Patents

Literature

45results about How to "Eliminate maintenance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

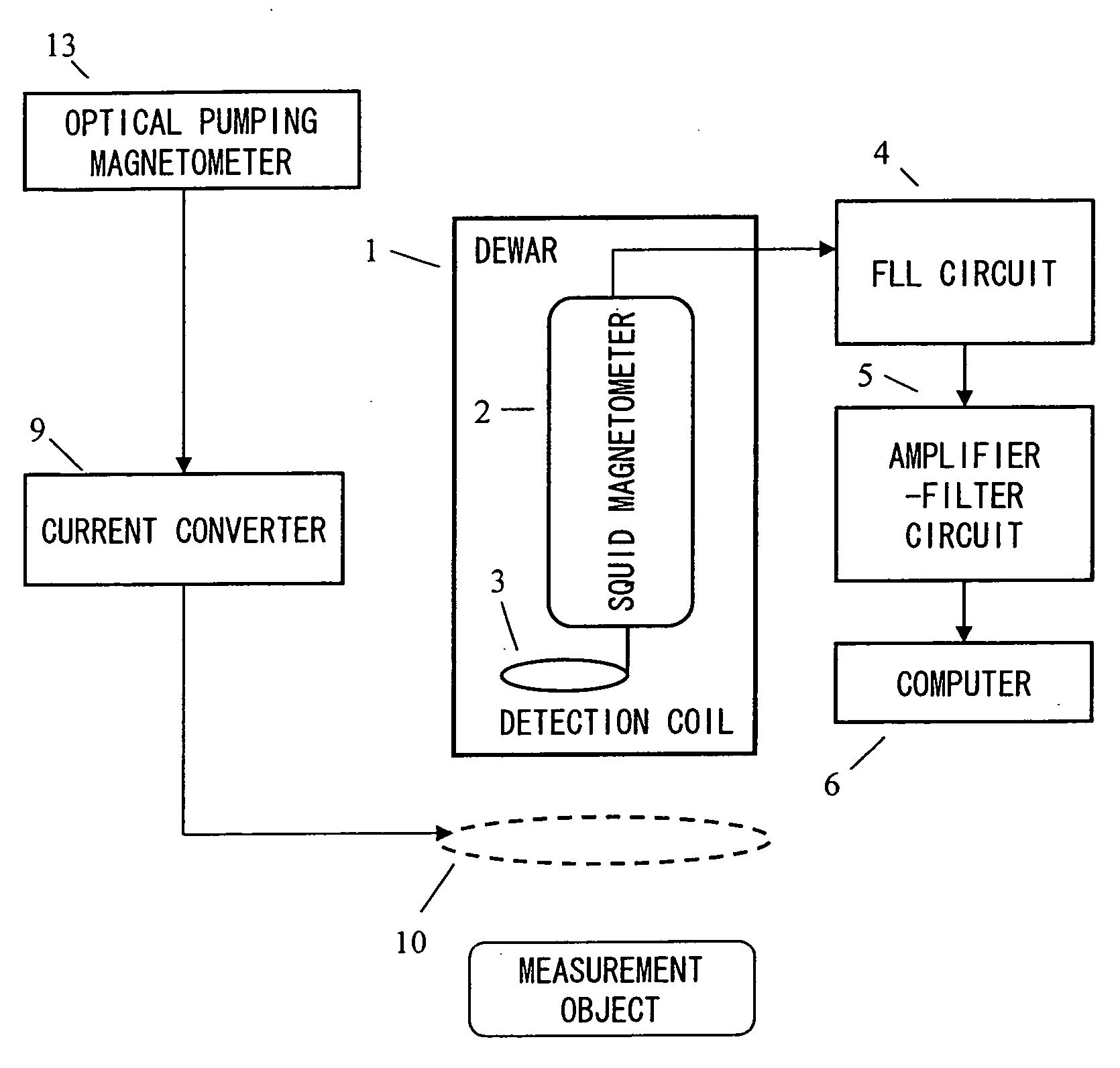

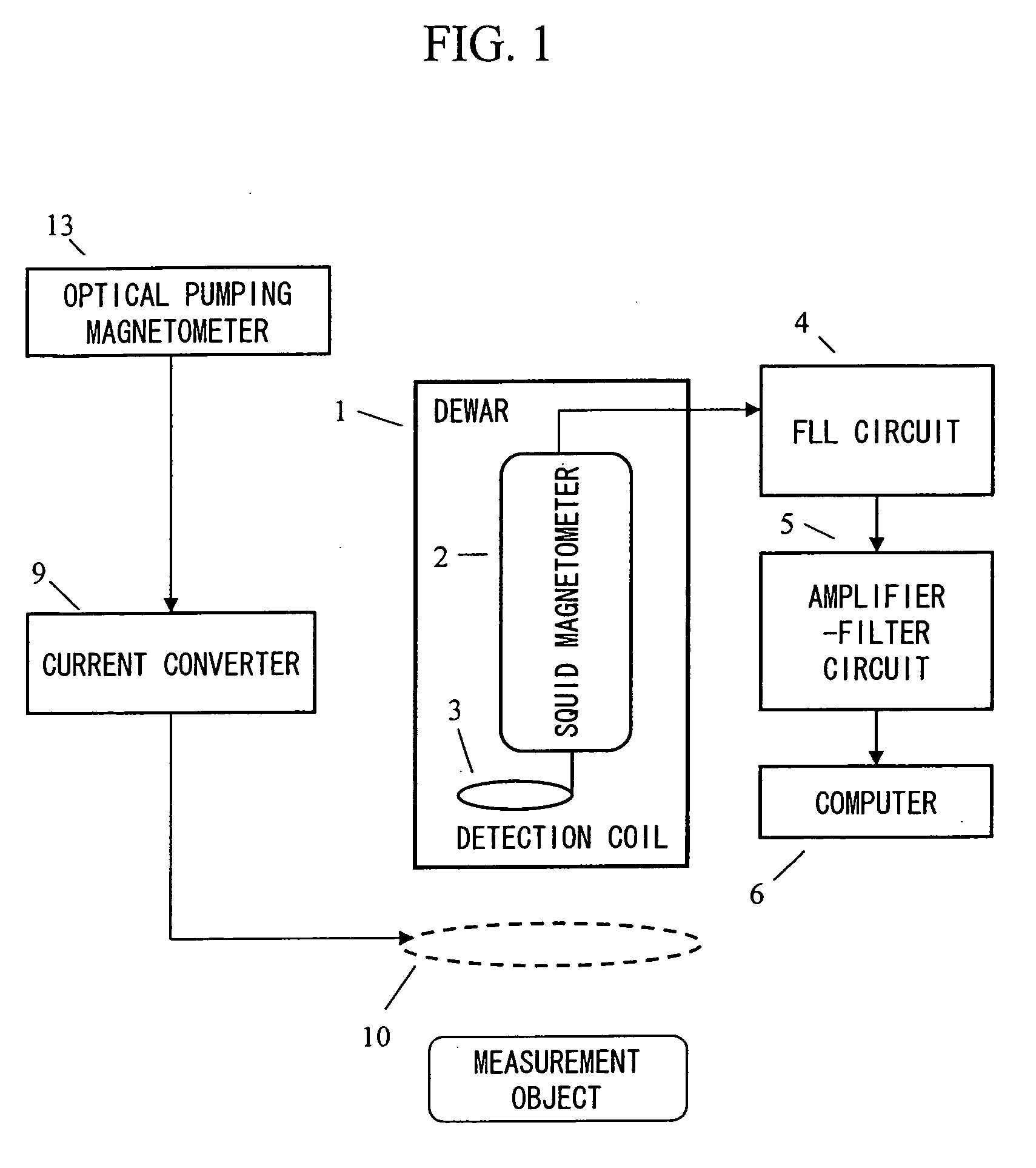

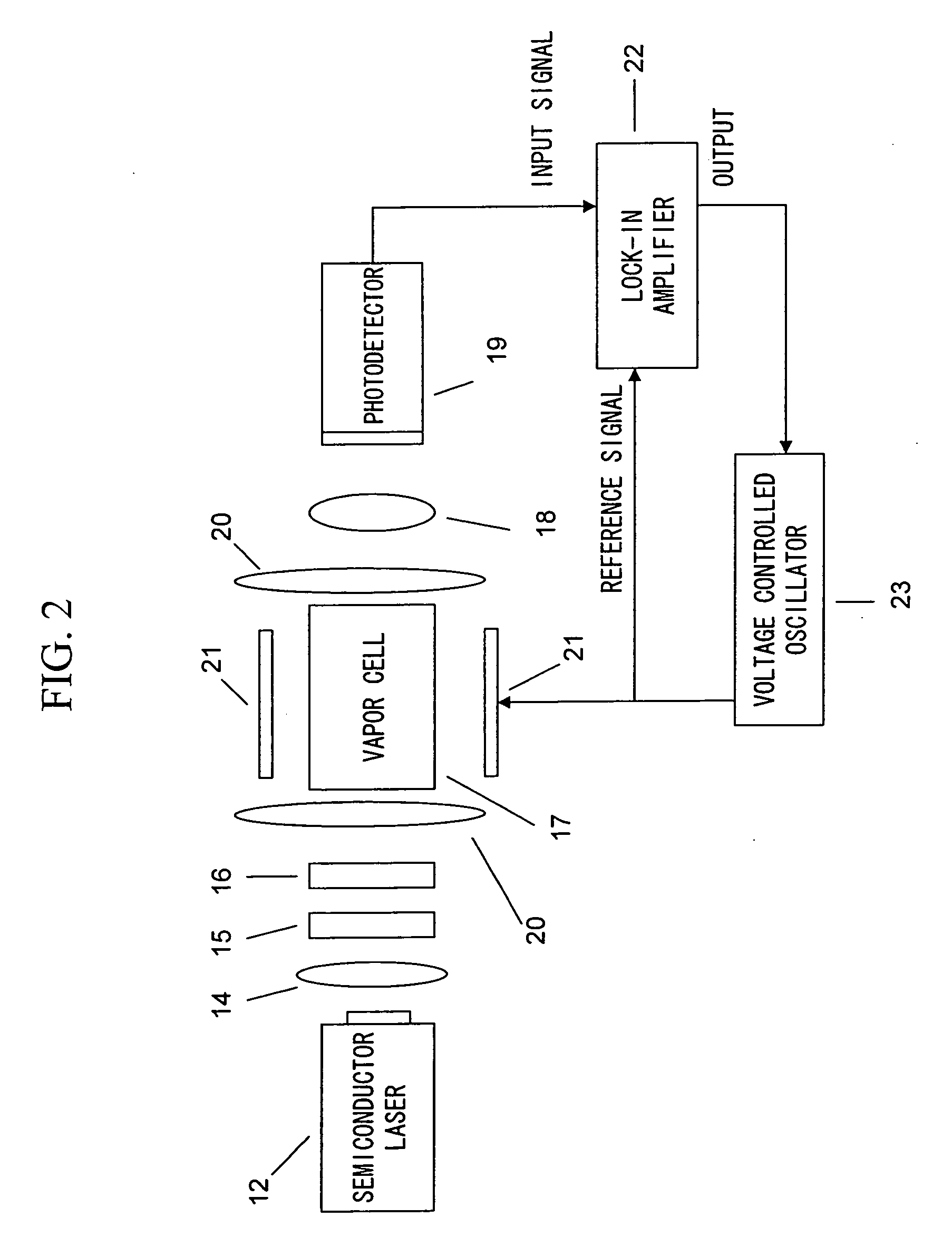

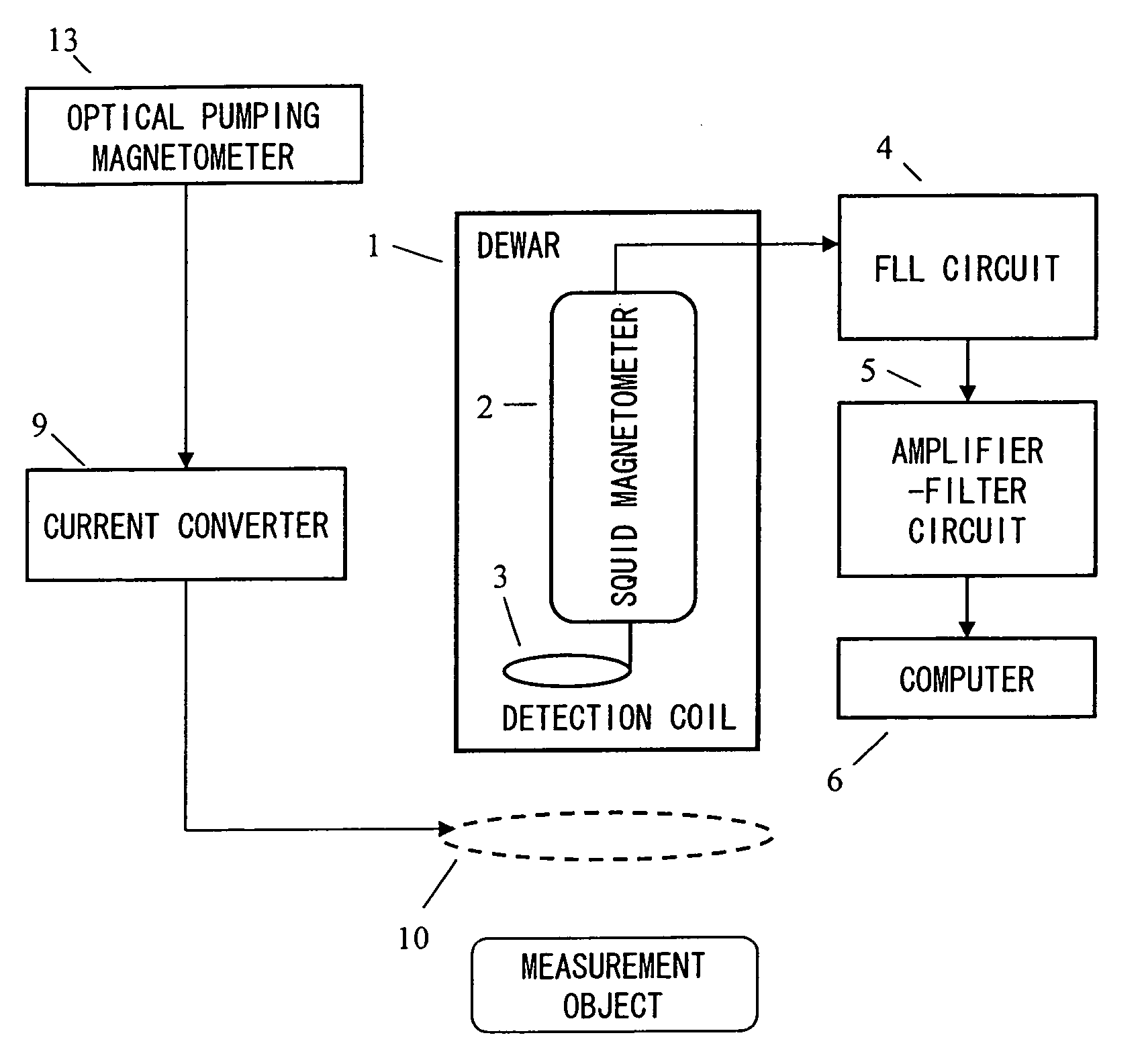

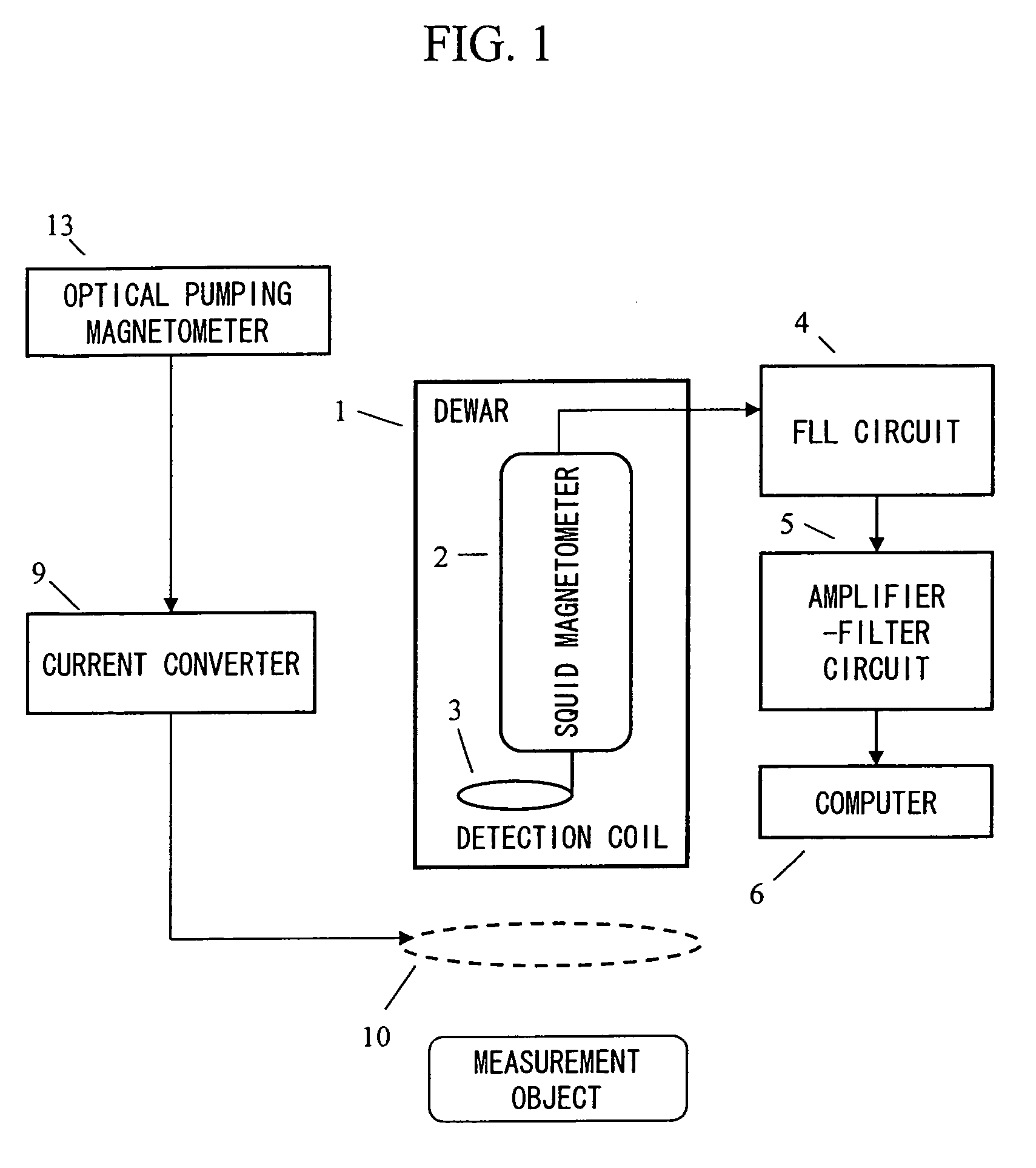

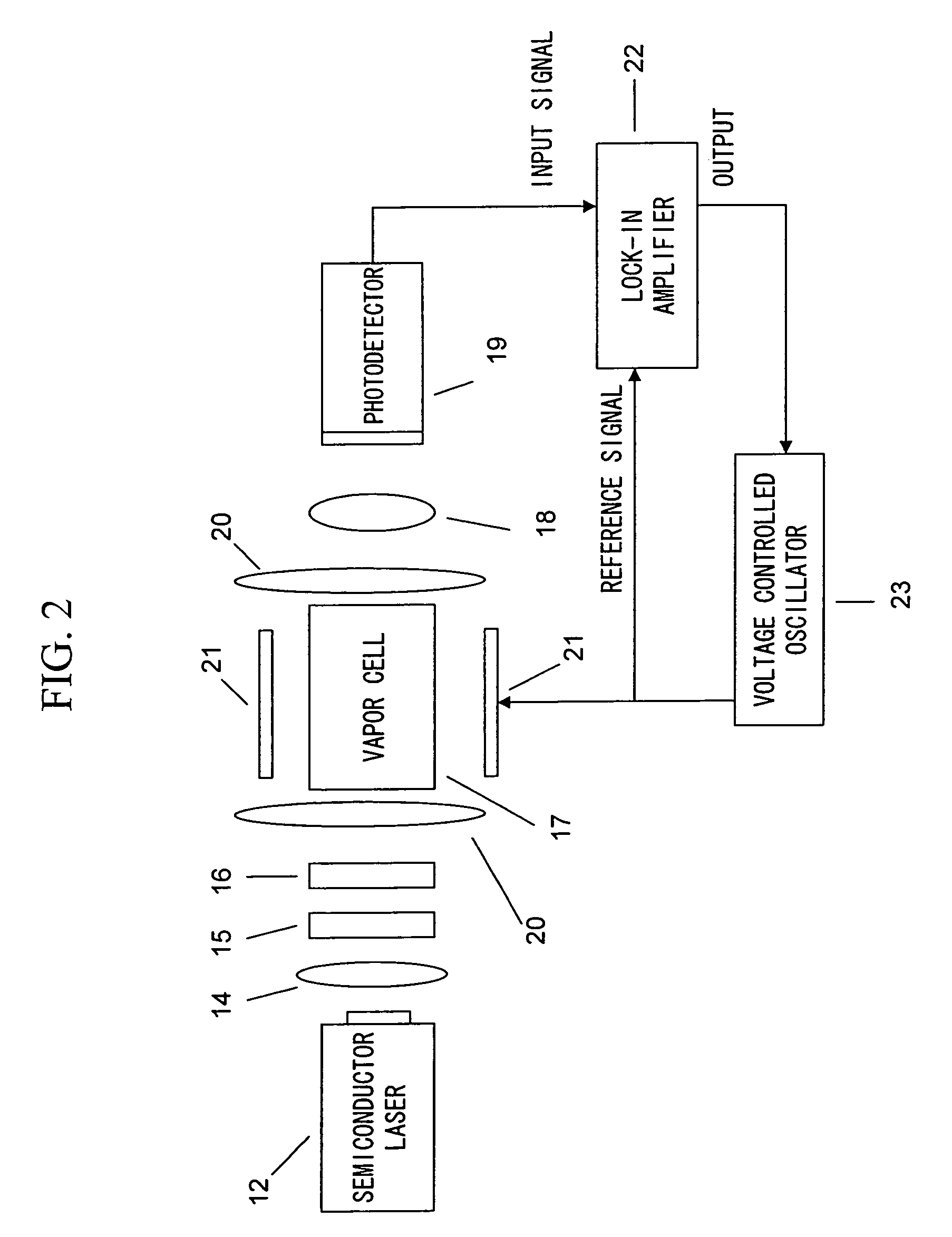

Magnetic field measurement system and optical pumping magnetometer

ActiveUS20070120563A1Reduce magnetic noiseAffect operationSuperconductors/hyperconductorsMagnetic field measurement using superconductive devicesElectricityComing out

Provided is a highly accurate optical pumping magnetometer, in which a static magnetic field and an oscillating field to be applied to a vapor cell are stabilized. To this end, the optical pumping magnetometer includes: Helmholtz coils for applying a constant static magnetic field to a vapor cell serving as a magnetic field detector; fluxgate magnetometers for detecting environmental magnetic noise in two directions of X-axis direction and Y-axis direction other than Z-axis direction which is a direction for detecting a magnetic field coming out of a measurement object while locating the vapor cell in the center thereof; magnetometer drive circuits for driving the fluxgate magneotometers; current converters for converting outputs of the magnetometer drive circuits into amount of currents; and magnetic field generating coils for generating a magnetic field in a phase opposite to the environmental magnetic noise in the two directions.

Owner:HITACHI HIGH-TECH CORP

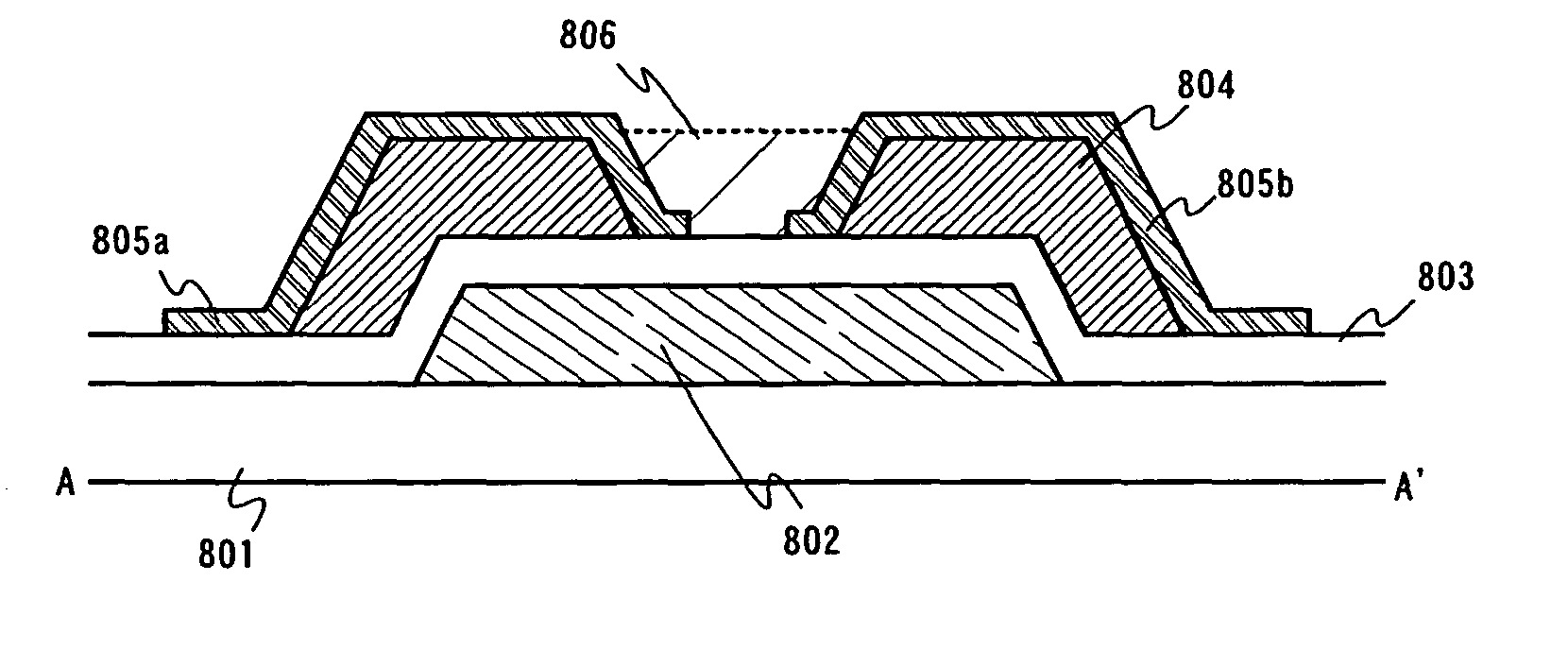

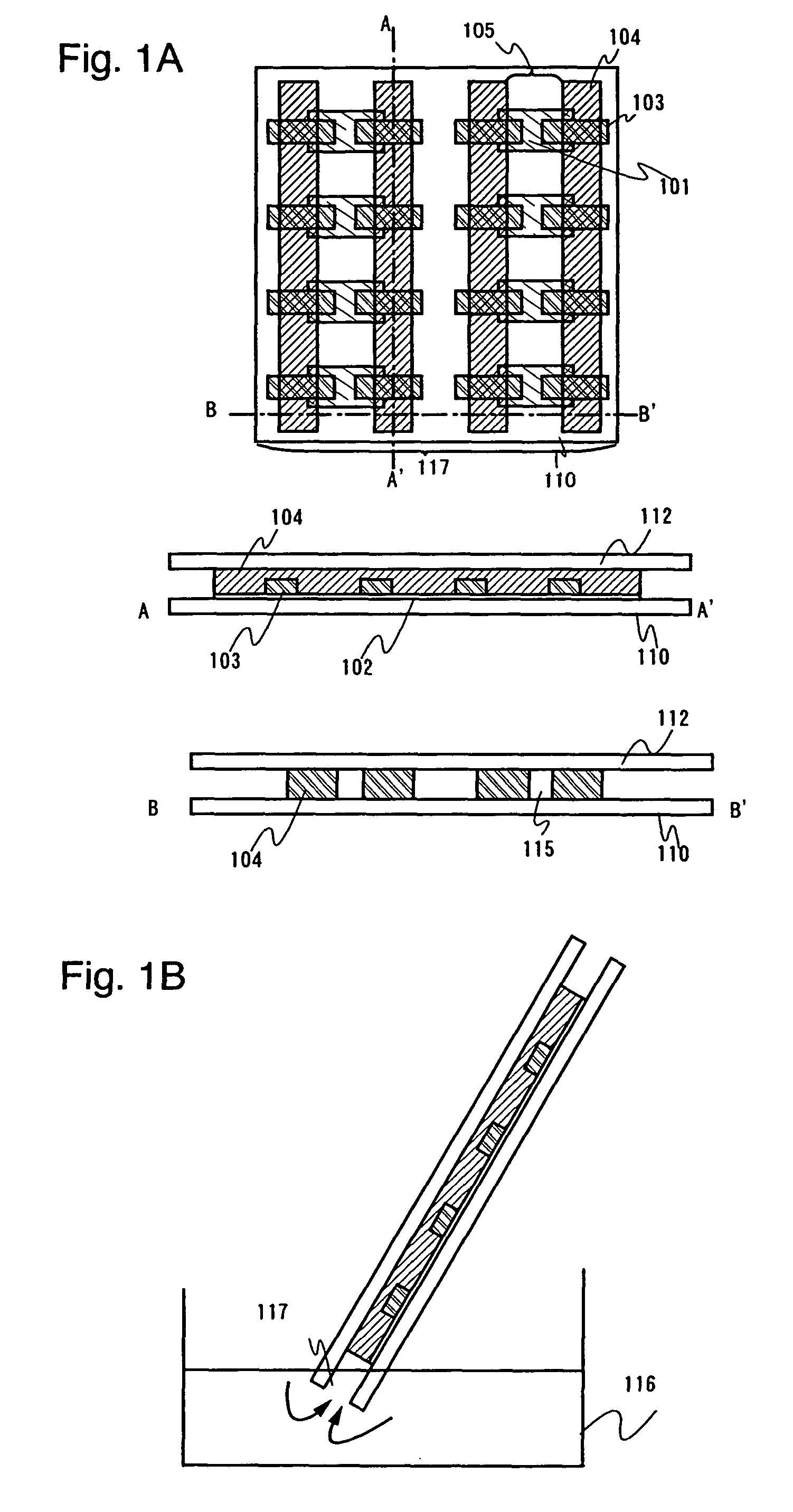

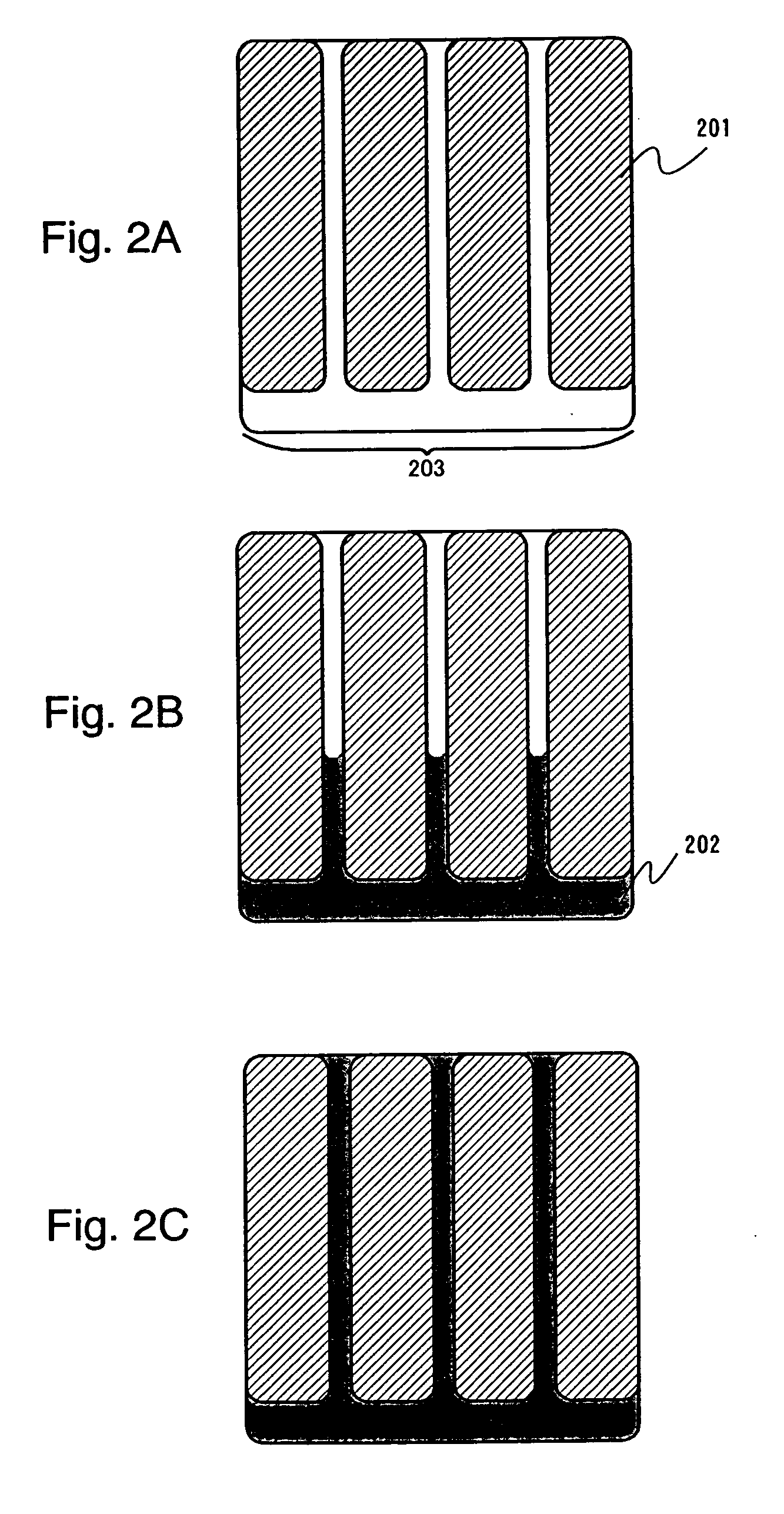

Organic thin film transistor and method of manufacturing the same, and semiconductor device having the organic thin film transistor

InactiveUS20040023447A1Simple manufacturing processThin thicknessSolid-state devicesSemiconductor/solid-state device manufacturingMan-hourEngineering

There have been problems in that a dedicated apparatus is needed for a conventional method of manufacturing an organic thin film transistor and in that: a little amount of an organic semiconductor film is formed with respect to a usage amount of a material; and most of the used material is discarded. Further, apparatus maintenance such as cleaning of the inside of an apparatus cup or chamber has needed to be frequently carried out in order to remove the contamination resulting from the material that is wastefully discarded. Therefore, a great cost for materials and man-hours for maintenance of apparatus have been required. In the present invention, a uniform organic semiconductor film is formed by forming an aperture between a first substrate for forming the organic semiconductor film and a second substrate used for injection with an insulating film formed at a specific spot and by injecting an organic semiconductor film material into the aperture due to capillarity to the aperture. The insulating film formed at the specific spot enables formation of the organic semiconductor film with high controllability. Further, the insulating film can also serve as a spacer that holds the aperture, that is, an interval (gap) between the substrates.

Owner:SEMICON ENERGY LAB CO LTD

Magnetic field measurement system and optical pumping magnetometer

ActiveUS7656154B2Reduce magnetic noiseAffect operationSuperconductors/hyperconductorsMagnetic field measurement using superconductive devicesElectricityComing out

Provided is a highly accurate optical pumping magnetometer, in which a static magnetic field and an oscillating field to be applied to a vapor cell are stabilized. To this end, the optical pumping magnetometer includes: Helmholtz coils for applying a constant static magnetic field to a vapor cell serving as a magnetic field detector; fluxgate magnetometers for detecting environmental magnetic noise in two directions of X-axis direction and Y-axis direction other than Z-axis direction which is a direction for detecting a magnetic field coming out of a measurement object while locating the vapor cell in the center thereof; magnetometer drive circuits for driving the fluxgate magneotometers; current converters for converting outputs of the magnetometer drive circuits into amount of currents; and magnetic field generating coils for generating a magnetic field in a phase opposite to the environmental magnetic noise in the two directions.

