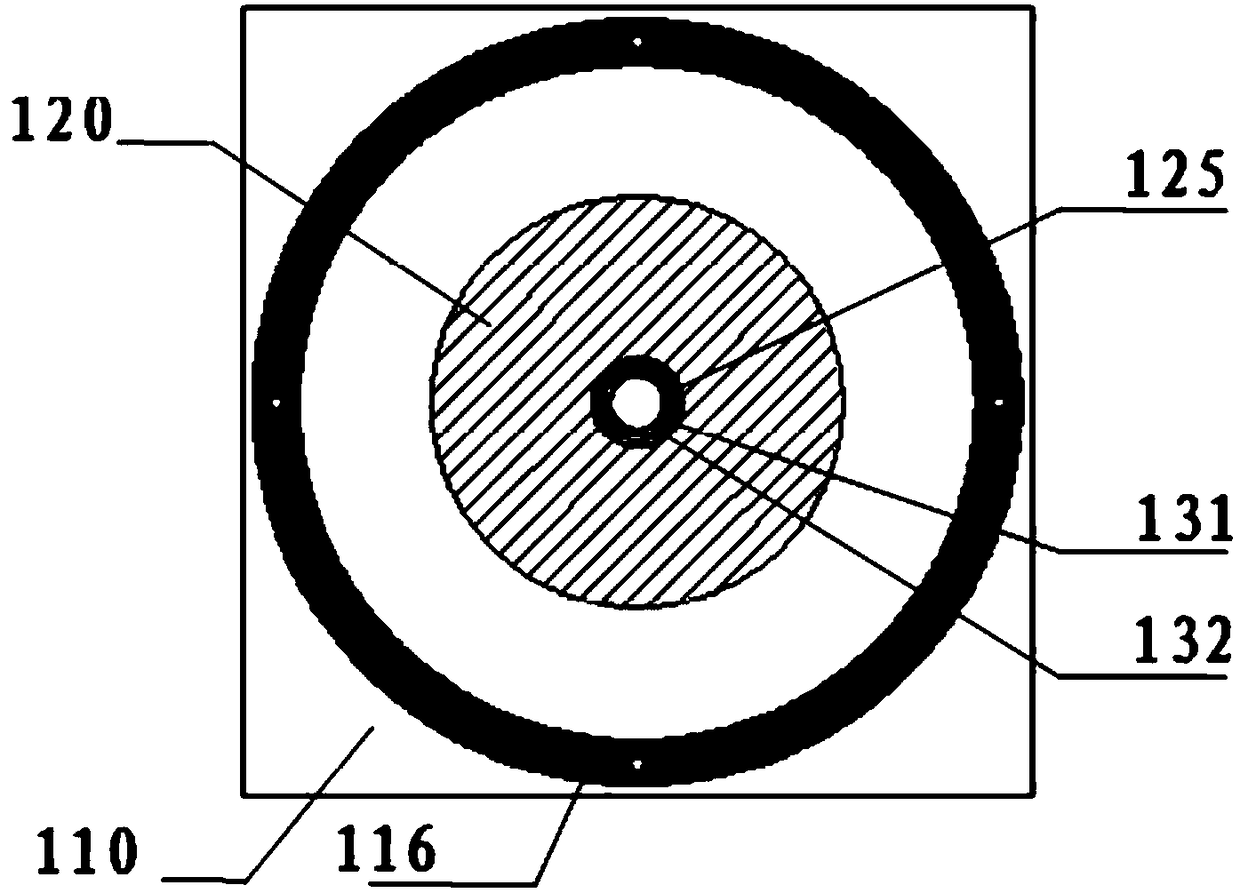

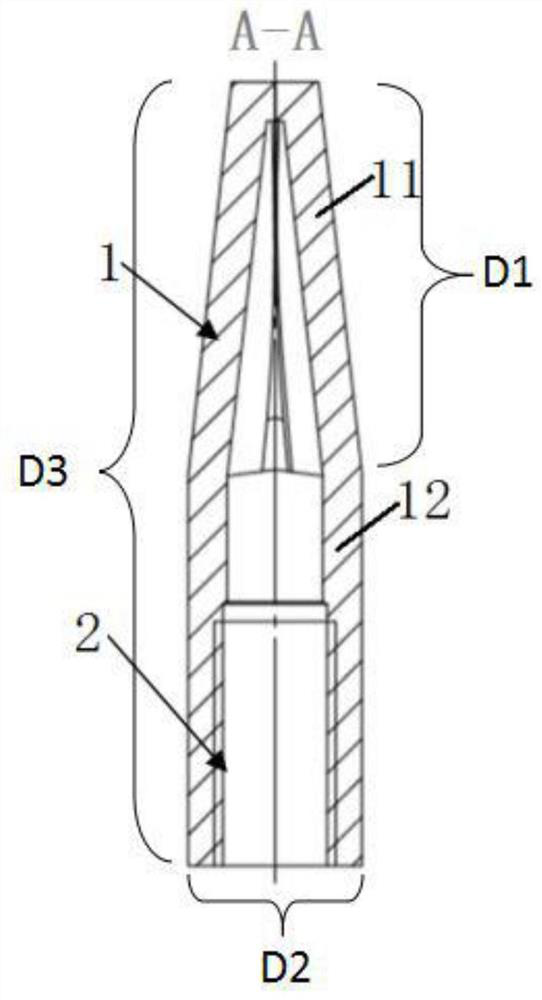

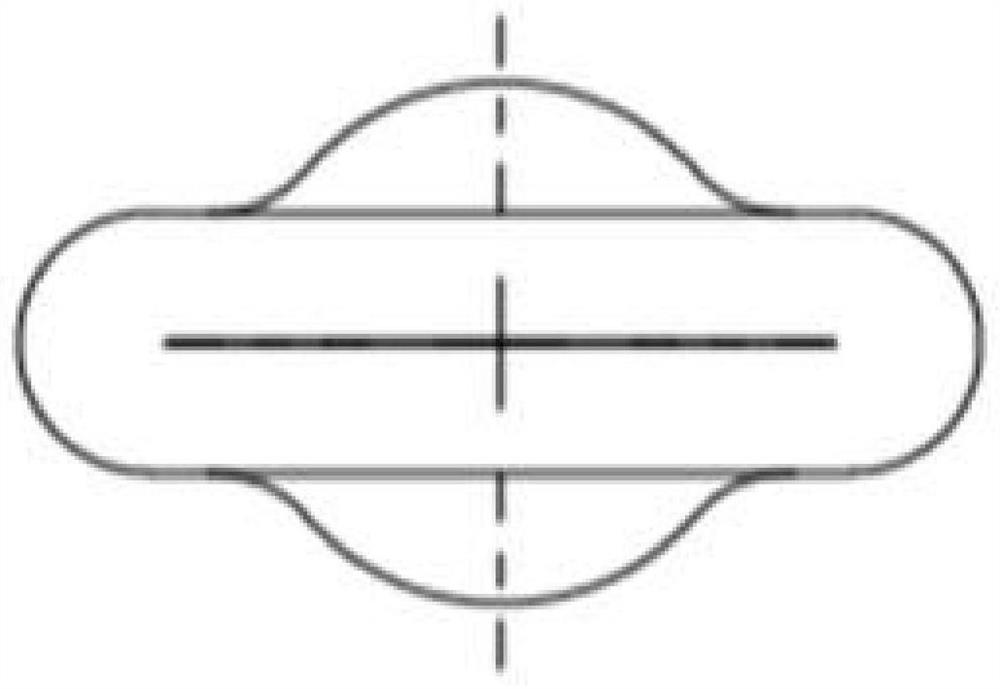

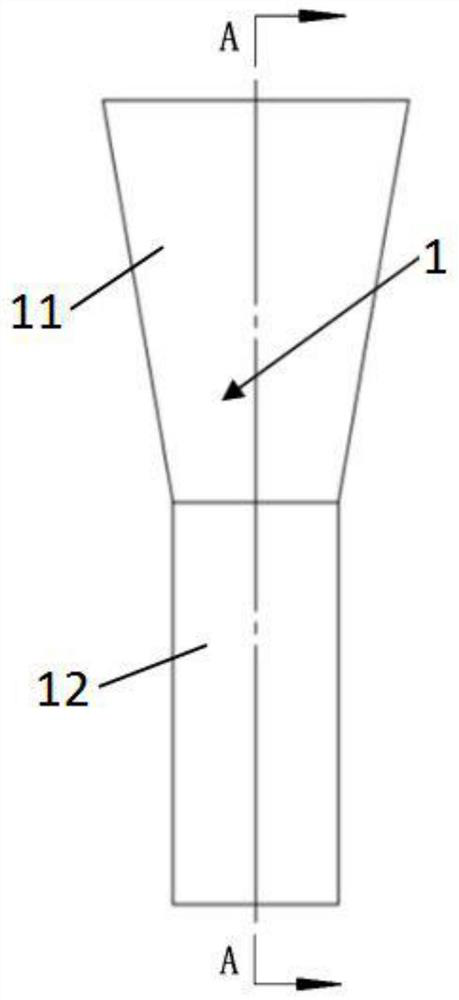

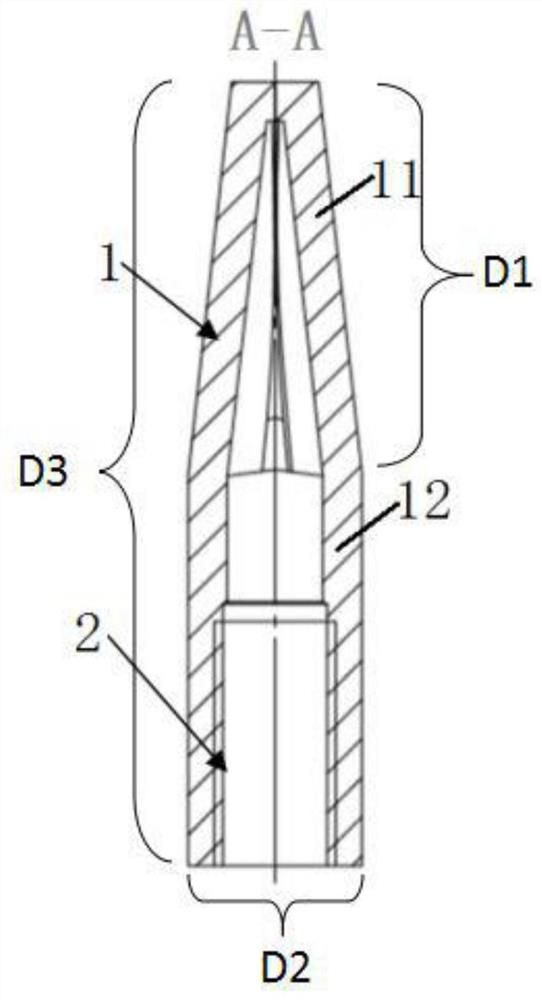

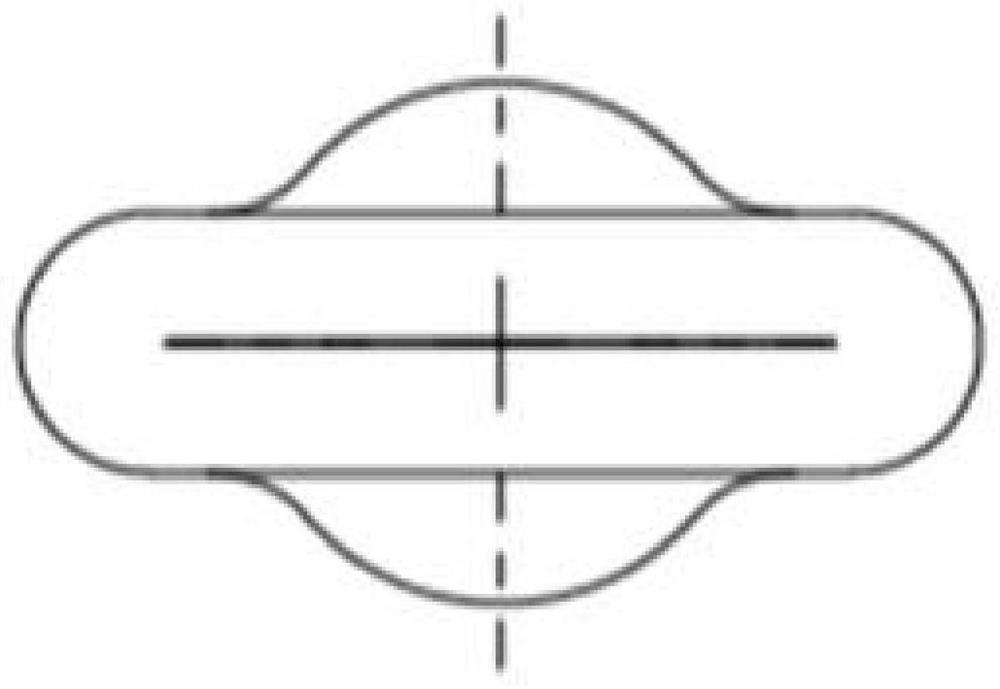

friction pendulum sliding bearing

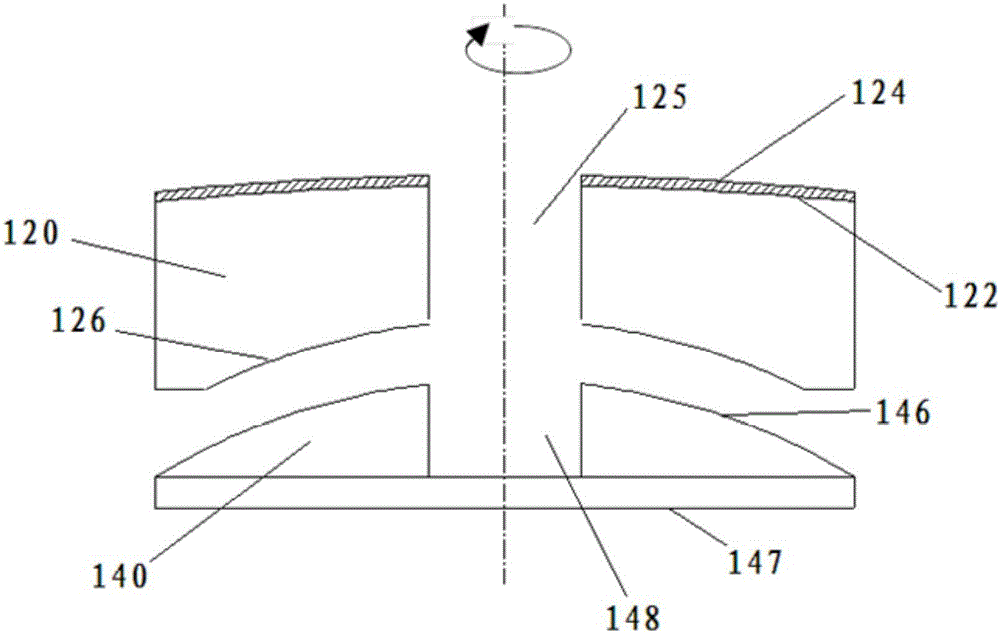

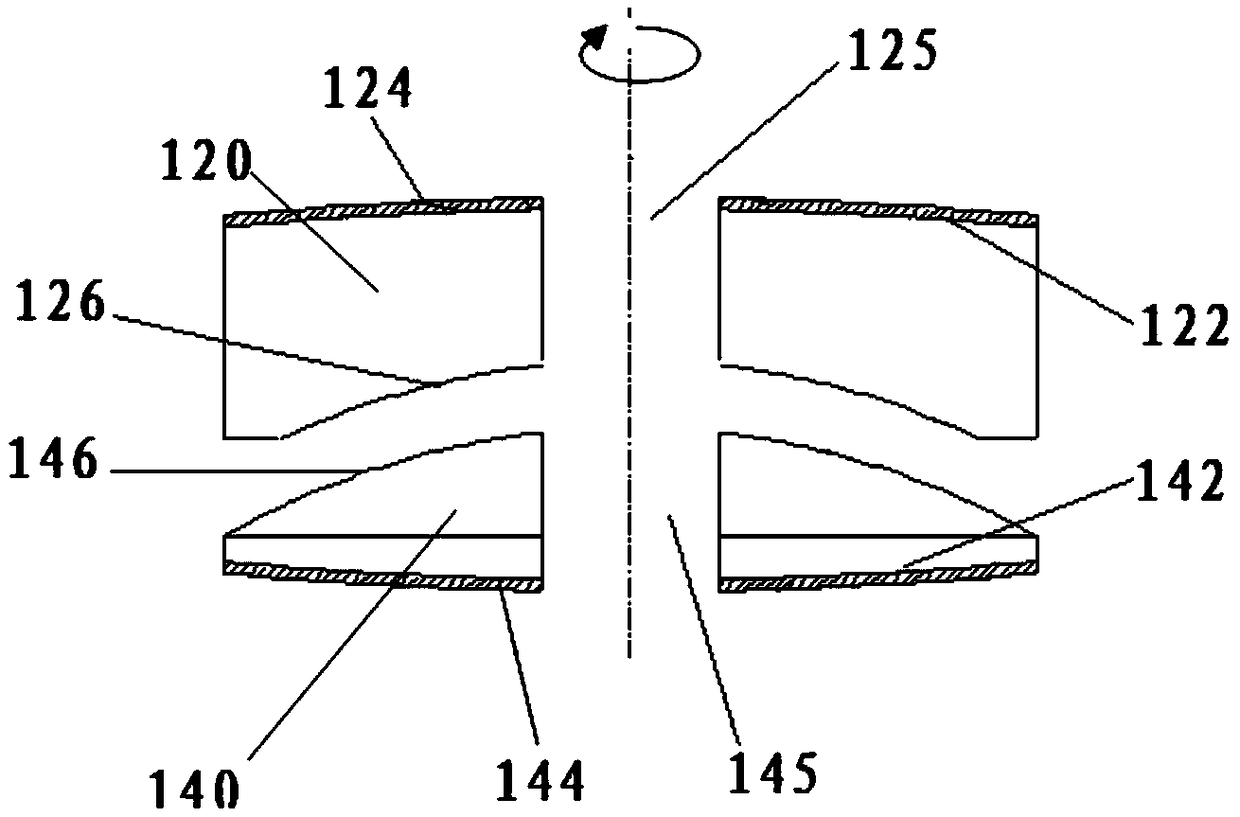

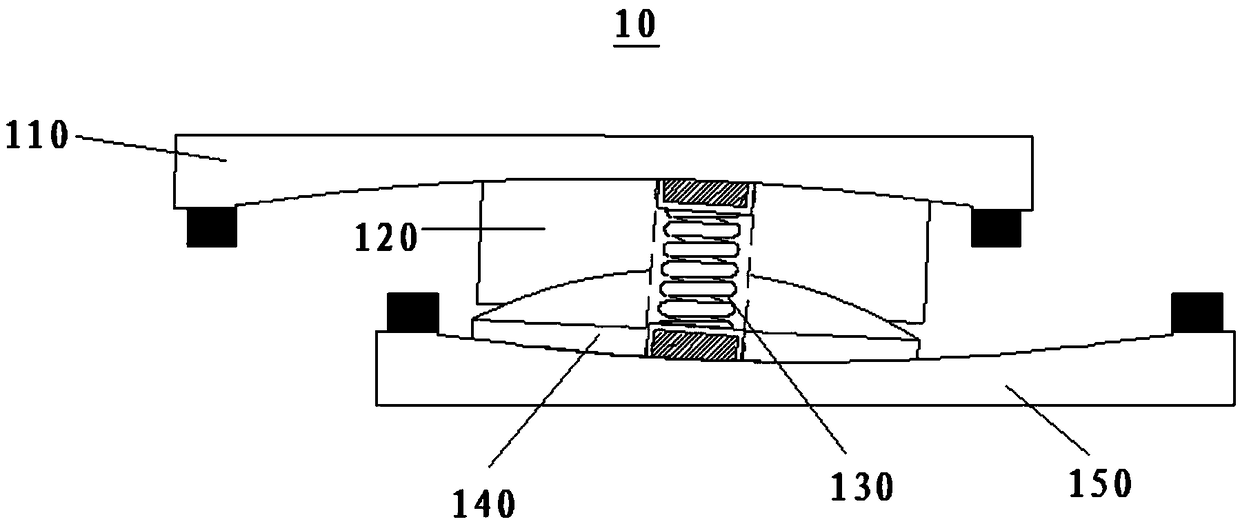

ActiveCN106522375BImprove stabilityUse long-actingBuilding constructionsProtective buildings/sheltersPressure functionEngineering

The invention provides a frictional pendulum sliding support. Through a first slide block and a second slide block which are arranged at intervals and arranged between a first installing plate and a second installing plate, and a through hole arranged in the center of the first slide block and the second slide block, an elastic element is arranged in the through hole. Friction plates at both ends of the elastic element, and the first installing plate and the second installing plate are respectively rubbed with a first friction curve face of the first installing plate and a second friction curve face of the second installing plate under the pressure function provided by the elastic element so as to eliminate the shock energy. For the elastic element can continuously provide stable pressure for the first friction curve face and the second friction curve face, the frictional pendulum sliding support has higher stability, and can be used for a long time.

Owner:TSINGHUA UNIV

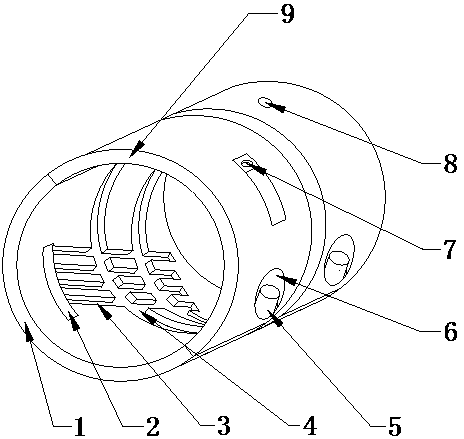

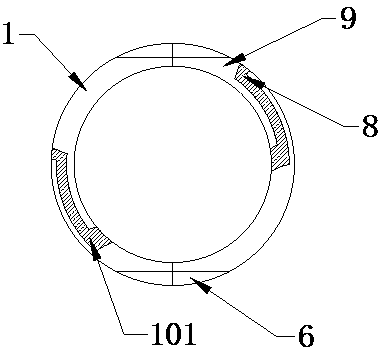

High-temperature-resistance bearing bush with heat dissipation easy to carry out

InactiveCN108626246AAvoid the situation of adding moreUse long-actingBearing coolingEngineeringEmbedment

