Iron and steel casting welding slag removal device facilitating welding slag removal

A technology for steel and castings, which is applied in the field of slag removal devices for welding of steel castings, can solve the problems of reducing production speed, time-consuming and laborious, hidden dangers, etc., and achieves the effects of improving production speed, reducing labor, and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

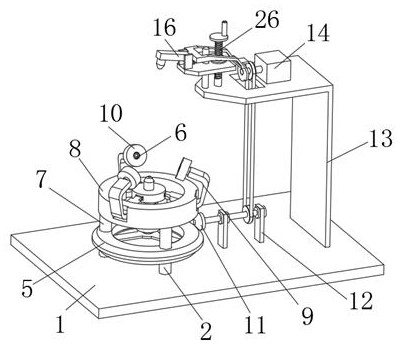

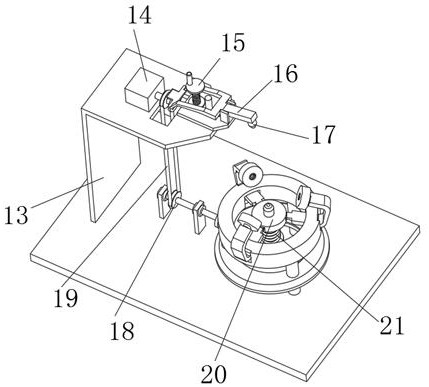

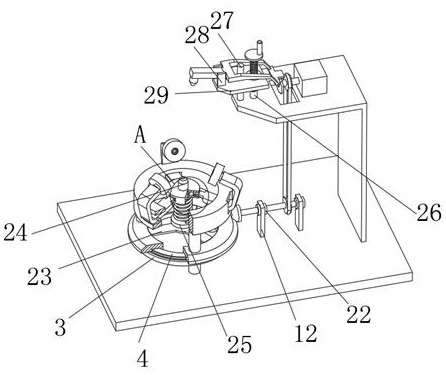

[0040] Example: Reference Figure 1-8 The slag removal device for iron and steel casting welding that is convenient for cleaning welding slag is shown, including an operation table 1, which can be a steel plate in the prior art.

[0041] The top of the console 1 is fixedly connected with a plurality of lower columns 2, and the number of the lower columns 2 can be two, three, or four. In this embodiment, the number of the lower columns 2 is three. The lower column 2 can be a metal column in the prior art, which is fixedly connected with the operating table 1 by welding.

[0042] A base 3 is fixedly connected to the tops of the plurality of lower columns 2, and the base 3 may be a metal plate in the prior art, and is fixedly connected to the lower columns 2 by welding.

[0043] A slide rail 4 is fixedly connected to the top of the base 3, and the slide rail 4 and the base 3 may be connected by any connection method in the prior art, such as screw connection.

[0044] The top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com