Owner:HITACHI HIGH-TECH CORP

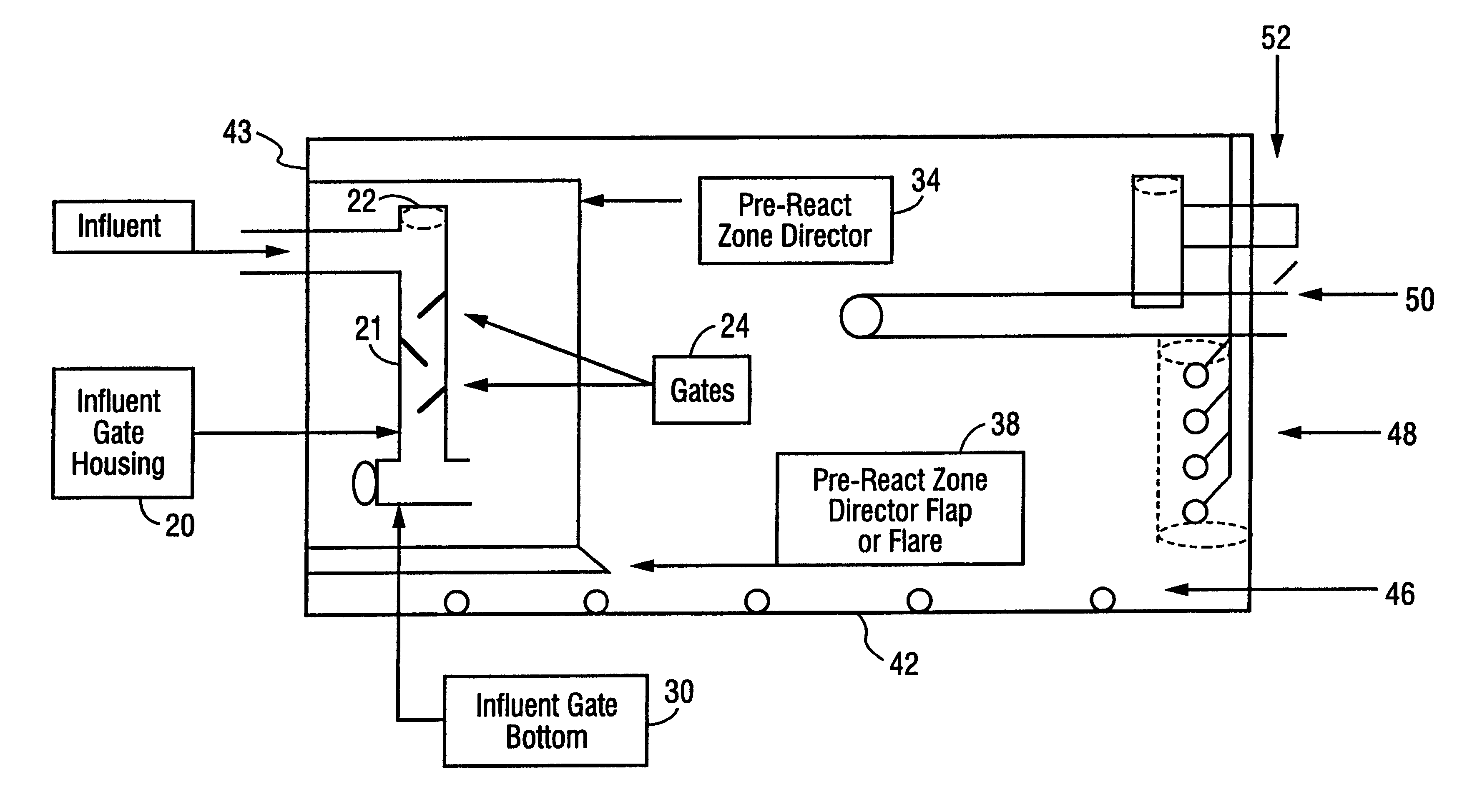

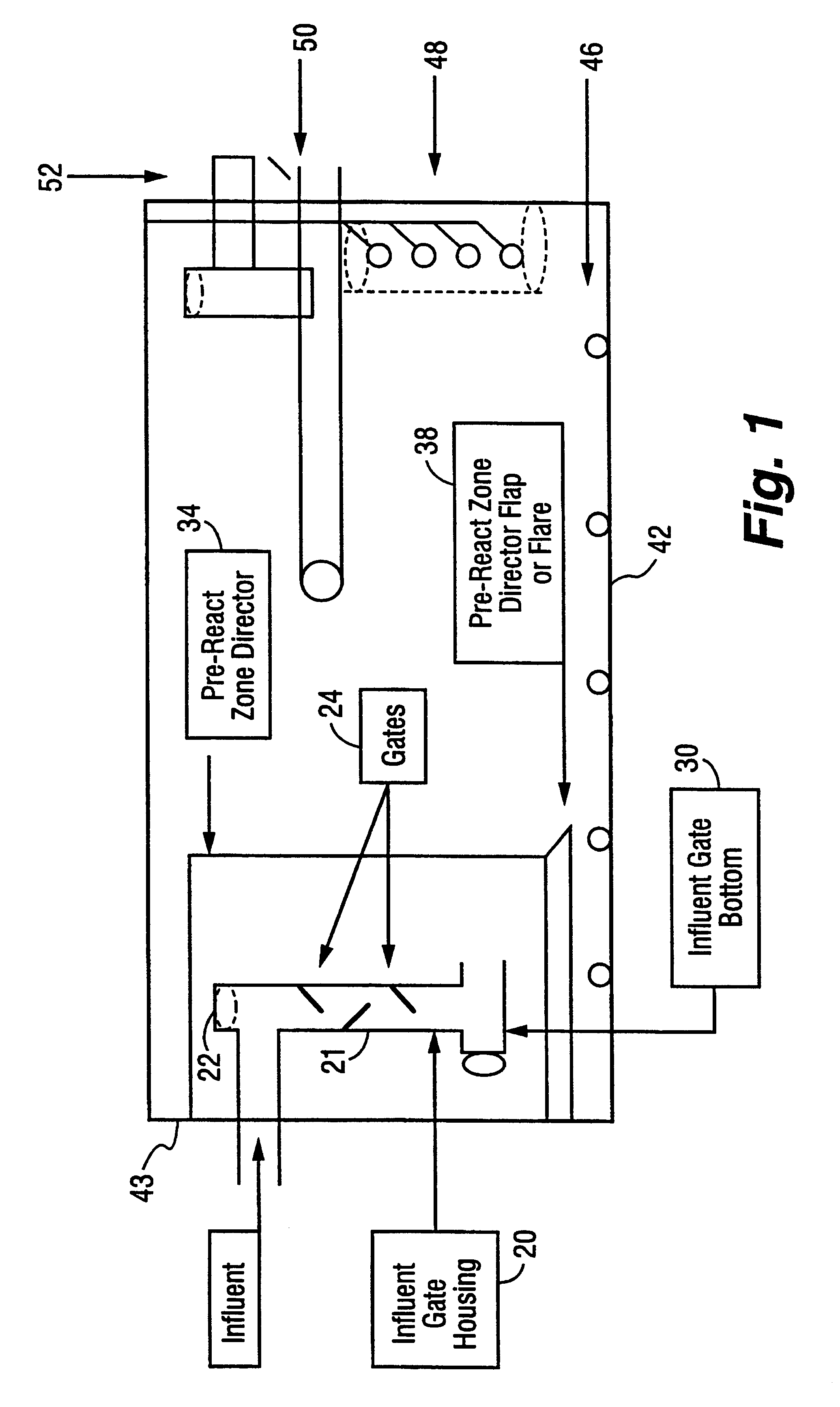

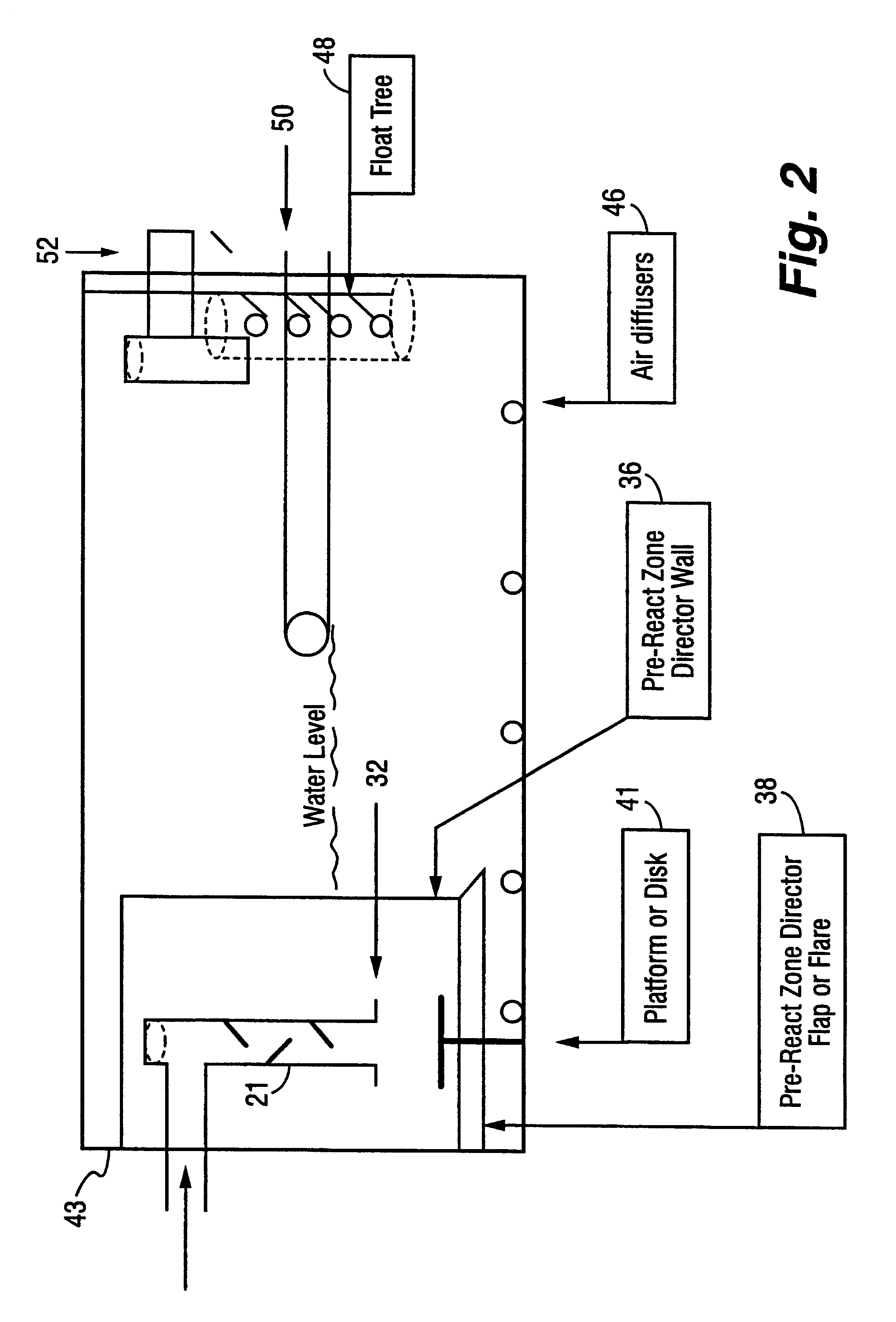

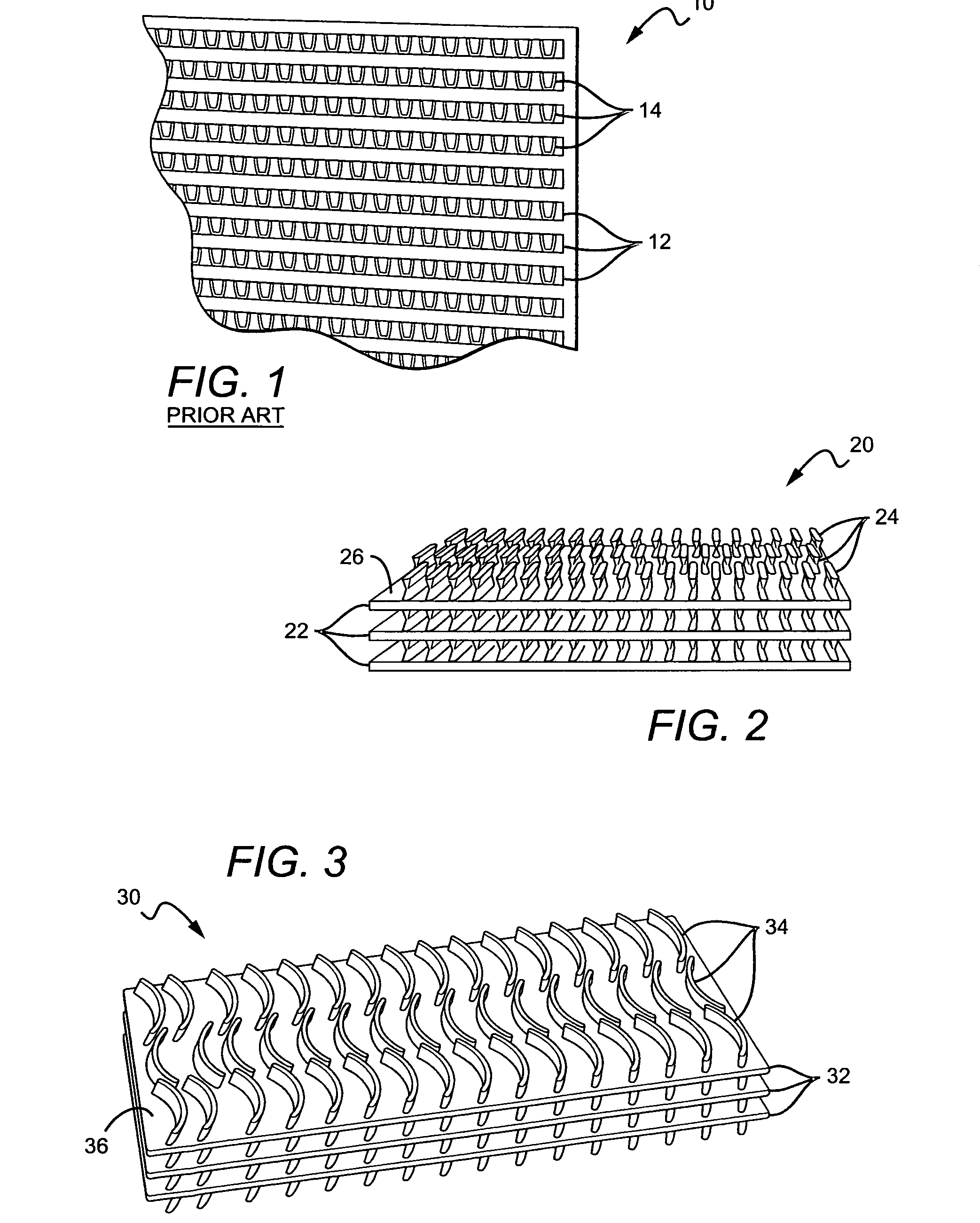

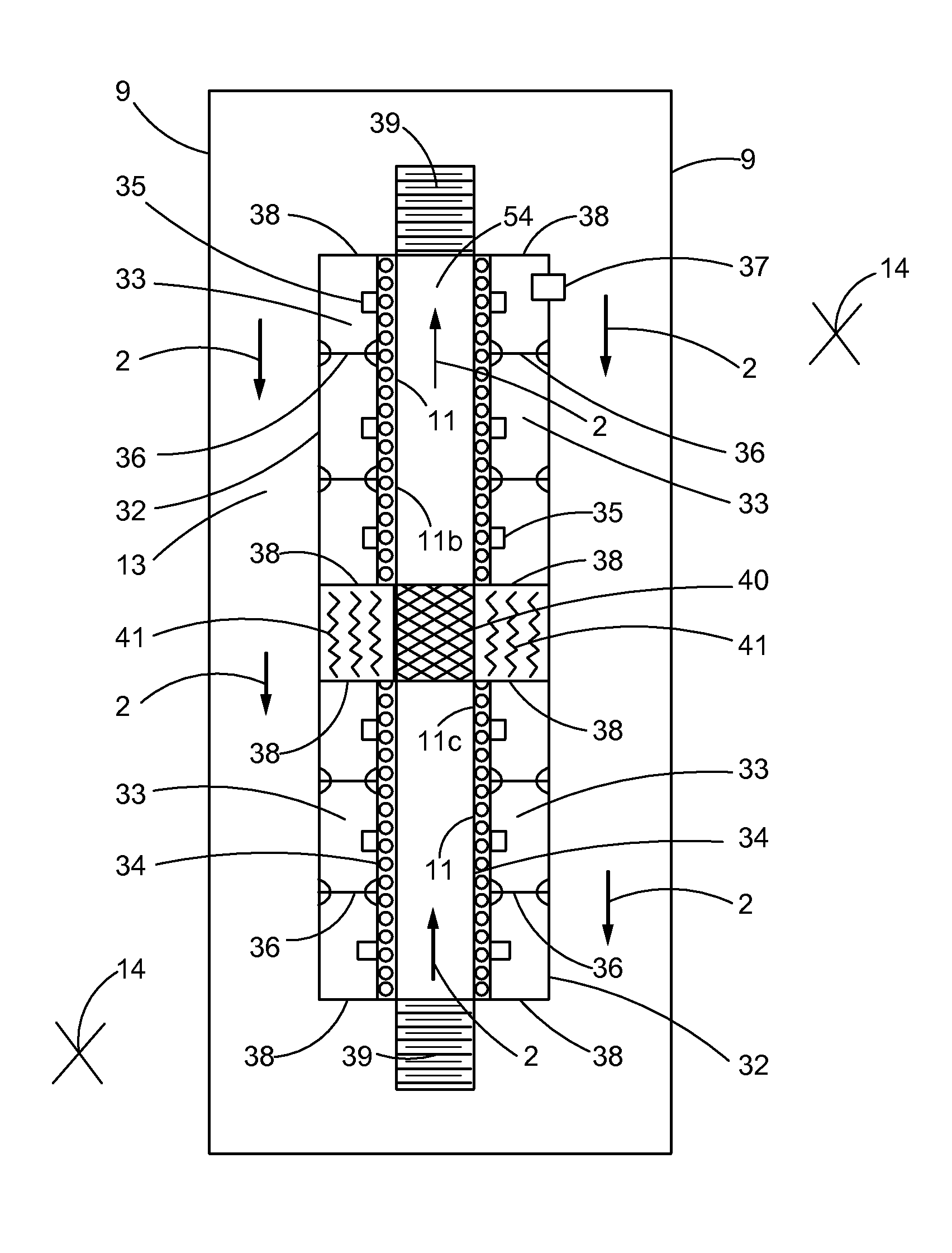

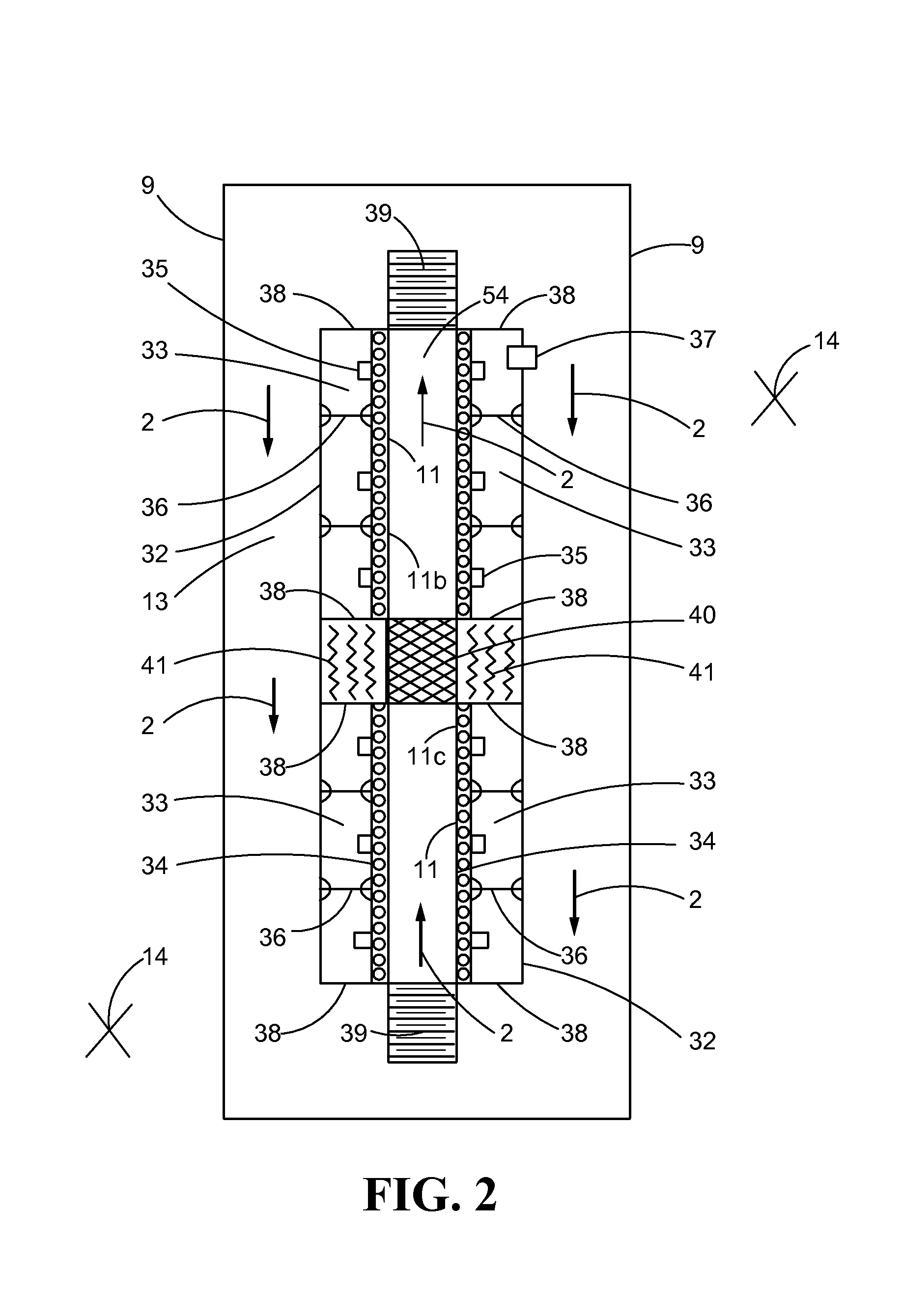

Wastewater treatment tank with influent gates and pre-react zone with an outwardly flared lower portion

InactiveUS6303026B1Reduce flow rateAvoid interferenceWater treatment parameter controlTreatment using aerobic processesSludgeBiological filter

A wastewater treatment tank with influent gates (24) and pre-react zone with an outwardly flared lower portion. Influent passes over influent gates (24), which introduce turbulence, causing aeration, and reducing flow velocity. As influent flows out of the influent gate housing (20), flow velocity is further reduced by contact with the surface of the wastewater in the basin and influent flow is directed laterally by an influent gate bottom (30). A pre-react zone director (34) spaced apart from the bottom (42) of the basin encloses the influent gate housing (20) and utilizes an outwardly flared lower portion, or flap (38), to further reduce flow velocity and enhance laminar flow. This results in minimal disturbance of settled sludge blanket, allowing it to act as a natural biological filter, which in turn results in a superior supernatant.

Owner:LINDBO GLEN D

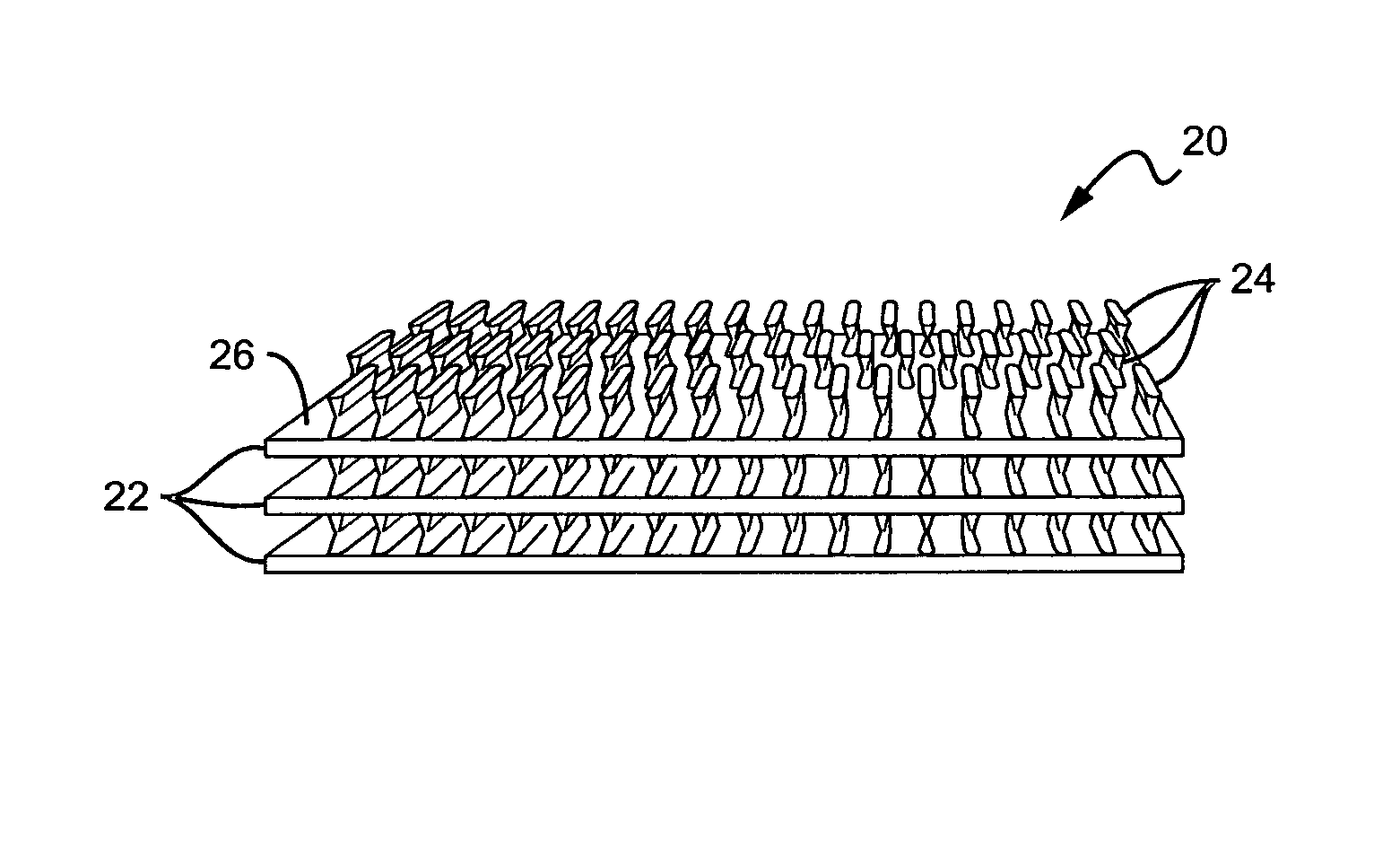

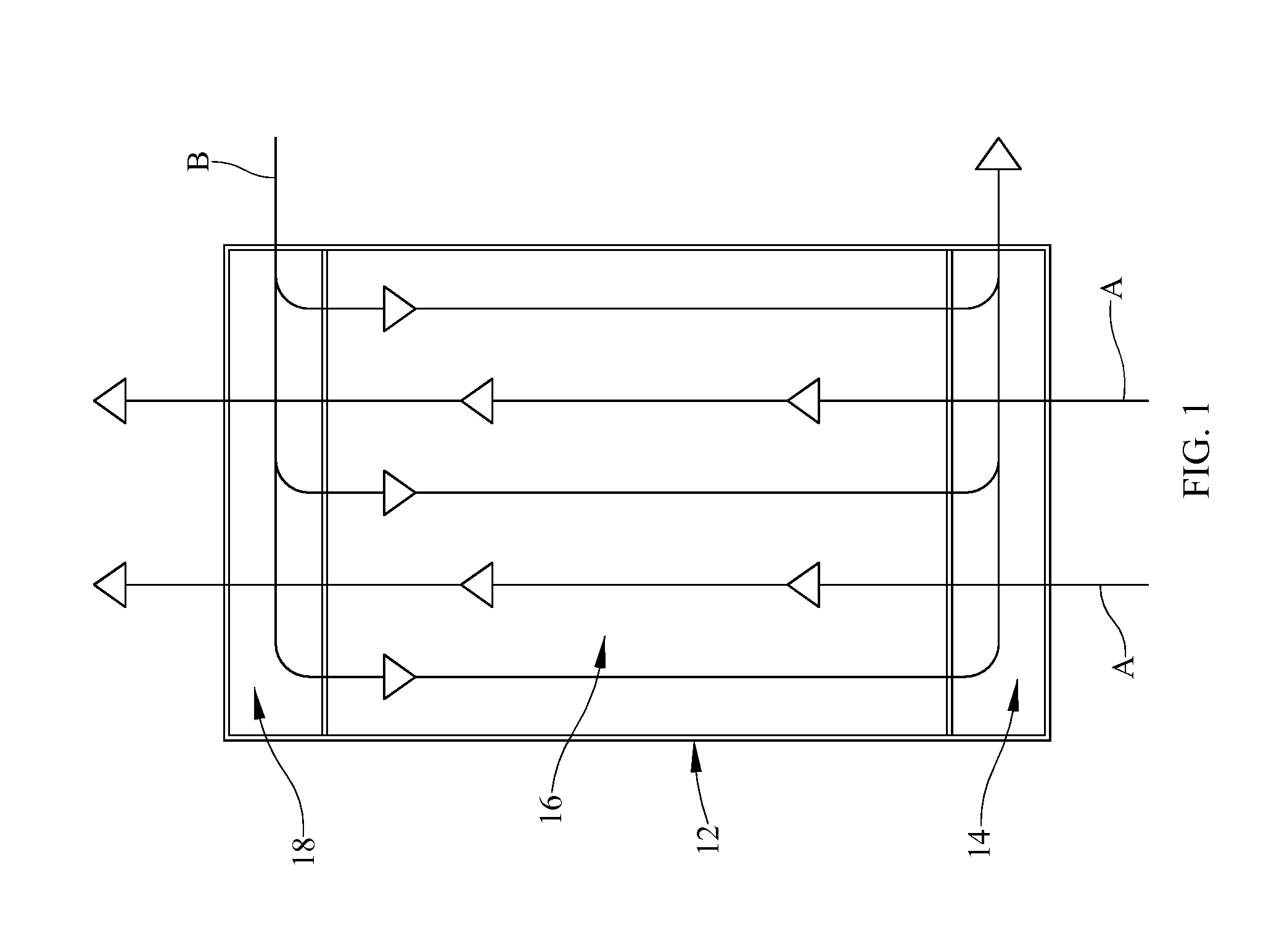

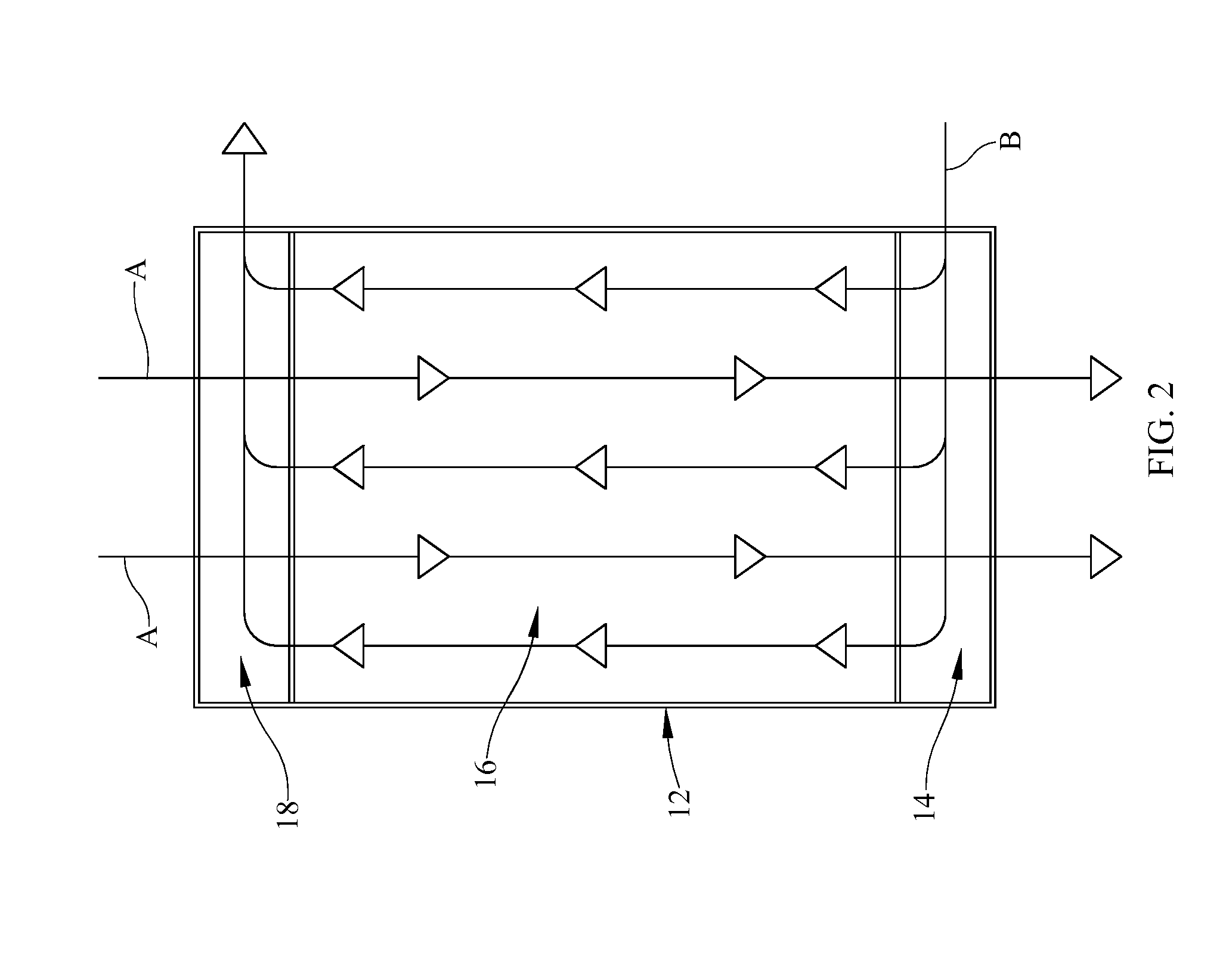

Method of making a heat exchanger

ActiveUS7810552B2Increased complexity of componentReduce manufacturing costAdditive manufacturing apparatusPhotomechanical apparatusEngineeringDesign data

Owner:THE BOEING CO

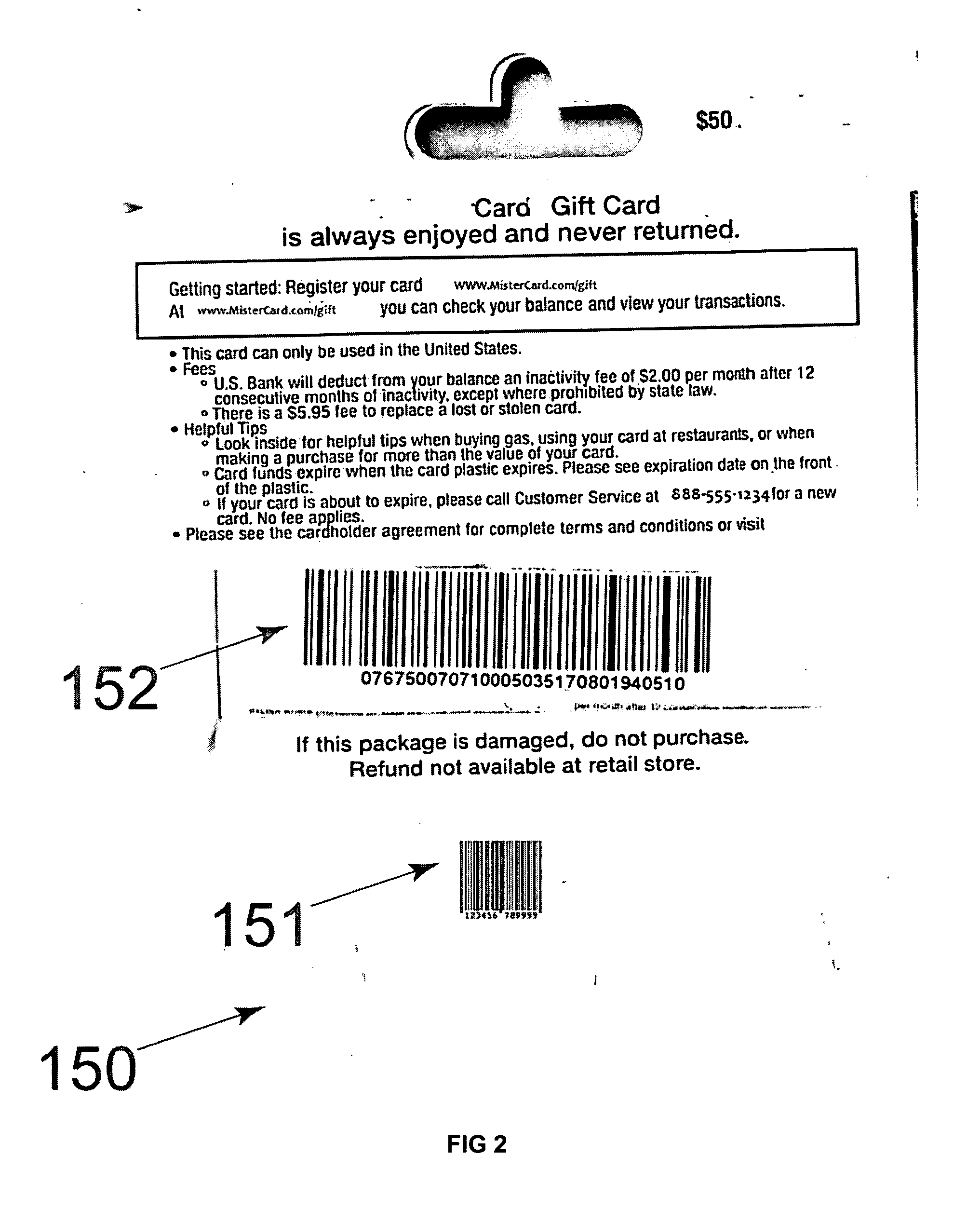

Method for optically decoding a debit or credit card

InactiveUS20130202185A1Eliminate logistical needReduce confusionAcutation objectsCharacter and pattern recognitionCredit cardComputer hardware

A method for collecting and transmitting information desired for a commercial transaction from a debit or credit card uses a processor configured with optical character recognition (OCR) capability. At least one optical image of the debit or credit card is collected by the processor. The edges of the card are algorithmically defined from the collected image. Predefined offsets are applied to the algorithmically defined edges of the debit or credit card to algorithmically locate an area in the collected image having the desired transactional data. The transactional data within the located area is encoded and transmitted for further processing of the commercial transaction.

