Power driving device for mixed power vehicle

A technology for power transmission devices and hybrid electric vehicles, applied to transmission devices, gear transmission devices, transmission device control, etc., can solve the problems of low synthesis efficiency, difficult implementation, poor controllability, etc., and achieve simple structure and high transmission efficiency High, to achieve the effect of power transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

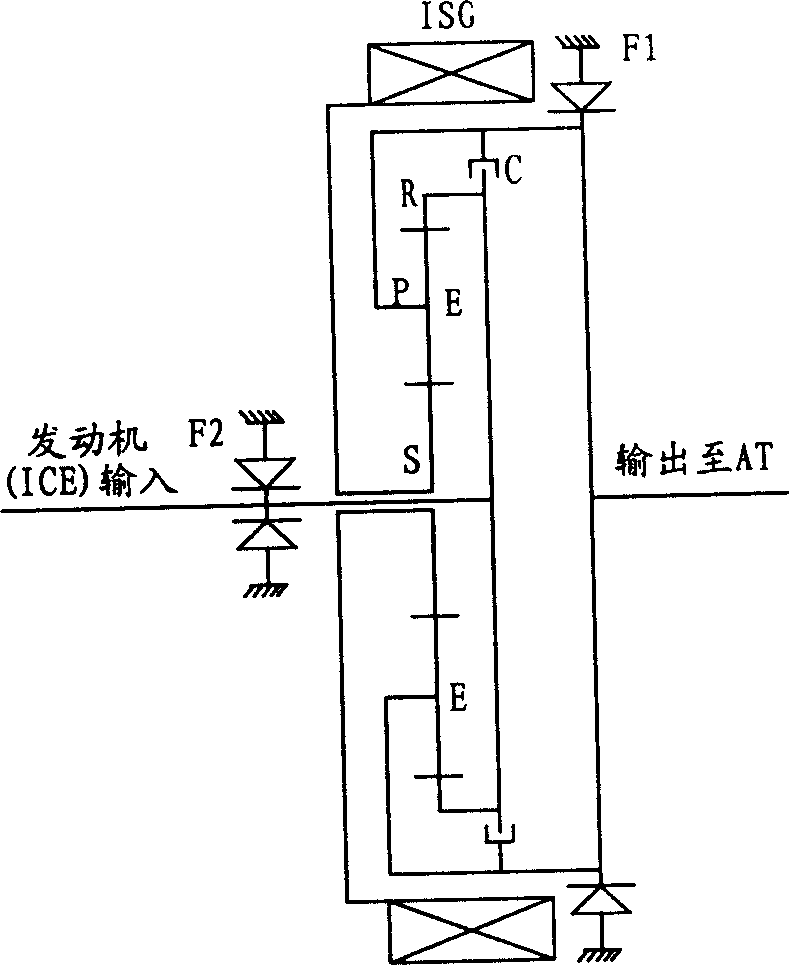

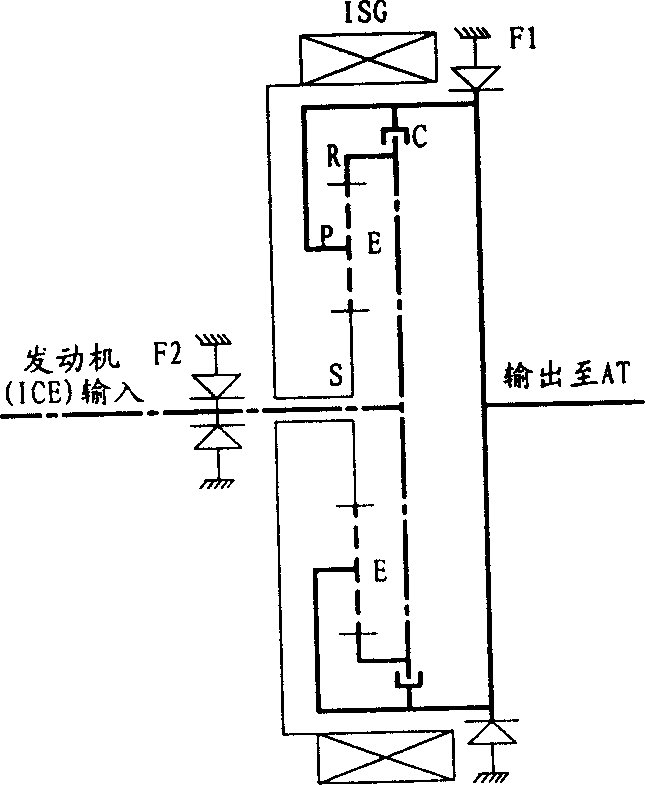

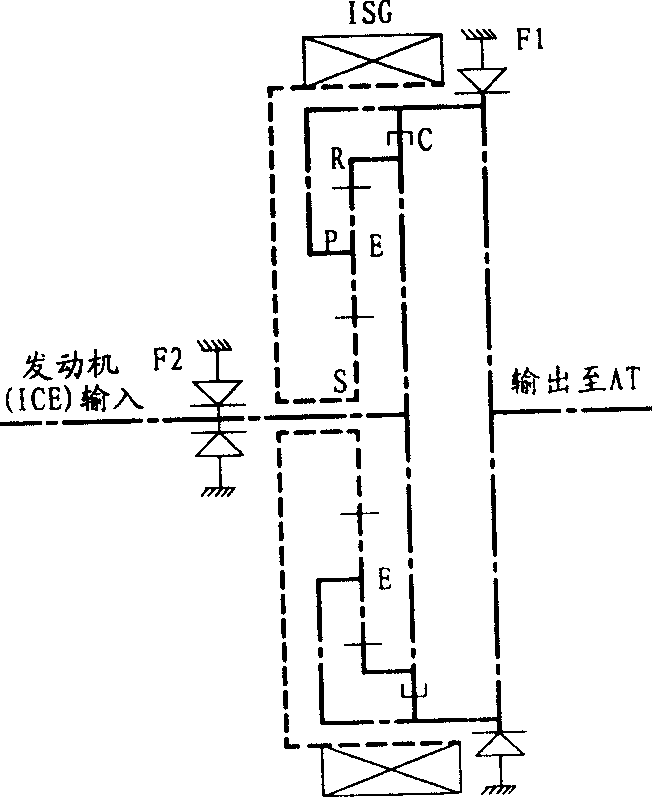

[0019] Embodiment 1, the following parts are pressed Figure 1-Figure 9 Those skilled in the art can successfully implement the connection in the manner shown.

[0020] The device of the present invention is located between the engine and the automatic transmission AT, and consists of a starter / generator ISG, a clutch C, a one-way clutch F, and a planetary gear mechanism, wherein the planetary gear mechanism consists of a sun gear S, a planetary gear E, a planet carrier P, The ring gear R is composed of the planetary gear E, which is externally meshed with the sun gear S and internally meshed with the ring gear R. The output shaft of the engine is connected to the ring gear through a flange, and the rotor of the starter / generator ISG is connected to the center shaft of the sun gear S through splines. The planetary carrier P is connected to the input shaft of the automatic transmission AT through a flange, and the output shaft of the engine ICE and the output shaft of the plane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com