The invention provides a high-temperature-resistance bearing bush with heat dissipation easy to carry out. The high-temperature-resistance bearing bush with heat dissipation easy to carry out comprises a left bearing bush ring, fasteners, embedment guide grooves and a right bearing bush. Each fastener and the corresponding embedment guide groove are in mutual nesting. The left bearing bush ring and the right bearing bush ring abut against each other. The left bearing bush ring and the right bearing bush ring are fixedly connected through the fasteners. An oil storage tank is integrally inlaidin the inner side of the left bearing bush ring. An oil delivery port is integrally arranged at the top end of the interior of the oil storage tank. Four oil delivery ports communicate with the rightside of the interior of the oil storage tank. Four oil limiting screens are fixedly arranged on the inner sides of the four oil delivery ports respectively. According to the high-temperature-resistance bearing bush with heat dissipation easy to carry out, a left air passage and a right air passage are arranged, and because of the left air passage and the right air passage are symmetrical to each other, both the interior of the left bearing bush ring and the interior of the right bearing bush ring have a certain function of ventilation with the air in the outside world for heat dissipation; andfurthermore, because the left air passage and the right air passage are each arranged in a Z-shaped structure, the interior of the left bearing bush ring and the interior of the right bearing bush ring form the process of internal circulation of heat dissipation air respectively, and a good heat dissipation effect is achieved.

