Heat transfer bridge

a heat transfer bridge and heat transfer technology, applied in the direction of basic electric elements, semiconductor devices, lighting and heating apparatus, etc., can solve the problems of reducing the insulating properties of materials, affecting the operation of transformers, and aging of insulating materials, so as to improve the cooling effect of transformers, increase the capacity of operating transformers, and improve the effect of cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

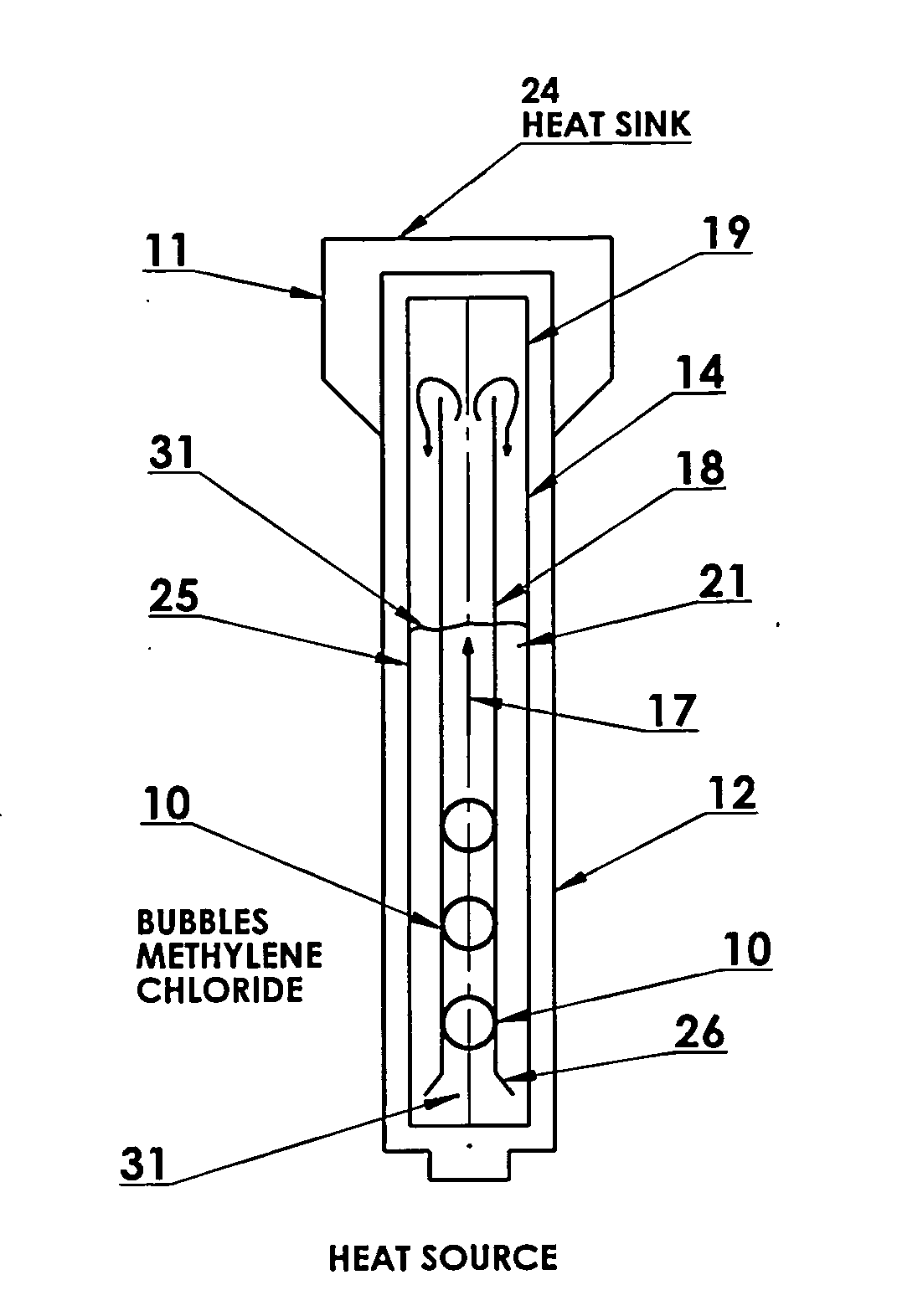