Owner:SCI GAMES INT

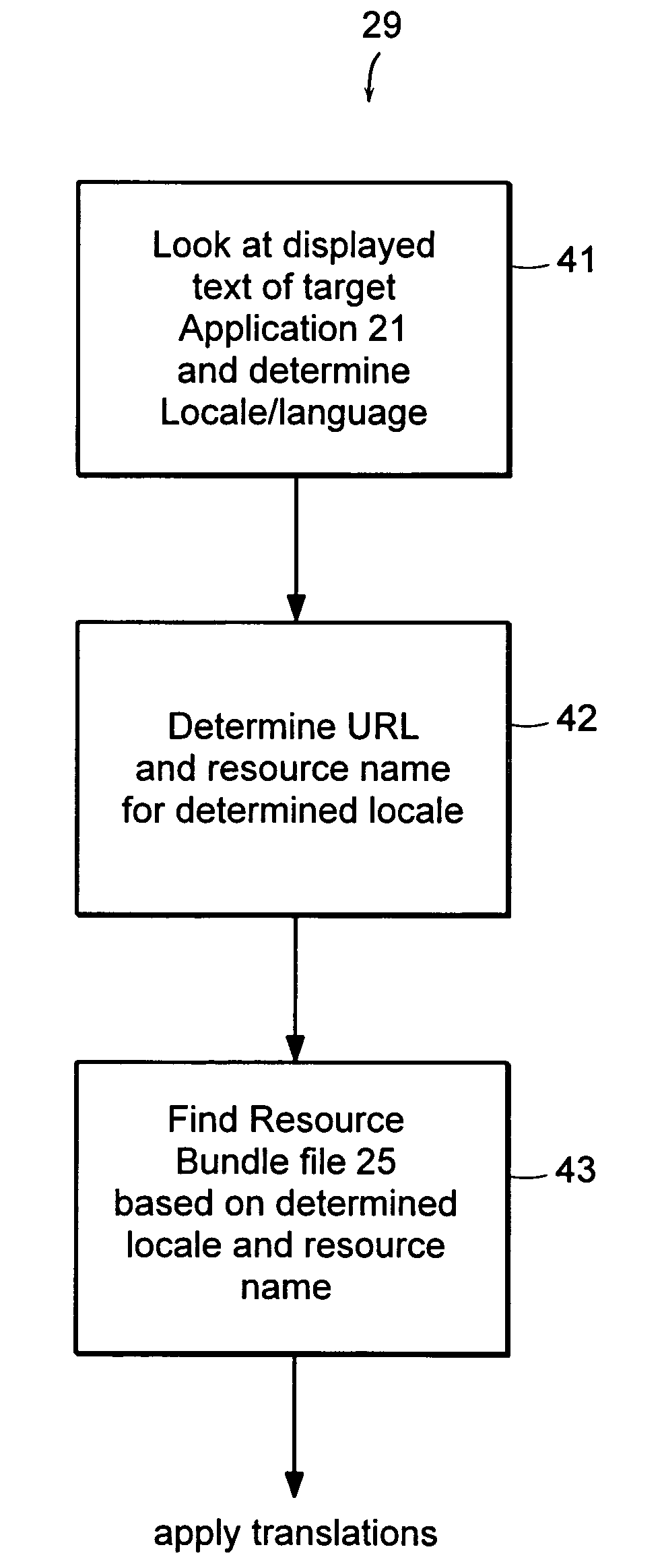

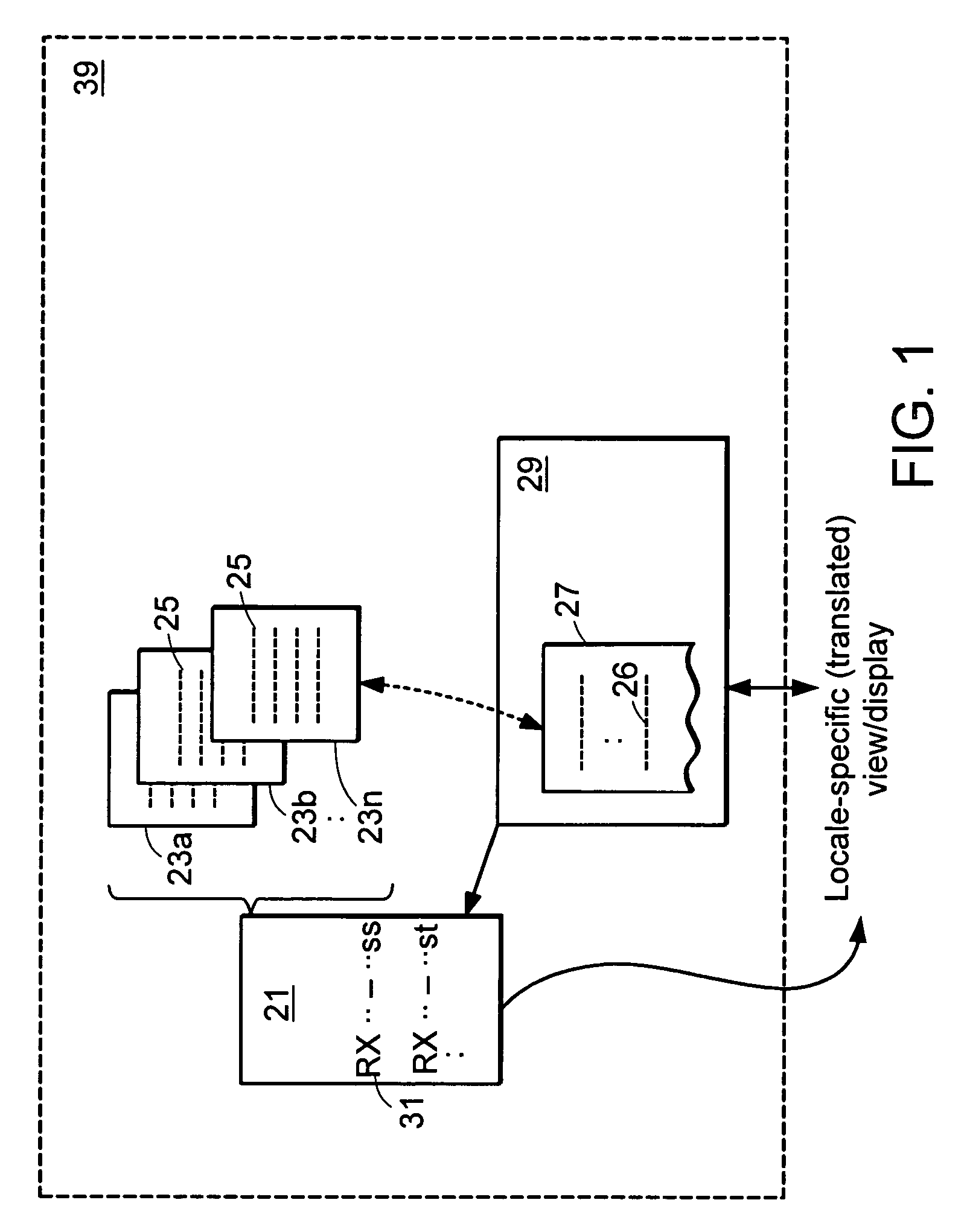

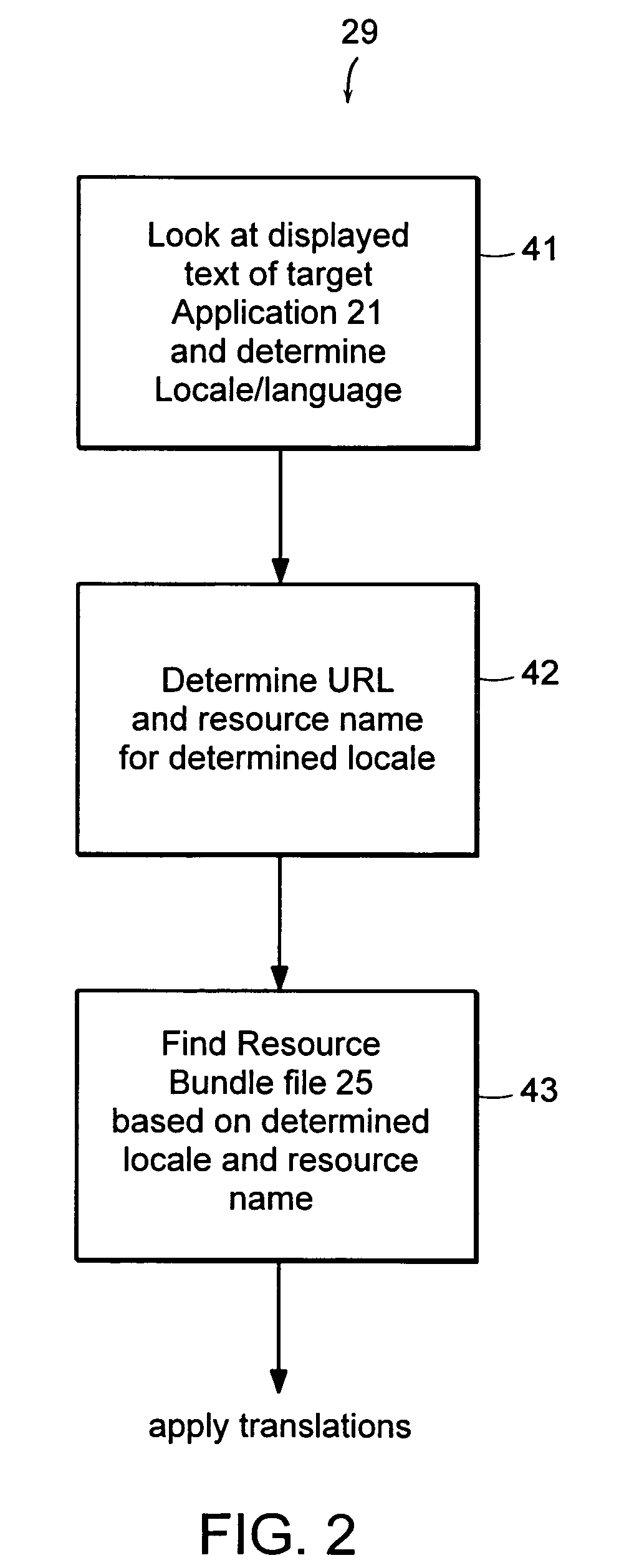

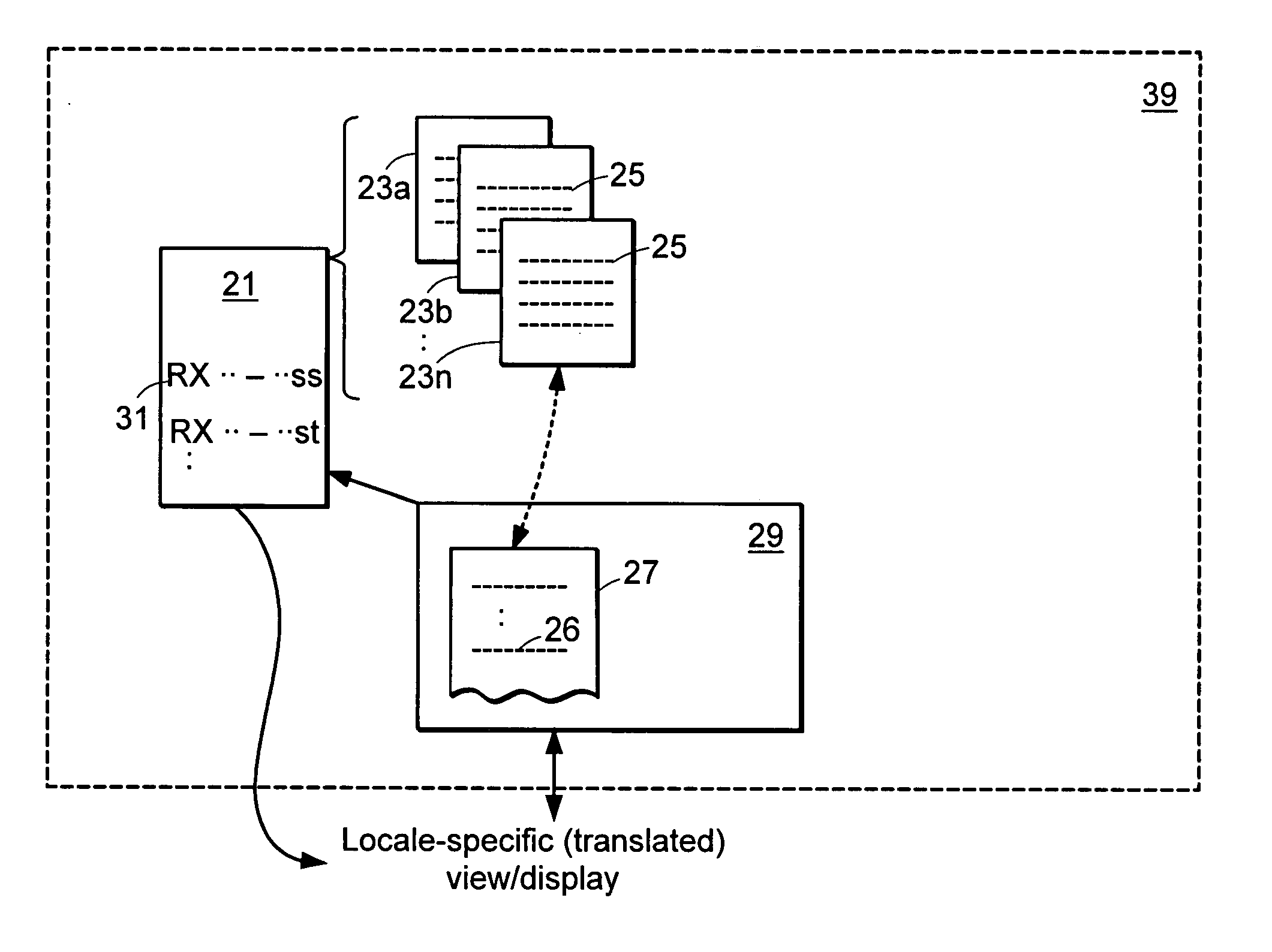

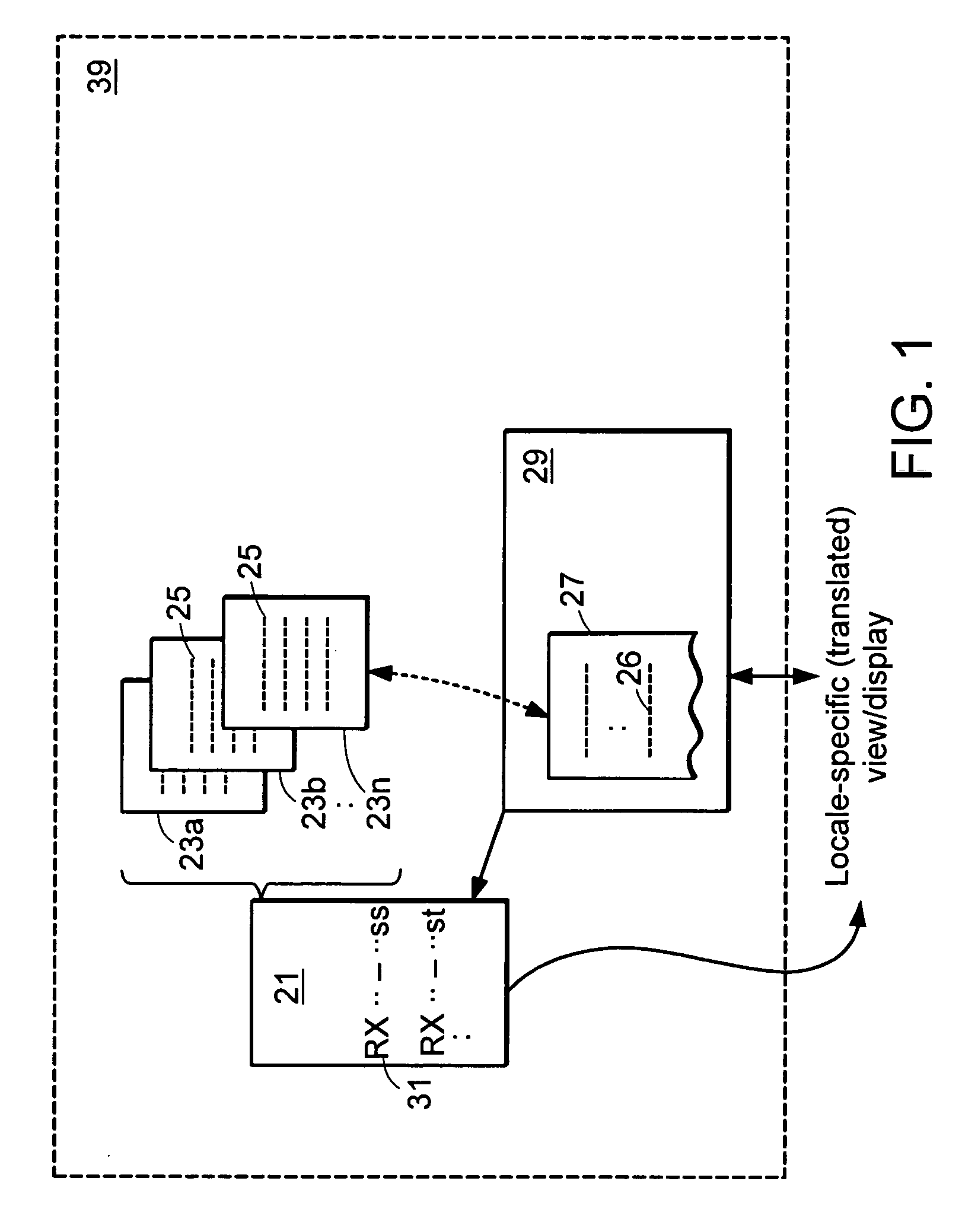

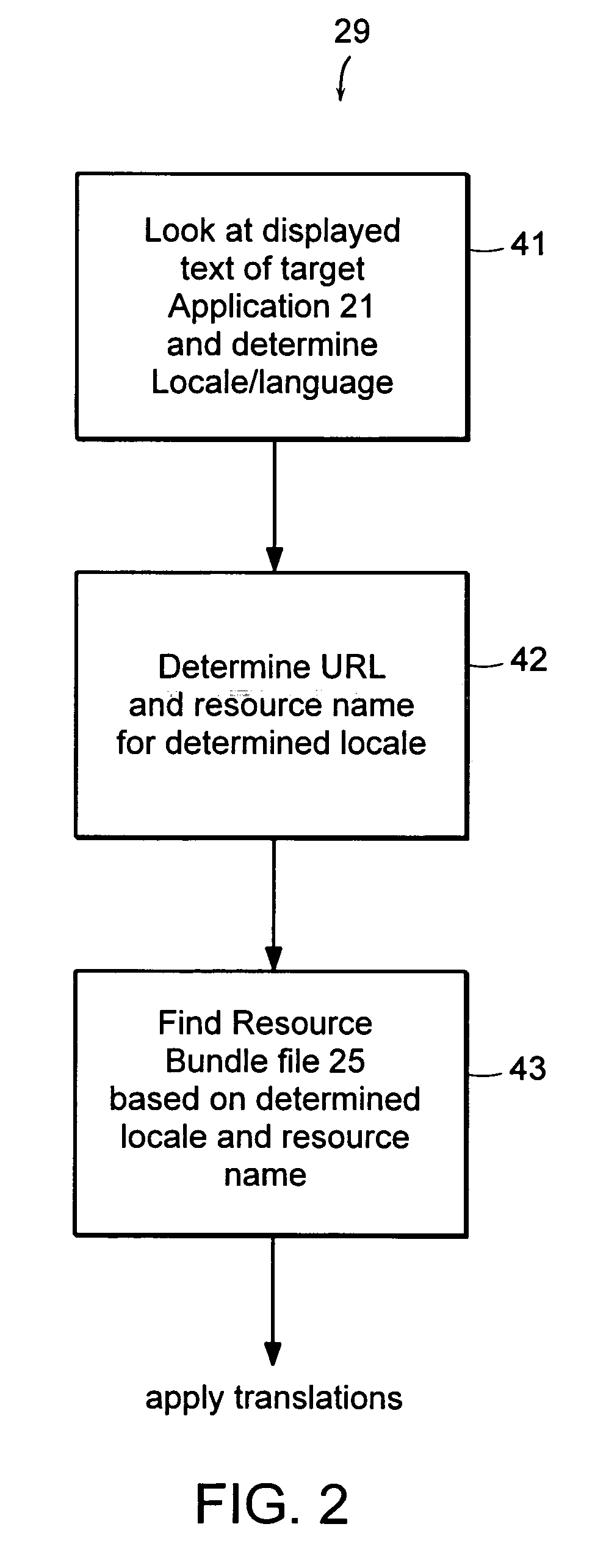

Automated multilingual software testing method and apparatus

ActiveUS7543189B2Reduce translation costsApplication to testingError detection/correctionSpecial data processing applicationsMethod testOperational system

A computer system and method tests various language installations of an application program using a single test script. The various language translations existing with the application program are used to provide translations of test command strings from one language to the specific language of the application program (operating system locale for executing the program). The test script may then be translated at runtime using the predefined program-established translations to allow the testing program to test the application program in accordance with the language of the application program / operating system locale.

Owner:IBM CORP

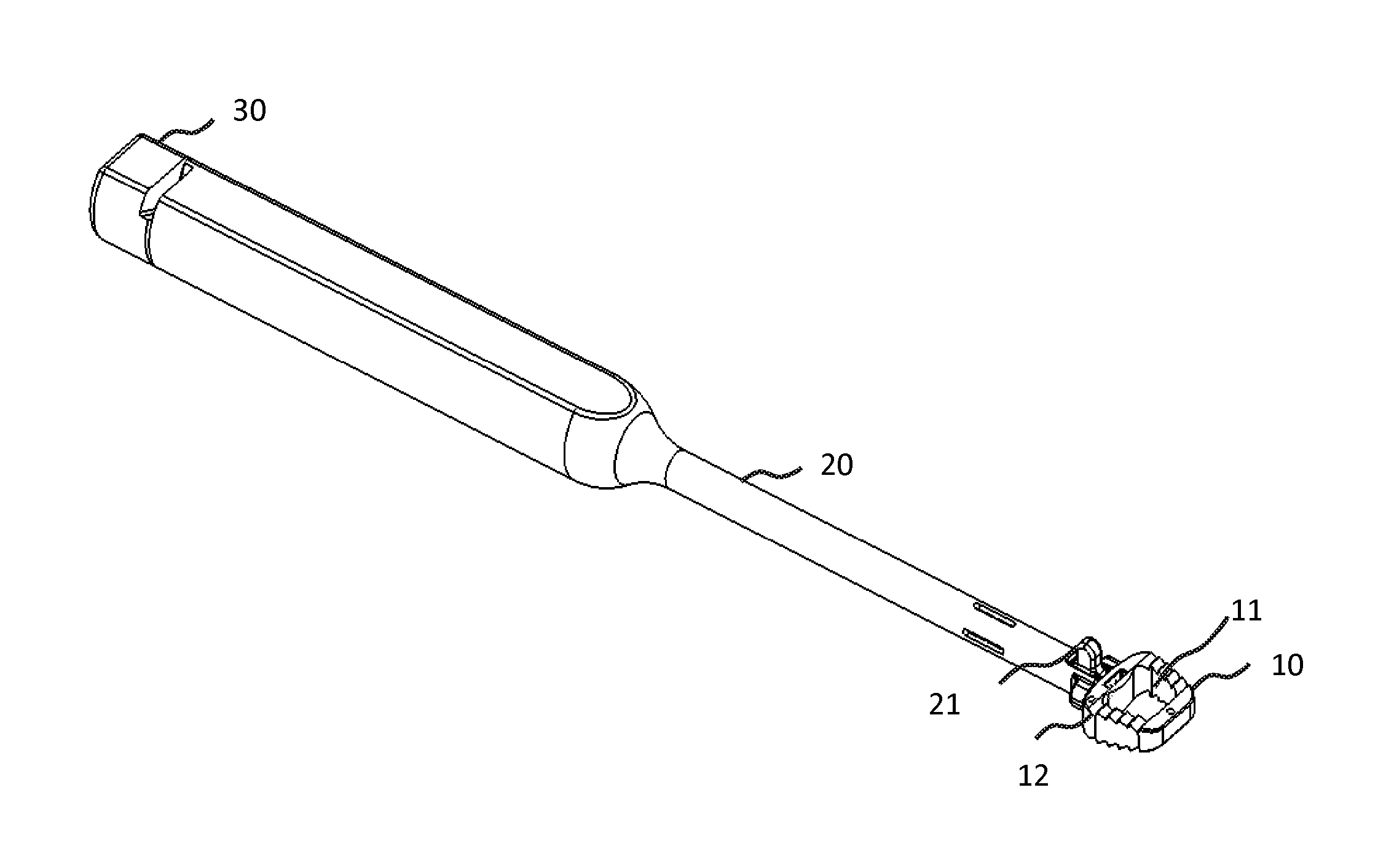

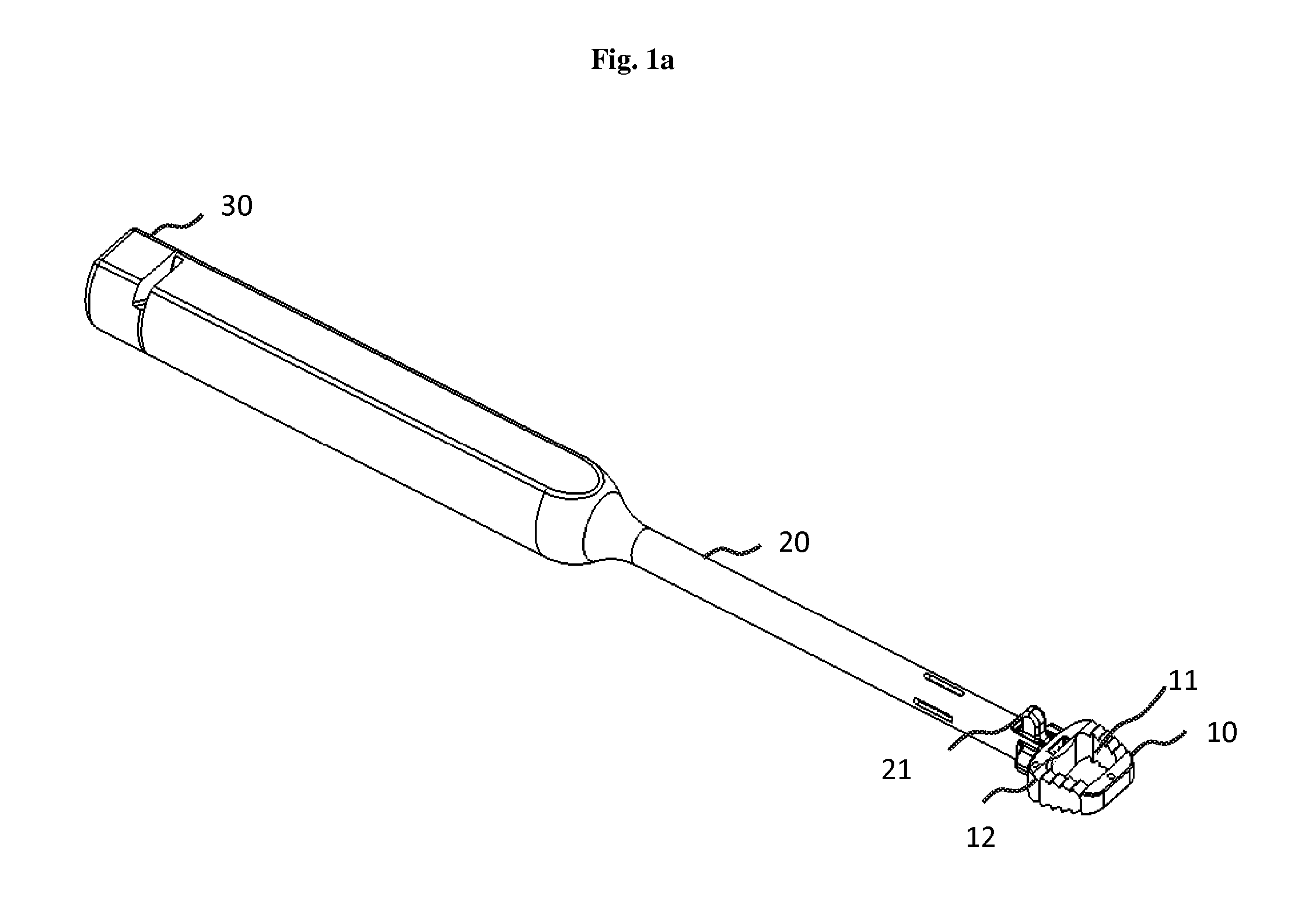

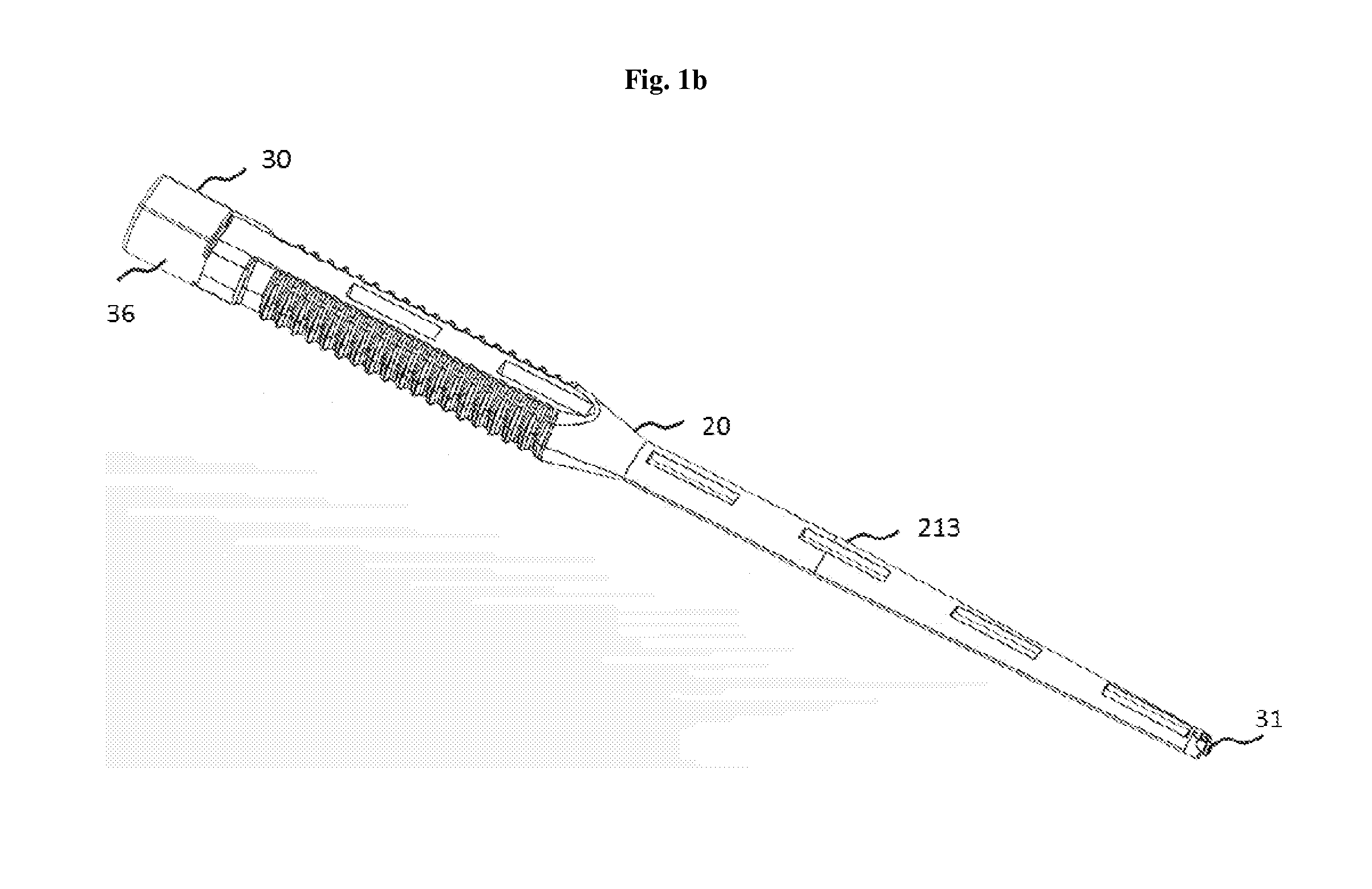

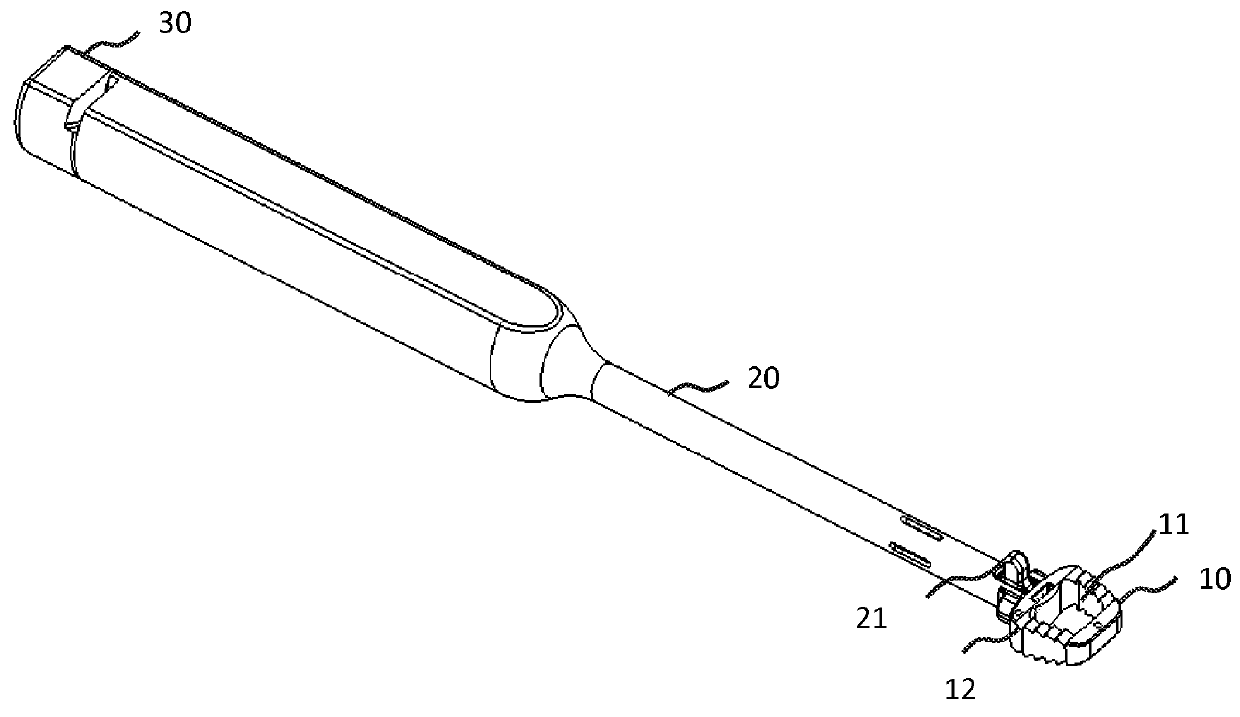

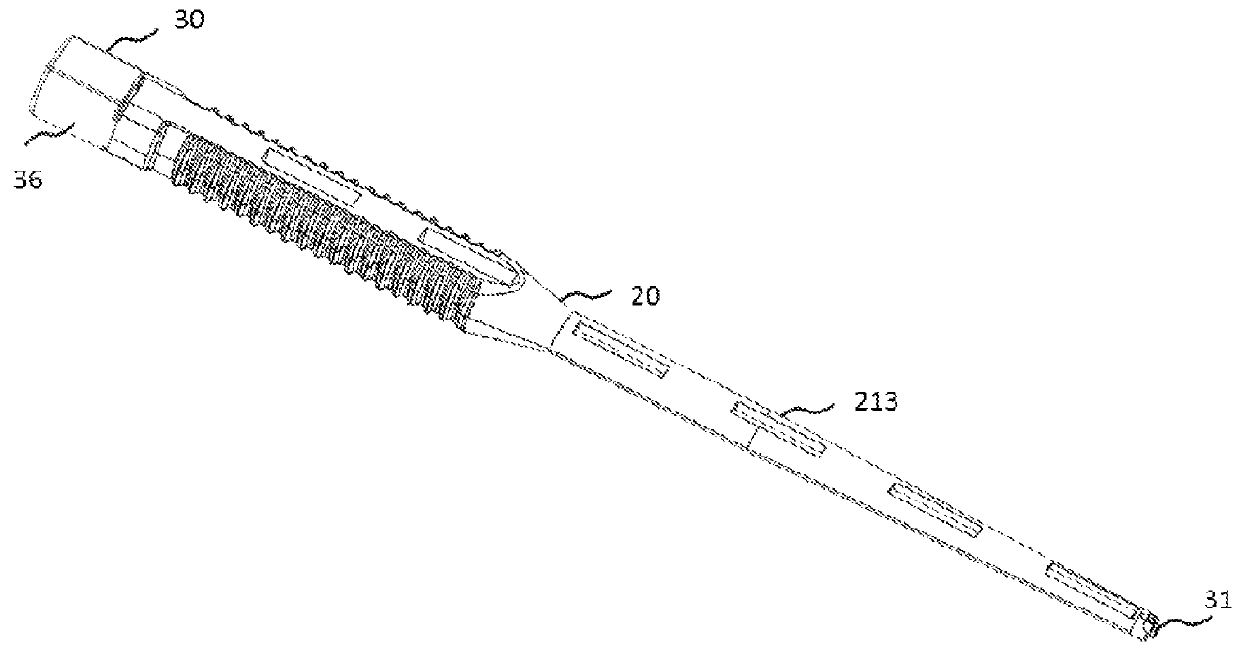

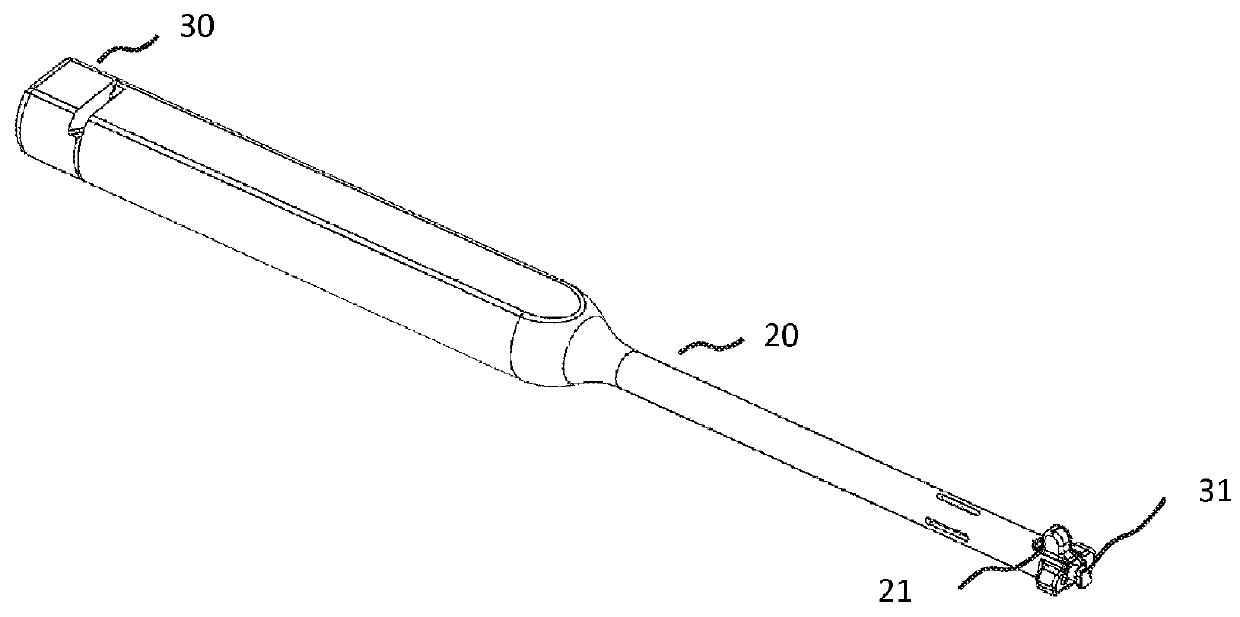

Lock and release implant delivery system

ActiveUS20150157469A1Low priceSimple processInternal osteosythesisJoint implantsLocking mechanismMachining

Injection-molded devices and systems for graft or other tissue delivery, methods for their single-use in delivery of an implant, and kits for their sterile delivery to a practitioner are disclosed herein. Systems for implant delivery comprise an injection moldable implant body and an insertion device comprising: an inner and outer shaft that form a locking mechanism that secures an implant body in place and releases it upon placement within a patient. Systems are configured to be manufactured by injection molding, such that they can be cost-effectively manufactured and discarded after a single use to avoid costs and risks associated with re-sterilization and cleaning, but can in some cases optionally also be manufactured by machining to be re-sterilized and reused.

Owner:XENCO MEDICAL

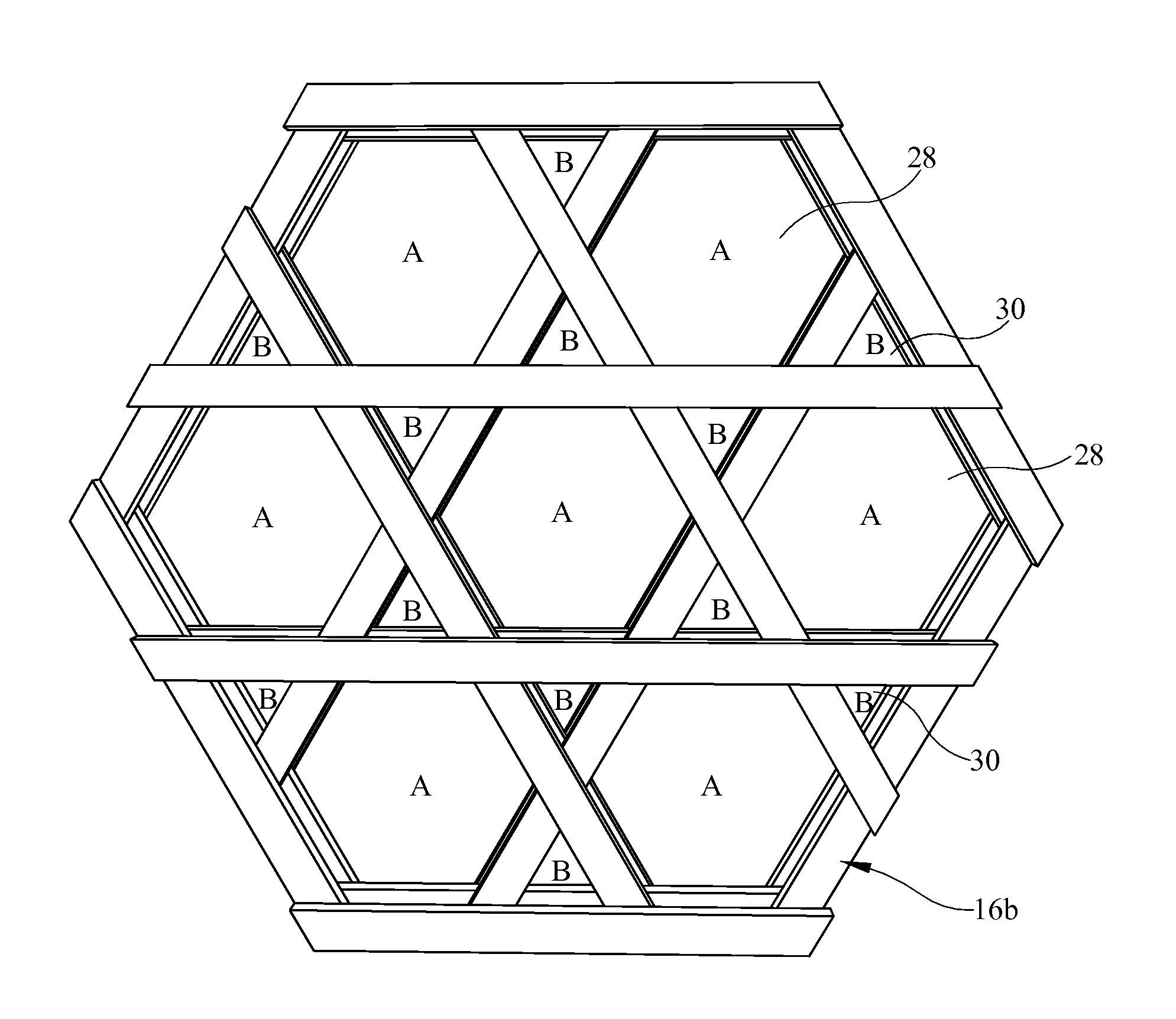

Fill material for direct-contact heat/mass exchangers

InactiveUS20150048528A1Reduced dysfunctionSmall sizeAdditive manufacturing apparatusUsing liquid separation agentFilling materialsLinear element

Fill material for a direct contact heat exchanger wherein the fill material has flow pathways bounded by an array of linear elements, namely a mesh. The invention intentionally uses surface tension and capillary action to anchor the fluid / fluid interface in a desired location. The heat exchanger is wick or collector in direct contact with the fill material (matrix) to extract fluid without formation of large droplets. The mesh is made from a neutrally wetting material.