Owner:楼昱东

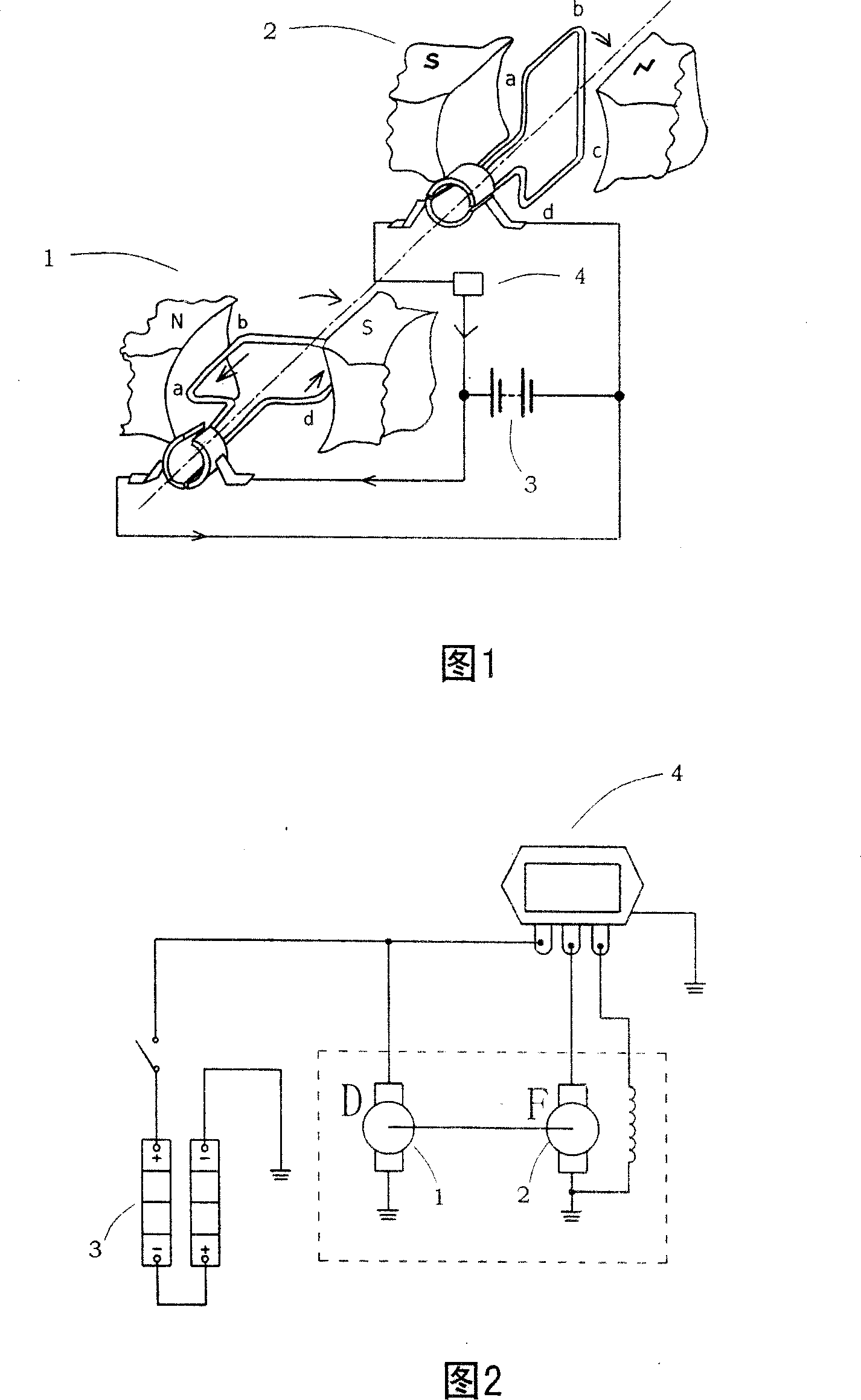

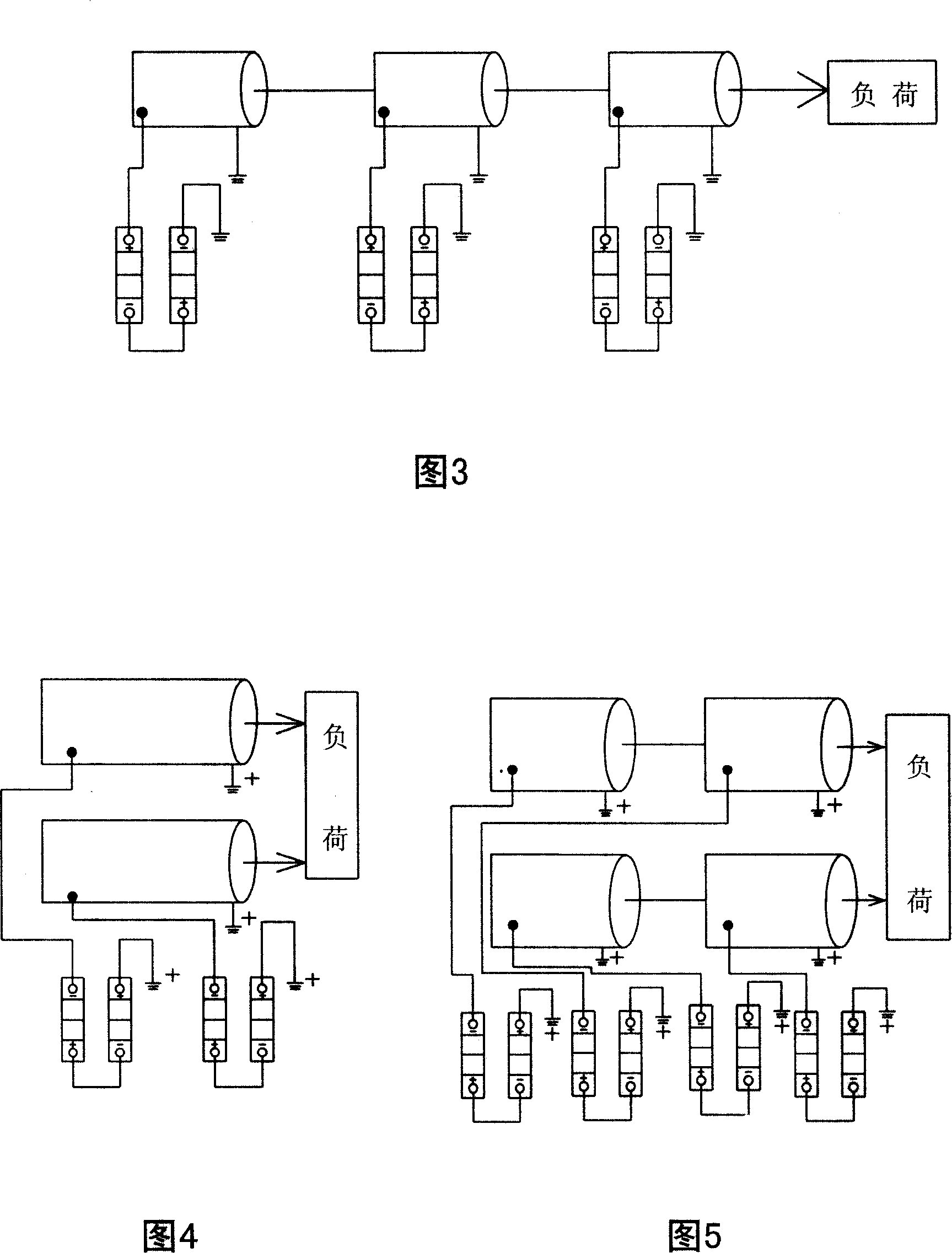

Electromagnetic motor

InactiveCN1996727AAchieve normal operationReduce consumptionDynamo-electric machinesEnergy recoveryAnode

This invention discloses one electromagnetic motor, which comprises one motor, one power generator connected to motor by same axis, one adjuster and memory battery set, wherein, the input end of motor is connected to memory battery set anode; the motor output end is connected to memory battery set cathode; the said motor output end is connected with one adjuster and then to one battery set anode set; the said motor input end is connected to the cathode end of battery set.

Owner:蔡均

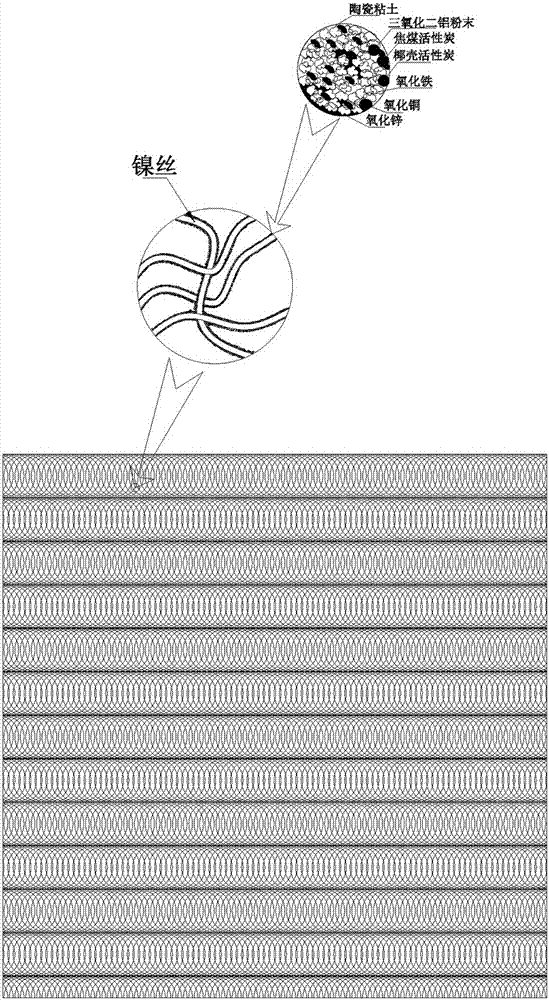

Method for preparing nickel-based composite metallic oxide ceramic air filter

InactiveCN107983403AWide range of applicationsContinuous maintenance-free useMolecular sieve catalystsOther chemical processesMolecular sieveActivated carbon

The invention provides a method for preparing a nickel-based composite metallic oxide ceramic air filter and belongs to the technical field of manufacturing and processing of composite activated carbon and composite catalyst air purification filters. The nickel-based composite metallic oxides are prepared from the following components in percentage by mass: 32% of Al2O3 zeolite molecular sieve powder, 11% of coking coal powder, 11% of coconut shell powder, 6% of ceramic clay, 2% of an organic plasticizer, 1% of citric acid, 35% of water, 1% of Fe2O3, 0.5% of CuO and 0.5% of ZnO. The ceramic air filter prepared from the nickel-based composite metallic oxides has self-cleaning, moisture-proof and maintenance-free functions, does not need sun drying and can realize long-acting maintenance-free sustainable use. Moreover, disposable materials for replacing new from old in HEPA made of PP are completely changed, and the phenomenon of resource waste is avoided.

