Dual-coil magnetic force driving device for high-voltage line inspection robot

An inspection robot, magnetic drive technology, applied in the direction of magnetic attraction or thrust holding device, electrical components, etc., can solve the problems of low driving force, inspection robot slipping, low efficiency of line inspection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

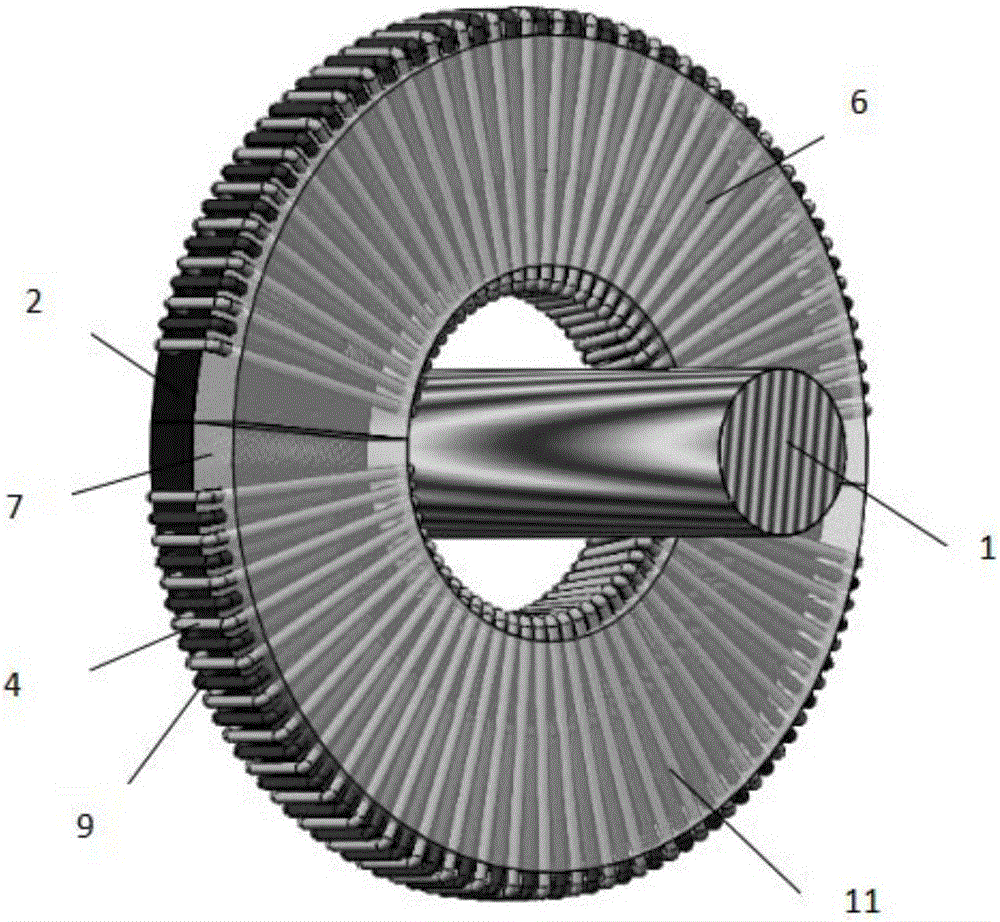

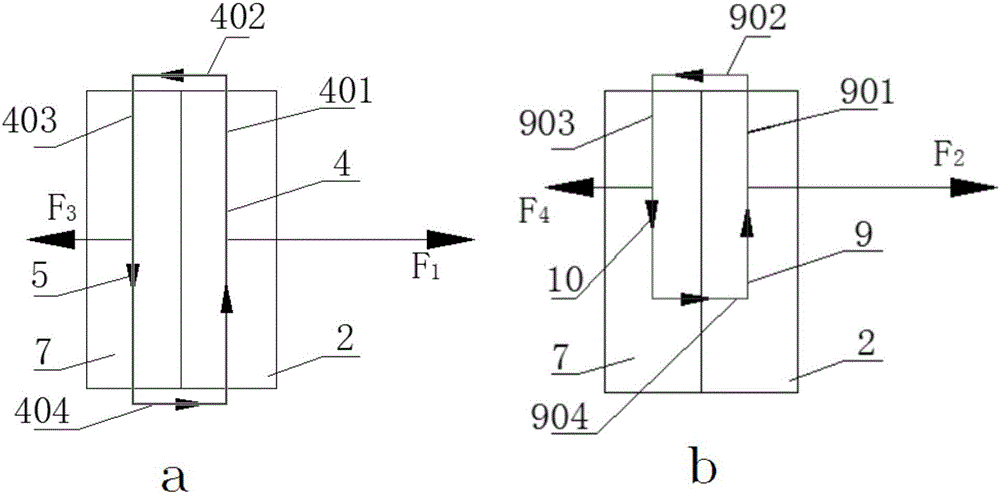

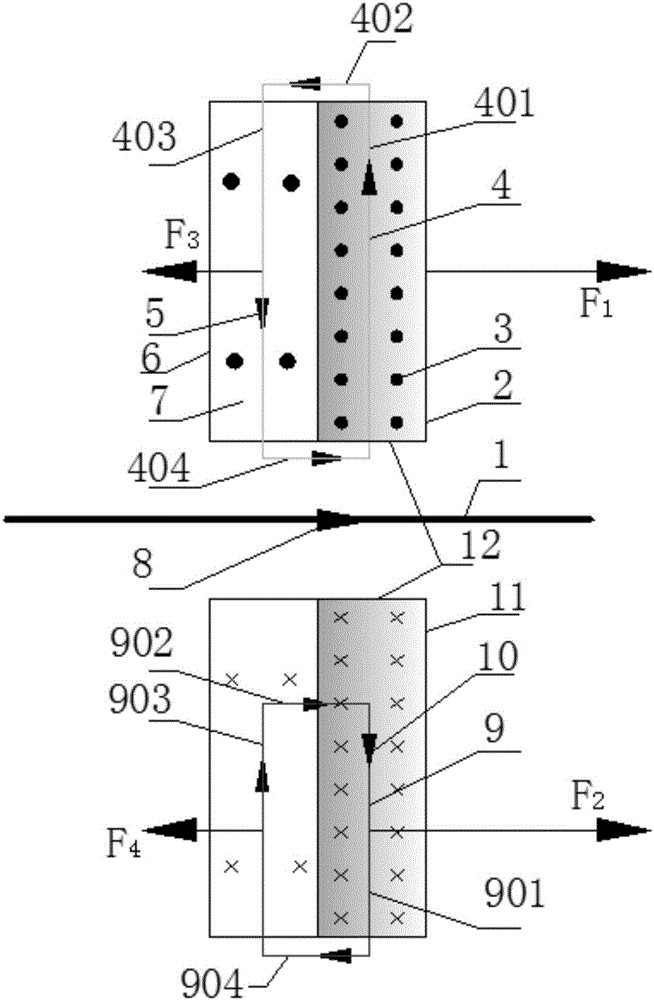

[0036] see figure 1 — Figure 7 , the double-coil magnetic driving device of the high-voltage transmission line operation robot uses the ampere force of the magnetic field generated by the high-voltage wire current 8 on the current-carrying wire to make the driving body 12 move; the driving body 12 includes two identical structures that can be opened and closed. The upper drive body 6 and the lower drive body 11 are arranged on the upper and lower sides of the high-voltage wire 1. The upper drive body 6 is composed of a magnetic core 2, a layer 7, a large rectangular coil 4, and a small rectangular coil 9.

[0037] join Figure 4 , the magnetic core 2 is in the shape of a semicircular tube, made of strong magnetically permeable material, used to strengthen the magnetic field generated by the high-voltage wire current 8, and has a radial guide hole 201 and an axial guide hole 202 through the magnetic core. The function of the radial guide hole 201 of the magnetic core is to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com