Disc cutter trimming mechanism of sheet extrusion machine

A disc cutter and disc cutter technology, applied in metal processing and other directions, can solve problems such as easy slippage, and achieve the effect of eliminating slippage, simple structure and good use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

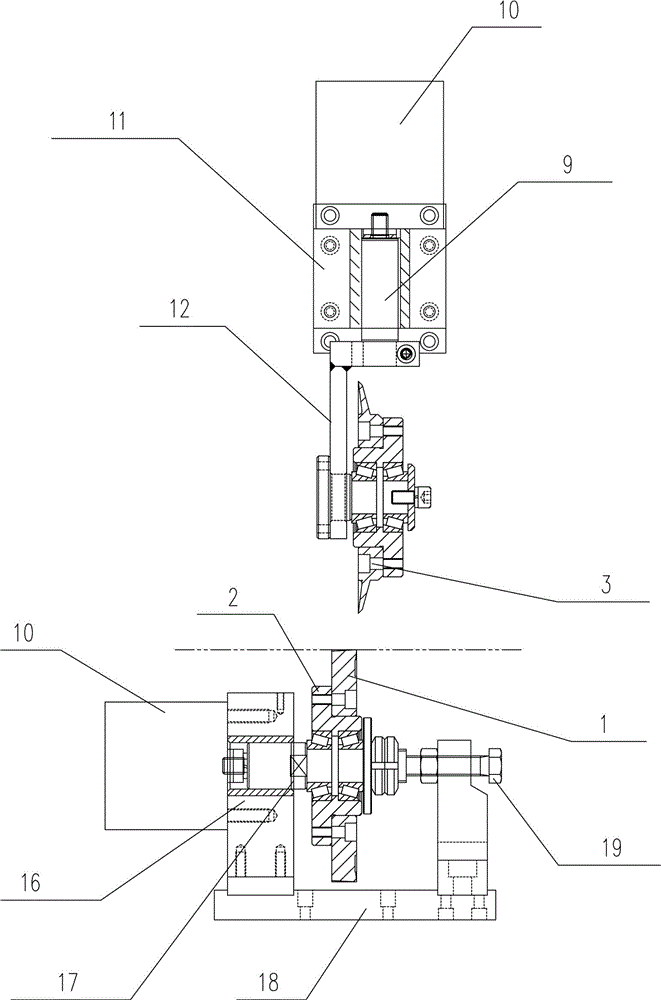

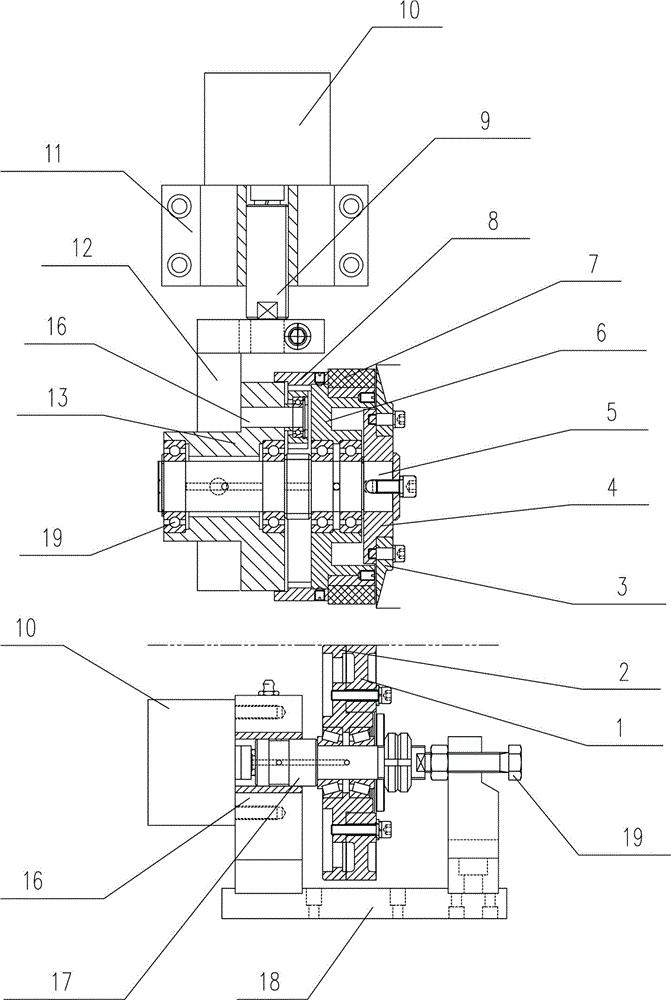

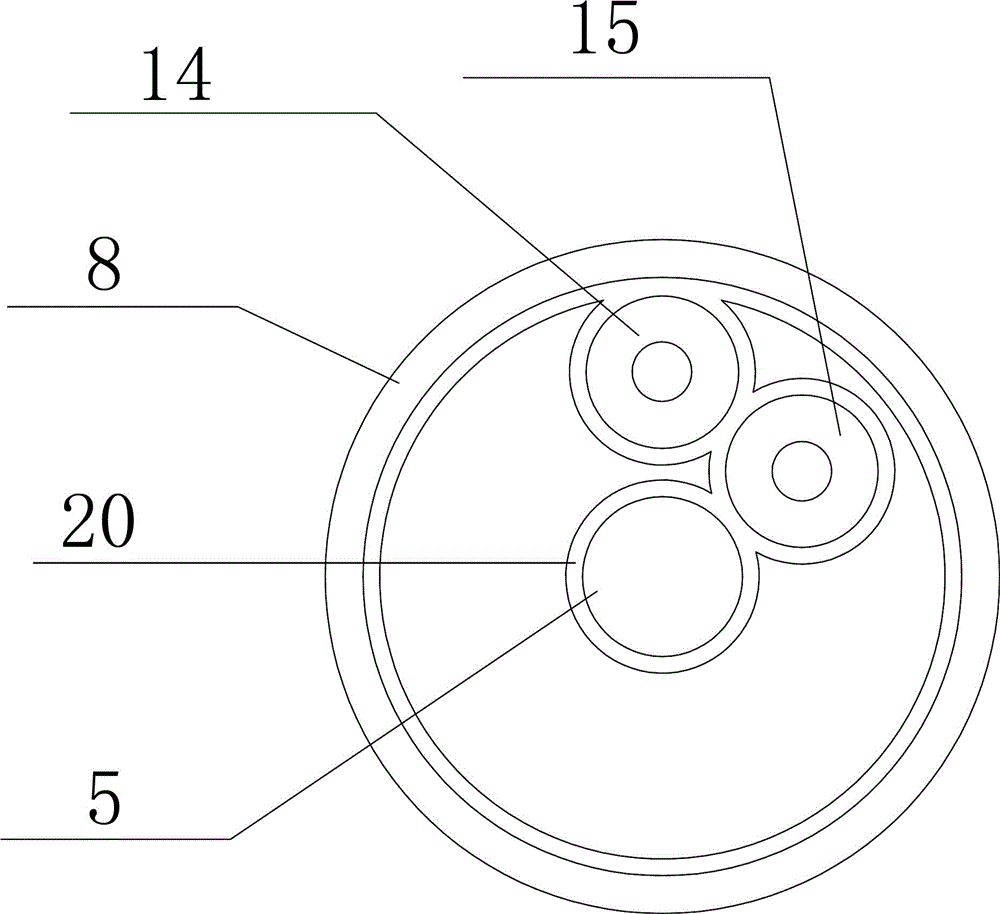

[0017] Such as Figure 2-4 As shown, the disc cutter trimming mechanism of the extrusion sheet machine in this embodiment includes a lower disc knife 1, a first rotating shaft 5, an upper knife seat 4, an upper knife seat positioning mechanism, and an upper disc knife 3 , the second rotating shaft 17, the lower knife seat 2, and the lower knife seat positioning mechanism.

[0018] The first rotating shaft 5 is rotatably installed on the upper knife seat positioning mechanism, the upper knife seat 4 is installed on the first rotating shaft 5, and the upper disc knife 3 is rotatably installed on the upper knife seat 4, The second rotating shaft 17 is rotatably installed on the lower knife seat positioning mechanism, the lower knife seat 2 is installed on the second rotating shaft 17, the lower disc knife 1 is rotatably installed on the lower knife seat 2, and the upper circle The disc cutter 3 is arranged opposite to the lower disc cutter 1.

[0019] The upper knife seat 4 is ...

Embodiment 2

[0028] The disc cutter edge trimming mechanism of the extruded sheet machine in this embodiment differs from that of Embodiment 1 in that:

[0029] The third gear 20 and the first rotating shaft 5 are replaced by gear shafts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com