Owner:ZHEJIANG XINGYI VENTILATOR ELECTRICAL APPLIANCE

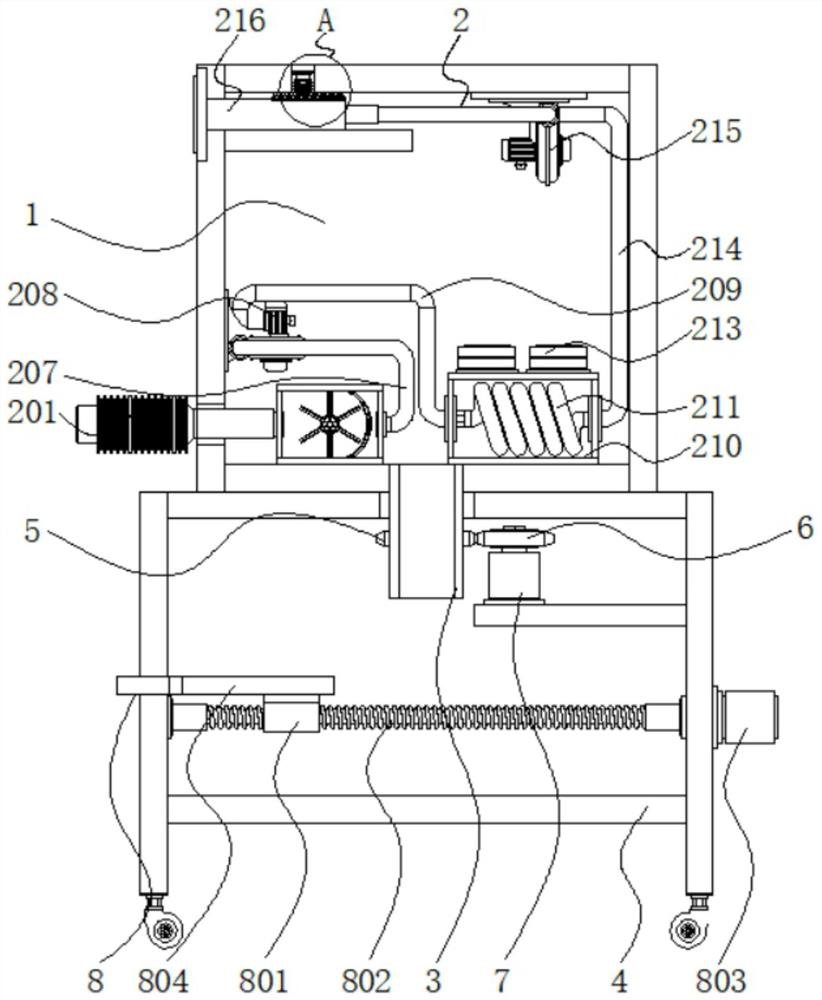

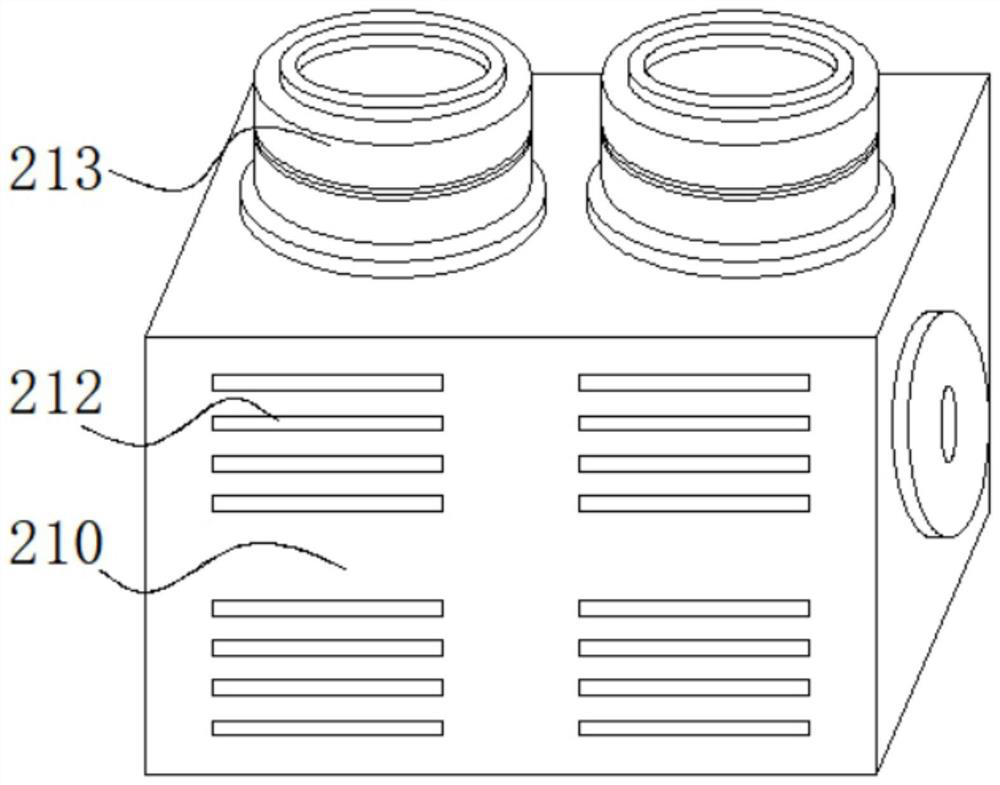

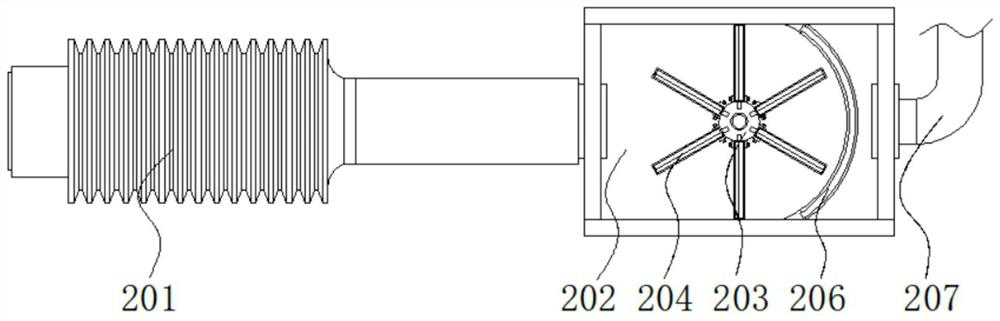

Protective device for electrical automation of electrical engineering based on Internet of Things

ActiveCN113115553AReduce the temperatureReduce cleaningResilient/clamping meansCooling/ventilation/heating modificationsGear wheelElectric machinery

The invention discloses a protective device for electrical automation of electrical engineering based on the Internet of Things, and relates to the technical field of electrical automation of electrical engineering, in particular to a protective device for electrical automation of electrical engineering based on the Internet of Things, which comprises a cover box, an auxiliary heat dissipation mechanism is arranged in the cover box, and a bottom shaft is arranged on the cover box. A side gear is fixedly embedded in the outer wall of the bottom shaft, one side of the side gear is connected with a steering gear in an engaged mode, the input end of the steering gear is connected with a driving motor, and a bottom box is arranged at the bottom of the cover box. The protective device for electrical automation of electrical engineering based on the Internet of Things is provided with a guide clamping mechanism, clamping plates can be effectively pulled to rotate along the outer portion of a connecting pin by adjusting a hydraulic oil cylinder, the rotating angle of the clamping plates can be effectively changed, and therefore the distance between the clamping plates can be effectively changed; and therefore, grabbing of the clamping plates can be effectively controlled, and short-distance picking or grabbing can be effectively achieved.

Owner:贾祎飞

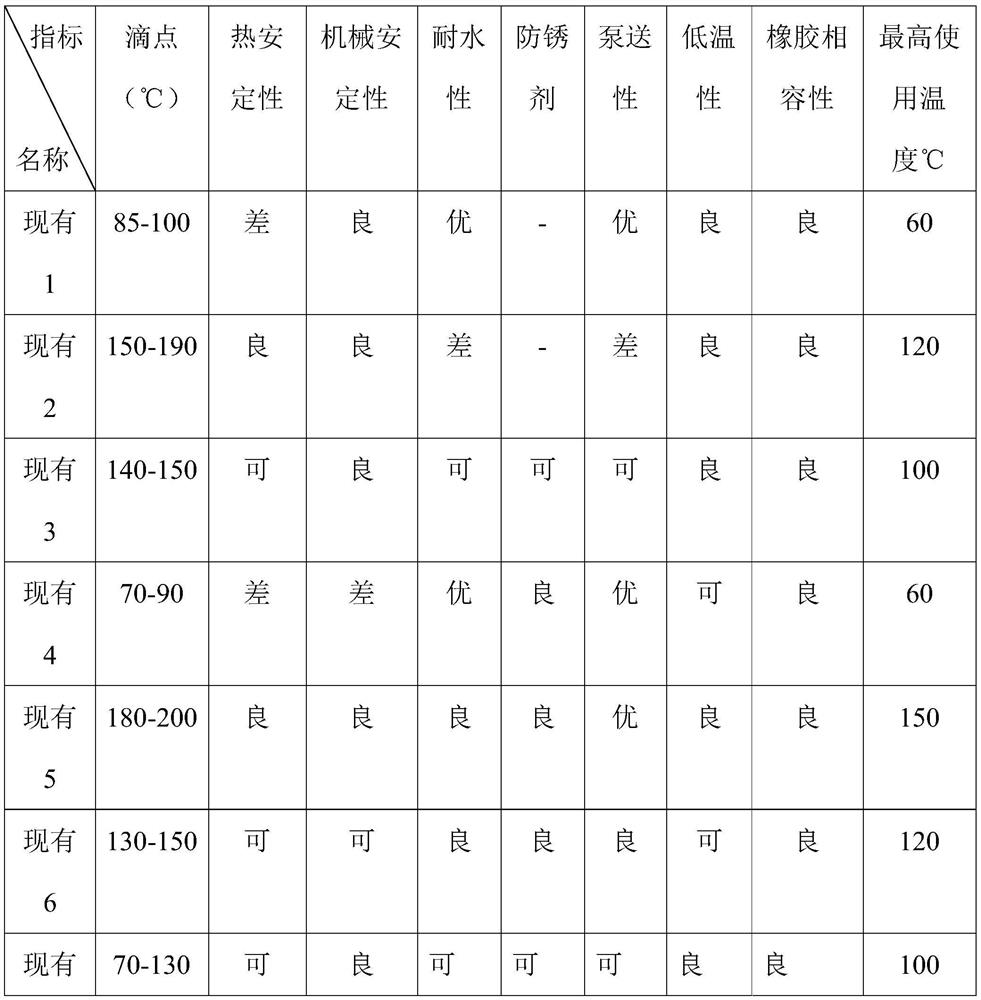

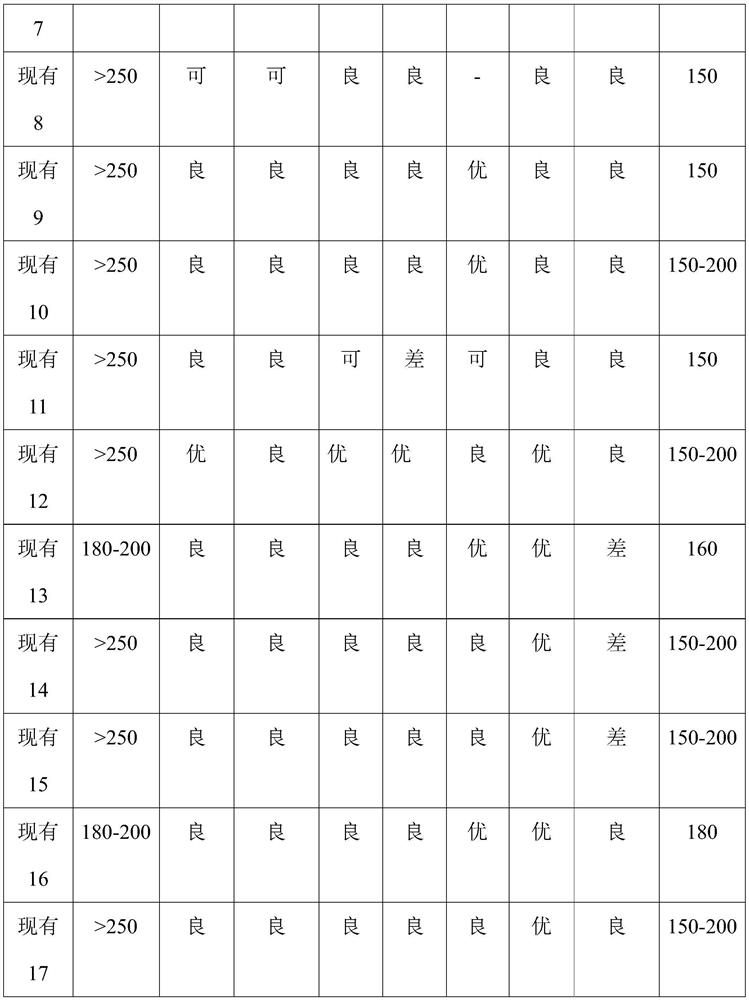

Multifunctional composite lubricating grease and preparation method thereof

InactiveCN113388437AImprove shear resistanceImprove low temperature fluidityLubricant compositionOil and greaseBase oil