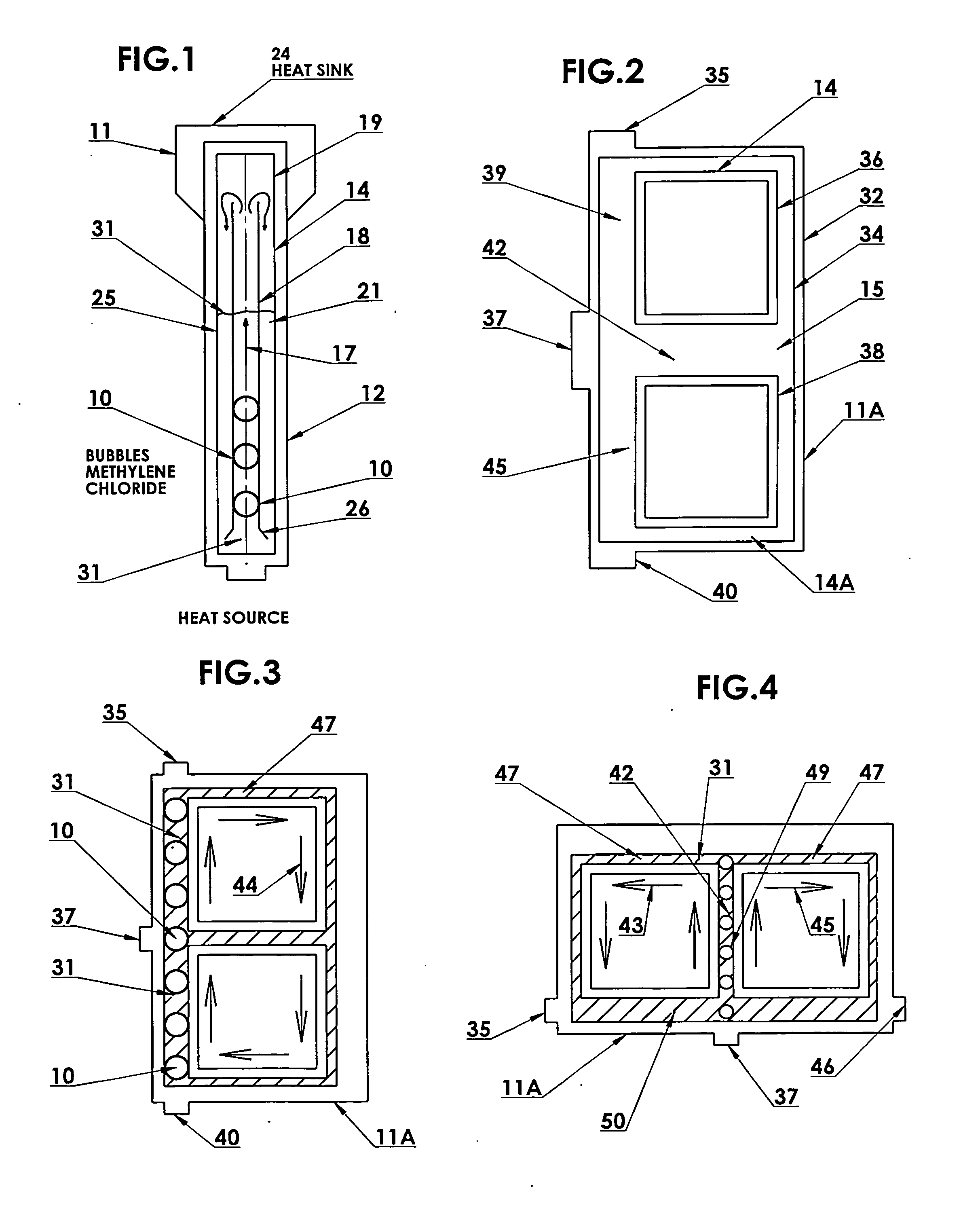

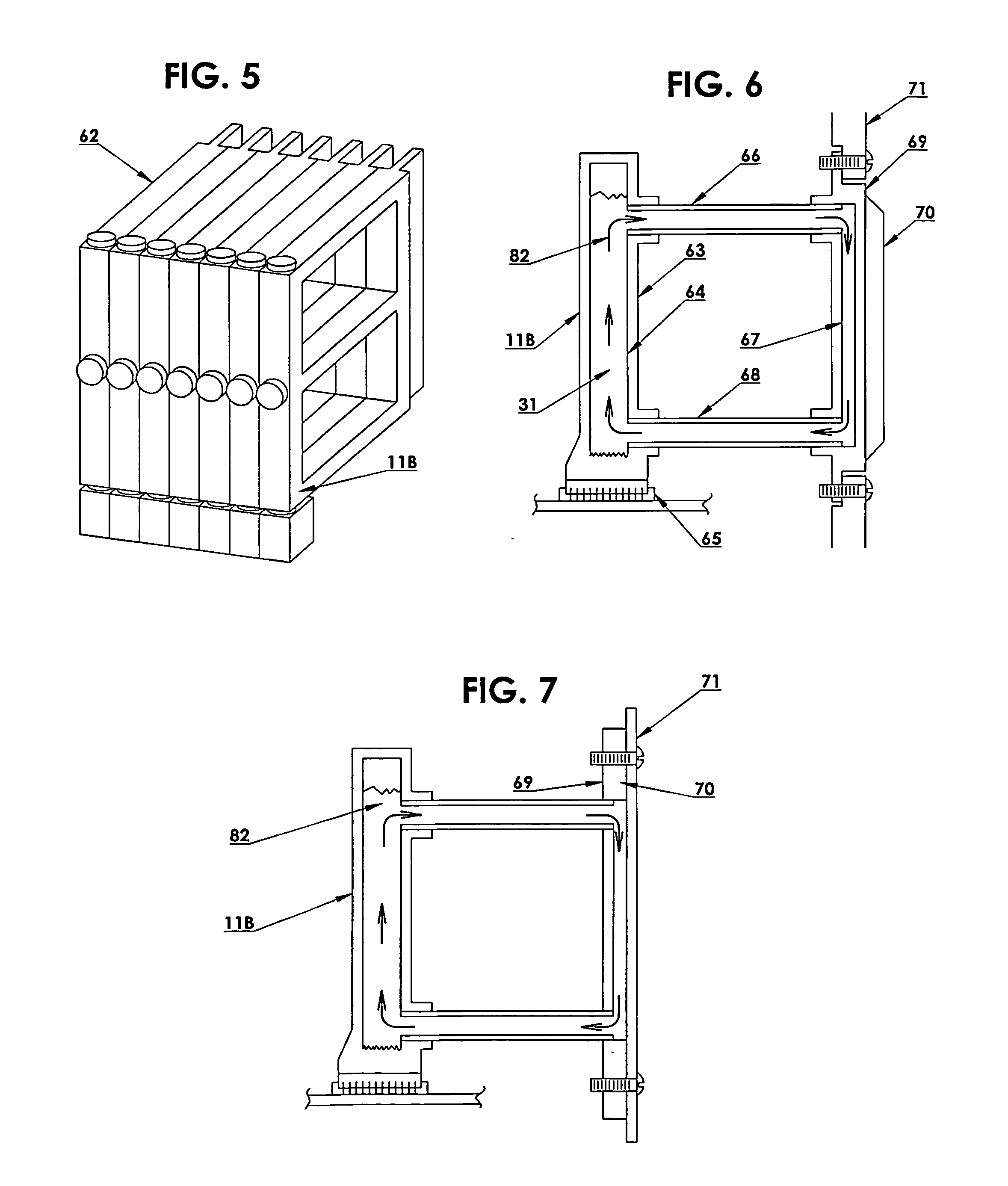

[0052]As alluded to above, one of the problems for developing circuit boards and IC chips, is the need for dissipating the heat generated by the components which operate at higher output / wattage. Further a problem for dissipating heat from circuit boards and IC chips is that the boards and chips are mounted in various orientations and in environments which may restrict air flow. The restricted and oft times minimal air flow will reduce the cooling capacity of hot surface and heat sinks / dissipating structure. The electronic junctions used in circuit boards are very small, therefore to be effective as a heat dissipation module, a module heat must efficiently absorb and dissipate heat energy from this small area.

[0053]It has been found that liquid cooling for circuit boards and IC chips is one of the most effective ways of cooling these components. It is standard practice to utilize pumps and compressors and refrigeration cycles to provide the liquid flow in a closed loop to carry the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com