Owner:BARTON SEAN ANDERSON

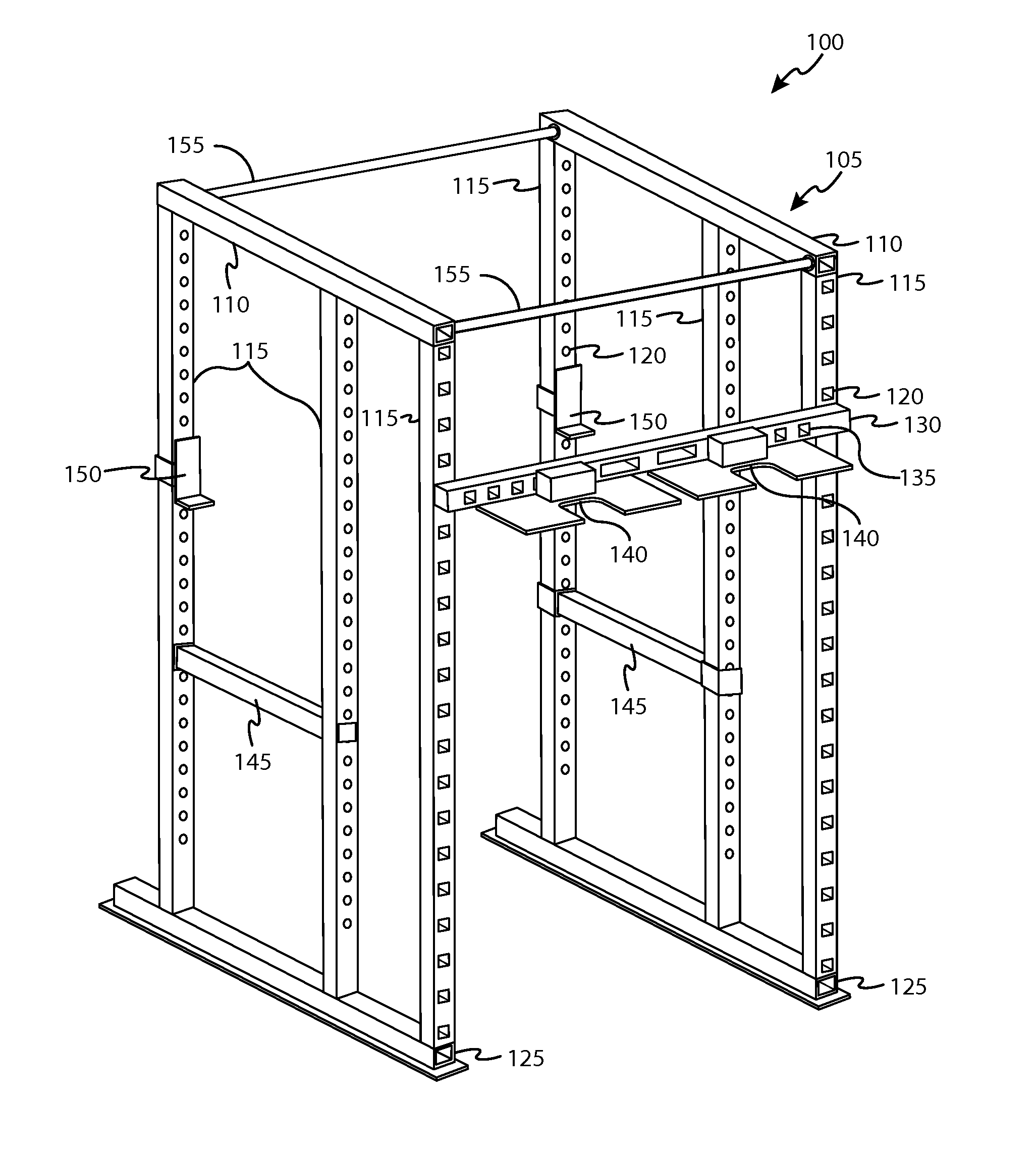

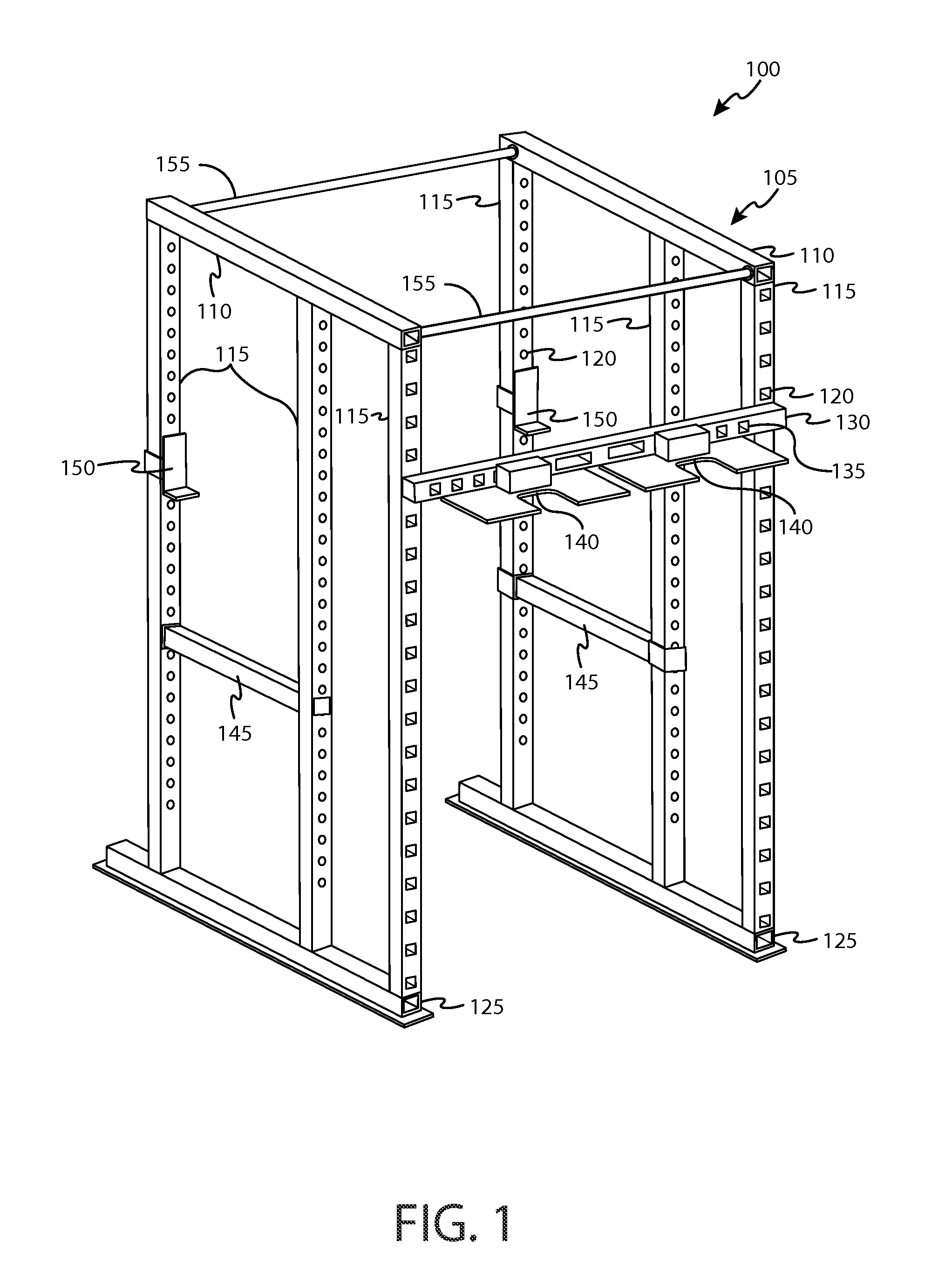

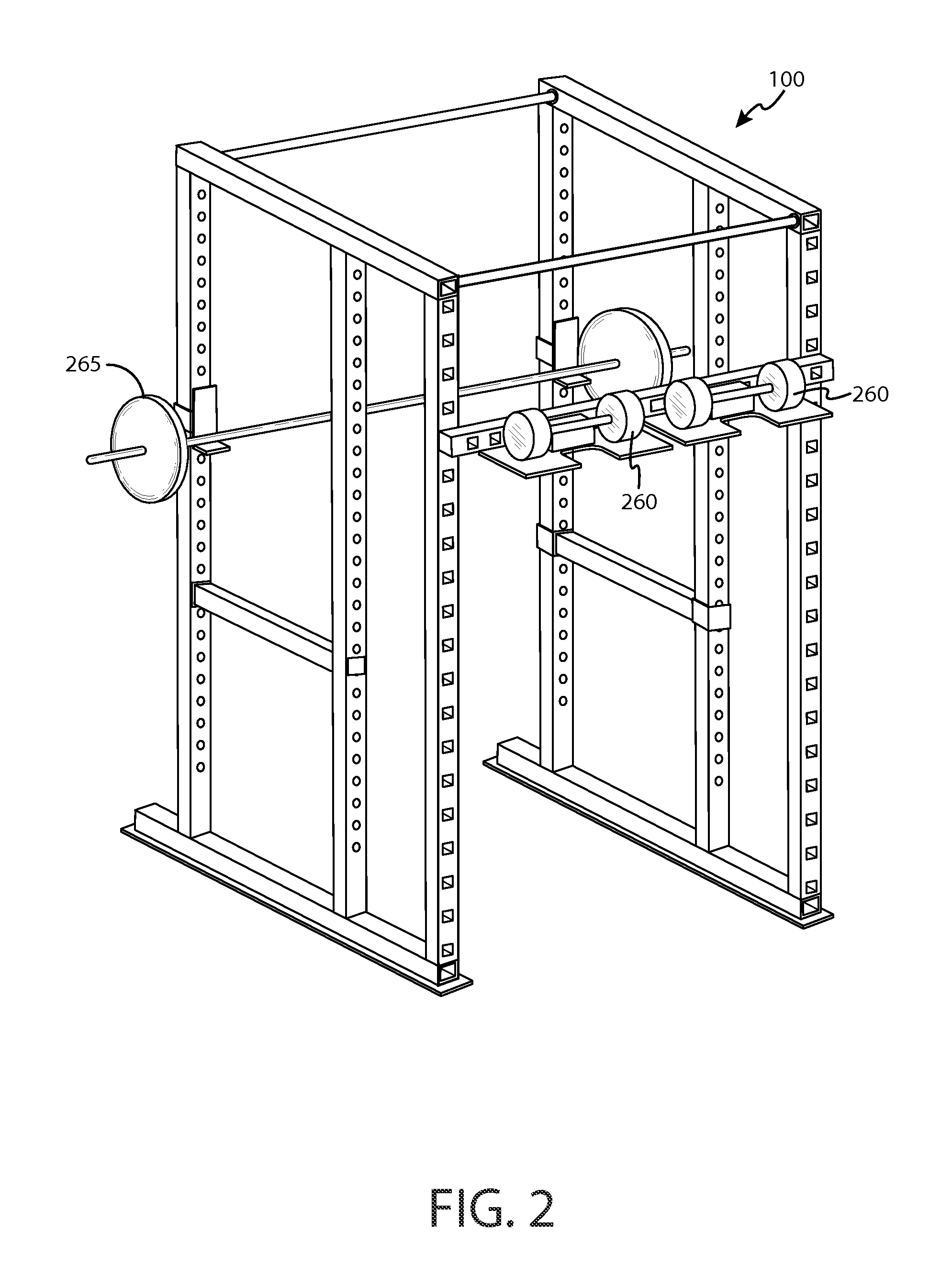

Dumbbell power rack apparatus

ActiveUS9492701B1Reduce usageSimple designDumb-bellsHorizontal barsDumbbellElectrical and Electronics engineering

The present invention provides, in at least one embodiment, a power rack apparatus for lifting dumbbells. The apparatus can have a conventional cage design or a novel cage design with dual pull up bars. The apparatus also has novel dumbbell trays configured to attach to a novel horizontal support. The horizontal support is configured to attach to the cage in a plurality of vertical positions and the horizontal support contains a plurality of slots for horizontal width adjustment of the dumbbell trays. The slots on the horizontal support are configured to receive a plurality of inclined dumbbell trays. The apparatus can be a combo power rack configured to hold barbells and dumbbells or a simplified power rack apparatus configured to just hold dumbbells.

Owner:BOGNATZ DON

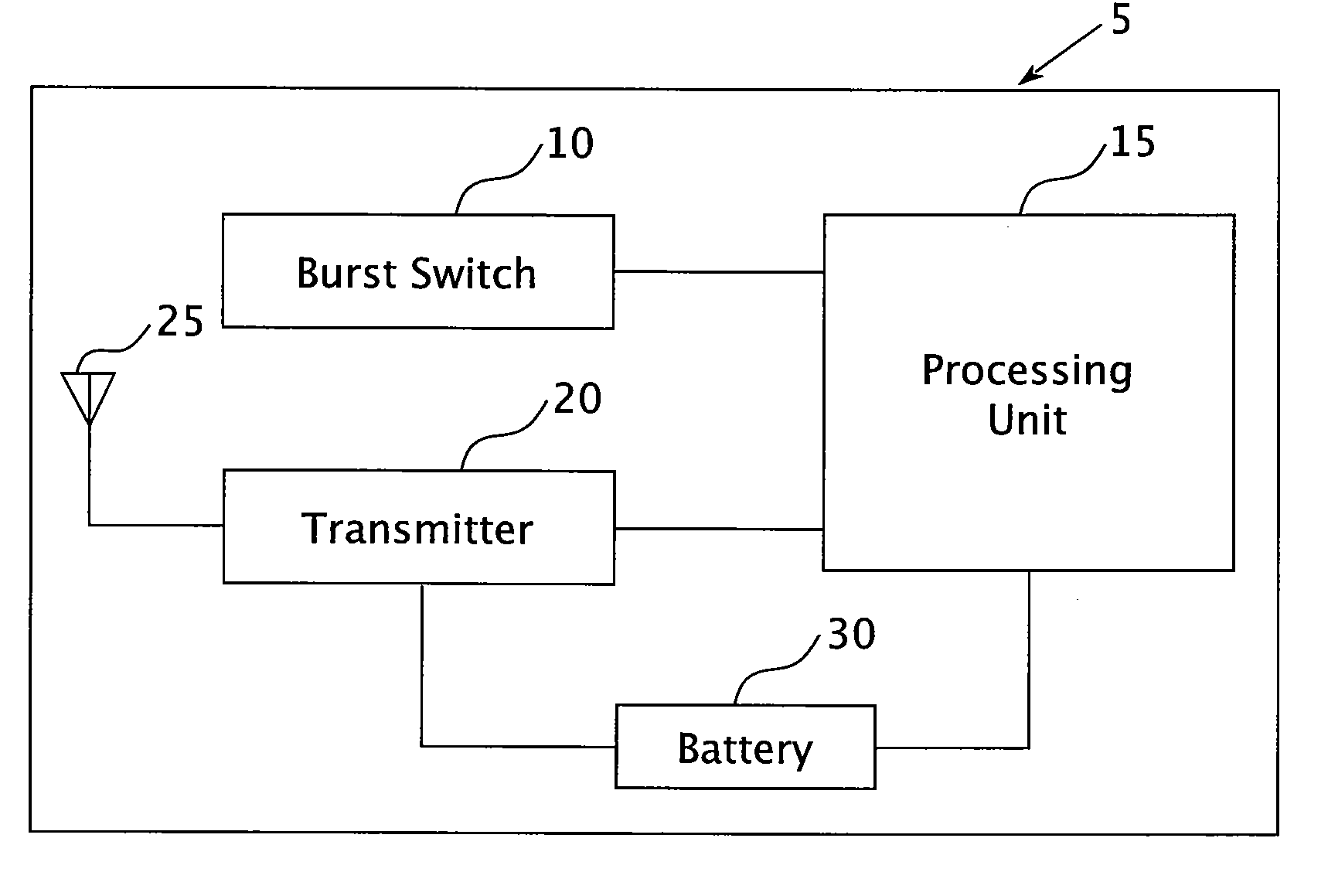

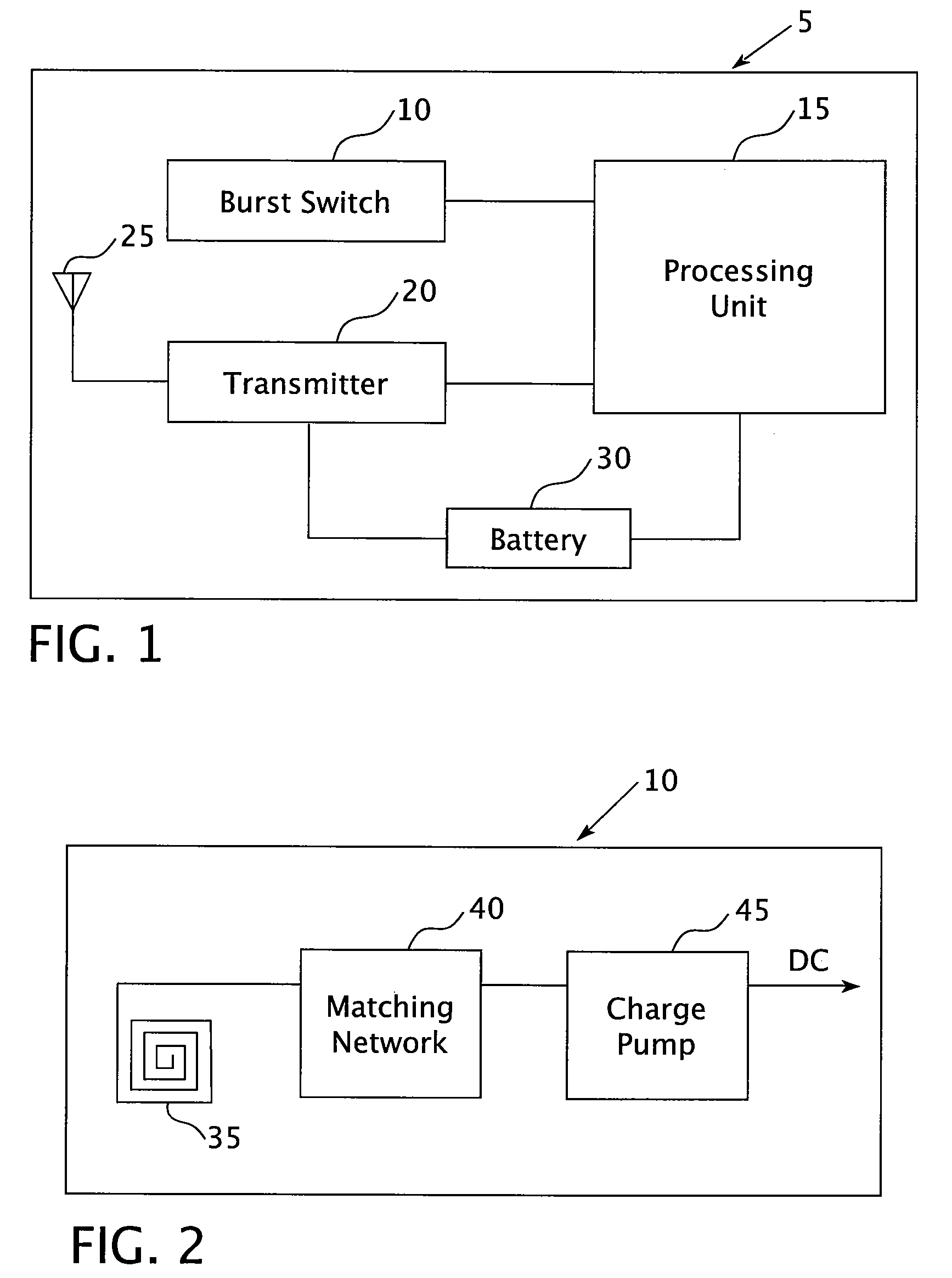

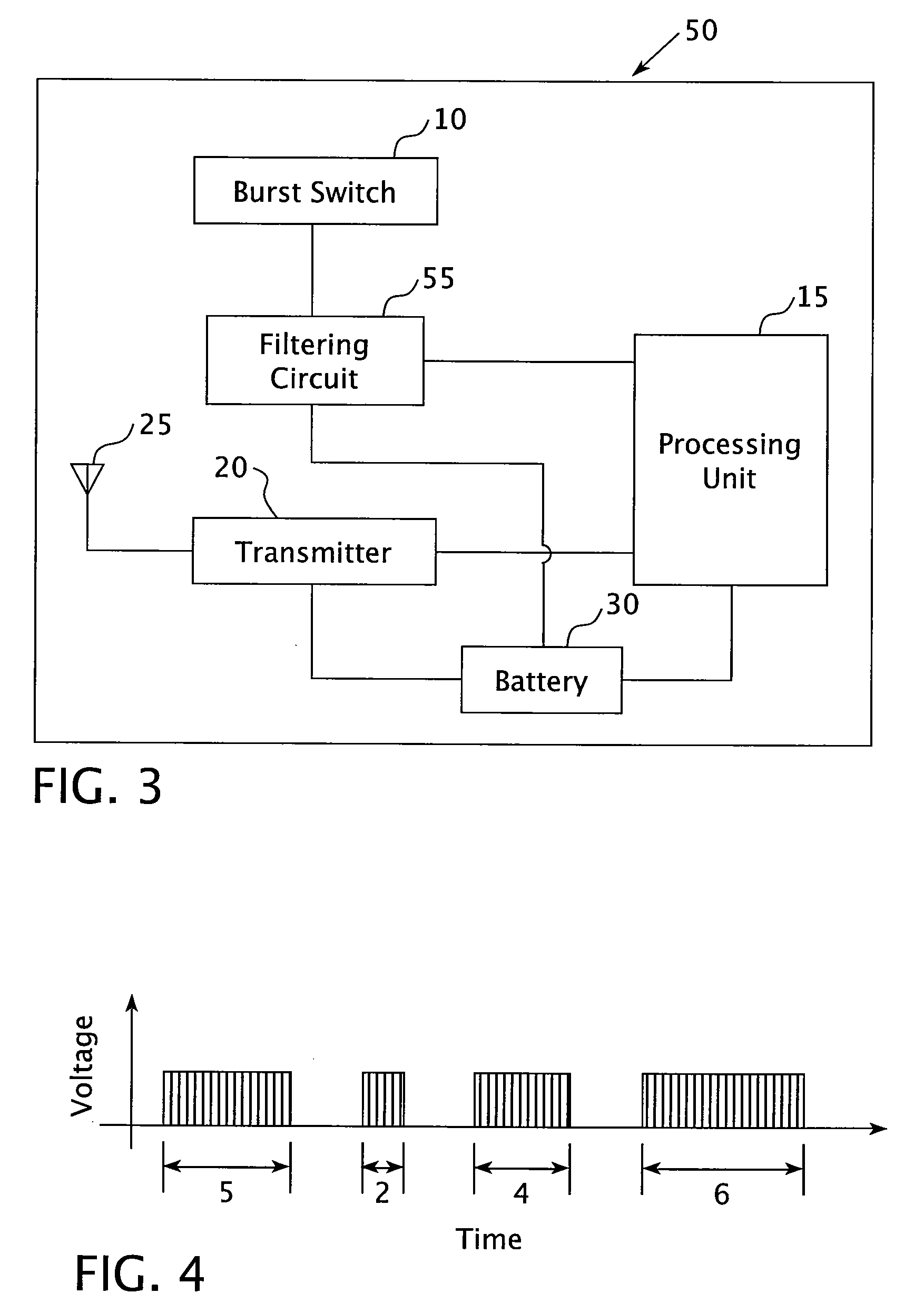

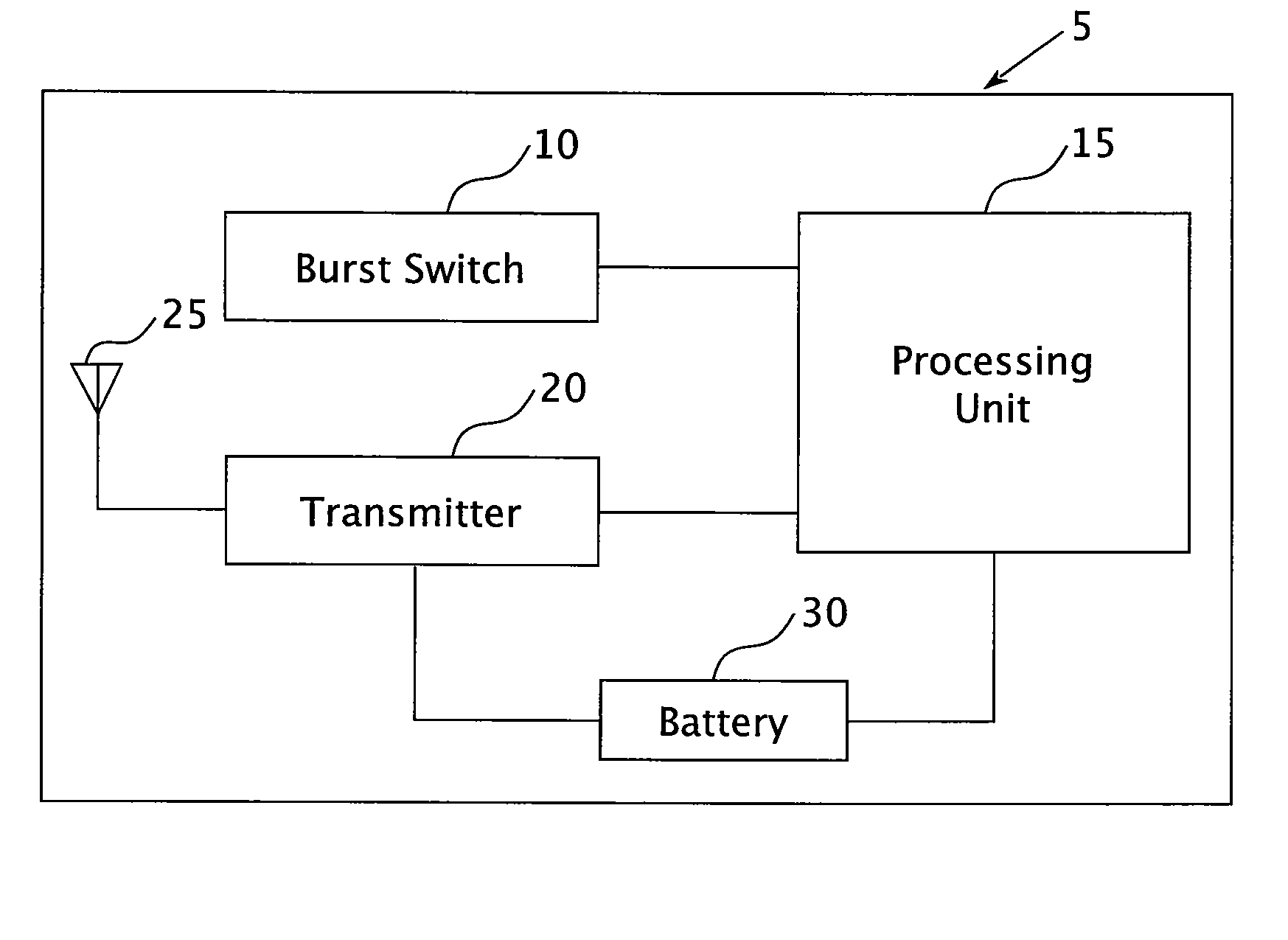

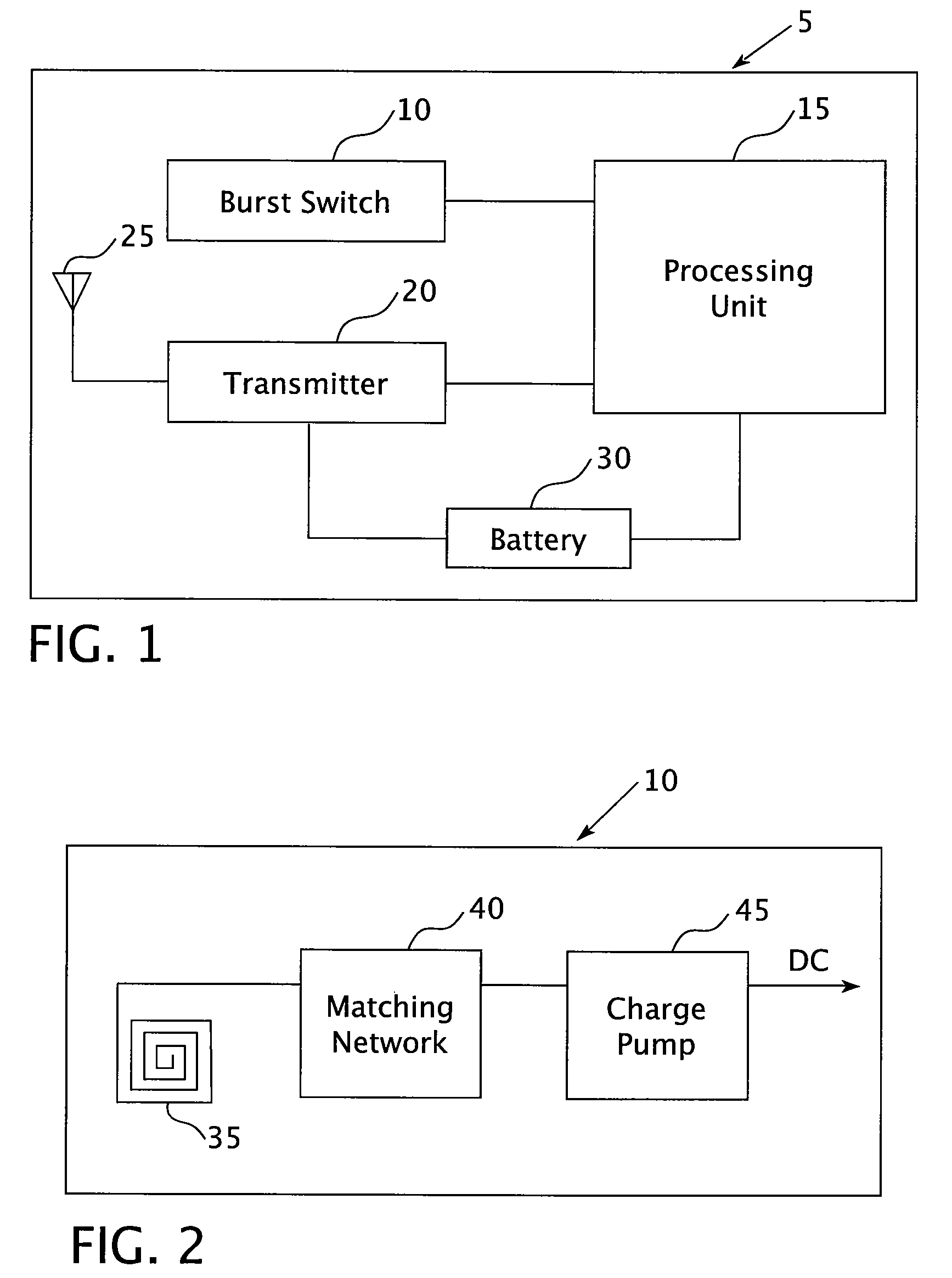

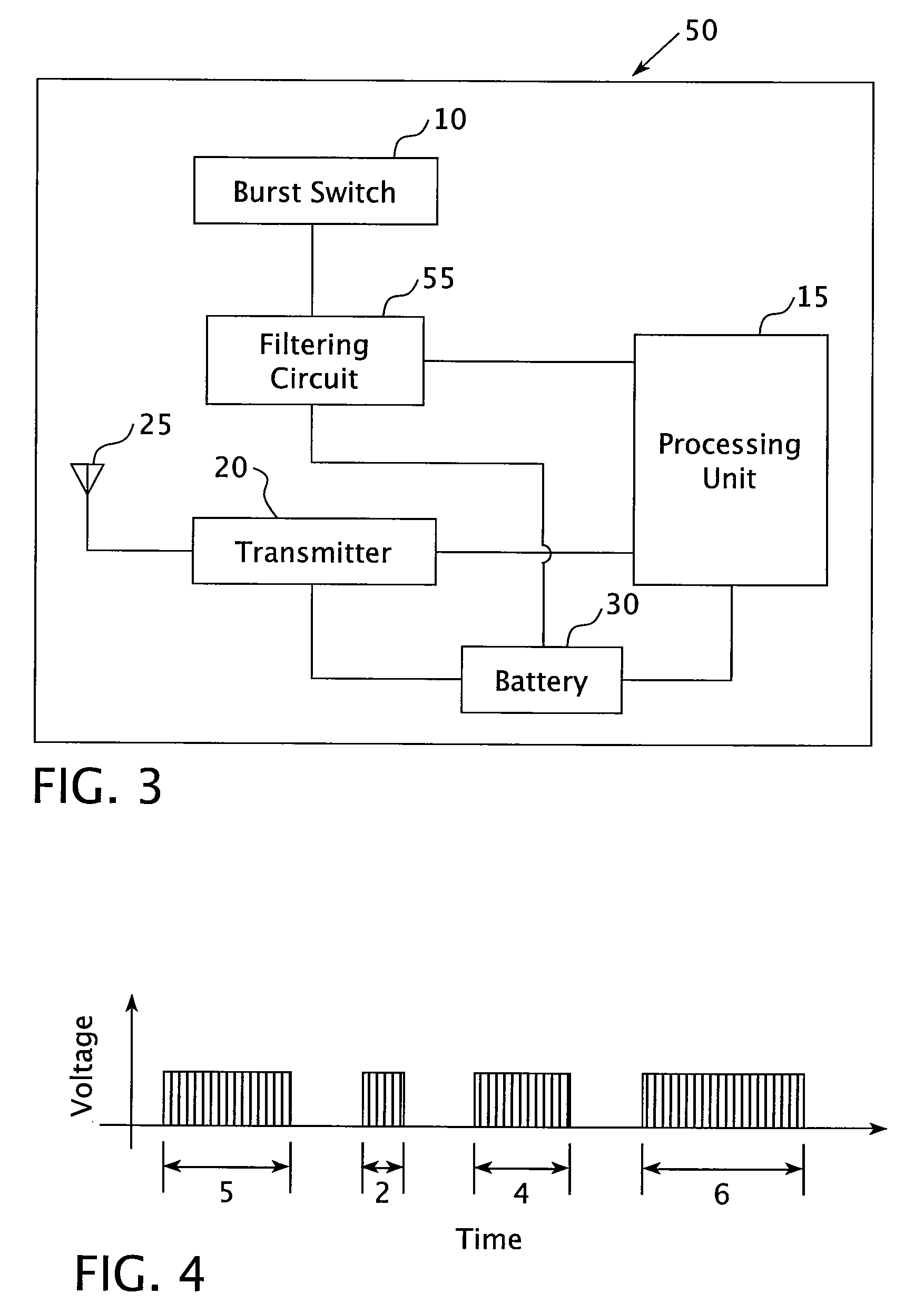

Methods and apparatus for switching a transponder to an active state, and asset management systems employing same

ActiveUS20070205873A1Eliminate maintenanceReduce energy consumptionElectric signal transmission systemsAntennas earthing switches associationEngineeringAsset tracking

A transponder that may be used as an RFID tag includes a passive circuit to eliminate the need for an “always on” active RF receiving element to anticipate a wake-up signal for the balance of the transponder electronics. This solution allows the entire active transponder to have all circuit elements in a sleep (standby) state, thus drastically extending battery life or other charge storage device life. Also, a wake-up solution that reduces total energy consumption of an active transponder system by allowing all non-addressed transponders to remain in a sleep (standby) state, thereby reducing total system or collection energy. Also, the transponder and wake-up solution are employed in an asset tracking system.

Owner:UNIVERSITY OF PITTSBURGH

Automated multilingual software testing method and apparatus

ActiveUS20070006039A1Eliminates hard-coded pathEliminates maintenance issueError detection/correctionSpecial data processing applicationsMethod testOperational system

A computer system and method tests various language installations of an application program using a single test script. The various language translations existing with the application program are used to provide translations of test command strings from one language to the specific language of the application program (operating system locale for executing the program). The test script may then be translated at runtime using the predefined program-established translations to allow the testing program to test the application program in accordance with the language of the application program / operating system locale.