The invention discloses multifunctional composite lubricating grease and a preparation method thereof. The multifunctional composite lubricating grease comprises the following components in parts by weight: 5-20 parts of fatty acid, 10-50 parts of grease, 12-30 parts of a strong alkali aqueous solution, 5-30 parts of organic bentonite, 2-5 parts of an anti-wear agent, 0.1-0.3 part of an anti-rust agent, 0.1-0.2 part of a stabilizer, 5-6 parts of an extreme pressure agent and 10-50 parts of base oil. The multifunctional composite lubricating grease has the following advantages that the dropping point reaches about 420 DEG C, the cutting resistance is high, the oxidation resistance is excellent, use is long-acting, the low-temperature fluidity is high, the use range is wide, the biodegradability is high, the extreme pressure performance is high, the rust resistance is strong, the water resistance is high, and the like.

Owner:郭霞胡

Nylon composite material with low temperature resistance and high temperature resistance at same and preparation method thereof

The invention belongs to a nylon composite material with low temperature resistance and high temperature resistance. The nylon composite material is prepared from the following raw materials in parts by weight: 65-90 parts of nylon-66 resin, 5-20 parts of nylon-6 resin, 2-10 parts of polyolefin elastomer, 0.1-1 part of cuprous iodide, 0.1-1 part of a nucleating agent and 0.1-1 part of montan wax. The prepared nylon composite material has low temperature resistance and high temperature resistance at the same time and can be used in a long-acting manner under the condition that high temperature of 180 DEG C and low temperature of -40 DEG C are alternate.

Owner:HENAN SHENMA HUAWEI PLASTIC CO LTD

Friction-type coupler

InactiveCN102252047BNo excessive wear and tearAchieve power transmissionSlip couplingFriction clutchesDrive shaftEngineering

The invention relates to a friction-type coupler which comprises a main transmission shaft (3), a friction plate (7), a clutch shell (5), an inner spline connecting sleeve (17) and a device, wherein the device positions the friction plate (7) in axial direction and is subjected to axial spring pressure; when the coupler is started, a friction block (25) is in contact friction with the radial inner surface of the clutch shell (5) under the action of centrifugal force to control the friction between the friction plate (7) and friction rings (6 and11) at the inner side surface of the clutch shell, and power transfer is realized; in overload, the friction plate and the friction rings have friction to cause temperature rise, liquid in an enclosed cavity (12) of the friction plate has temperature rise and expands to force the fraction plate to separate from the friction rings, and then a motor is separated from the load. The friction-type coupler has the advantages of light weight, stable connection, sensitive power transfer, great contact friction force and long-acting effect in use, and the surface temperature of the coupler can be controlled; the over-temperature safety hazard is eliminated thoroughly, and the couple is especially suitable for occasions with the high temperature safety requirement.

Owner:XUZHOU ZHIDIAN ELECTROMECHANICAL EQUIP

Three-dimensional isolation bearing

ActiveCN106381934BImprove stabilityAchieve consumptionProtective buildings/sheltersShock proofingElastic componentEngineering

The invention provides a three-dimensional shock insulation supporting seat which realizes consumption of seismic energy by rubbing a first friction hook face with a first rubbing piece arranged at the first end of a first elastic component. As the elastic component can continuously supply stable pressure for the first rubbing piece, the three-dimensional shock insulation supporting seat has relatively high stability, and can be used effectively for a long time.

Owner:TSINGHUA UNIV

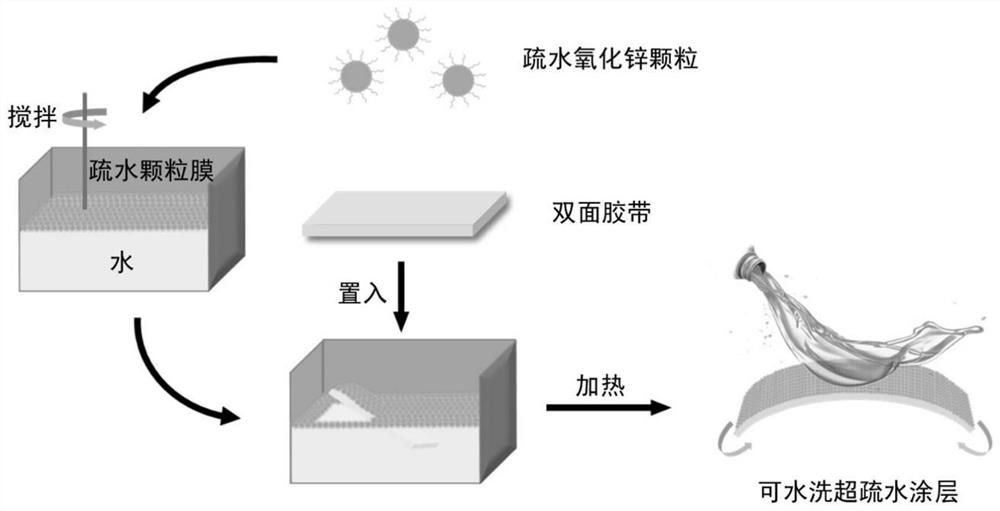

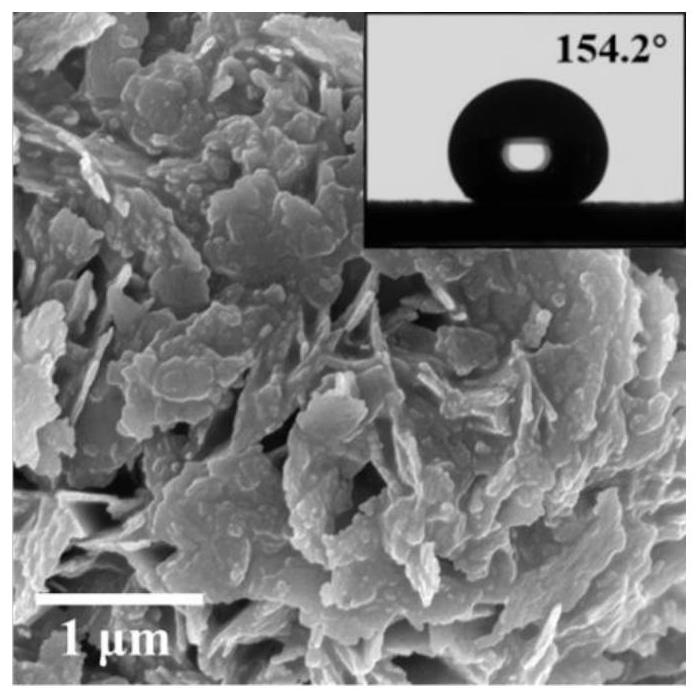

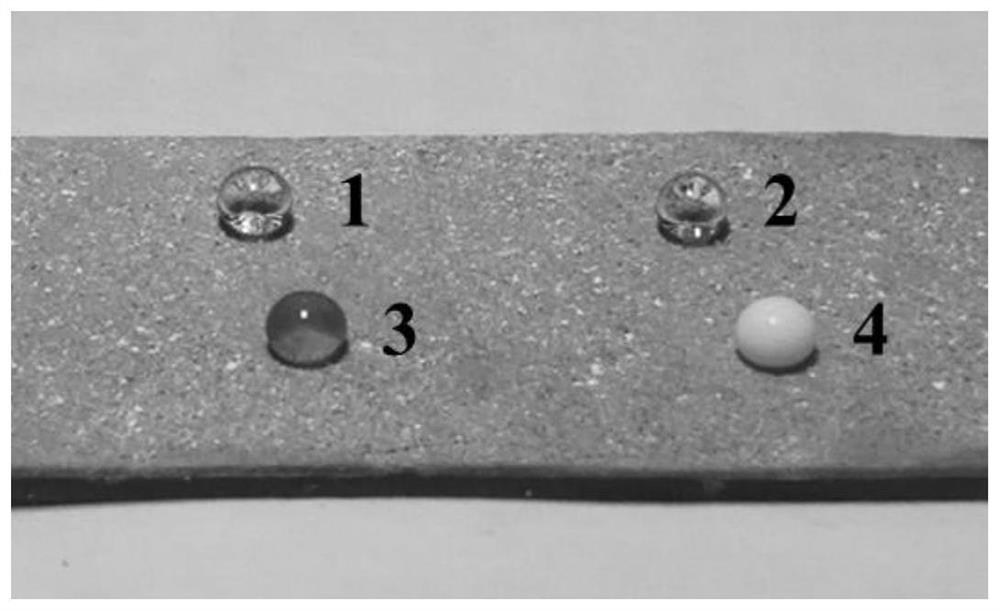

Washable antibacterial super-hydrophobic coating as well as preparation method and application thereof

ActiveCN114226211AImprove antibacterial propertiesGood underwater stabilityLiquid surface applicatorsAntifouling/underwater paintsFood industryTextile printer

The invention discloses a washable antibacterial super-hydrophobic coating and a preparation method and application thereof.According to the method, hydrophobic interaction is utilized, after hydrophobic nano-particles form a compact hydrophobic particle film on the water surface, a drainage sedimentation technology is changed into a printing technology, namely, a base plate with a double-face bonding layer is vertically placed into water, then the base plate is rotated to the horizontal angle to be slowly lifted, and the base plate is subjected to water washing; and the particle film is attached to the double-sided bonding layer, heating is carried out to enhance the bonding force of the particle film and the double-sided bonding layer, and the super-hydrophobic coating is obtained. The preparation method takes water as a medium, does not need to use an organic solvent, and has the characteristics of simple process and environmental protection; the printing process can greatly simplify the process flow, reduce the production cost and is suitable for large-area preparation. The prepared super-hydrophobic coating has the advantages of good antibacterial performance, good super-hydrophobic performance, good underwater stability, washability, good flexibility and the like, has high practical value and good application prospects, and can be applied to the fields of medical treatment and public health, food industry, antifouling, environmental protection and the like.

