Geothermal Cooling System for an Energy-Producing Plant

a technology of geothermal cooling and energy-producing plants, which is applied in the direction of domestic cooling apparatus, lighting and heating apparatus, machines/engines, etc., can solve the problems of limited power plant locations, high water treatment costs, and cooling towers of the prior, so as to reduce the cost of water treatment, and eliminate the time and expense of obtaining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

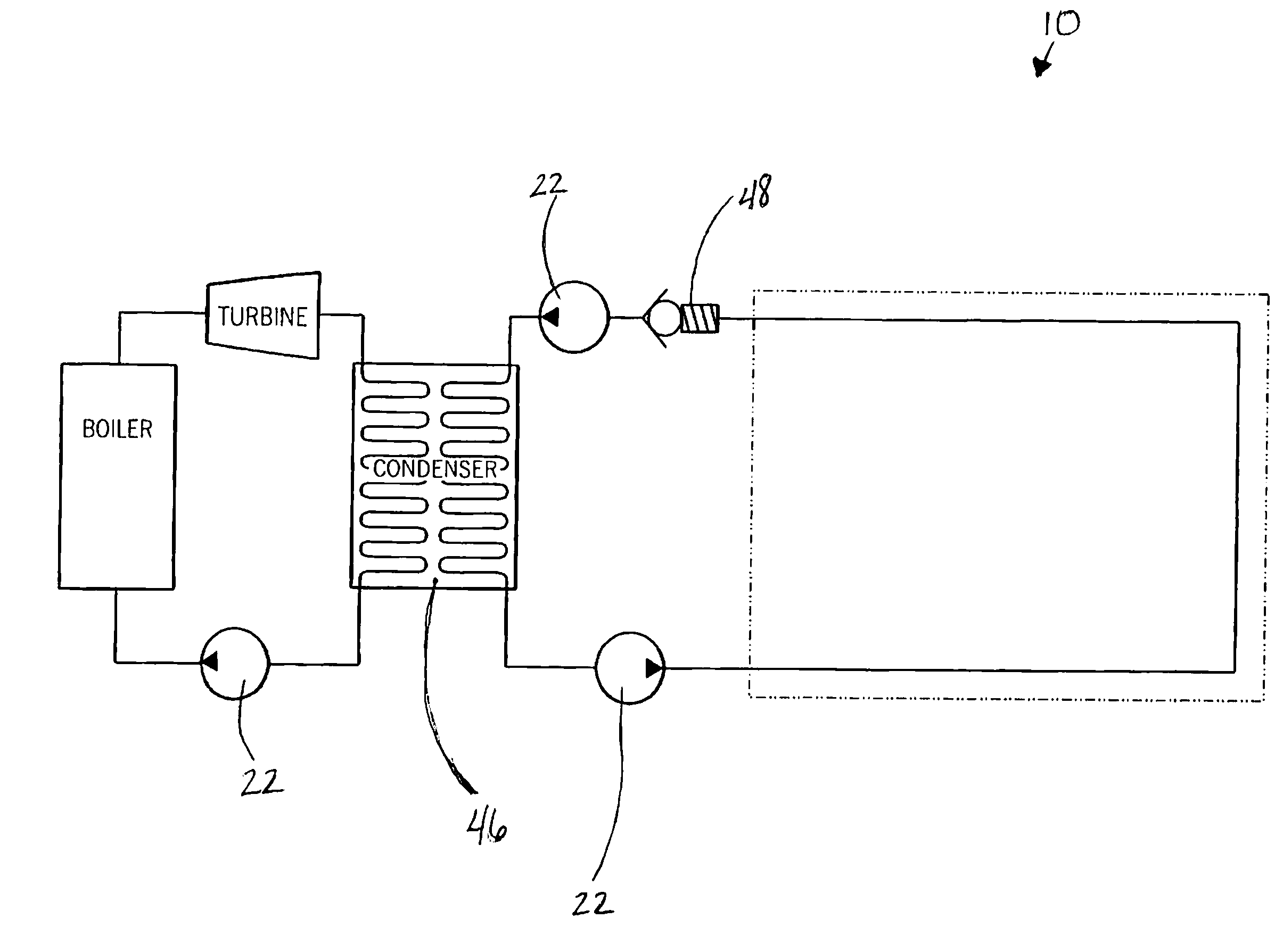