Owner:IBM CORP

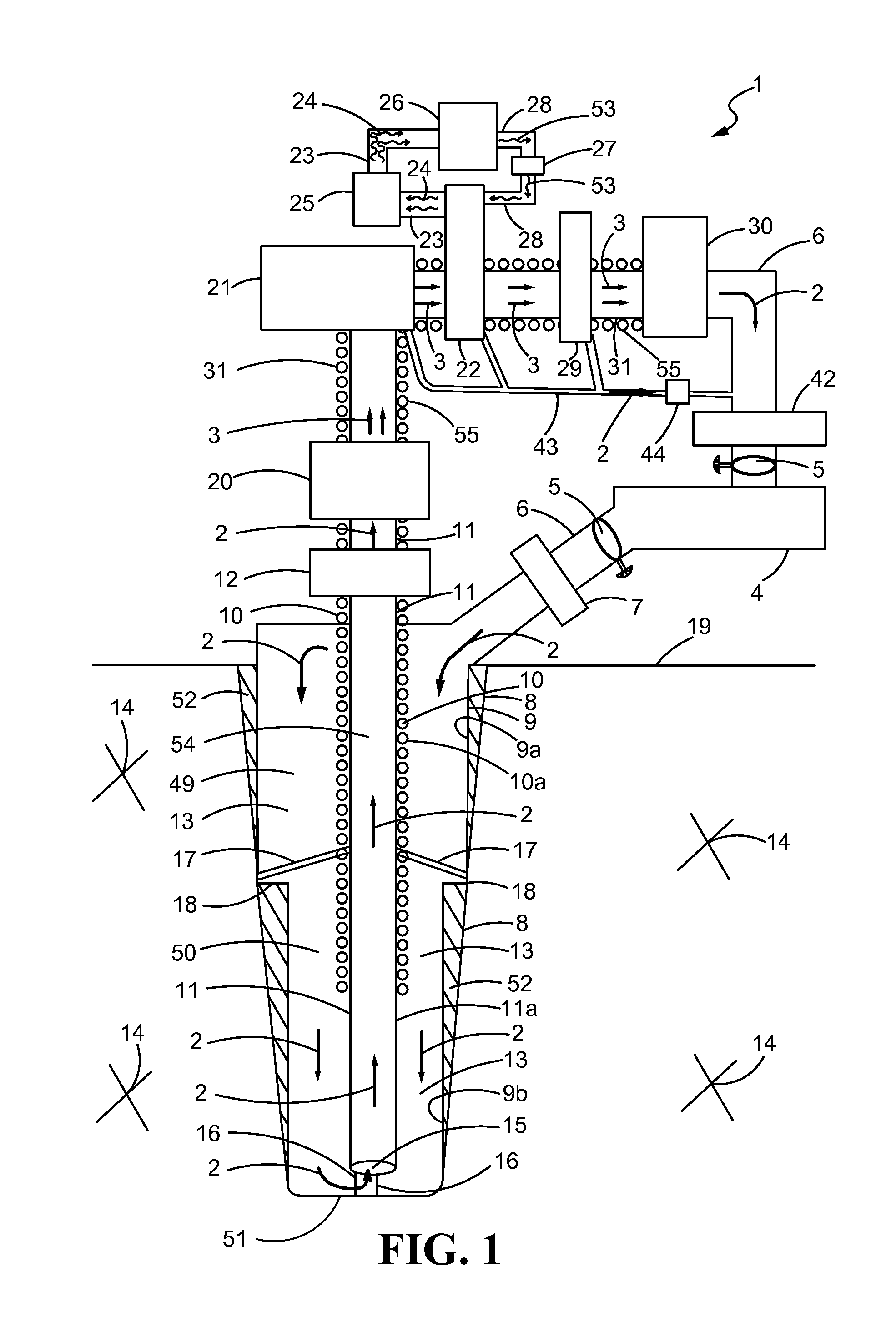

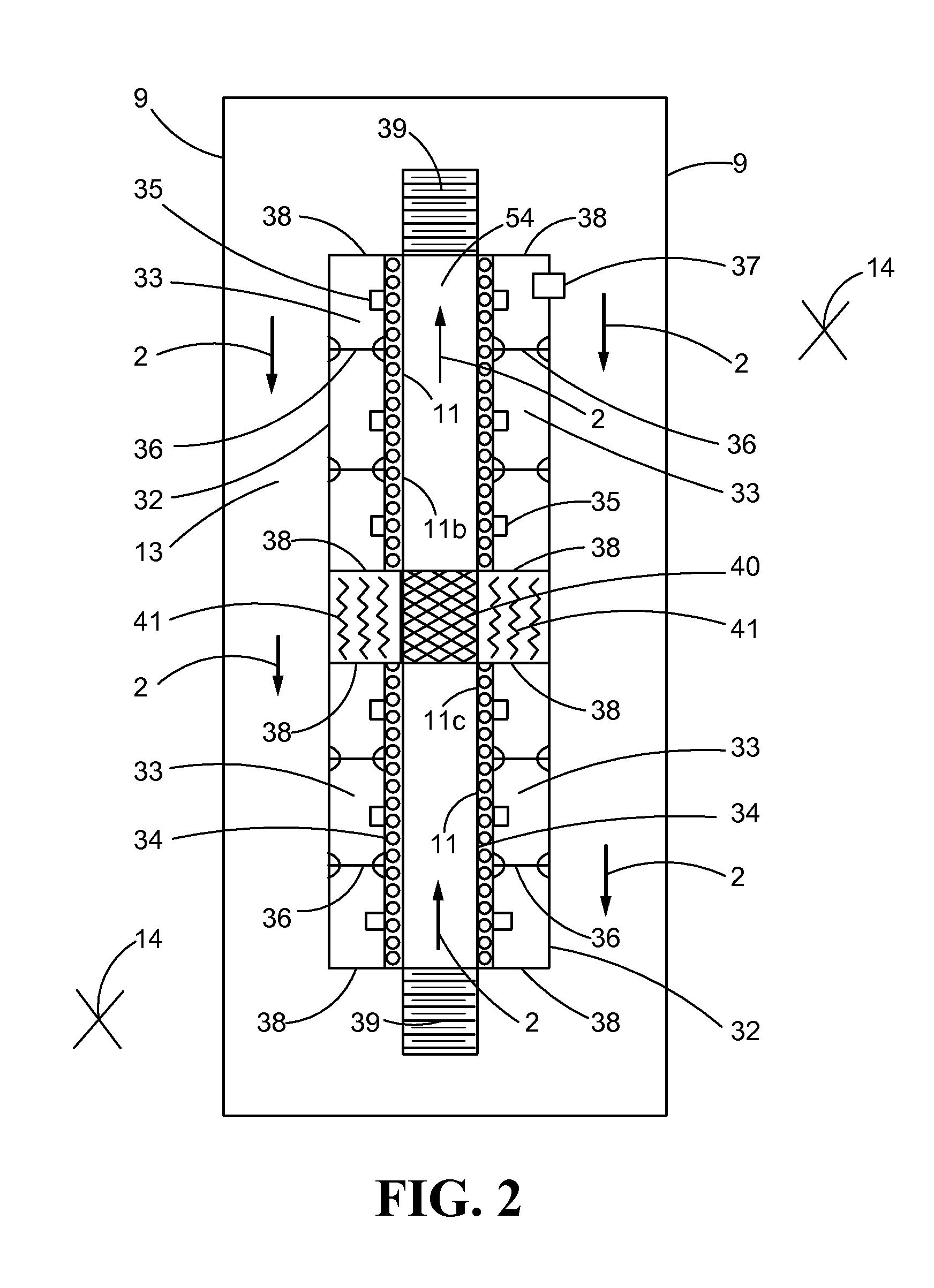

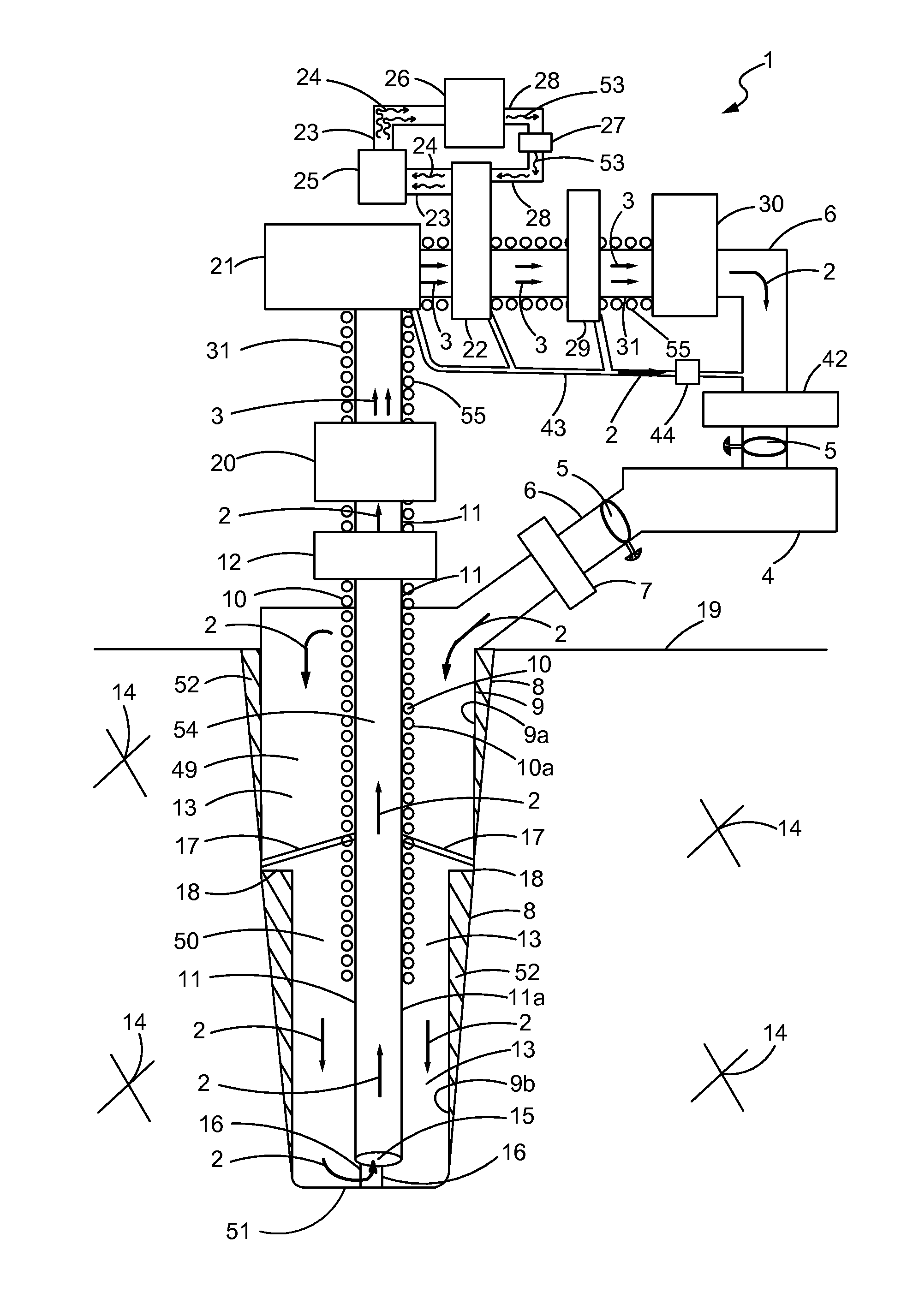

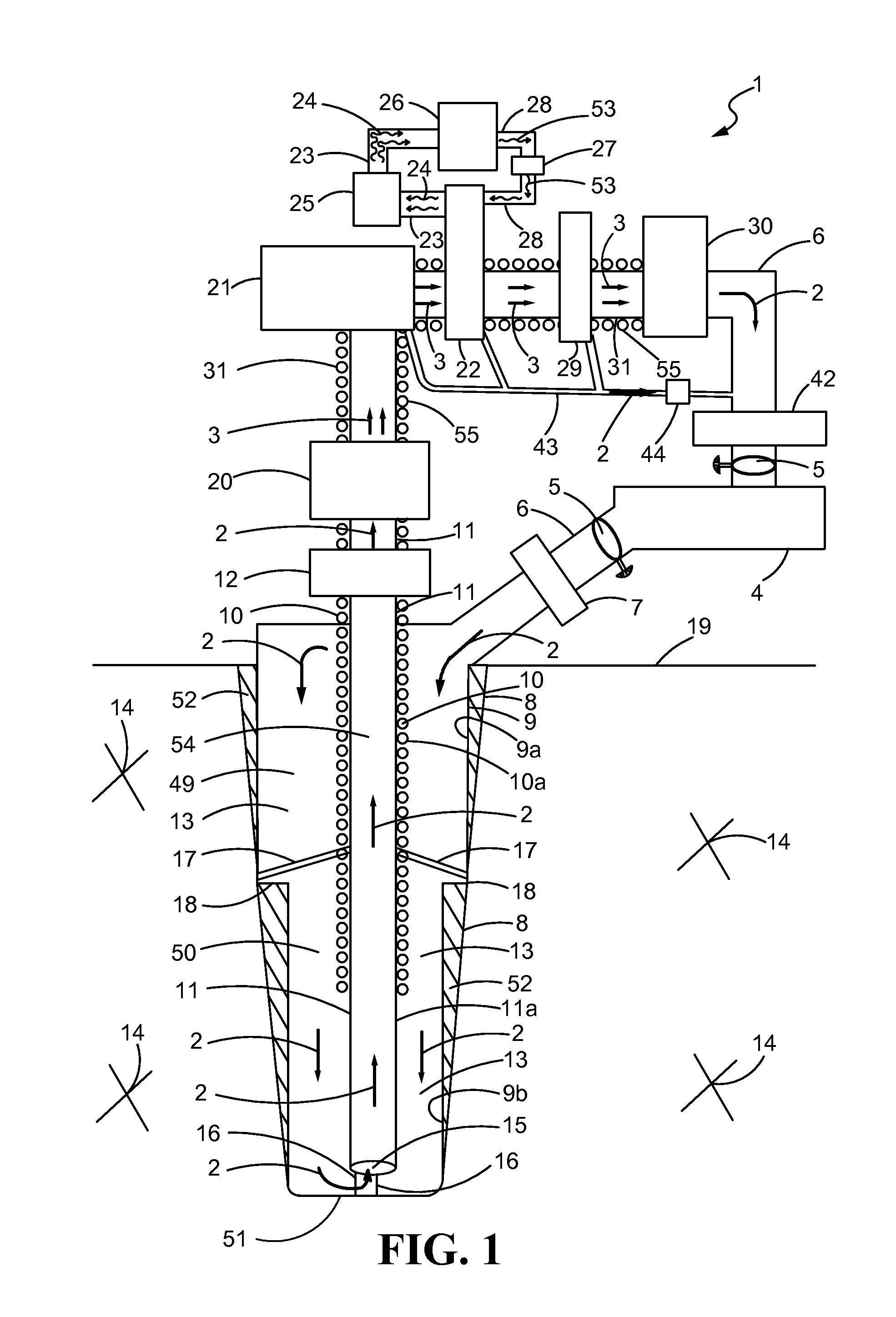

Single well, self-flowing, geothermal system for energy extraction

ActiveUS9394771B2Reduce and eliminate parasitic power drawImproving overall environmental impact and economic feasibilityCollector components/accessoriesOther heat production devicesWorking fluidEngineering

A renewable energy, single well, primarily self-flow, geothermal heat / power production system that acquires naturally occurring sub-surface geothermal heat to heat water and / or produce mechanical / electrical power using a heat exchangers or a turbine / generator. The sub-surface structures defining a working fluid flow path may be insulated, such as with vacuum insulation, to increase system efficiency and ensure a substantially self-generating working fluid flow.

Owner:DEEP WELL POWER

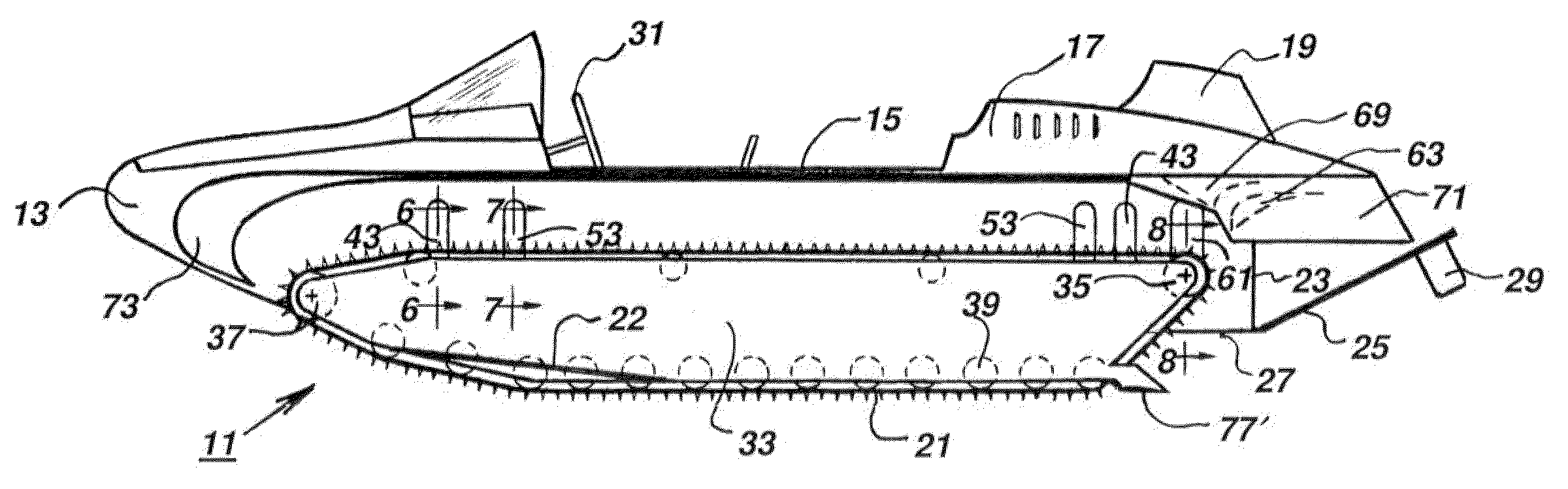

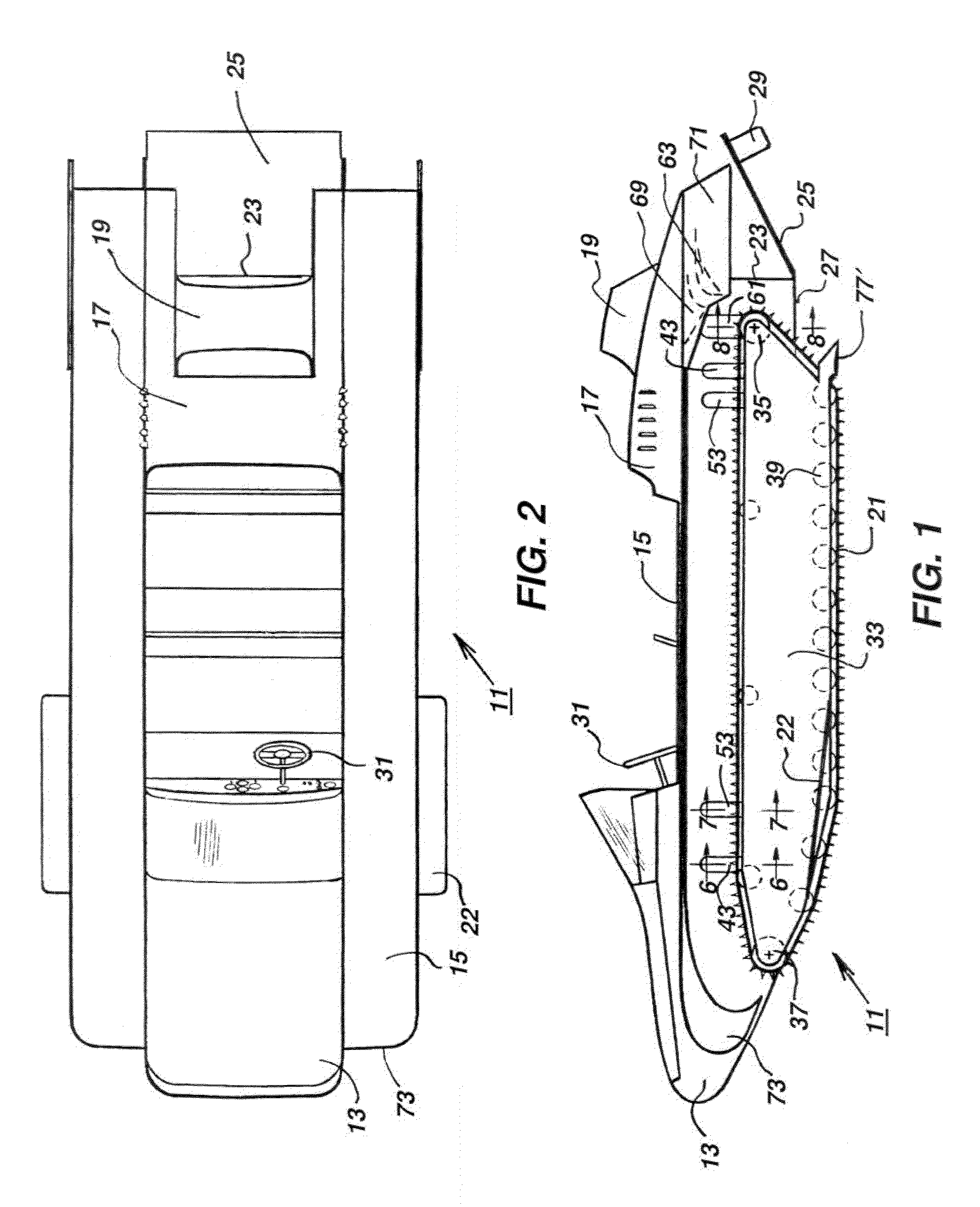

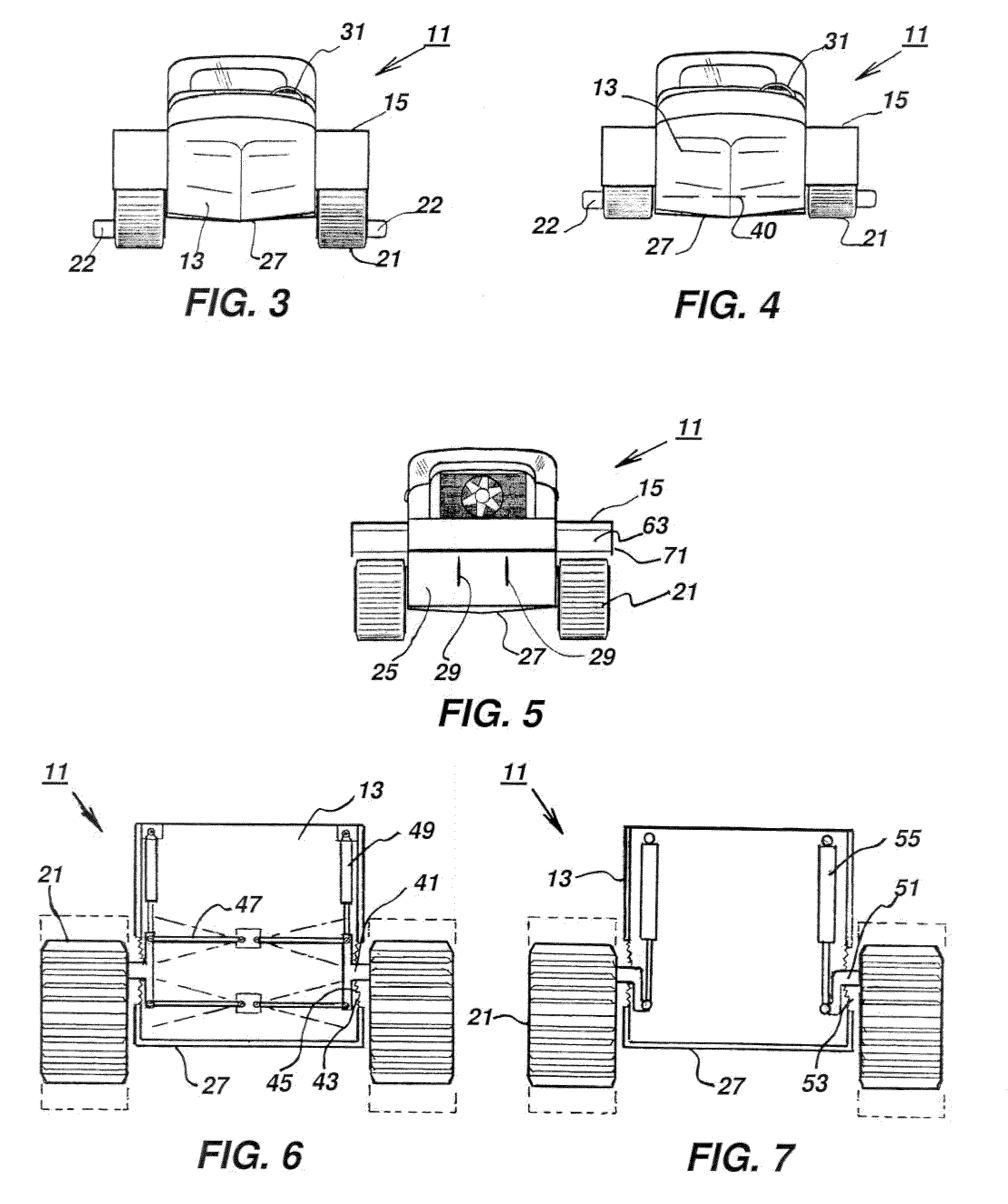

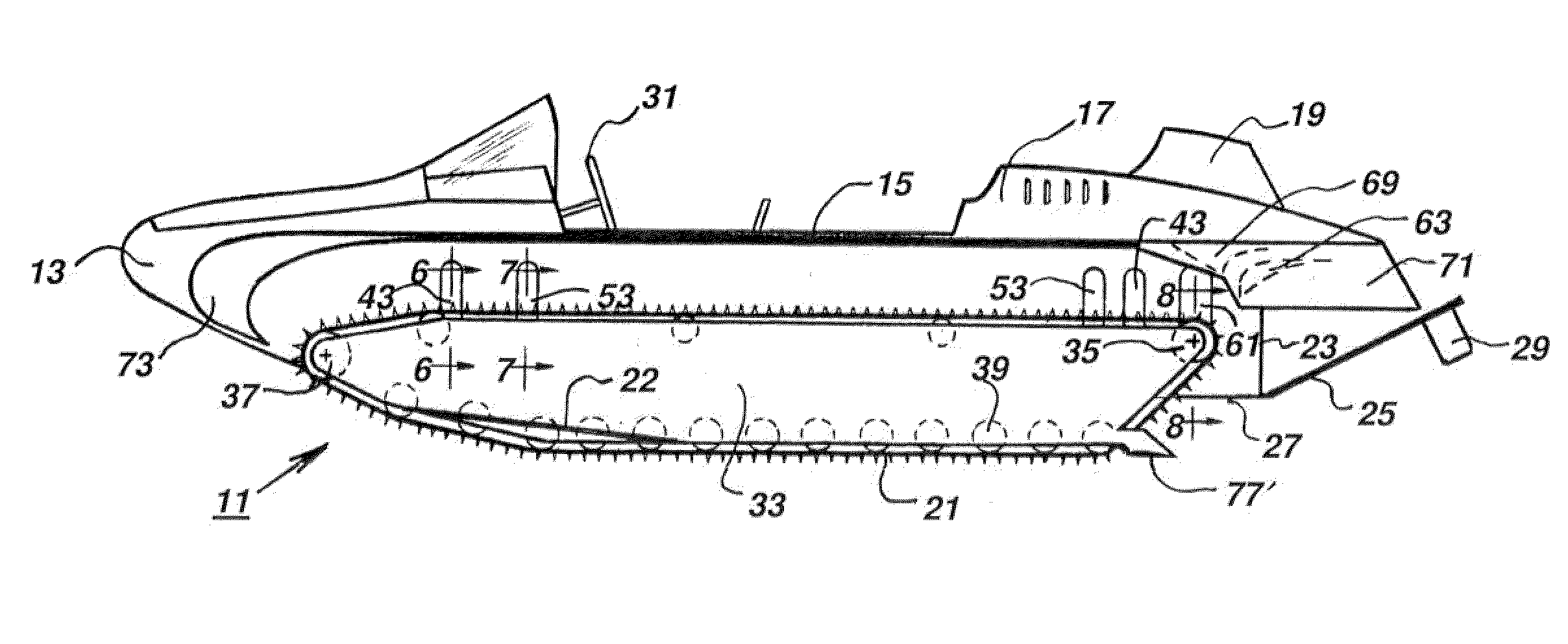

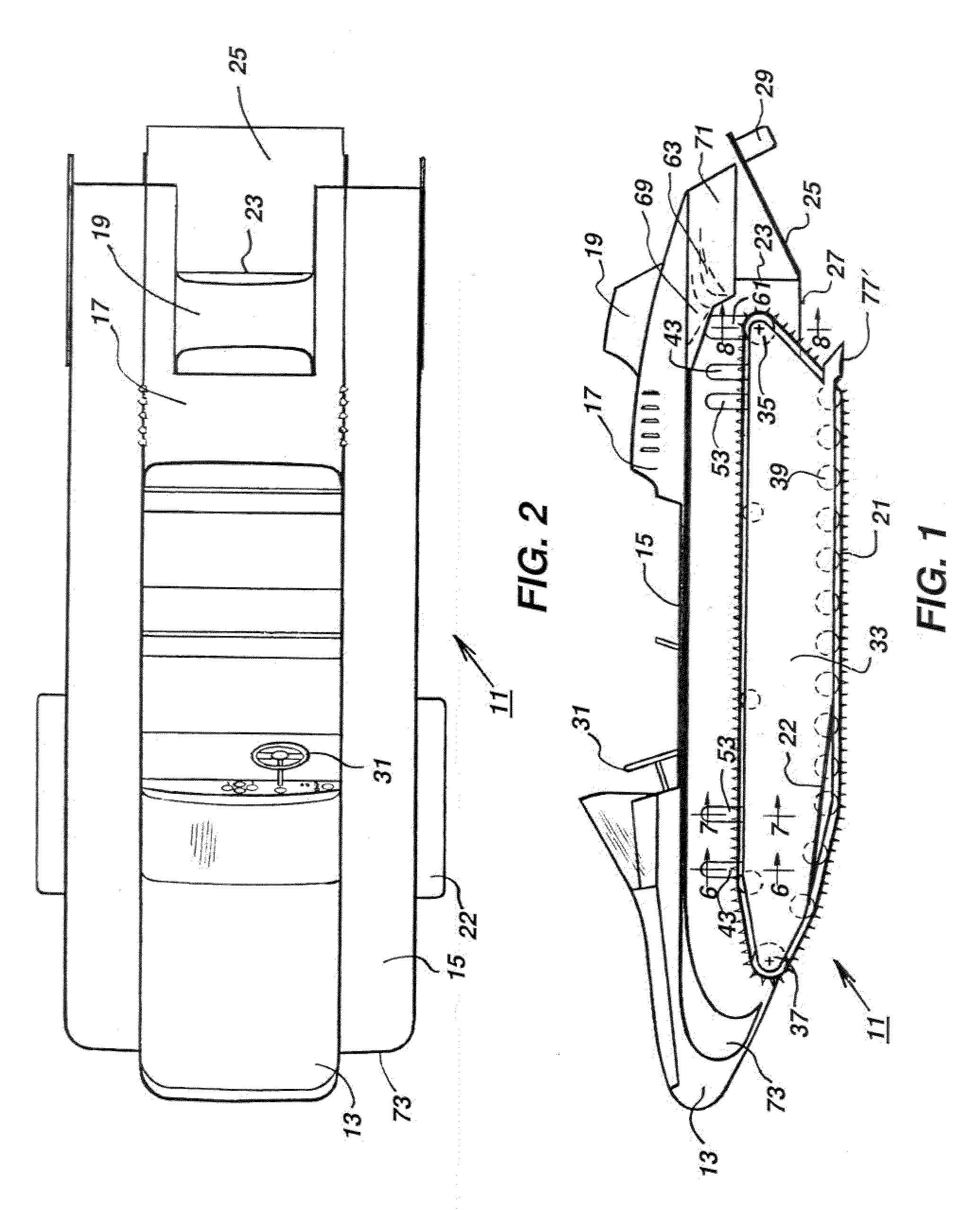

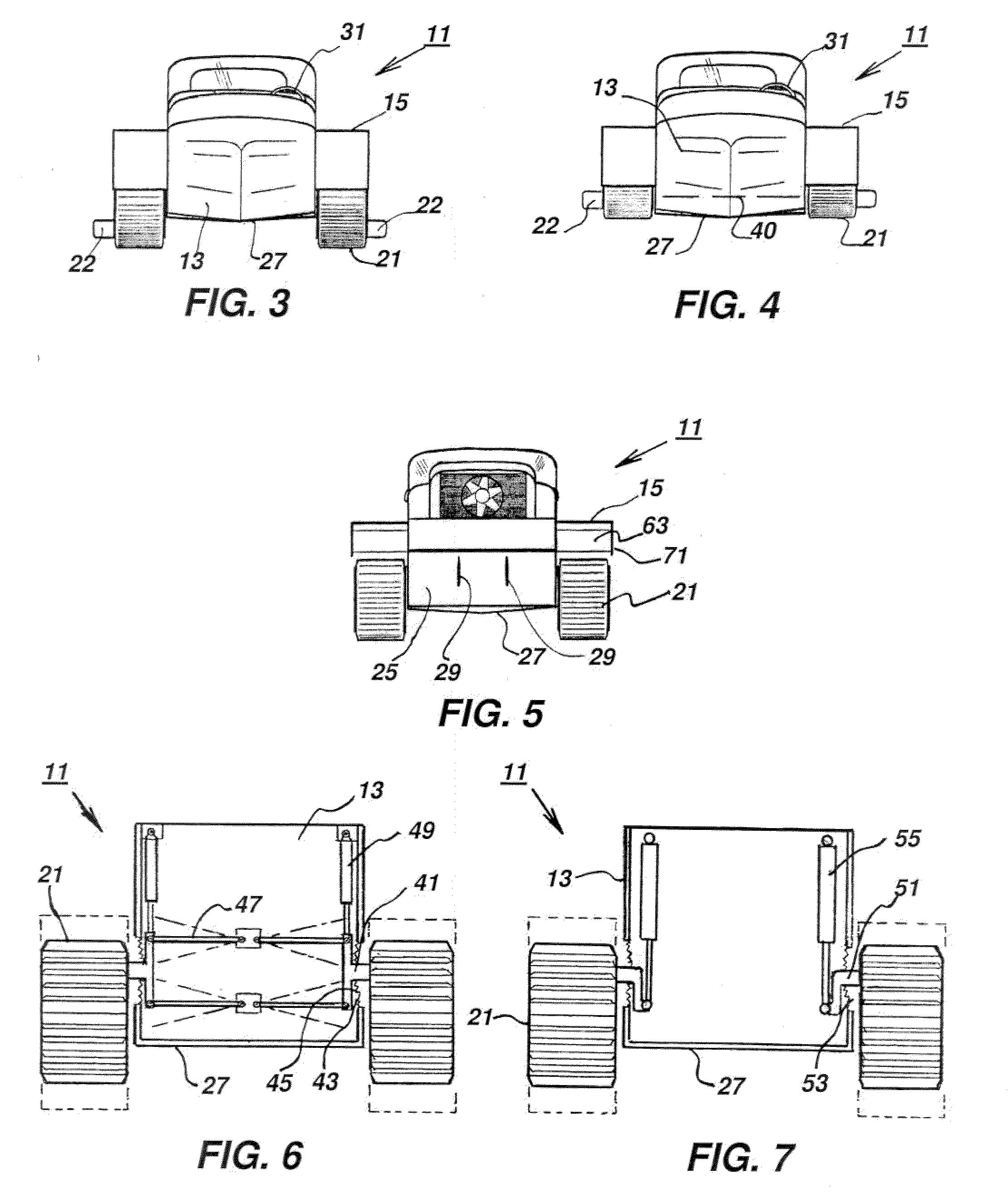

High water-speed tracked amphibian

ActiveUS8002596B2Remove complexityEliminate weightLiquid resistance brakesSteering ruddersLand TravelCavitation

An amphibious vehicle capable of high speeds on the water has a buoyant hull with driven tracks on each side of the hull. The tracks are movable between an upper position and a lower position relative to the hull. The tracks propel the vehicle both for land travel and water travel. Water diverter vanes at the aft end of each track divert water being carried forward by the tracks. Water diverter vanes at the forward ends direct water carried on the upper runs in a downward and aft direction. A cavitation plate is located behind each of the tracks while waterborne and below the waterline of the hull. A tiltable transom flap is attached to the transom and extends rearward.

Owner:FAST TRACK AMPHIBIAN

Single Well, Self-Flowing, Geothermal System for Energy Extraction

ActiveUS20130192816A1Improve sealingReduce and eliminate parasitic power drawCollector components/accessoriesOther heat production devicesWorking fluidEngineering

A renewable energy, single well, primarily self-flow, geothermal heat / power production system that acquires naturally occurring sub-surface geothermal heat to heat water and / or produce mechanical / electrical power using a heat exchangers or a turbine / generator. The sub-surface structures defining a working fluid flow path may be insulated, such as with vacuum insulation, to increase system efficiency and ensure a substantially self-generating working fluid flow.

Owner:DEEP WELL POWER

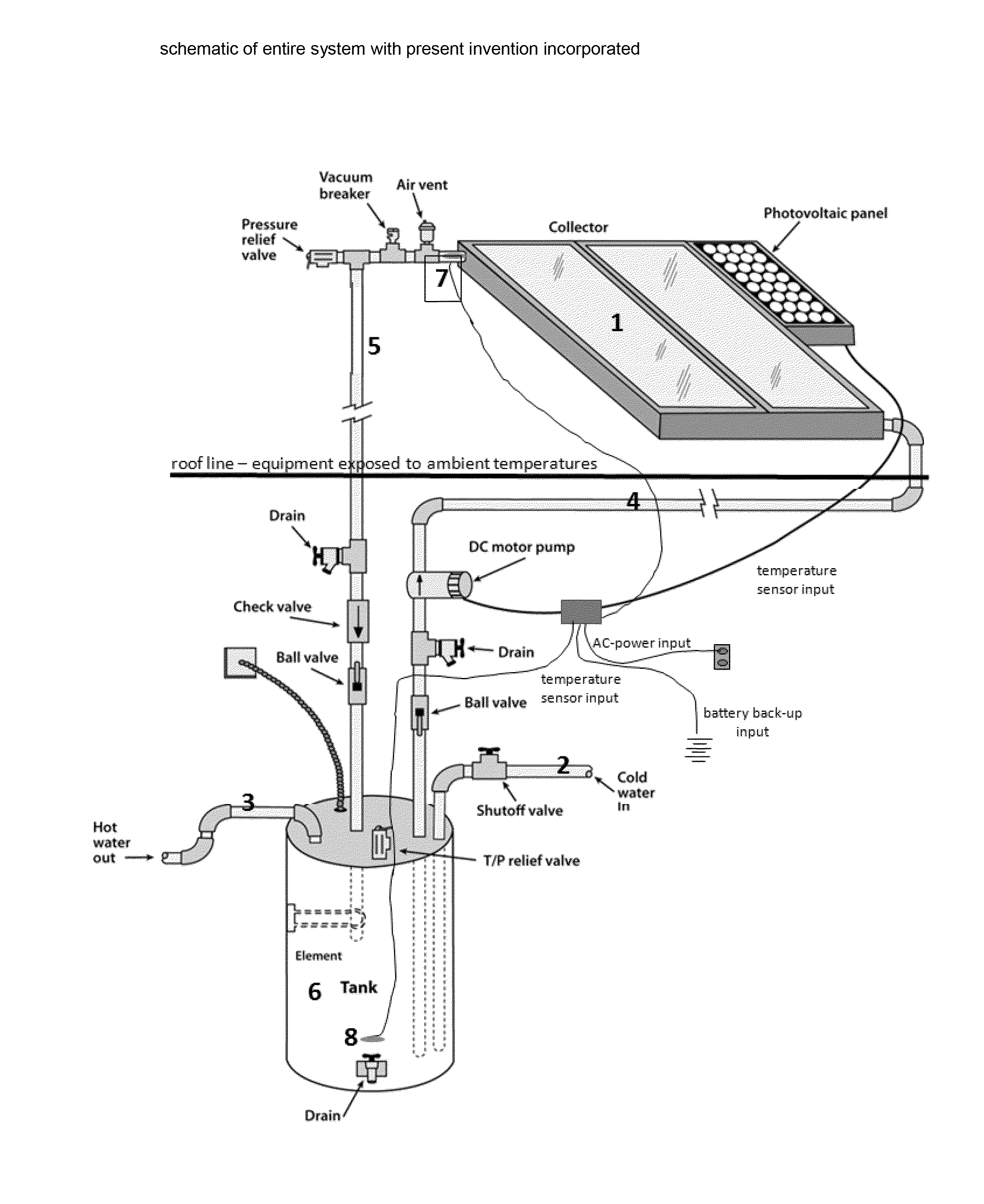

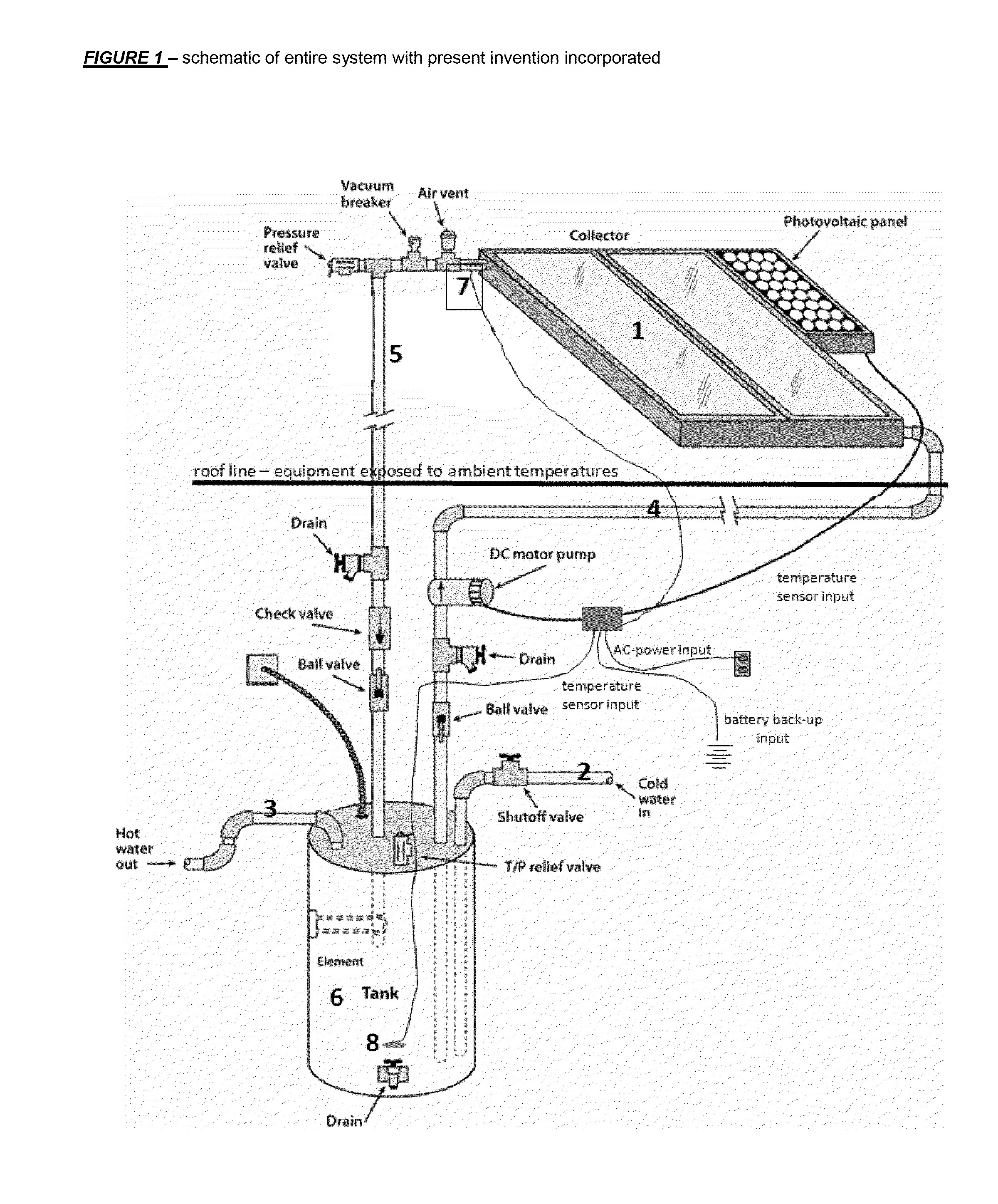

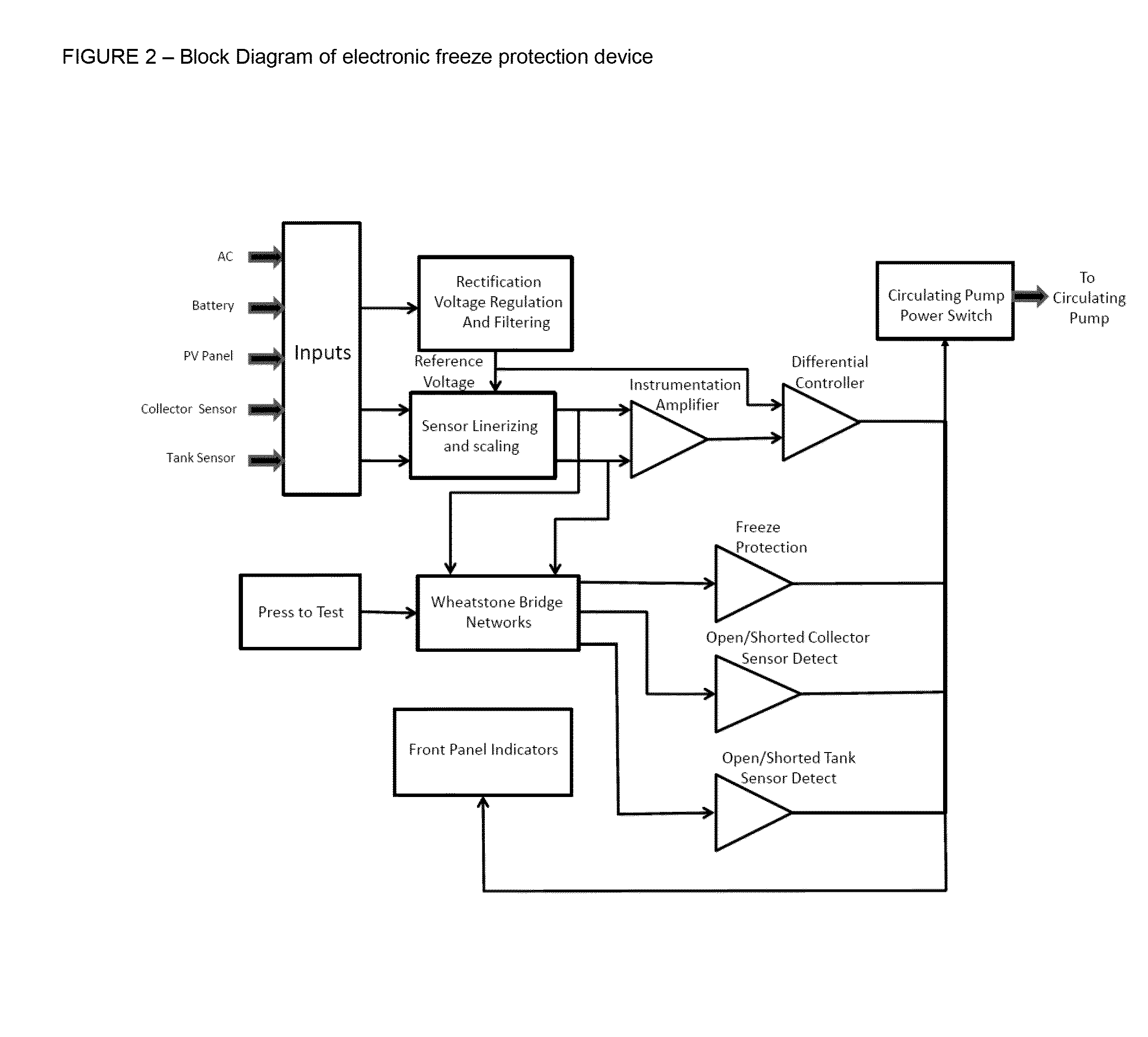

Solar collector electronic freeze protection system, with differential circulation control of pump and automatic freeze protection

InactiveUS20100241401A1Simple and cost-effectiveEffective solar energy collectionSolar heating energySpace heating and ventilationCirculator pumpProtection system

An automatic and electronic freeze protection system for solar energy collector systems. The system includes a solar collector for collecting solar energy in the form of heat, a circulation pump operated by a DC power source (typically a small photovoltaic module), a storage tank, an ac current connection to provide freeze protection at times when no sun is available, and various valves and piping to complete. Sensors are provided at both the storage tank and the solar collector to monitor the temperature of the water and also the temperature of the collector (more specifically, the temperature of the fluid in the collector). Whenever the fluid in the collector approaches its freeze point, the electronic freeze protection will use AC or battery power to energize the DC circulation pump, thereby circulating water from the storage tank to and through all components of the system. When the temperature of the collector (the temperature of the fluid in the collector) rises to a predetermined point and freezing is no longer imminent or possible, the electronic freeze protection will shut off the circulation pump. This process will repeat as often as is necessary to protect the collector and system components that are exposed to freezing temperatures. The primary difference between our current invention and existing systems is that there is no electronic freeze protection device available for DC-solar systems. In addition, we have combined existing DC differential control with electronic freeze protection for a truly unique and extremely useful improvement. Differential control of the circulation pump will increase efficiency of the system, thereby increasing total solar gain. Finally, and uniquely, this invention includes fault protection in the event of an open or shorted sensor at the collector. In the event of a fault, the present invention will energize the circulation pump, thereby preventing freezing and making the system fail-safe. The invention is unique by three means: combination of electronic freeze protection AND differential control in a single unit, automatic backup with battery and ac power, and fault protection for fail-safe operation.