Owner:NAT UNIV OF DEFENSE TECH

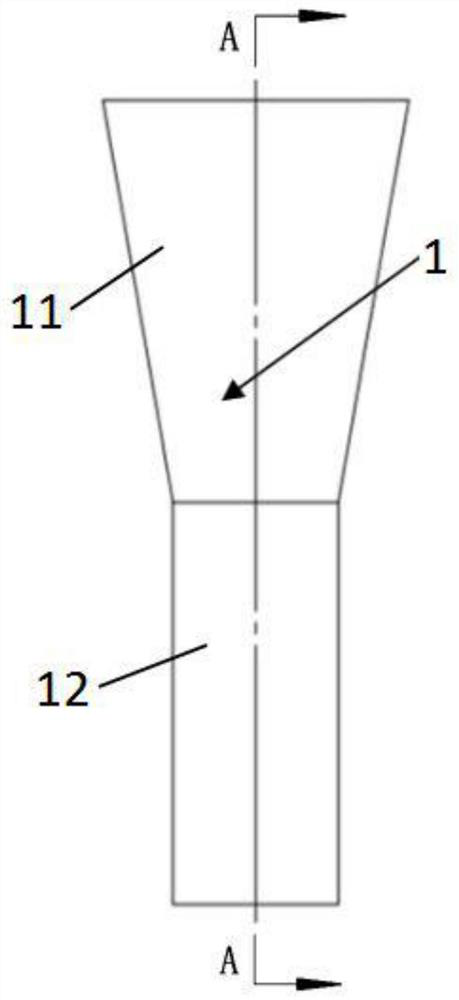

Anti-loosening stainless steel pre-embedded sleeve

PendingCN112761264AGuaranteed StrengthGuaranteed Axial Pullout ForceRailway tracksBuilding constructionsEngineeringStructural engineering

The invention discloses an anti-loosening stainless steel pre-embedded sleeve. The anti-loosening stainless steel pre-embedded sleeve comprises a main body, wherein the main body comprises a sleeve body and an anti-pulling device; a center hole is formed in the sleeve body, and an anti-loosening internal thread is arranged at one end of the center hole; and the anti-pulling device and the sleeve body are integrally formed and manufactured, the anti-pulling device is arranged at the end, away from the anti-loosening internal thread, of the sleeve body, and the ratio of the height of the anti-pulling device to the outer diameter of the sleeve body to the height of the main body is (1.2-1.5): 1: (2.5-4). According to the anti-loosening stainless steel pre-embedded sleeve, the anti-pulling device and the sleeve body are integrally formed, the structure is simple, machining is convenient, and the production efficiency is high. The anti-loosening internal thread is arranged on the sleeve body, so that the pre-embedded sleeve has an anti-loosening function, loosening can be prevented, and fixing is firmer. The height of the anti-pulling device, the outer diameter of the sleeve body and the height of the main body are limited, so that the maximum limited axial pulling force is guaranteed, and the strength of the anti-loosening stainless steel pre-embedded sleeve meets the mechanical requirements for pulling resistance and rotary shearing.

Owner:广州威福文化传播有限公司 +1

Stainless steel embedded sleeve

PendingCN112761265AGuaranteed StrengthGuaranteed Axial Pullout ForceRailway tracksBuilding constructionsStructural engineeringSS - Stainless steel

The invention discloses a stainless steel embedded sleeve. The stainless steel embedded sleeve comprises a main body, wherein the main body comprises an anti-pulling device and a sleeve which are integrally formed and manufactured; a central hole is formed in the sleeve; an internal thread is arranged at one end of the central hole; the anti-pulling device is arranged at one end, far away from the internal thread, of the sleeve; and the ratio of the height of the anti-pulling device to the outer diameter of the sleeve to the height of the main body is (1.2-2): 1: (2.5-5). According to the stainless steel embedded sleeve, the anti-pulling device and the sleeve are integrally formed, the structure is simple, the processing is convenient, and the production efficiency can be effectively improved. In addition, the height of the anti-pulling device, the outer diameter of the sleeve and the height of the main body are limited, so that the maximum limited axial drawing force can be guaranteed, and the strength of the stainless steel embedded sleeve can be guaranteed to meet the mechanical requirements of pulling resistance and rotary shearing.

Owner:广州威福文化传播有限公司 +1

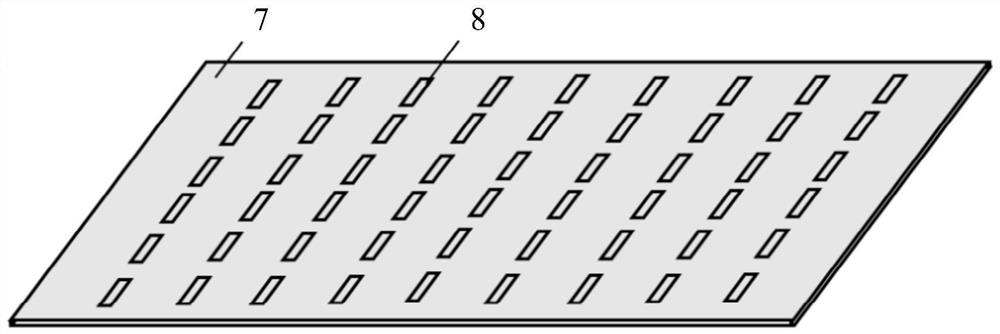

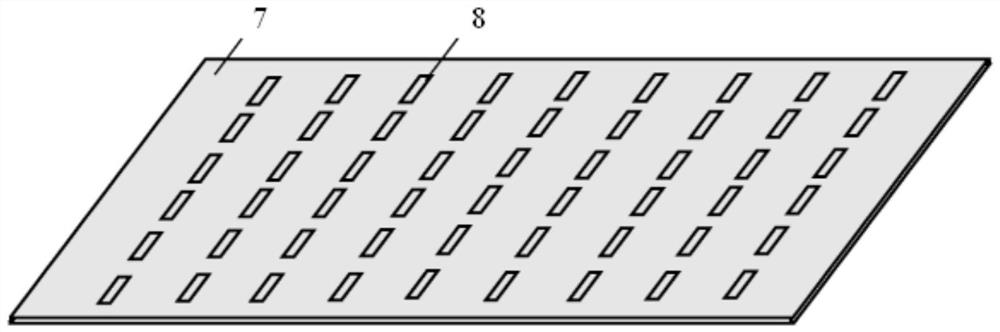

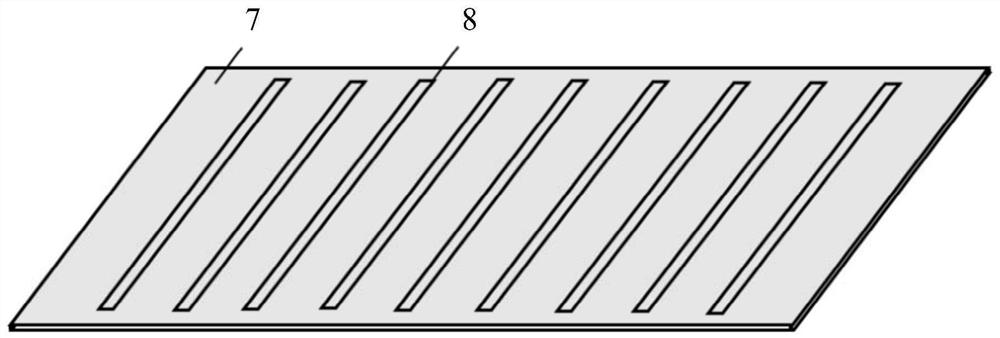

A kind of solar cell module and preparation method

ActiveCN111293190BImprove reliabilityReduced risk of splinteringFinal product manufacturePhotovoltaic energy generationElectrical batterySolar battery

The application discloses a solar cell module and its preparation method, which belongs to the technical field of solar cells, and solves the problem of external force at the edge of the overlapping area of the solar cell module in the prior art during the preparation process of the solar cell module and in the lamination process. It is prone to cracks or even slivers, and the problem of inconvenient processing. The preparation method of the present application includes the following steps: sequentially laying the first encapsulation film, the battery string, the second encapsulation film and the front cover on the rear cover to obtain a laminate; laminating the laminate to obtain a solar cell The assembly; the battery string includes a plurality of battery sheets connected in a head-to-tail overlapping manner; the first encapsulation film includes a main body and a plurality of local protrusions arranged on the main body and corresponding to the overlapping areas of the battery sheets, and / or Alternatively, the second encapsulation film includes a main body and a plurality of local protrusions disposed on the main body and corresponding to overlapping regions of the battery sheets. This application can be used for solar power generation.

Owner:晶澳(扬州)新能源有限公司

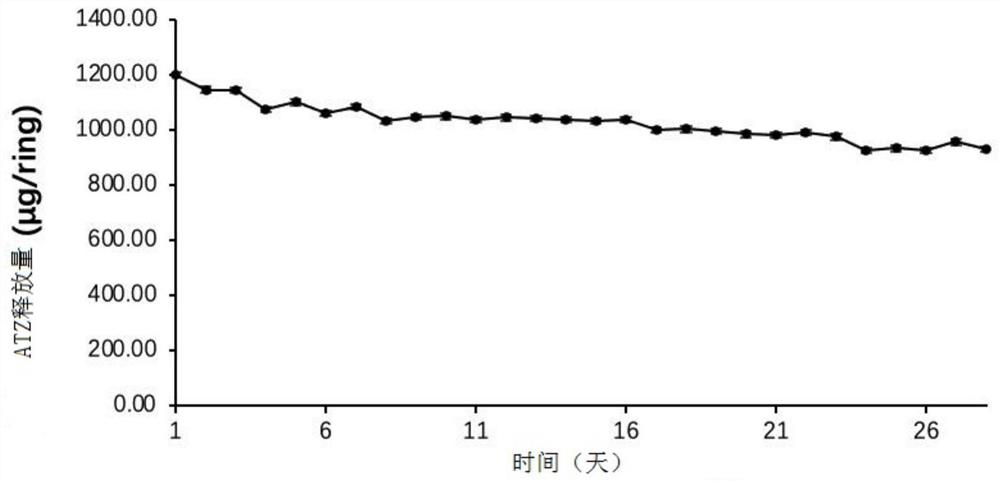

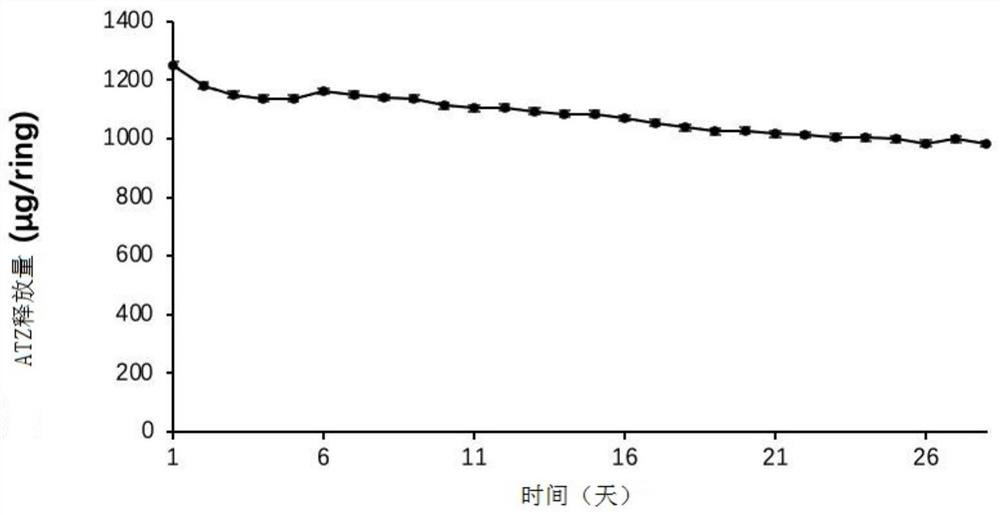

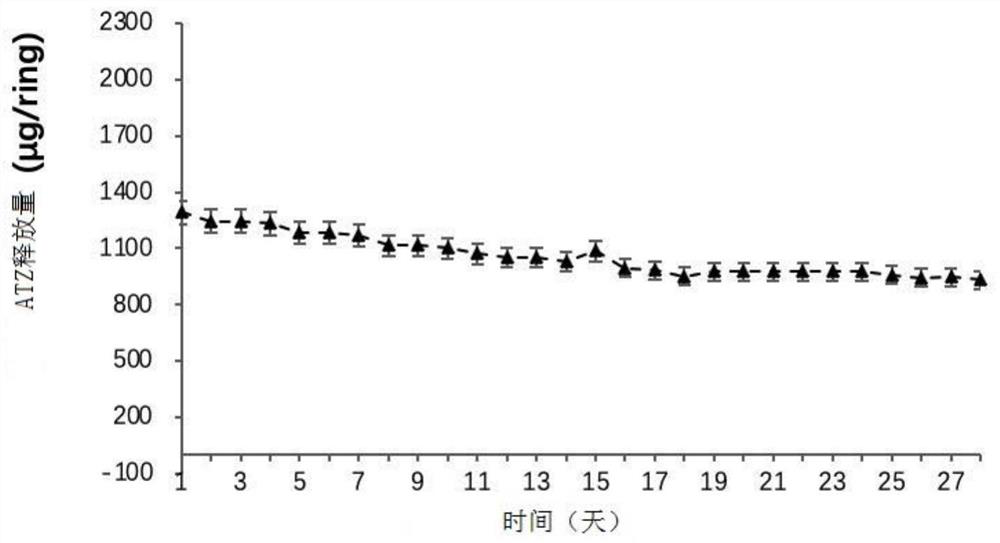

Vaginal sustained and controlled release drug delivery system containing aromatase inhibitor and preparation method thereof