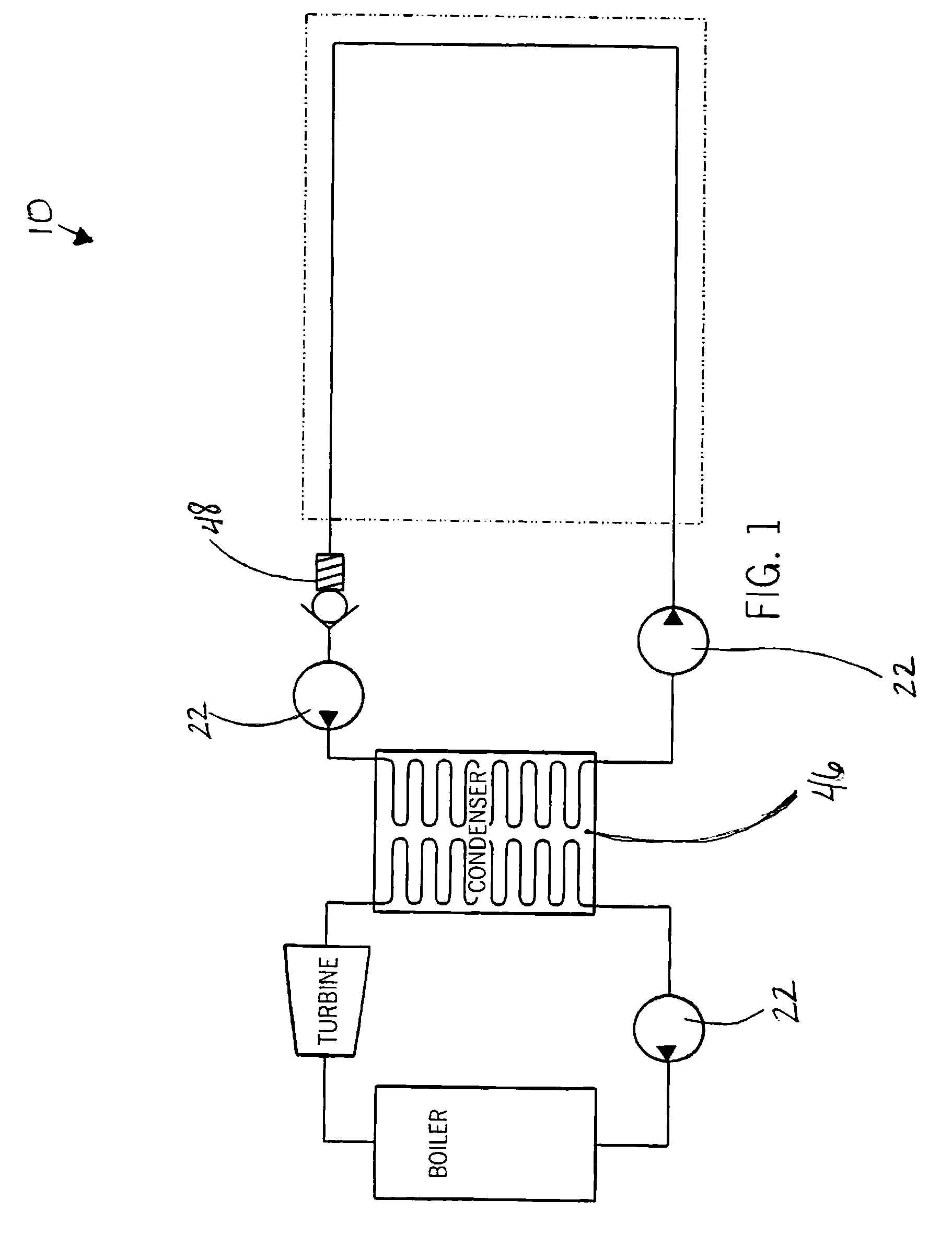

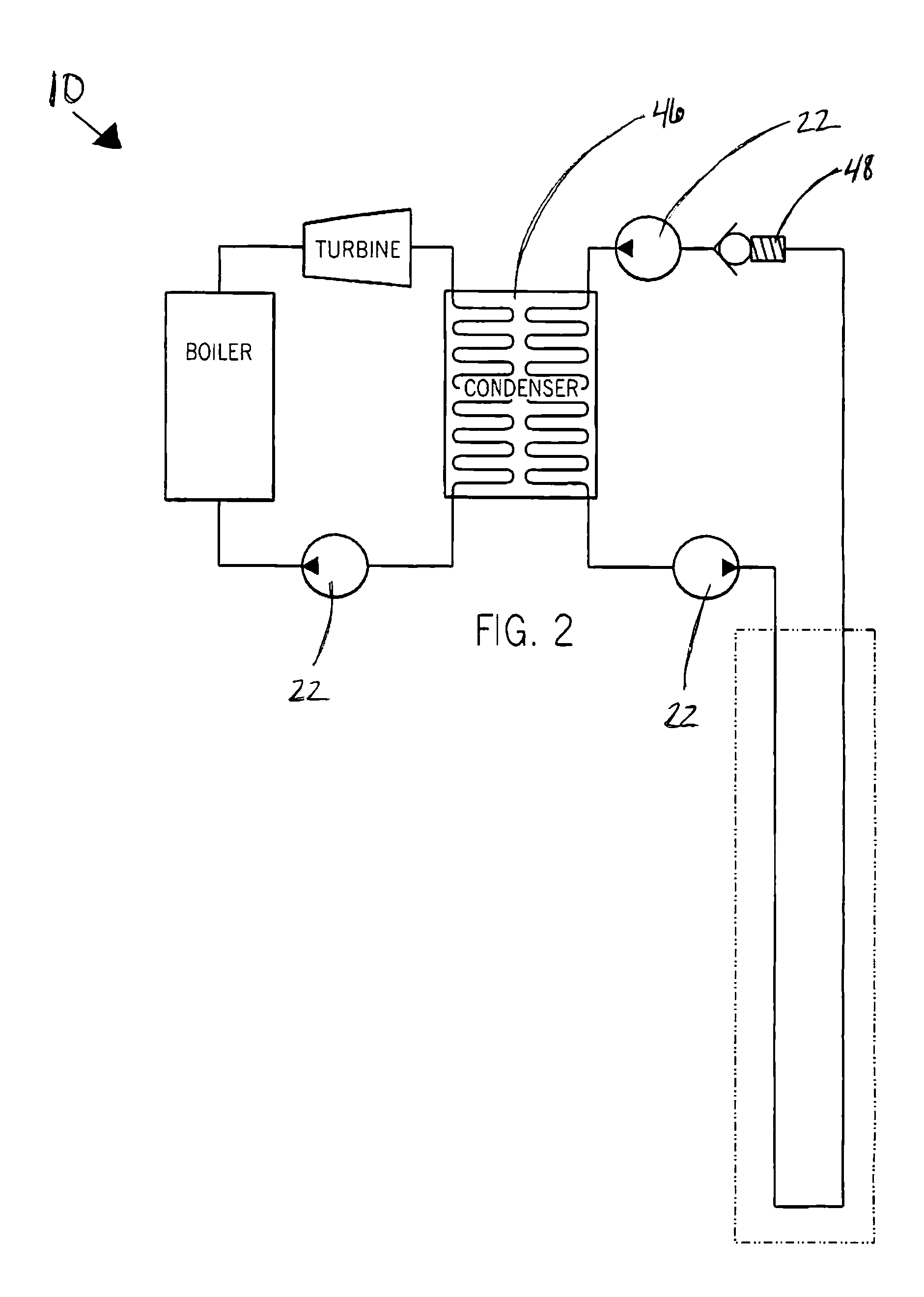

[0024]FIGS. 1-5 illustrate a preferred embodiment of an electrical-utility steam-turbine power-plant condensate cooling system (10) having subterranean horizontal tunneling having multiple connecting portions (24), an inlet portion (12), a discharge and cooling portion (14). Substantially all of the cooling portion (14) is a closed-loop tunneling system (16) beneath the surface (18) of the Earth as seen in FIGS. 1 and 3. Water (20) substantially fills the closed-loop system (16) and pump (22) facilitates flow through the closed-loop system (16) whereby water (20) flowing through the tunneling (16) is geothermally cooled.

[0025]As illustrated in FIGS. 1 and 3, a highly preferred embodiment has tunneling (16) configured in a generally horizontal direction. In an alternate embodiment, tunneling (16) is in a generally vertical configuration and is substantially located within the Earth as seen in FIGS. 2 and 4. The bed of tunnels (16) is ideally in a horizontal configuration but can be c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com