Owner:RUSSELL & SUN SOLAR CORP

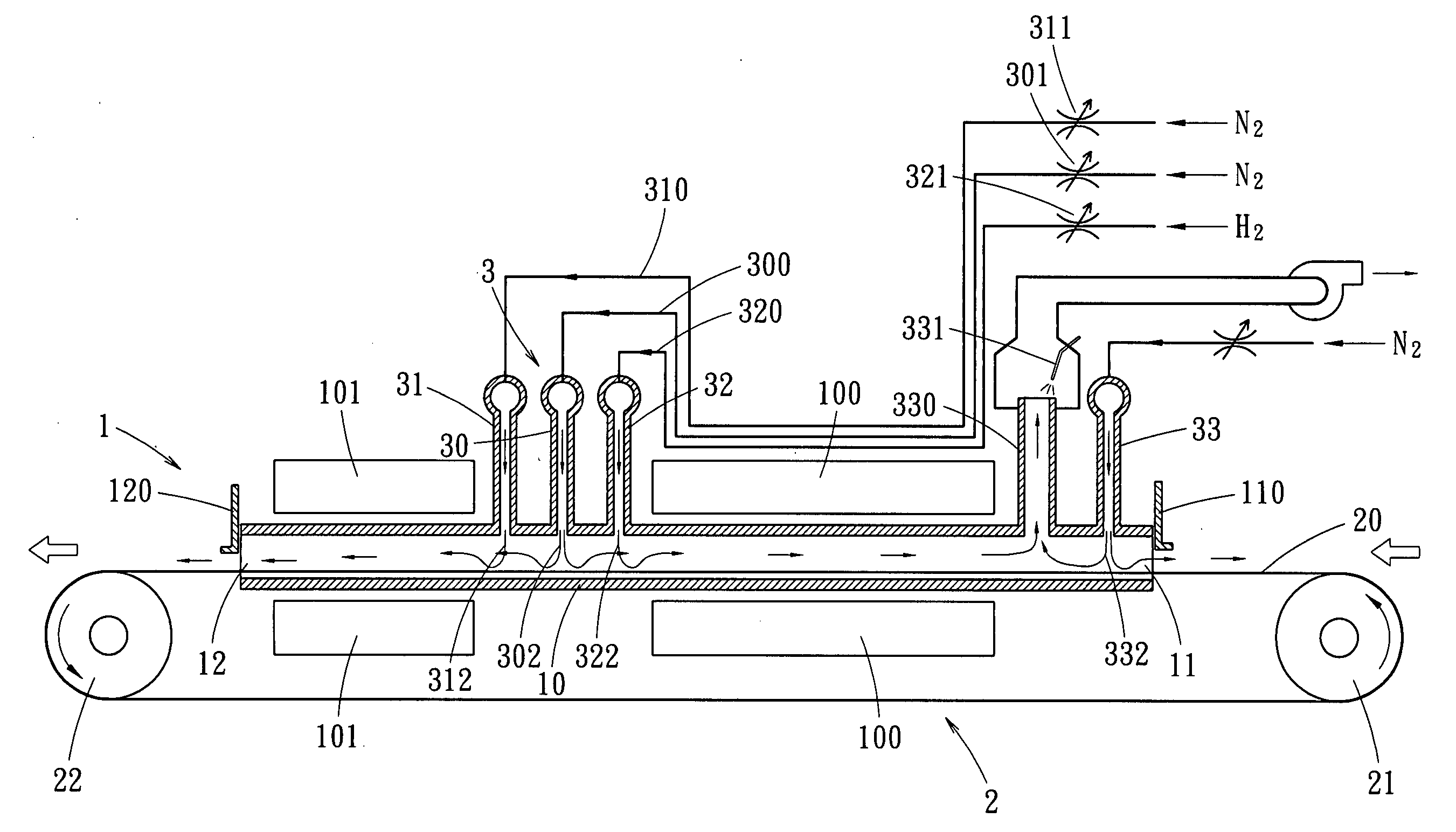

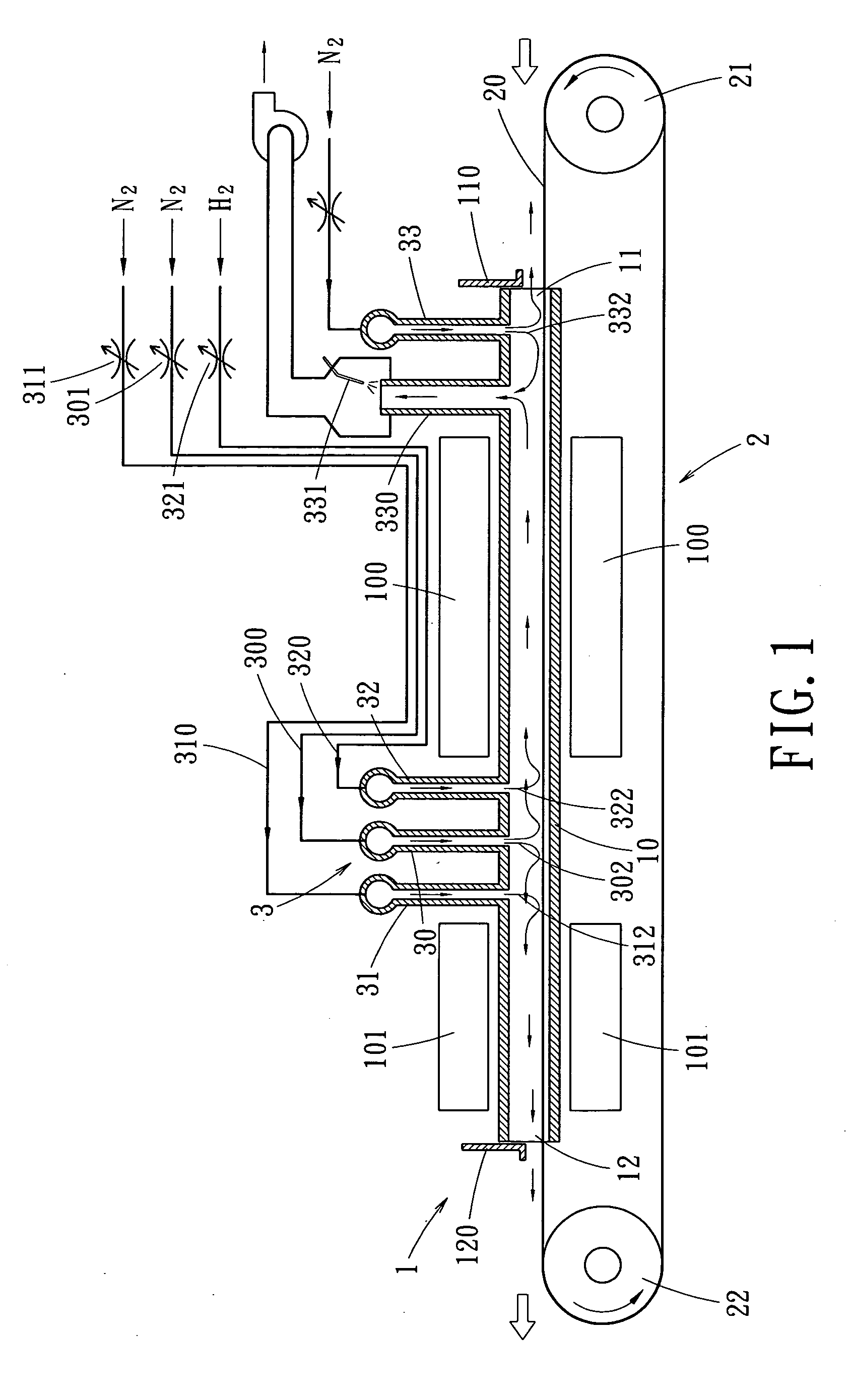

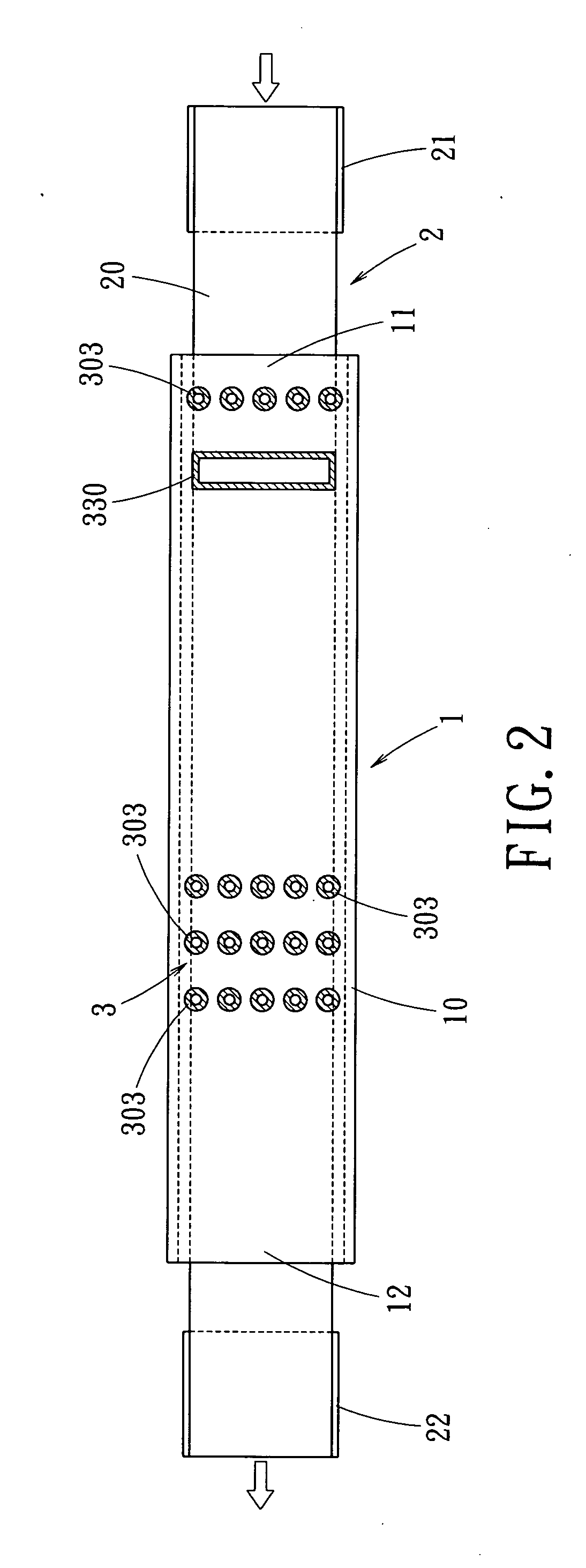

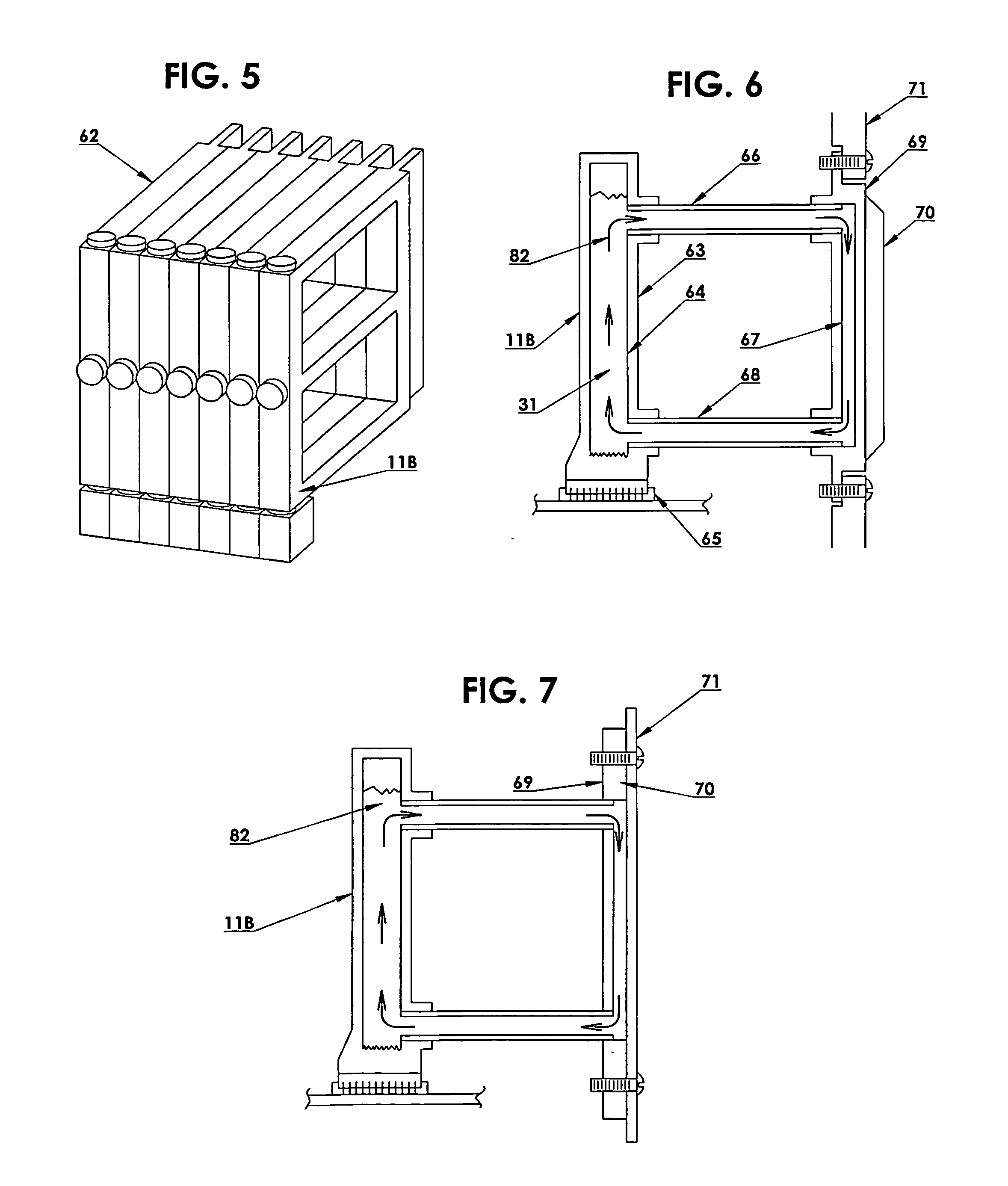

Annealing apparatus

InactiveUS20050012254A1Great fabricationEliminate riskFurnace typesHeat treatment furnacesProcess engineeringHeat pipe

An annealing apparatus includes a gas tight hollow main body, a conveying apparatus and a gas grid. A heating apparatus and a cooling apparatus are installed at an inlet and an outlet of the main body, respectively. The gas grid is installed between the inlet and the outlet to blow the protecting gas into the main body, so as to form a gas screen. The conveying apparatus extends to the inlet and the outlet to convey process material such as heat pipe. Thereby, an open, non-pressure differential environment is established for performing annealing on the process material.

Owner:HSU HUL CHUN

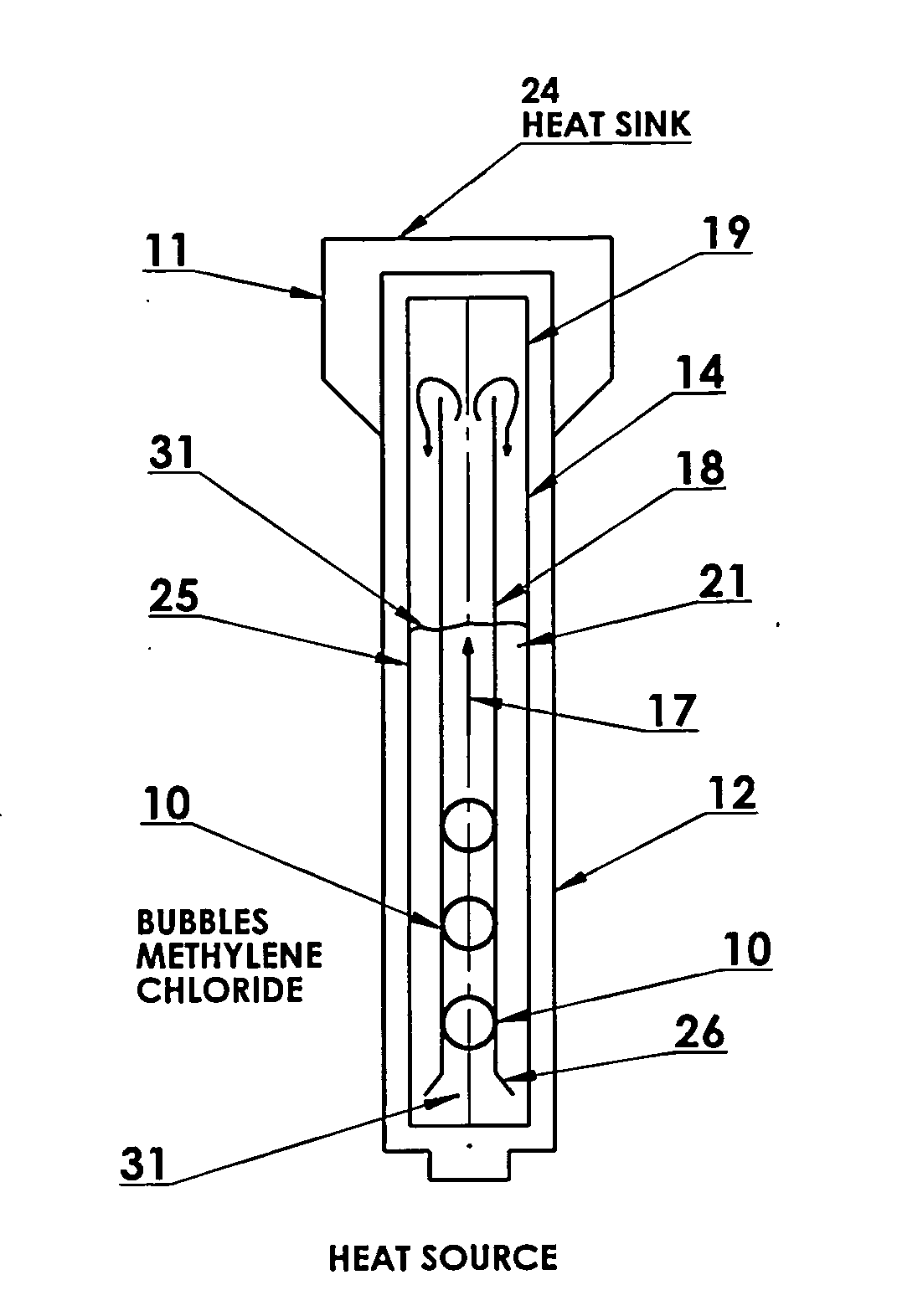

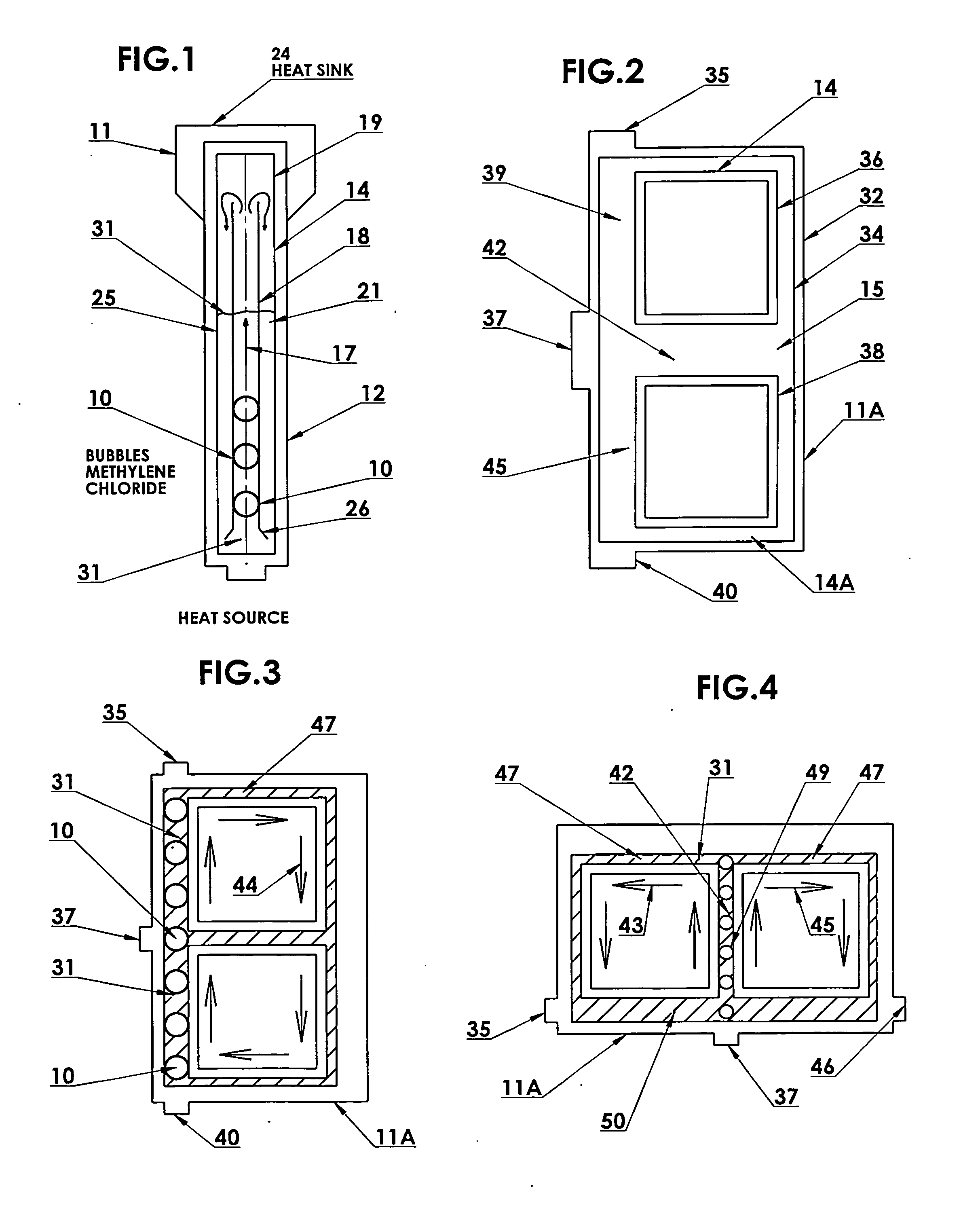

Heat transfer bridge

InactiveUS20130048254A1Small sizeLight weightTransformers/inductances coolingSemiconductor/solid-state device detailsDistribution transformerBoiling point

A heat transfer bridge for absorbing heat from electronic circuits and electrical distribution transformers to thereby cool said components is disclosed. The heat transfer bridge includes a passive pump for pumping a fluid having a low boiling point that readily creates bubbles when heated to its boiling point. The bubbles are directed via selected flow paths to effectively push or drive the fluid from adjacent a heat source such as an electronic circuit or transformer to heat dissipating components such as cooling fins. In one embodiment, the fluid in the inventive heat transfer bridge comprises a fluid comprising metallic slurry that provides many times the heat dissipation rate as compared to a clear fluid.

Owner:LIVINGSTON TROY W

Platform for processing semi-structured self-describing data

InactiveUS7519948B1Eliminates processing overheadEliminates maintenance issueSoftware engineeringSemi-structured data queryingSemi-structured dataProgramming idiom

An Extensible Markup Language (XML) Application Server for storing, processing, communicating, and displaying dynamic semi-structured information. It comprises a declarative specification language, a transactional indexed XML data store, and an XML application server engine. An integrated architecture (a) provides for optimization, indexing, and backtracking search in a business logic layer, (b) provides for general-purpose programming idioms including recursive function definitions, iteration, and dynamic dispatch in data layer queries and updates, and (c) eliminates processing overhead and maintenance issues caused by transforming between relational, object-oriented, and semi-structured data paradigms.

Owner:CORNISH JUDSON AMES

High Water-Speed Tracked Amphibian

ActiveUS20090124142A1Efficient propulsionHigh speedLiquid resistance brakesSteering ruddersCLASS AMPHIBIAMarine engineering

An amphibious vehicle capable of high speeds on the water has a buoyant hull with driven tracks on each side of the hull. The tracks are movable between an upper position and a lower position relative to the hull. The tracks propel the vehicle both for land travel and water travel. Water diverter vanes at the aft end of each track divert water being carried forward by the tracks. Water diverter vanes at the forward ends direct water carried on the upper runs in a downward and aft direction. A cavitation plate is located behind each of the tracks while waterborne and below the waterline of the hull. A tiltable transom flap is attached to the transom and extends rearward.

Owner:FAST TRACK AMPHIBIAN

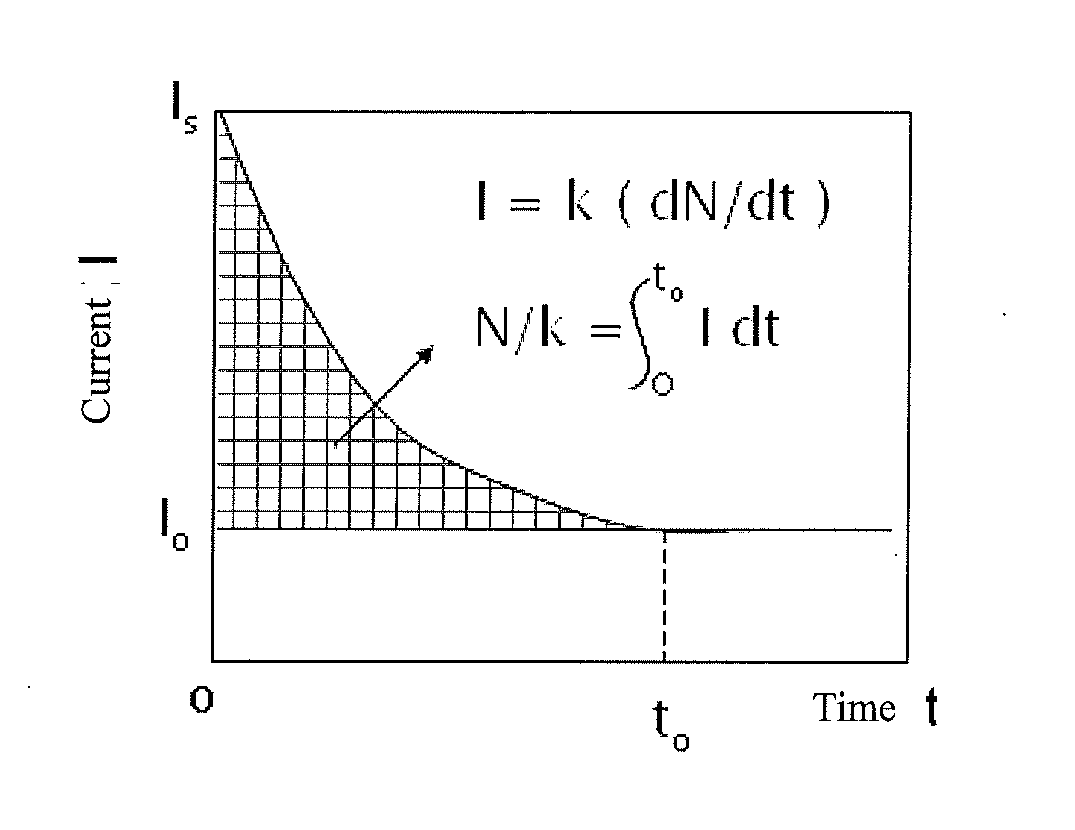

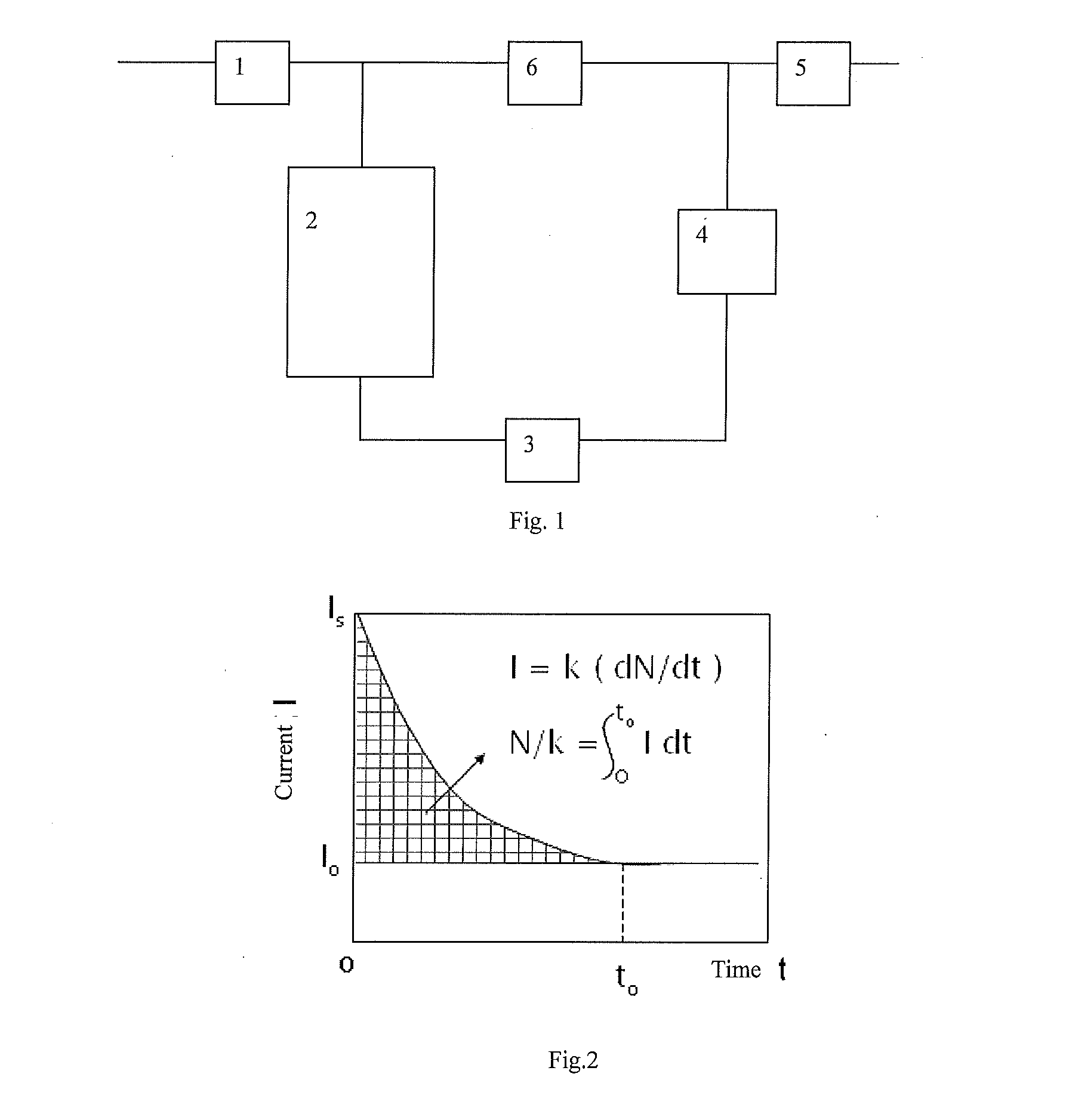

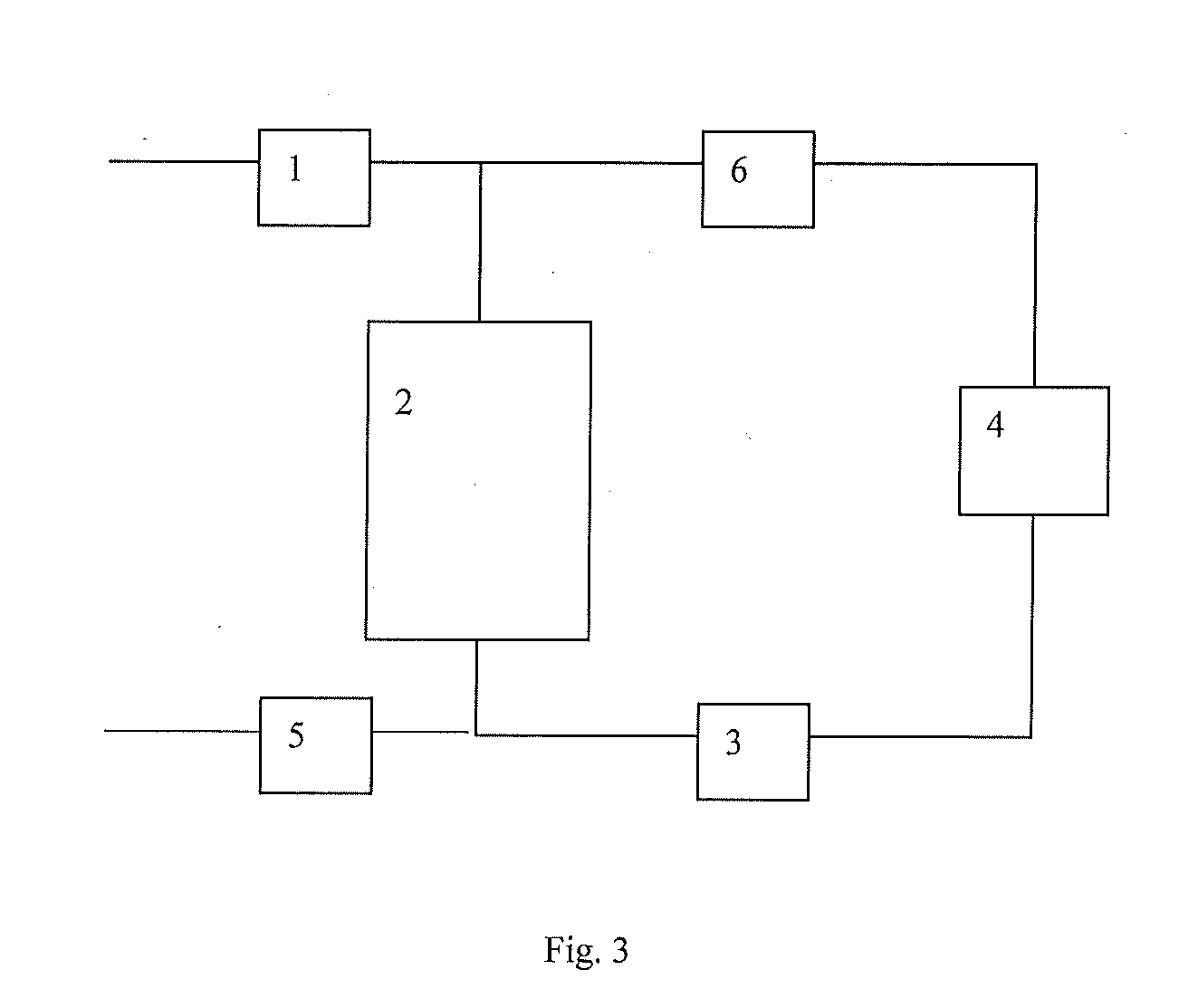

Self-calibrating gas sensor

InactiveUS20110197649A1Eliminates investment costEliminates maintenance costMaterial analysis by electric/magnetic meansMaterial analysis by optical meansCalibration gasControl valves

A self-calibrating gas sensor comprises a steady current measuring gas line composed of valves, pumps and a current-type electrochemical sensor, and a coulomb analyzing gas line composed of said valves, said pumps, said current-type electrochemical sensor and a sample chamber. The two gas lines can be interchanged between measurement and analysis by controlling valves. The sensor can measure gas concentrations, and self-calibrate its sensitivity without the need of standard gases for external calibration.