ActiveCN112315898BEasy to useUse long-actingOrganic active ingredientsAntipyreticAromatase inhibitorPharmaceutical drug

The invention provides a vaginal sustained and controlled release drug delivery system containing an aromatase inhibitor and a preparation method thereof. The drug delivery system is an aromatase inhibitor reservoir-type vaginal ring prepared by loading aromatase inhibitor drugs with EVA as a carrier material. The vaginal ring includes a core layer and a film layer wrapped outside the core layer. The core layer It is formed after the aromatase inhibitor drug is evenly mixed with the EVA material; the film layer is formed of the EVA material. The release period of the vaginal sustained and controlled release drug delivery system of the present invention is 28 days to 42 days, the use process is more flexible, the preparation cost is also lower, and there is no obvious burst release effect, and the desired release can be achieved in a short time Therefore, the drug release is more stable and the application is safer.

Owner:国家卫生健康委科学技术研究所

A kind of photocatalytic apatite wrapping technology sterilization and disinfection mask

ActiveCN112914173BSterilization hasAntibacterialProtective garmentSpecial outerwear garmentsPhoto catalysisNanotechnology

The invention belongs to the technical field of masks, and in particular relates to a sterilization and disinfection mask with a photocatalytic apatite wrapping technology, comprising a sterilization and disinfection outer layer and a textile inner layer in contact with a human face, wherein the sterilization and disinfection outer layer comprises a base fabric, and the The surface of the base fabric is coated with apatite-nano-titanium dioxide composite photocatalyst, and the base fabric is composed of three kinds of fibers: nano-silver fibers, bamboo charcoal fibers and photocatalytic fibers. The present invention improves the photocatalysis, sterilization and disinfection efficiency of titanium dioxide as a whole by coating the composite photocatalyst with titanium dioxide and apatite as materials on the outer layer of the mask as the main sterilization and disinfection agent, and the mask of the present invention has The effect of long-term use.

Owner:张斌翔

Cold smoking and deodorizing disinfectant as well as preparation method thereof

The invention relates to a cold smoking and deodorizing disinfectant, and belongs to the technical field of household daily chemical care. The cold smoking and deodorizing disinfectant disclosed by the invention comprises the following components: 80-90 parts of water, 0.1-2 parts of a germicide, 0.1-2 part of a deodorant, and 5-10 parts of a smoking agent. The cold smoking and deodorizing disinfectant has high-efficiency sterilization and long-acting antibacterial ability, and is capability of removing various peculiar smells while emitting natural faint scent; and thus, the disinfectant is ahealthy and safe deodorizing and sterilizing disinfectant for space environment.

Owner:GUANGZHOU KASDER CO LTD

A large slag tank repair technology

ActiveCN103567698BExtended service lifeReduce manufacturing costMetal working apparatusSlag% diameter reduction

Owner:SICHUAN DAZHOU IRON & STEEL GROUP

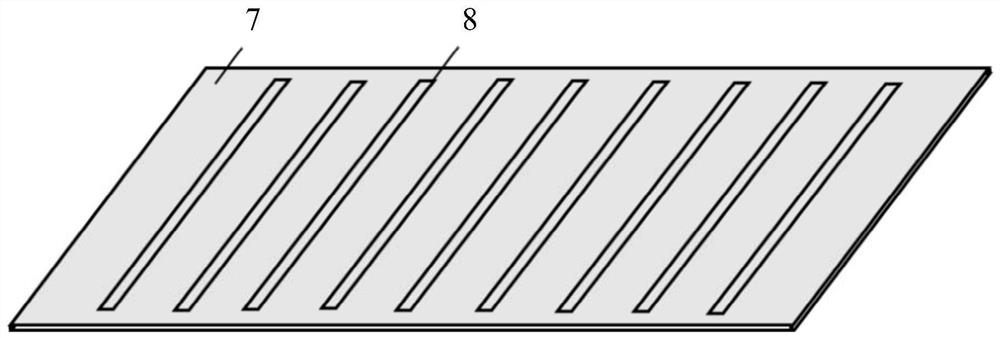

A kind of photovoltaic module and preparation method thereof

ActiveCN111293183BImprove reliabilityIncreasing the thicknessFinal product manufacturePhotovoltaic energy generationElectrical batterySolar cell

The application discloses a photovoltaic module and its preparation method, which belongs to the technical field of solar cells, and solves the problems caused by the external force at the edge of the overlapped area of the battery sheet in the lamination and lamination process in the photovoltaic module preparation process in the prior art. The effect is prone to the problem of cracks or even lobes. The preparation method of the present application includes the following steps: sequentially laying the first encapsulation film, the battery string, the second encapsulation film and the cover plate on the back plate to obtain a laminate; laminating the laminate; the battery string includes multiple The battery slices connected head to tail; the back plate includes a back plate main body and a plurality of back plate protrusions arranged on the surface of the back plate main body facing the battery string and corresponding to the overlapping area of the battery slices. The photovoltaic module of the present application and its preparation method can be used for solar power generation.

Owner:晶澳(扬州)新能源有限公司

Biodegradable flame-retardant lubricating grease special for main bearings and preparation method of biodegradable flame-retardant lubricating grease

The invention discloses a biodegradable flame-retardant lubricating grease special for main bearings. The biodegradable flame-retardant lubricating grease comprises, by weight percentage: 40.0-44.0% of methyl oleate, 42.0-45.0% of polyethylene glycol ether, 5.0-6.0% of 12-hydroxystearic acid, 0.5-1.0% of hydrogenated castor oil, 1.0-1.7% of lithium hydroxide, 0.1-0.3% of diphenylamine, 0.5-1.5% ofbarium dinonyl naphthalene sulfonate, 0.5-1.0% of a thiadiazole derivative, 0.8-2.0% of molybdenum oxide dialkyl dithiophosphate, 0.5 to 1.0% of ammonium phosphorothioate, 0.1-0.3% of zinc dialkyl dithiophosphate and 2.0-3.0% of melamine cyanurate. The lubricating grease has good extreme pressure wear resistance, water spraying resistance, mechanical stability, oxidation and corrosion resistance,biodegradability and combustion resistance, the requirement of a shield tunneling machine for safe production, lubrication and operation of a main shaft during underground tunneling of cities, riversand lakes is met, and accidents are avoided.

Owner:广饶科力达石化科技有限公司

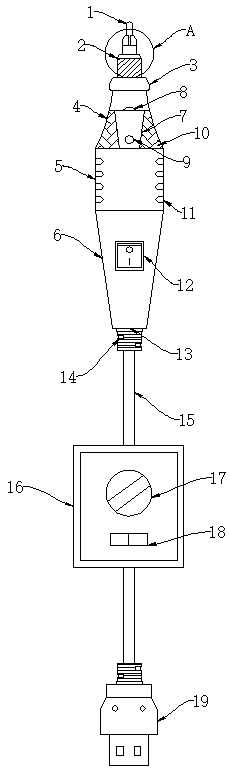

Electric engraving pen for ceramic artwork

PendingCN109228775AImprove conductivityFast chargingHand artistic toolsOther artistic work equipmentsEngravingEngineering

The invention discloses an electric engraving pen for a ceramic artwork. The electric engraving pen comprises an engraving cutter head, a hand-tight clamping head is arranged below the engraving cutter head, and a clamping jaw is arranged in the hand-tight clamping head; a hand-tight rotating body is arranged below the clamping jaw, and a clamping jaw driving part is arranged below the hand-tightrotating body; a clamping head shell is arranged on the outer wall of the clamping jaw driving part, a connection end is arranged below the clamping head shell, a gripping part is arranged below the connection end, an anti-slip thread is arranged on the outer wall of the gripping part, and a lampshade is arranged on one side of the gripping part; a lighting lamp is mounted in the lampshade, a lighting lamp button is arranged on the outer wall of the lampshade, and a motor part is arranged below the gripping part. According to the electric engraving pen for the ceramic artwork, a USB interfaceis formed in one end of a wire, and thus the electric engraving pen can be charged through multiple equipment such as a power supply interface, a computer and a mobile phone and makes outdoor travelling more convenient.

Owner:IANGSU COLLEGE OF ENG & TECH

A cleaning agent for removing gypsum residues on lost wax craft products

ActiveCN104017677BLong-term maintenance and useEfficient removalSurface-active non-soap compounds and soap mixture detergentsFluoboric acidCleansing Agents

Owner:深圳市汇利龙科技有限公司

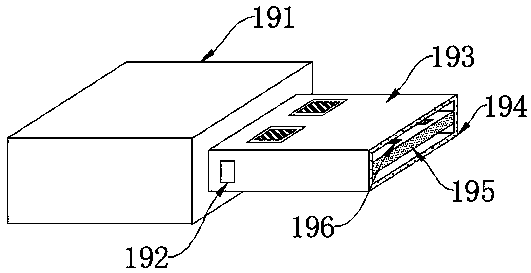

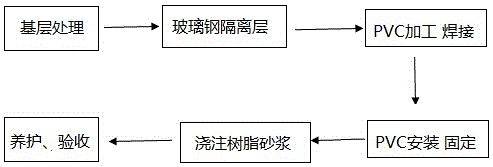

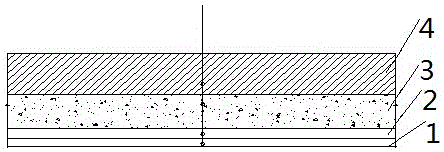

Anticorrosion method for improving anticorrosion effect and fixing rigid polyvinyl chloride plate through fusible interlining

InactiveCN105064756ASolve the problem of strengthening the effectiveness of anti-corrosionHigh strengthSynthetic resin layered productsGlass/slag layered productsInterliningScotch tape