Owner:WUXI SUNVOU BIOTECH

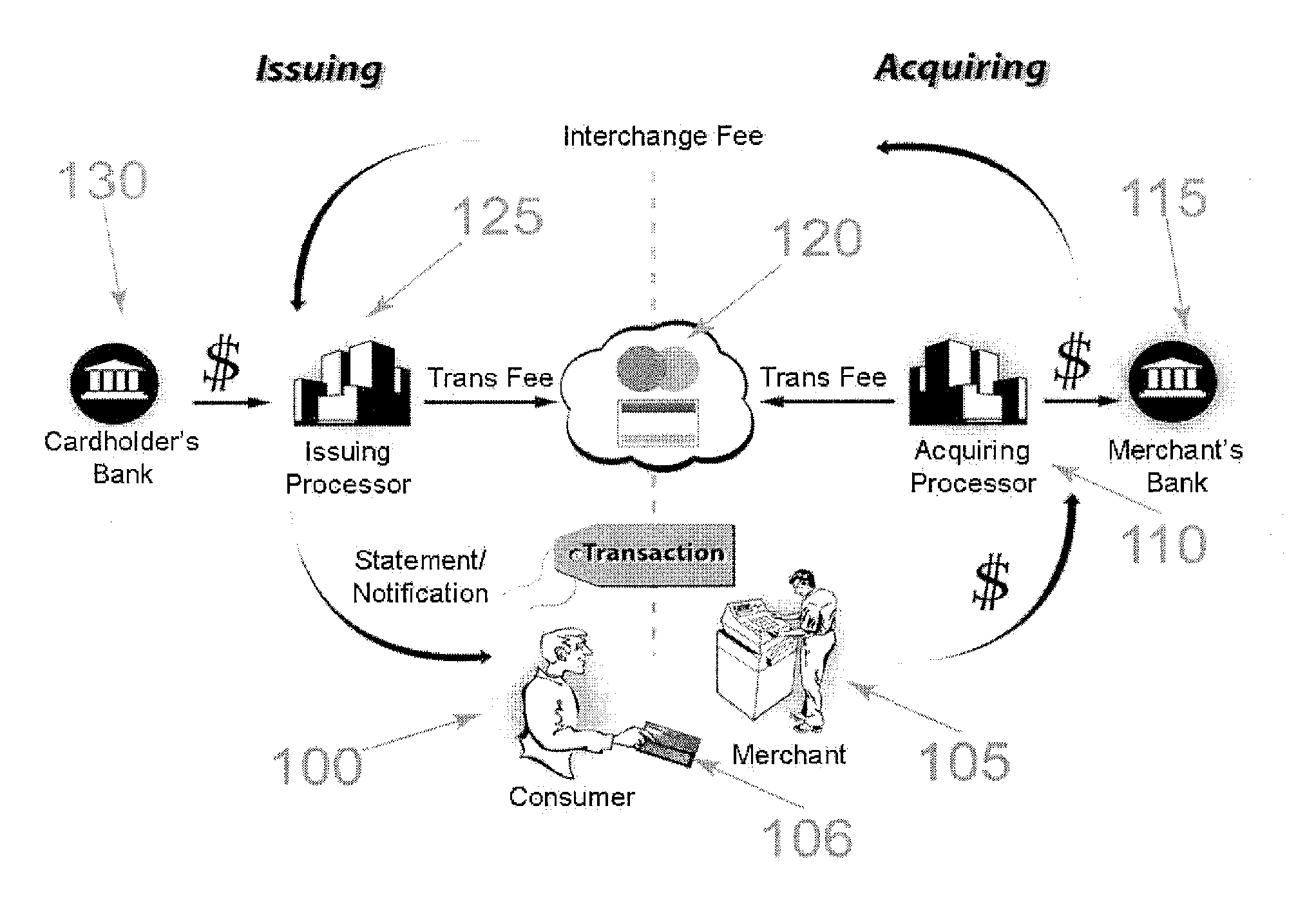

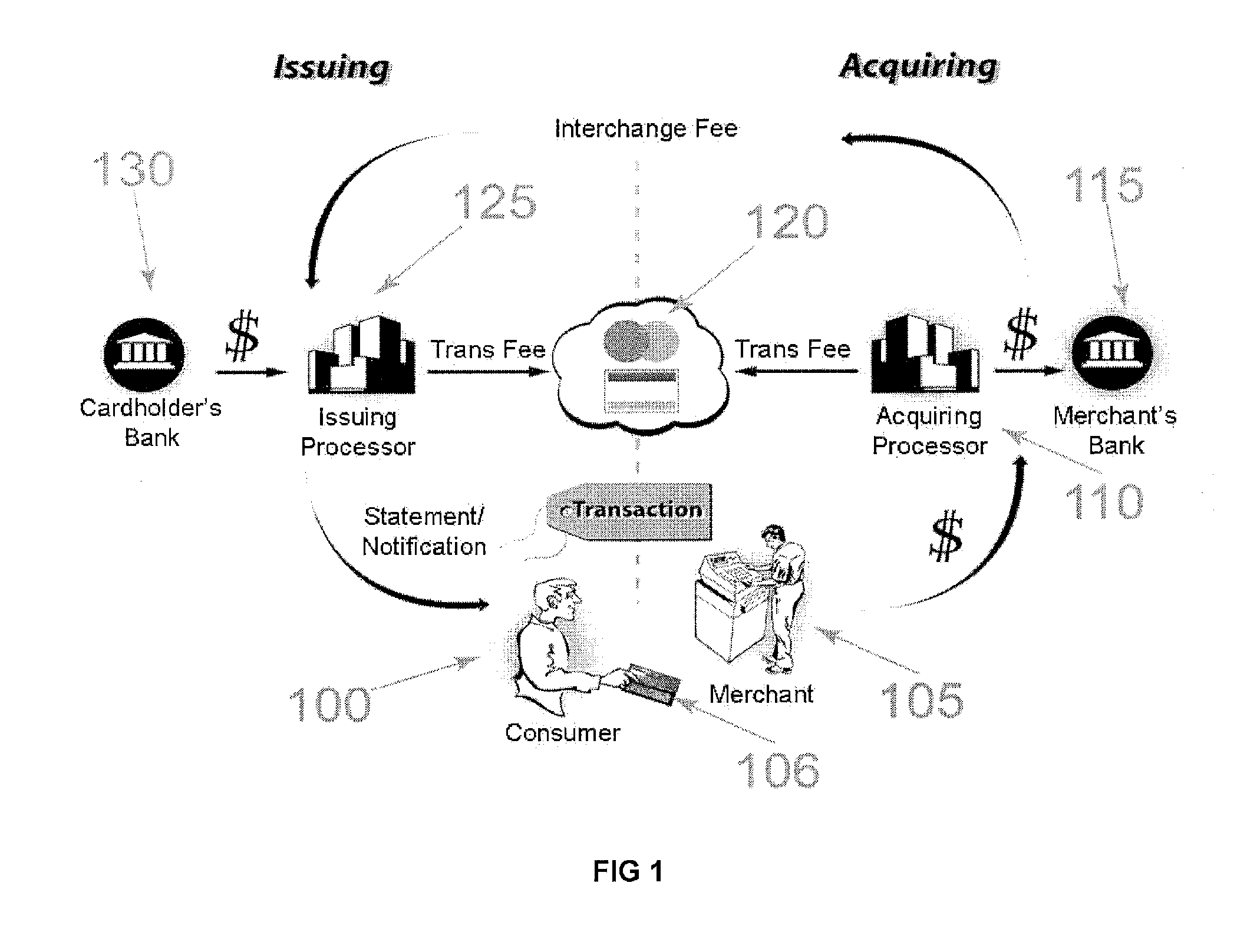

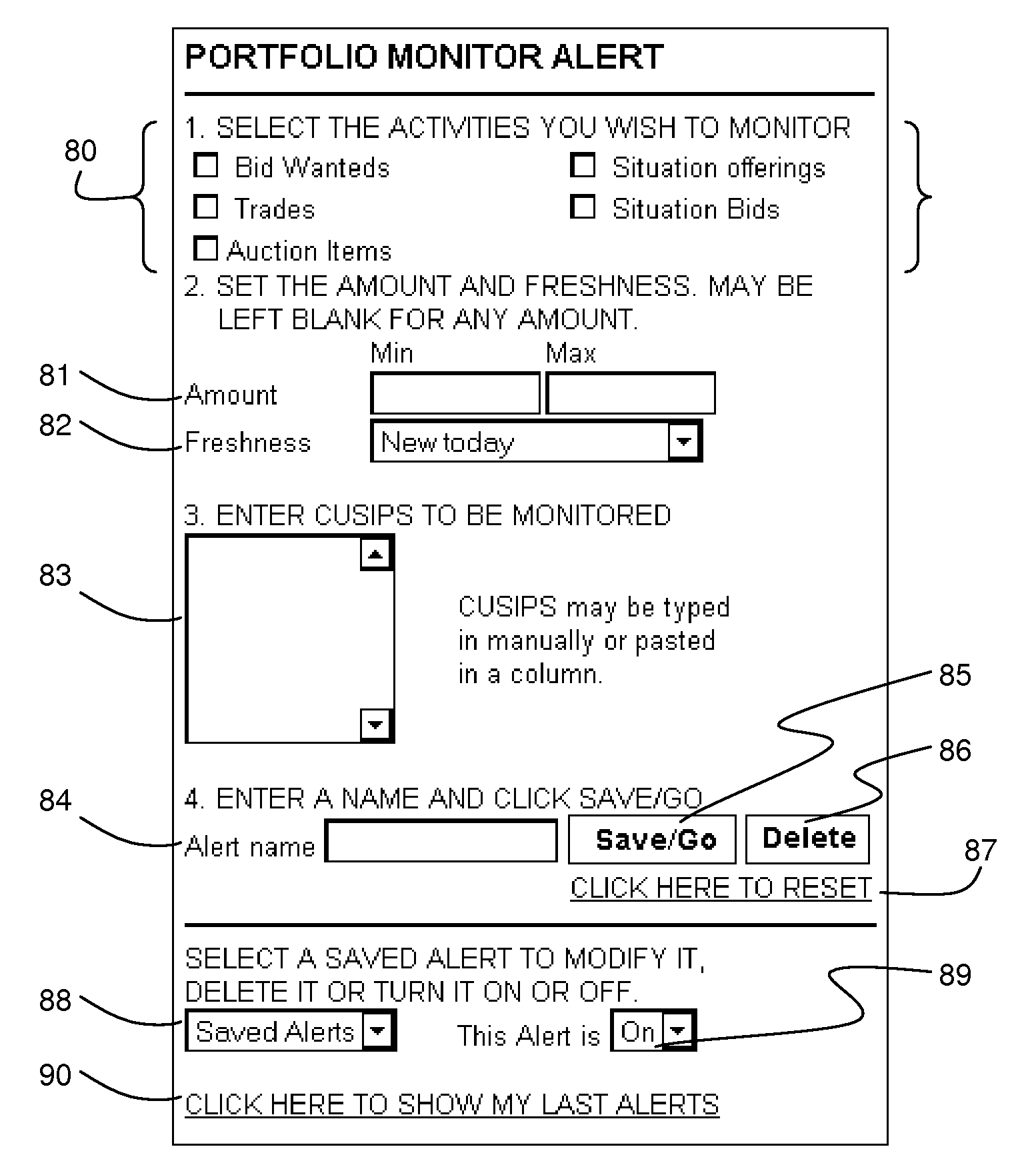

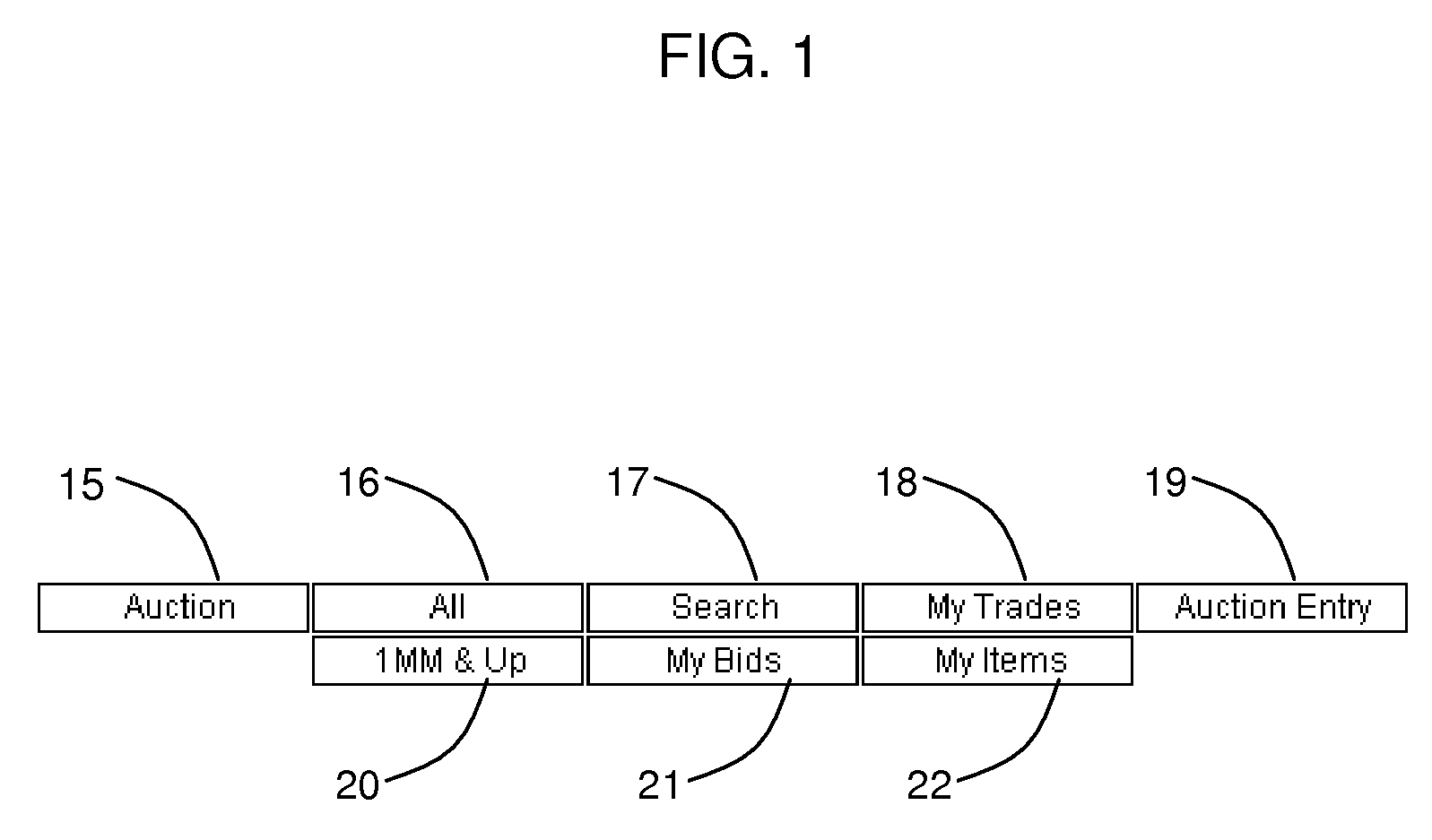

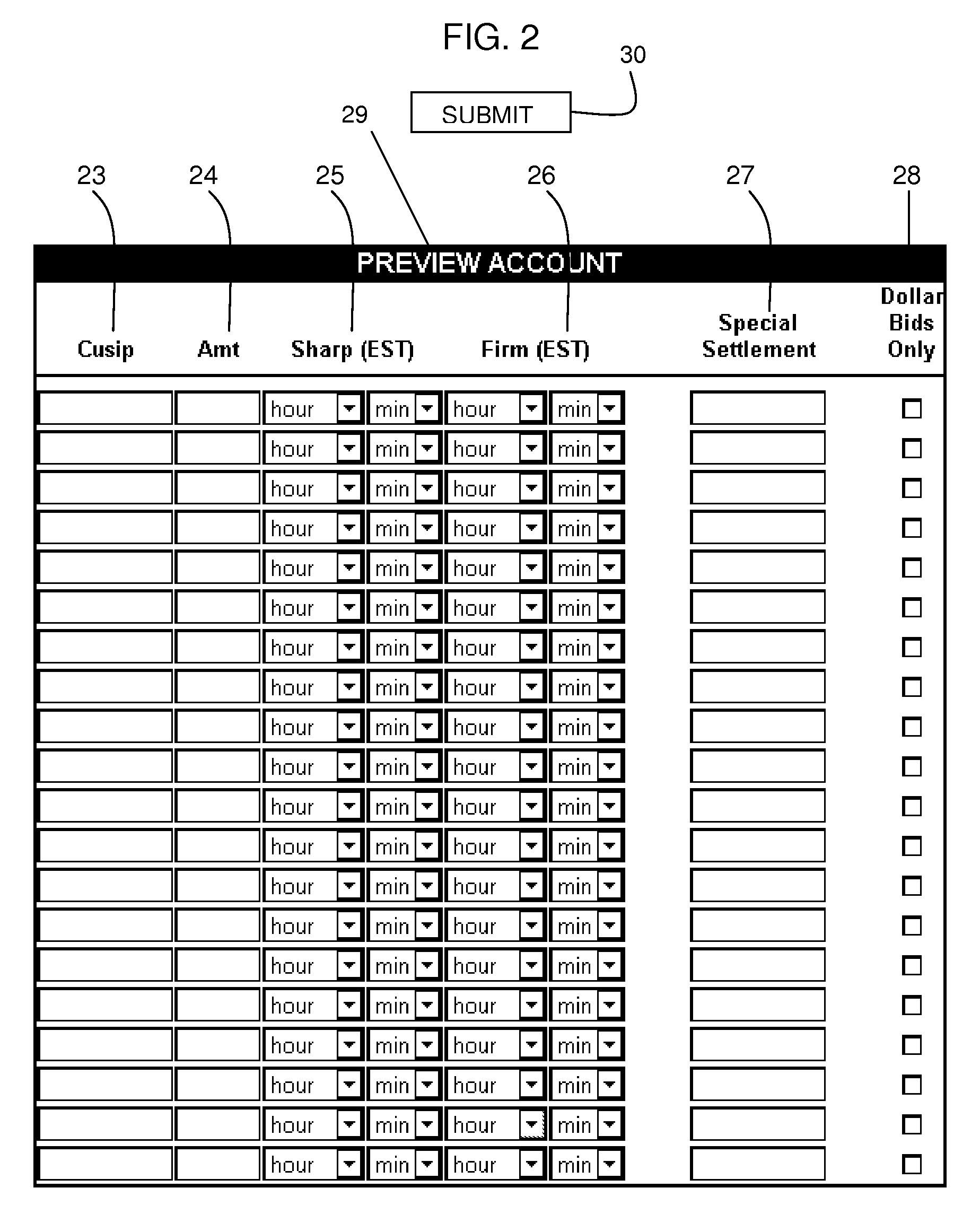

Securities Auction System and Method

ActiveUS20080126236A1Broaden their knowledgeHigh transparencyFinanceThe InternetFinancial transaction

A system and method of conducting a securities auction through the use of a computer network including programs and databases to be accessed by participants through the Internet using a standard browser. The seller inputs bid requests through a website that may be accessed by bidders once they are logged into the host computer network. All bids are entered into the computer and are accessible to all bidders on a real time basis as the auction proceeds. Additionally the bids and their times of entry are updated automatically as the auction proceeds so that all bidders are aware of the prices and status of all bids and whether any trades have been executed.

Owner:MUNIBROKERS LLC

Platform for processing semi-structured self-describing data with controlled side effects

InactiveUS8087009B1Eliminate maintenanceEliminate overheadData processing applicationsSoftware engineeringSide effectSemi-structured data

An Extensible Markup Language (XML) Application Server for storing, processing, communicating, and displaying dynamic semi-structured information. It comprises a declarative specification language, a transactional indexed XML data store, and an XML application server engine. An integrated architecture (a) provides for optimization, indexing, and backtracking search in a business logic layer, (b) provides for general-purpose programming idioms including recursive function definitions, iteration, and dynamic dispatch in data layer queries and updates, and (c) eliminates processing overhead and maintenance issues caused by transforming between relational, object-oriented, and semi-structured data paradigms.

Owner:CORNISH JUDSON AMES

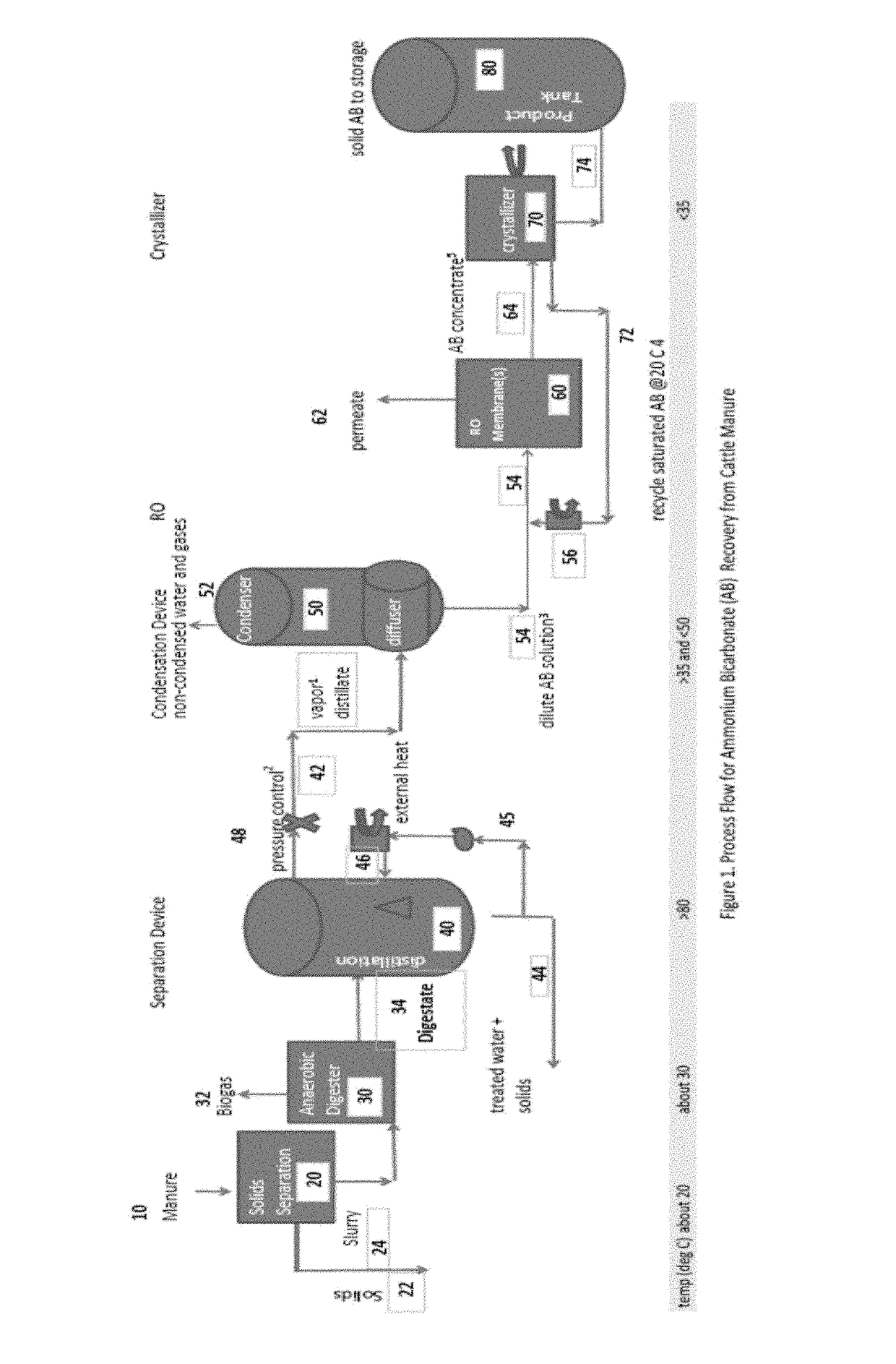

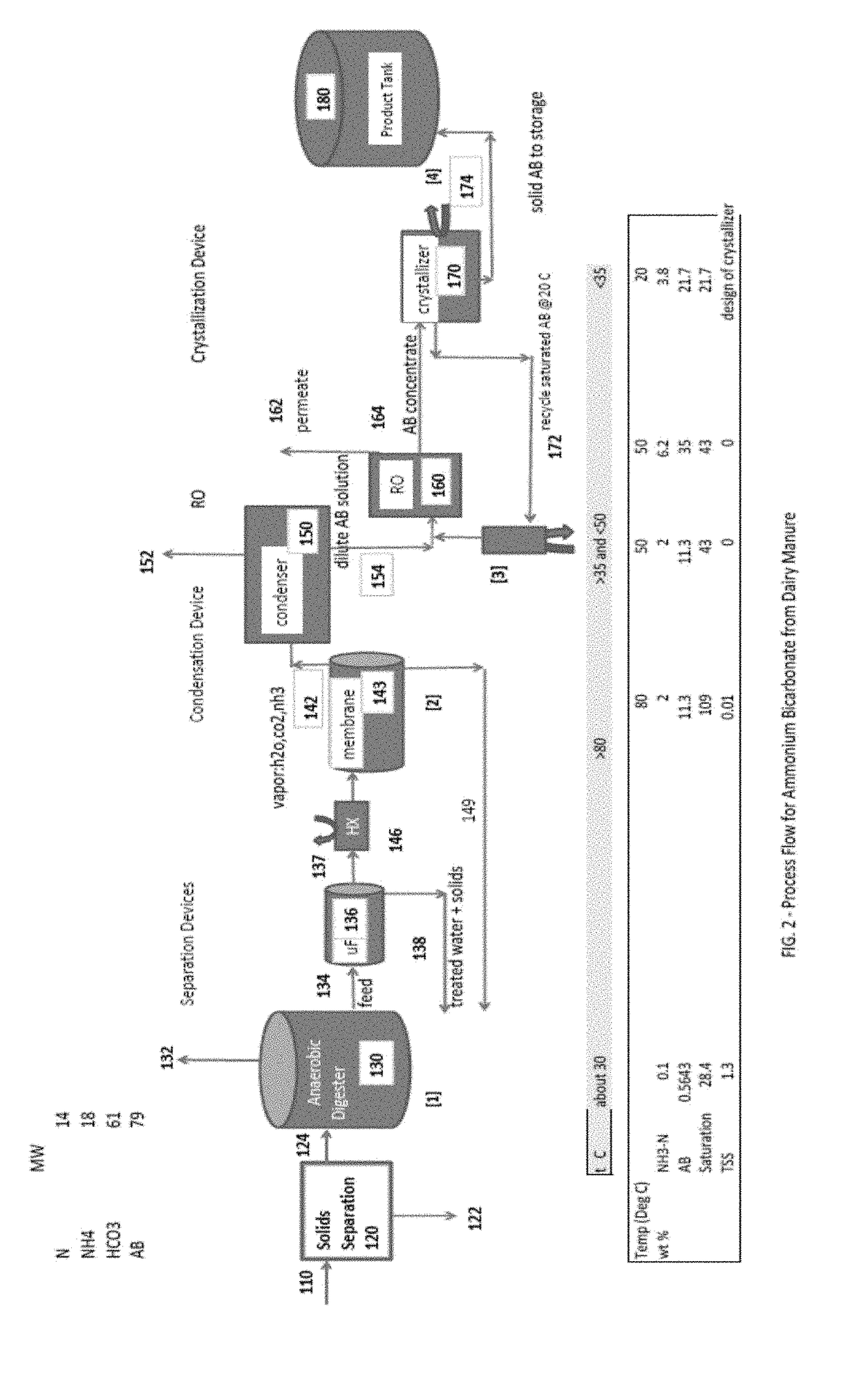

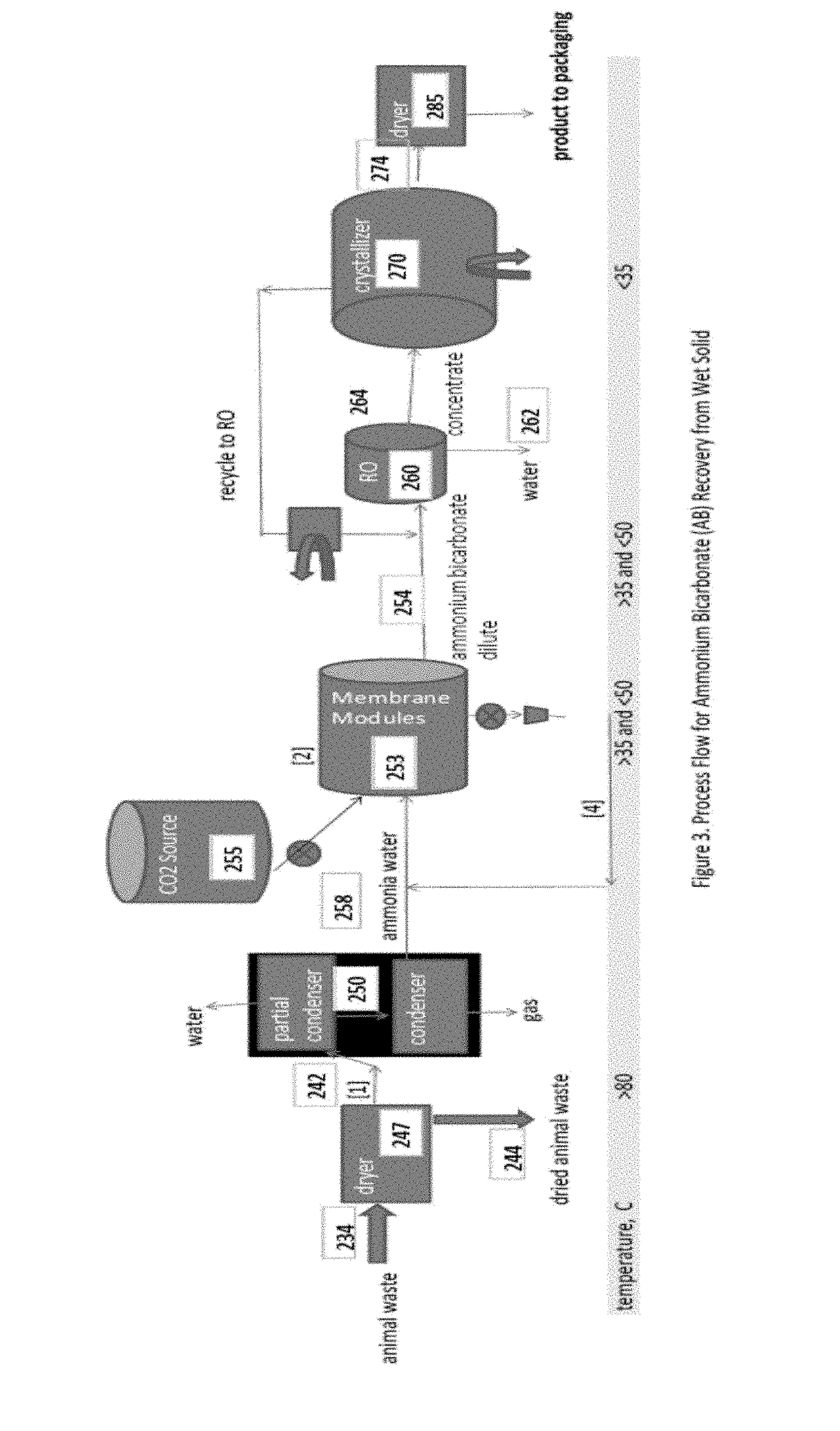

Process to recover ammonium bicarbonate from wastewater

ActiveUS20190071338A1Eliminate needConcentrates dissolved ammonium carbonate and ammonium bicarbonate more efficientlyWater treatment parameter controlSpecific water treatment objectivesCelsius DegreeSludge

The present invention is a process, a method, and system for recovery and concentration of dissolved ammonium bicarbonate from a wastewater containing ammonia (NH3) using gas separation, condensation, and crystallization, each at controlled operating temperatures. The present invention includes 1) removal of ammonia from waste (sludges, semi-solids, and solids and liquids) without the use of chemicals at a temperature of at least 80 degrees Celsius, 2) condensing the gaseous containing ammonia, carbon dioxide and water vapor to remove water vapor concentrating the amount of gaseous ammonia and carbon dioxide, 3) concentrating the ammonia and carbon dioxide in the water by established means, such as concentrating the gas using partial condensation followed by passing the concentrated gas through an absorption column at a temperature of between about 20 and 50 degrees Celsius to form dissolved ammonium carbonate and ammonium bicarbonate, or total condensation followed by dewatering using reverse osmosis, and 4) crystallizing concentrated dissolved ammonium carbonate and ammonium bicarbonate at a temperature of less than about 35 degrees Celsius to form solid ammonium bicarbonate and ammonium carbonate.

Owner:BION ENVIRONMENTAL TECH

Methods and apparatus for switching a transponder to an active state, and asset management systems employing same

ActiveUS7876225B2Eliminate maintenanceReduce energy consumptionElectric signal transmission systemsAntennas earthing switches associationEngineeringActive state

Owner:UNIVERSITY OF PITTSBURGH

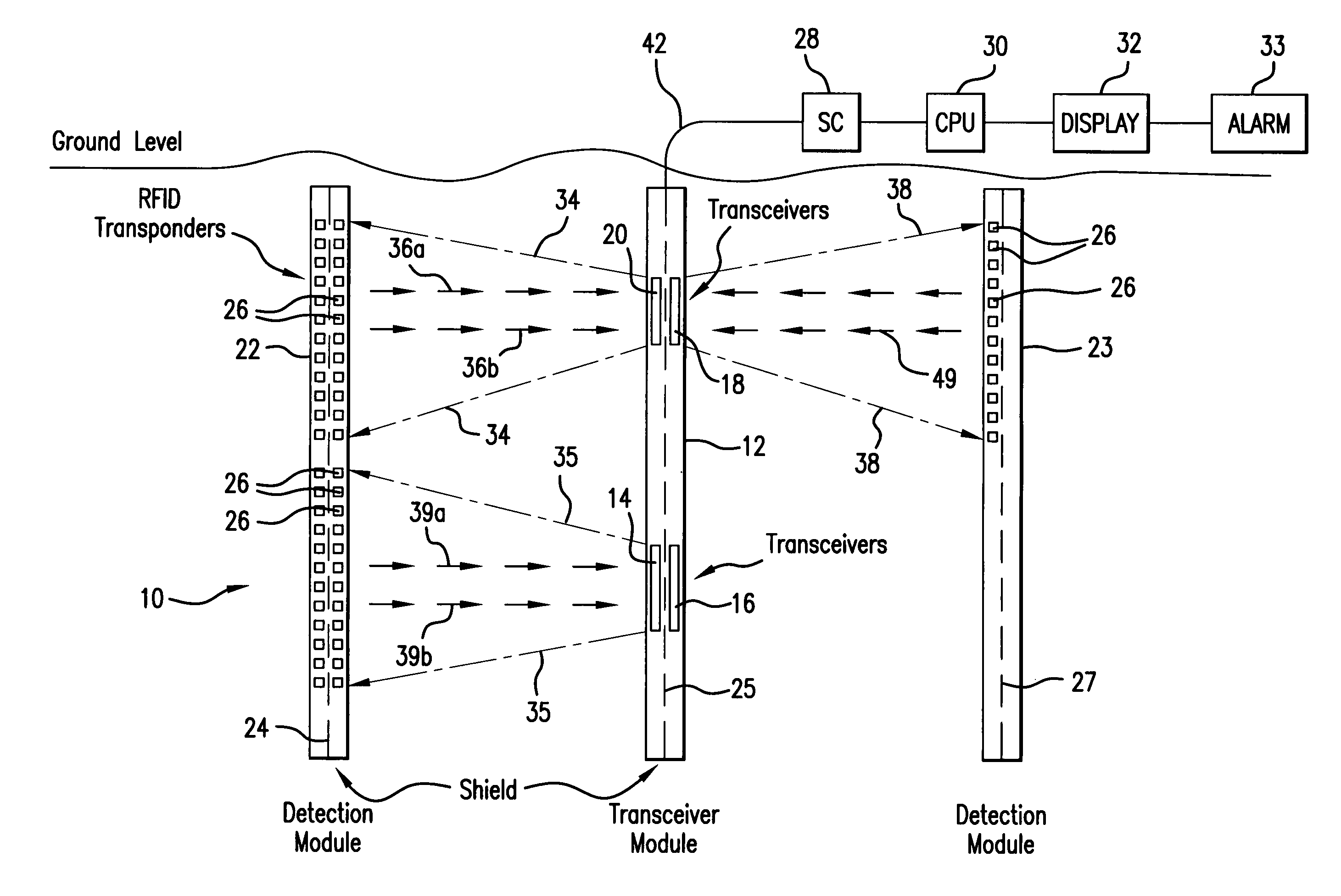

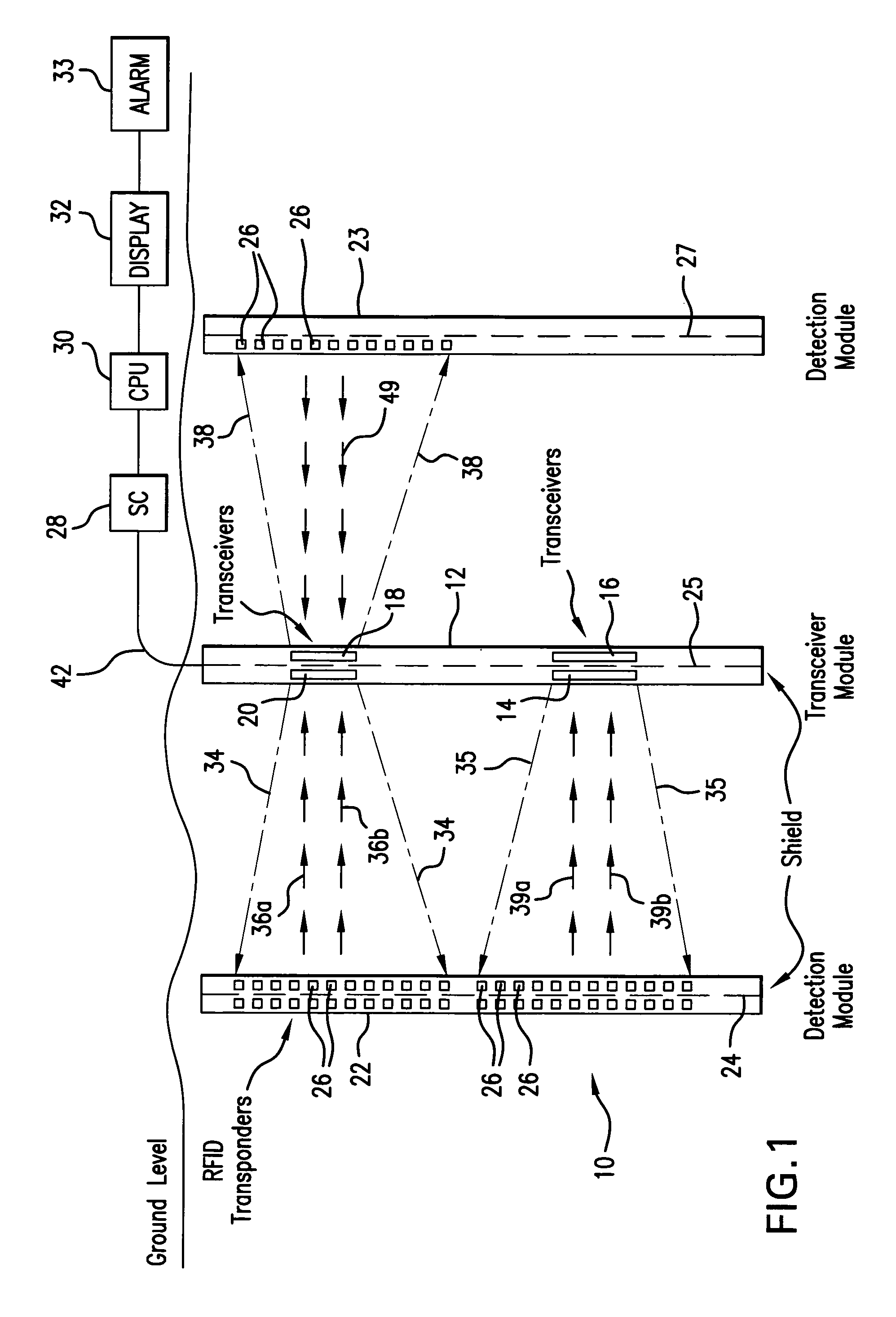

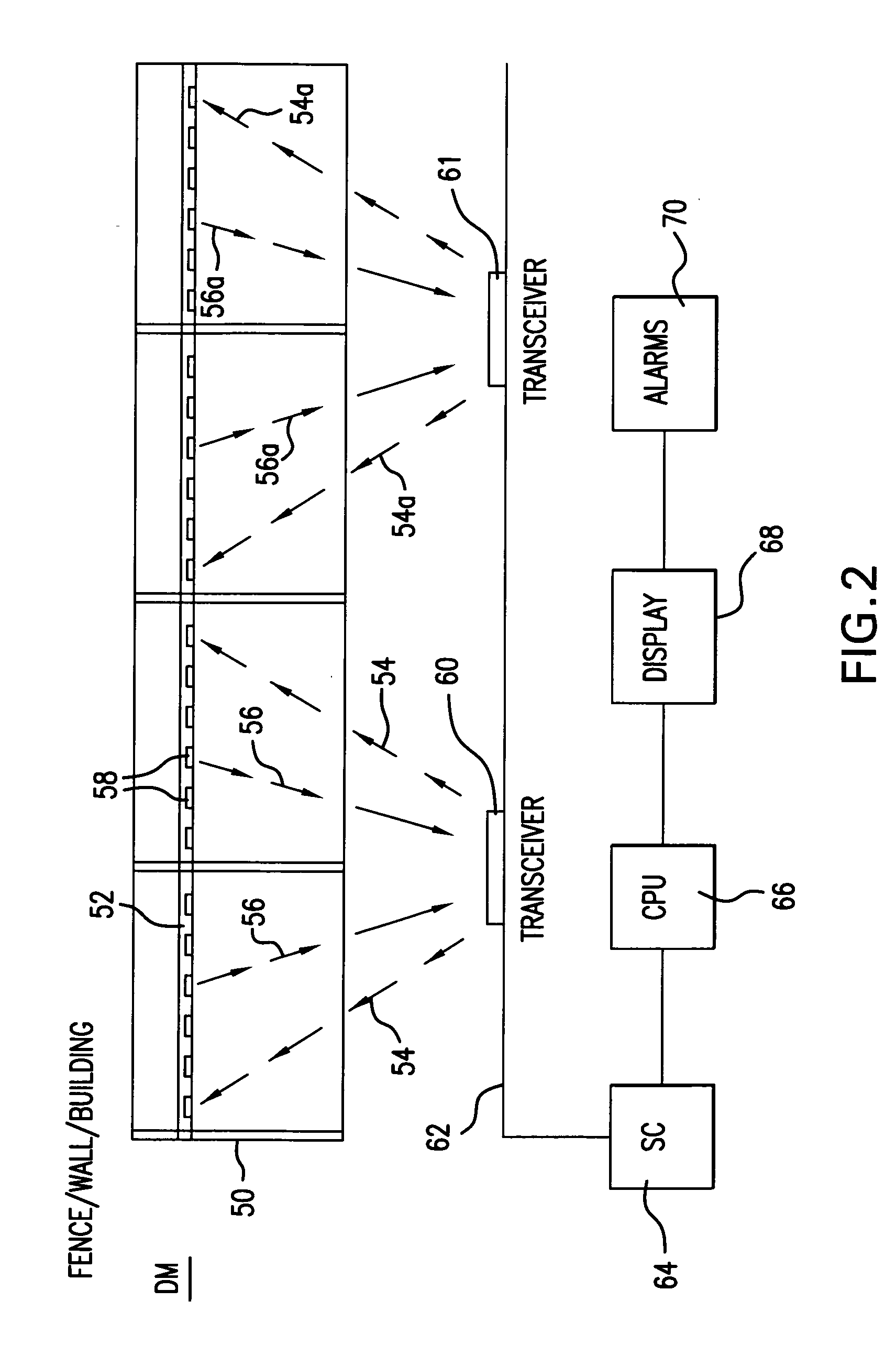

Intrusion detection system for underground/above ground applications using radio frequency identification transponders

InactiveUS20090309724A1Reduce site workImprove securityBurglar alarm by hand-portable articles removalBurglar alarm electric actuationTransceiverAbove ground

The present invention is directed to an underground as well as above ground system and method of determining the intrusion into a security zone. One or more transceivers would transmit a unique electromagnetic signal which would power a response from one or more RFID transponders. Each of the transponders would transmit a unique code to the transceiver indicating that there has been no intrusion in the vicinity of that transponder. Failure of a transponder to receive a signal produced by a transponder, would indicate the existence of an intrusion. The transponders as well as the transceivers can be provided in a PVC pipe buried in the ground, or provided in or on a structure located on or above the ground.

Owner:CECIL KENNETH B

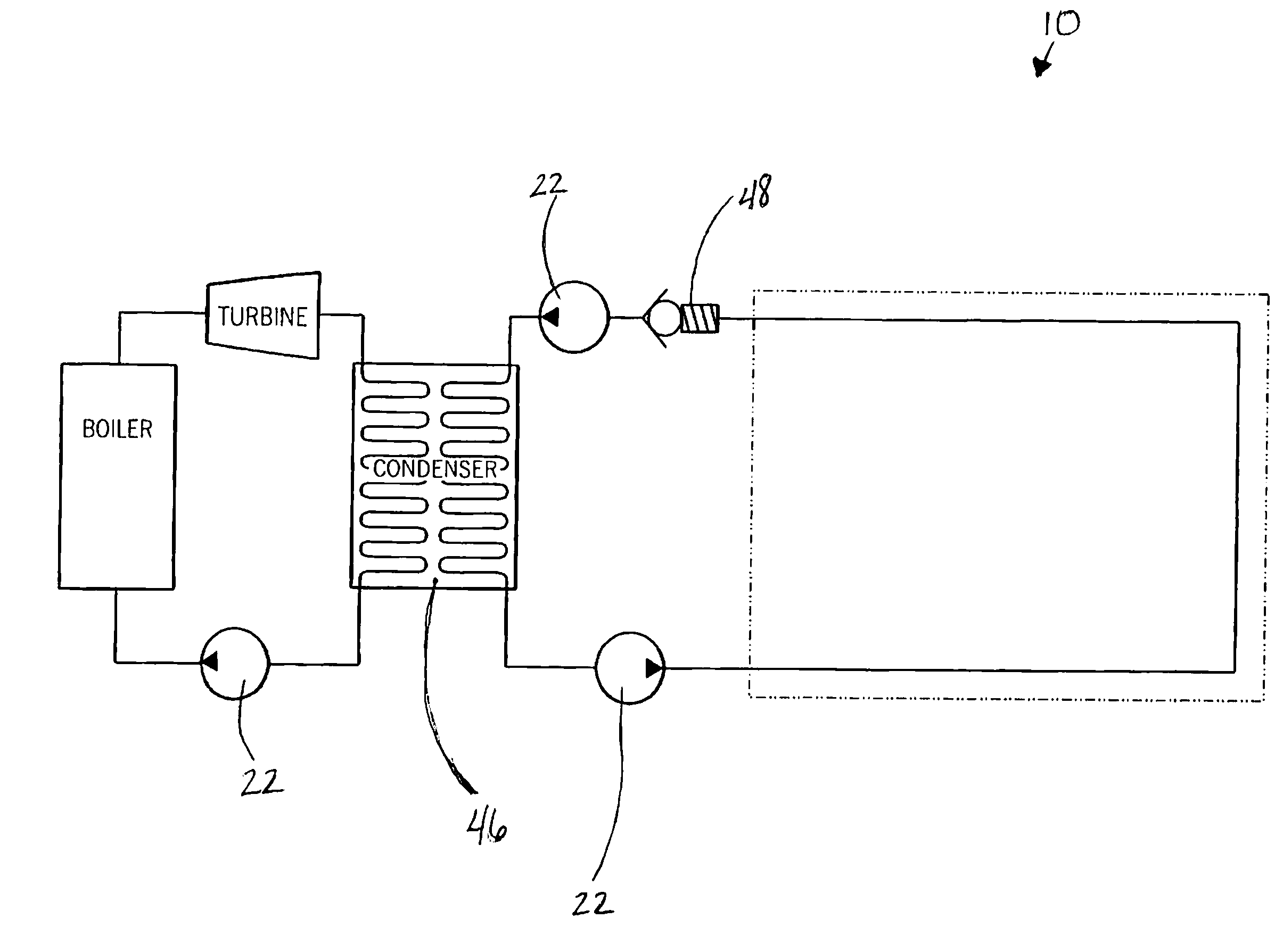

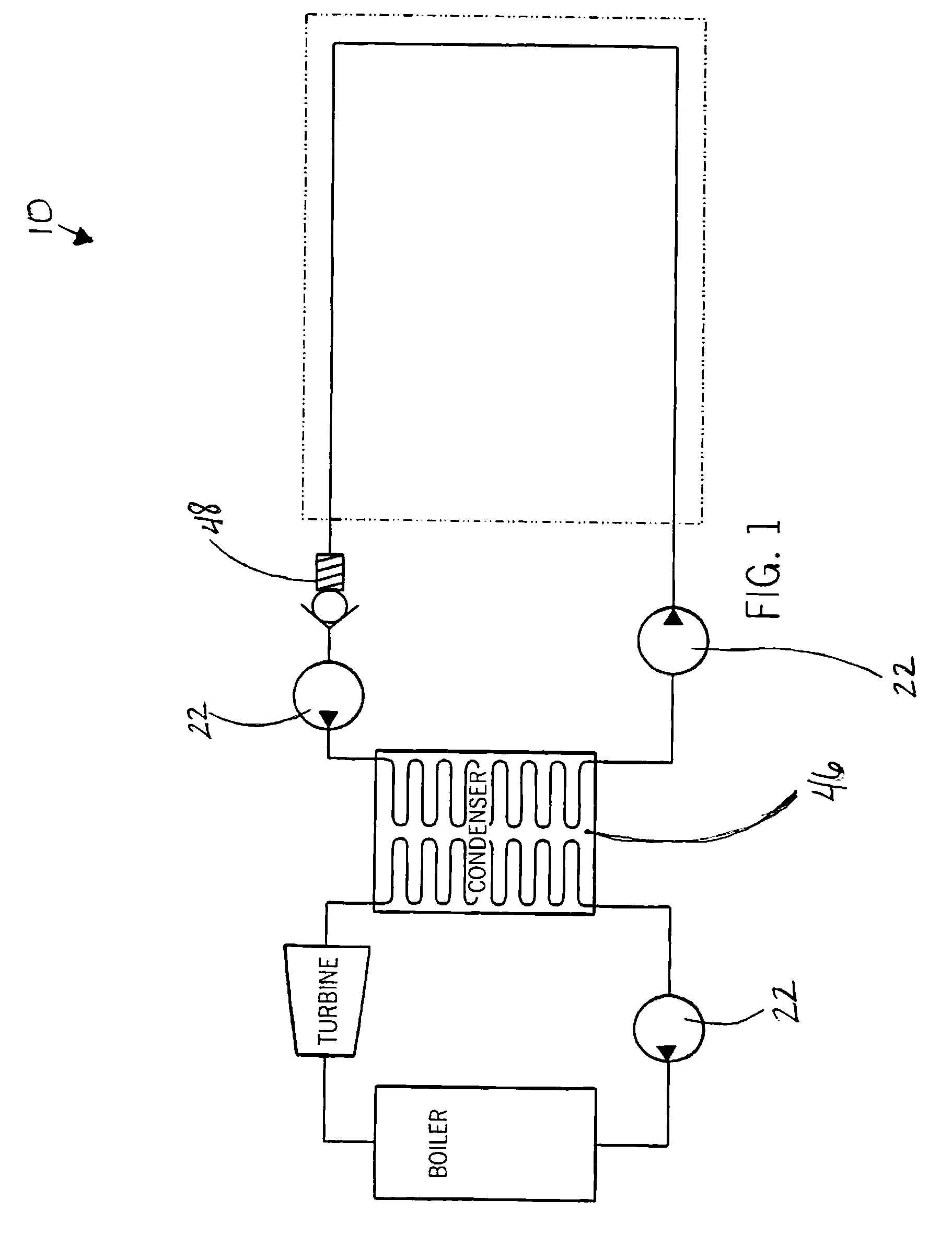

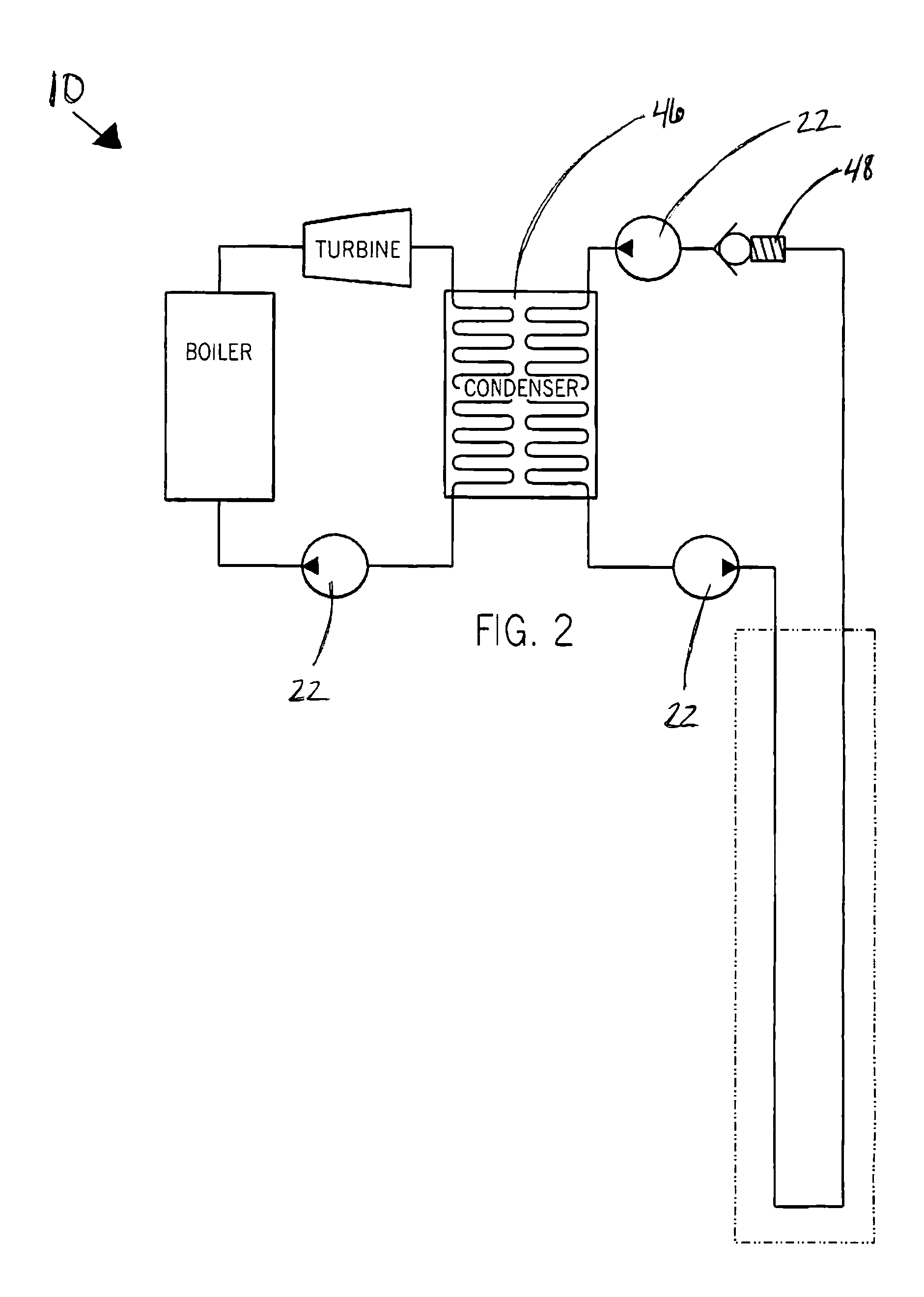

Geothermal Cooling System for an Energy-Producing Plant

InactiveUS20100212858A1Eliminate cooling tower costEliminate maintenanceDomestic cooling apparatusOther heat production devicesPower stationWater flow

An improved electrical-utility steam-turbine power-plant cooling system including a condenser with heat-exchange surfaces and cooling means. The cooling means has a closed-loop system with an intake, a discharge and a cooling portion. Substantially all of the cooling portion is tunneling beneath the surface of the Earth. Water substantially fills the closed-loop system and a pump facilitates flow through the closed-loop system whereby water flows through the tunneling and is geothermally cooled.

Owner:GUTH DAVID

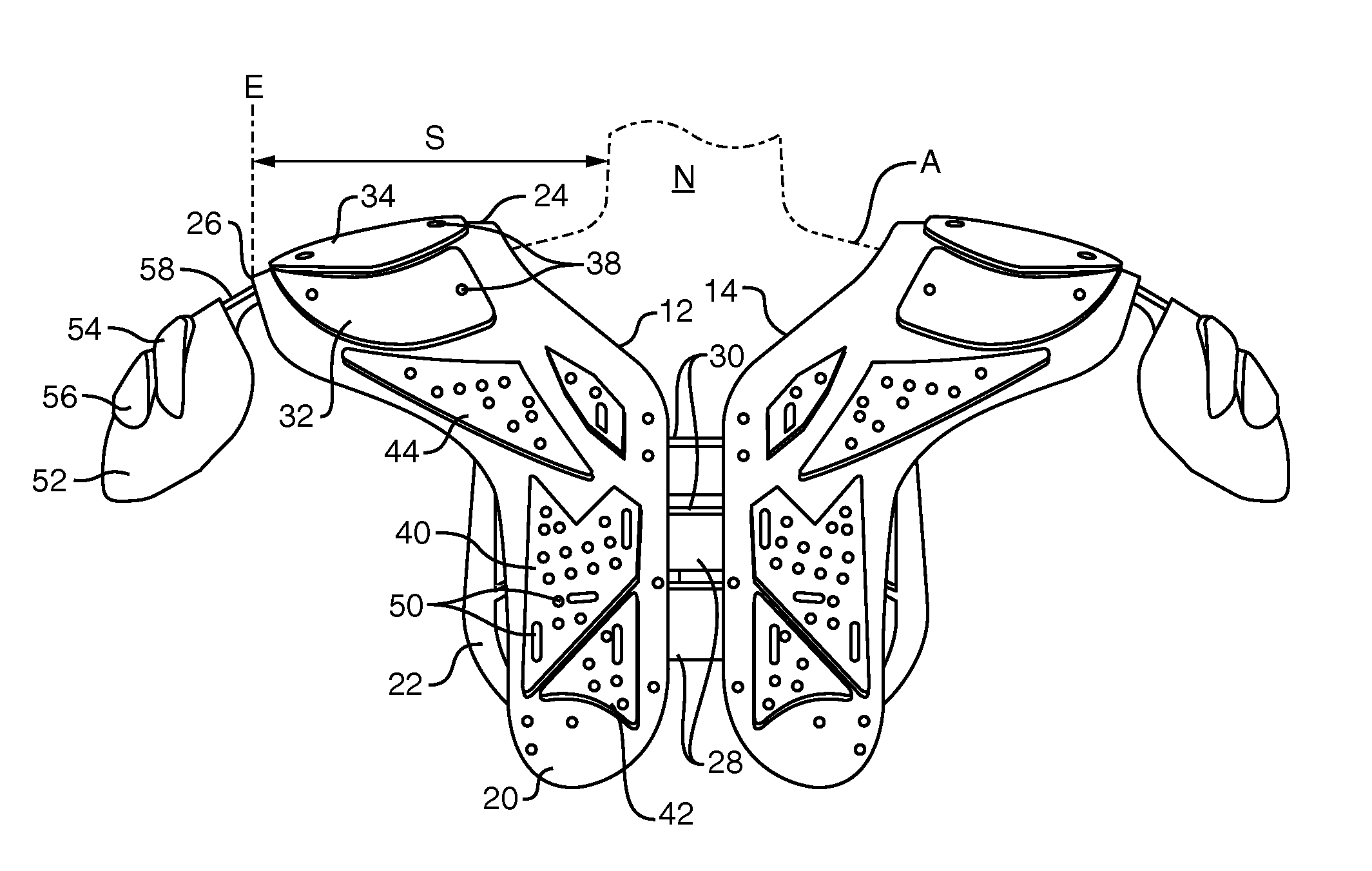

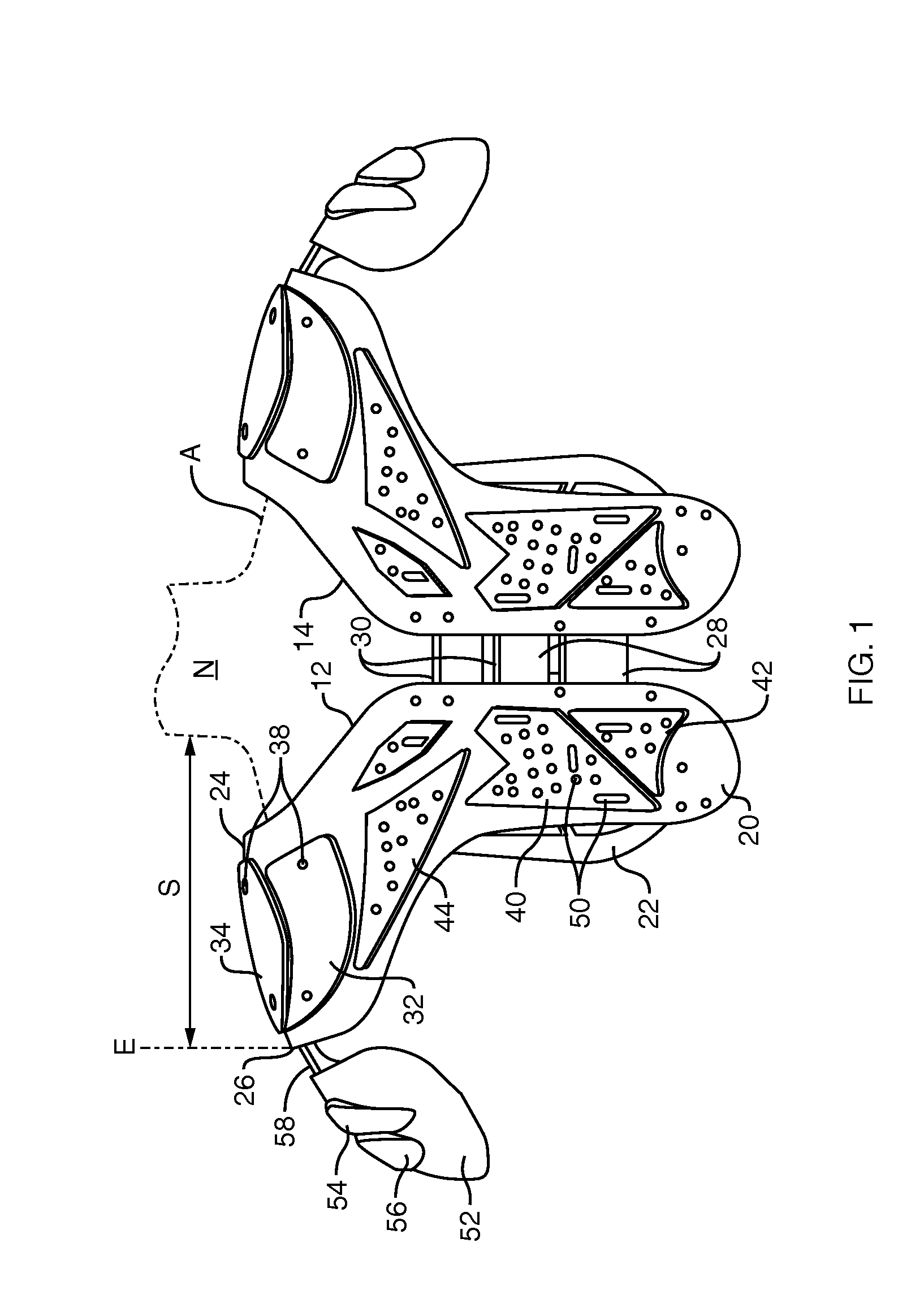

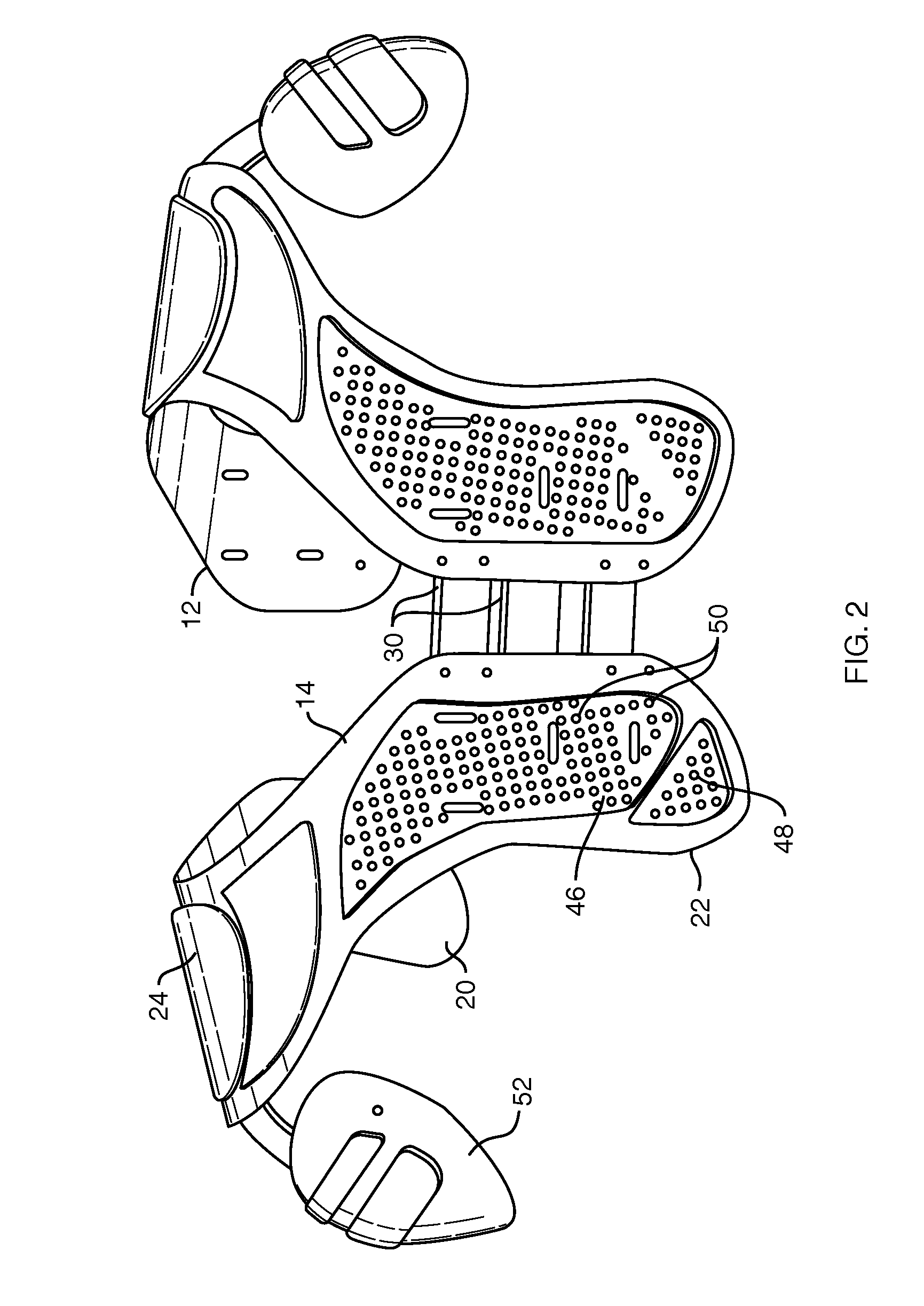

Non-epaulet shoulder pad

InactiveUS20100095441A1Low appearance requirementsEliminate maintenanceBall sportsProtective garmentChest regionEngineering

Owner:KRANOS IP CORP

Lock and release implant delivery system

Injection-molded devices and systems for graft or other tissue delivery, methods for their single-use in delivery of an implant, and kits for their sterile delivery to a practitioner are disclosed herein. Systems for implant delivery comprise an injection moldable implant body and an insertion device comprising: an inner and outer shaft that form a locking mechanism that secures an implant body in place and releases it upon placement within a patient. Systems are configured to be manufactured by injection molding, such that they can be cost-effectively manufactured and discarded after a single use to avoid costs and risks associated with re-sterilization and cleaning, but can in some cases optionally also be manufactured by machining to be re-sterilized and reused.

Owner:XENCO MEDICAL

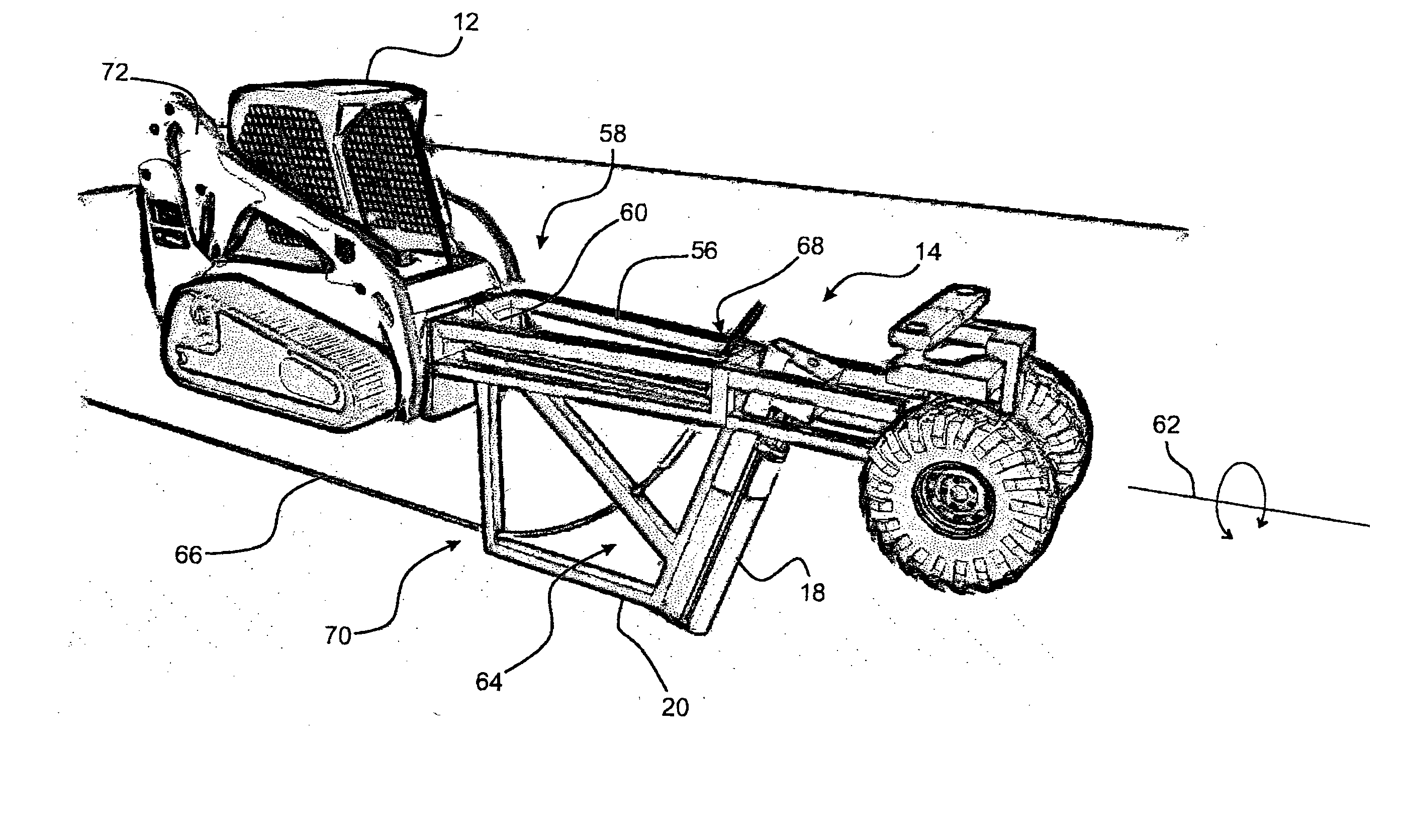

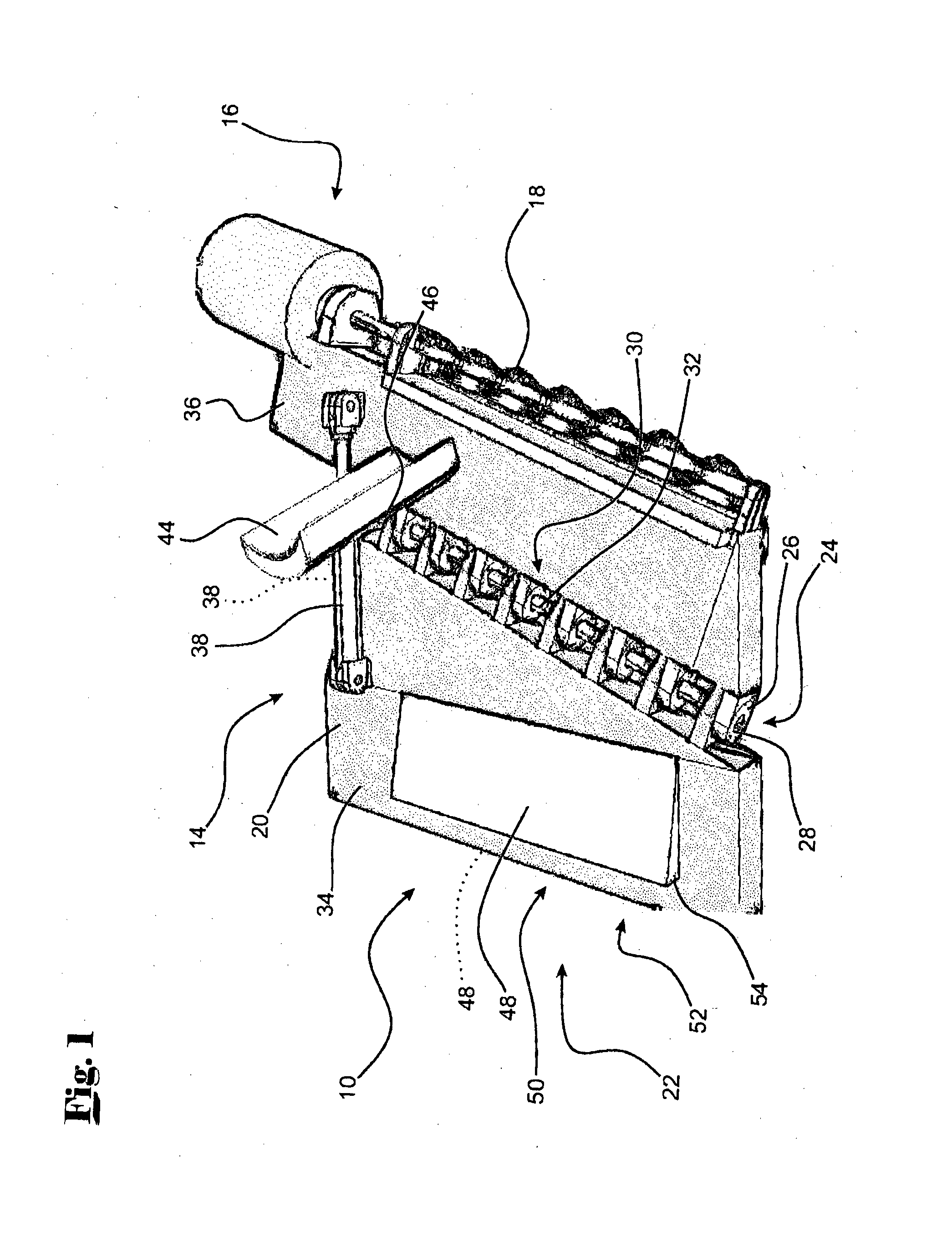

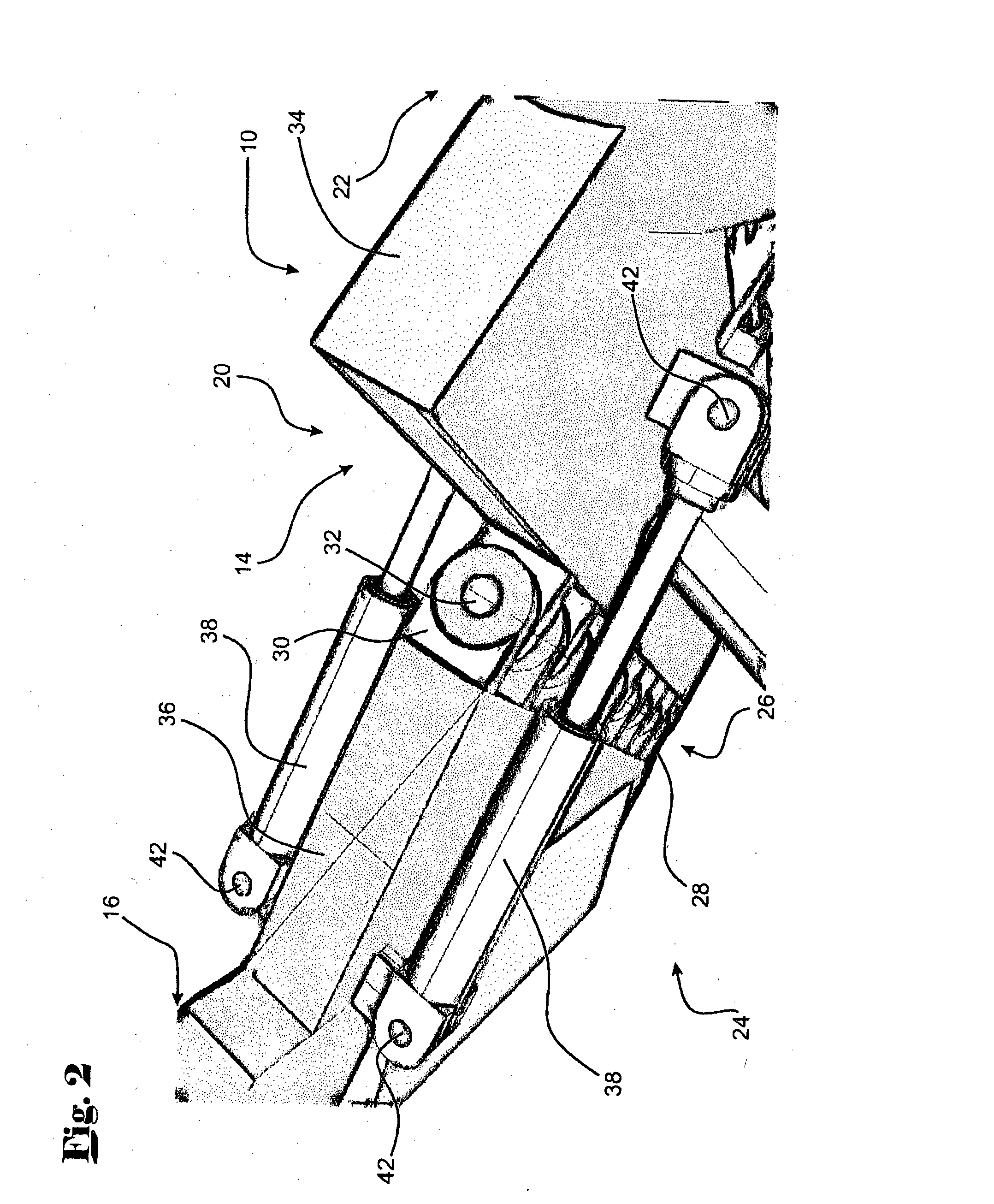

Excavation devices and methods

InactiveUS20150284932A1Prevent fallingEasy to disassemblePipe laying and repairMechanical machines/dredgersSteering system

In one preferred form there is provided an excavation system (10) for a vehicle (12). The excavation system (10) comprises a body (14) for connection to the vehicle (12). An excavation device (18) is provided for being moved by the vehicle (12) to excavate material from the ground. A steering system (24) is provided for altering the steering of the excavation device (10).

Owner:FUTURE CONSTR & CIVIL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com