The invention relates to an anticorrosion method for improving anticorrosion effect and fixing a rigid polyvinyl chloride plate through fusible interlining and belongs to the technical field of anticorrosion. an anticorrosion structure is composed of three layers, namely an isolation layer, resin mortar and the rigid polyvinyl chloride plate; the method comprises the steps of conducting treatment on a substrate, arranging the isolation layer on the surface of the substrate through fusible interlining, fixing the rigid polyvinyl chloride plate to the resin mortar through fusible interlining, wherein the thickness of the rigid polyvinyl chloride plate used for the fusible interlining is 2-25 mm, and drilling holes in the upper portion of the rigid polyvinyl chloride plate, wherein the drilling diameter is 3-10 mm and the drilling interval is 300-500 mm; before construction, covering the drilled holes with scotch tape in a pasted mode, and when fabricating and installing the rigid polyvinyl chloride plate, adjusting the position and distance to reach the requirements, and fixing the rigid polyvinyl chloride plate; after the rigid polyvinyl chloride plate is installed ready, pouring the resin mortar in the holes, using a wooden mallet or a vibrator for providing assistance, and making gaps be filled with the resin mortar slowly; judging the pouring height and filling condition of the resin mortar, till all the holes are filled through pouring completely; after the resin mortar is cured, combining the contact surface with the polyvinyl chloride plate into a whole by connecting the contact surface with the filling holes in an inserted mode, and achieving the purpose of fixing the polyvinyl chloride plate.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

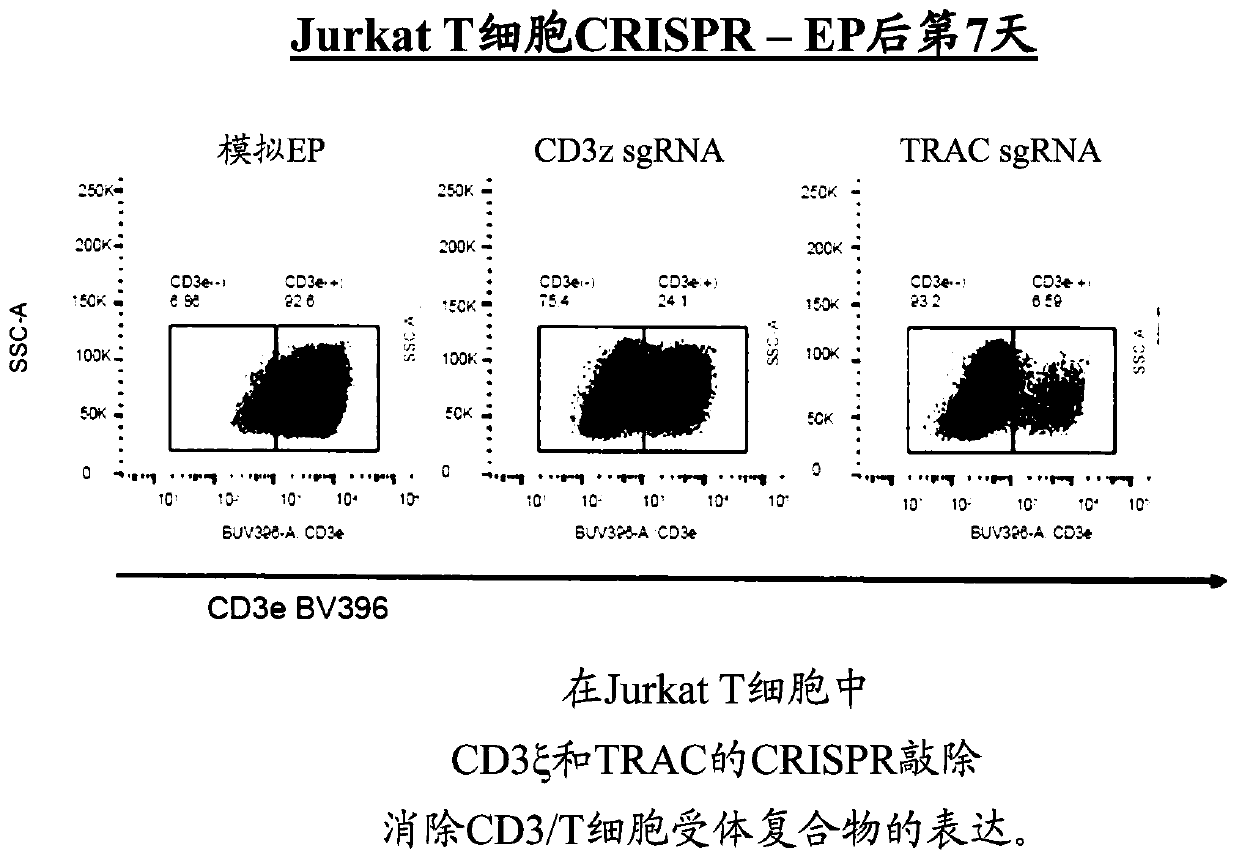

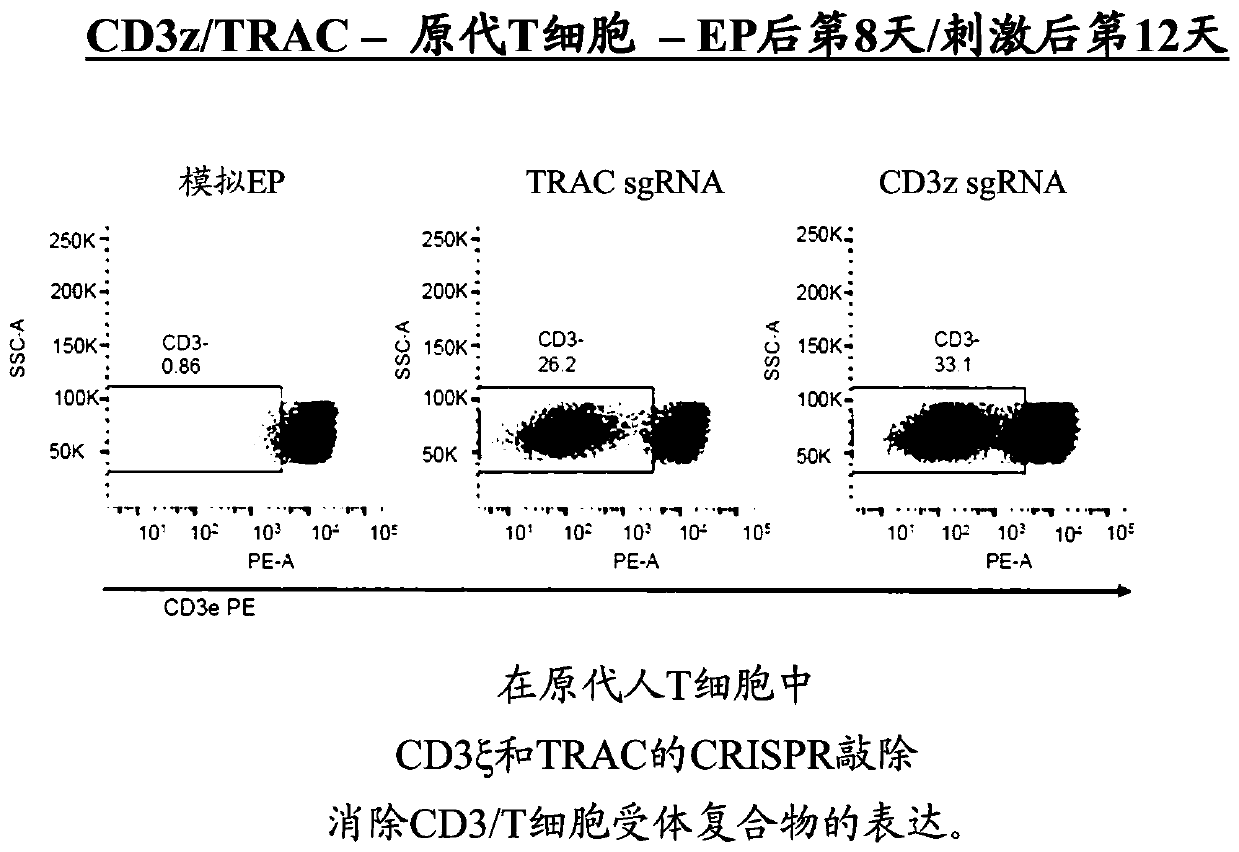

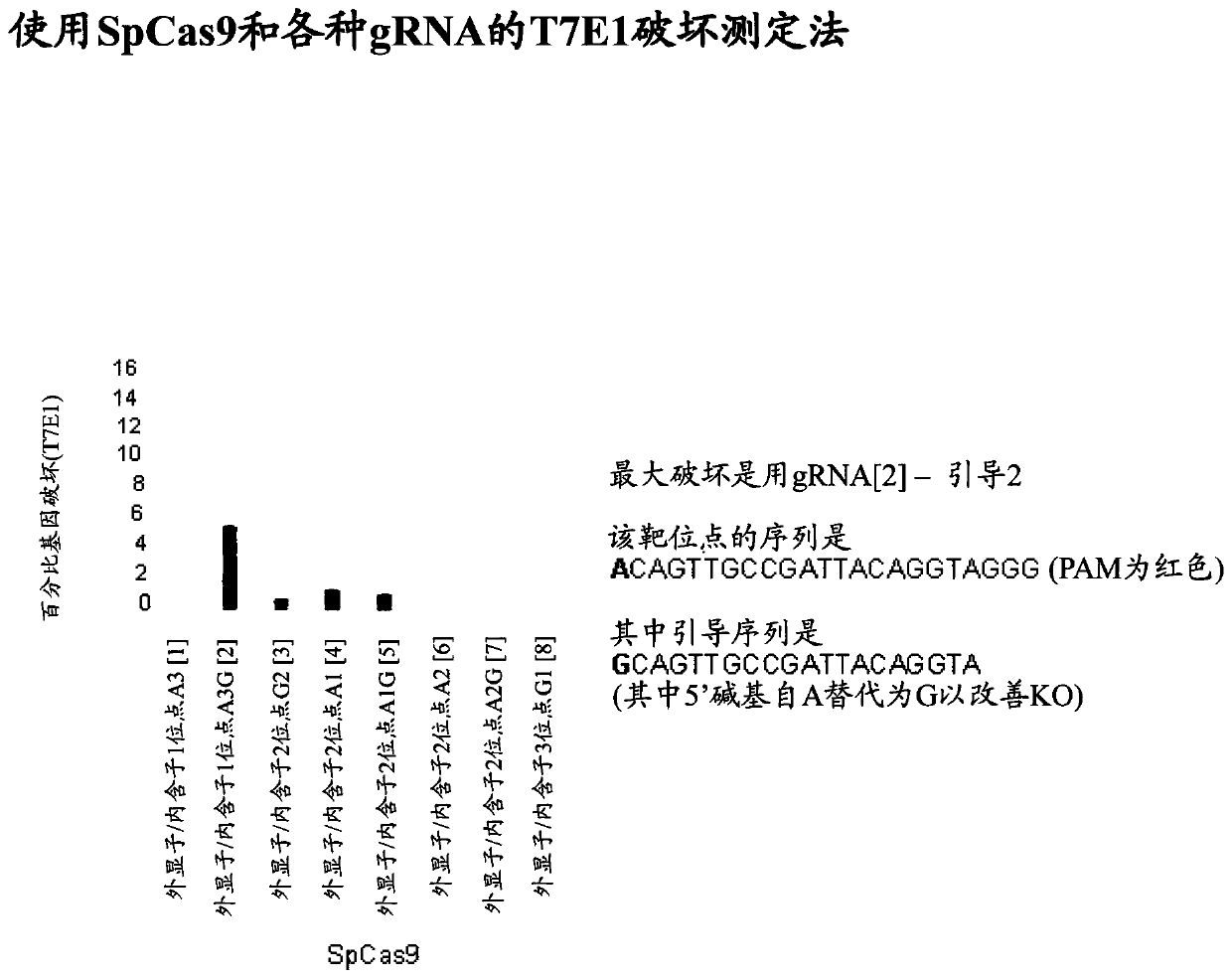

Modified t cells and methods of their use

PendingCN110268050AEliminate competitionEliminates the risk of GvH diseasePolypeptide with localisation/targeting motifImmunoglobulin superfamilyOncologyT cell

Owner:THE GENERAL HOSPITAL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com