Hydrodynamic suspension bearing for artificial heart

A suspension bearing and artificial heart technology, applied in the direction of suction equipment, etc., can solve the problems of increasing the complexity of the control system, and achieve the effects of reducing additional weight, avoiding design, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

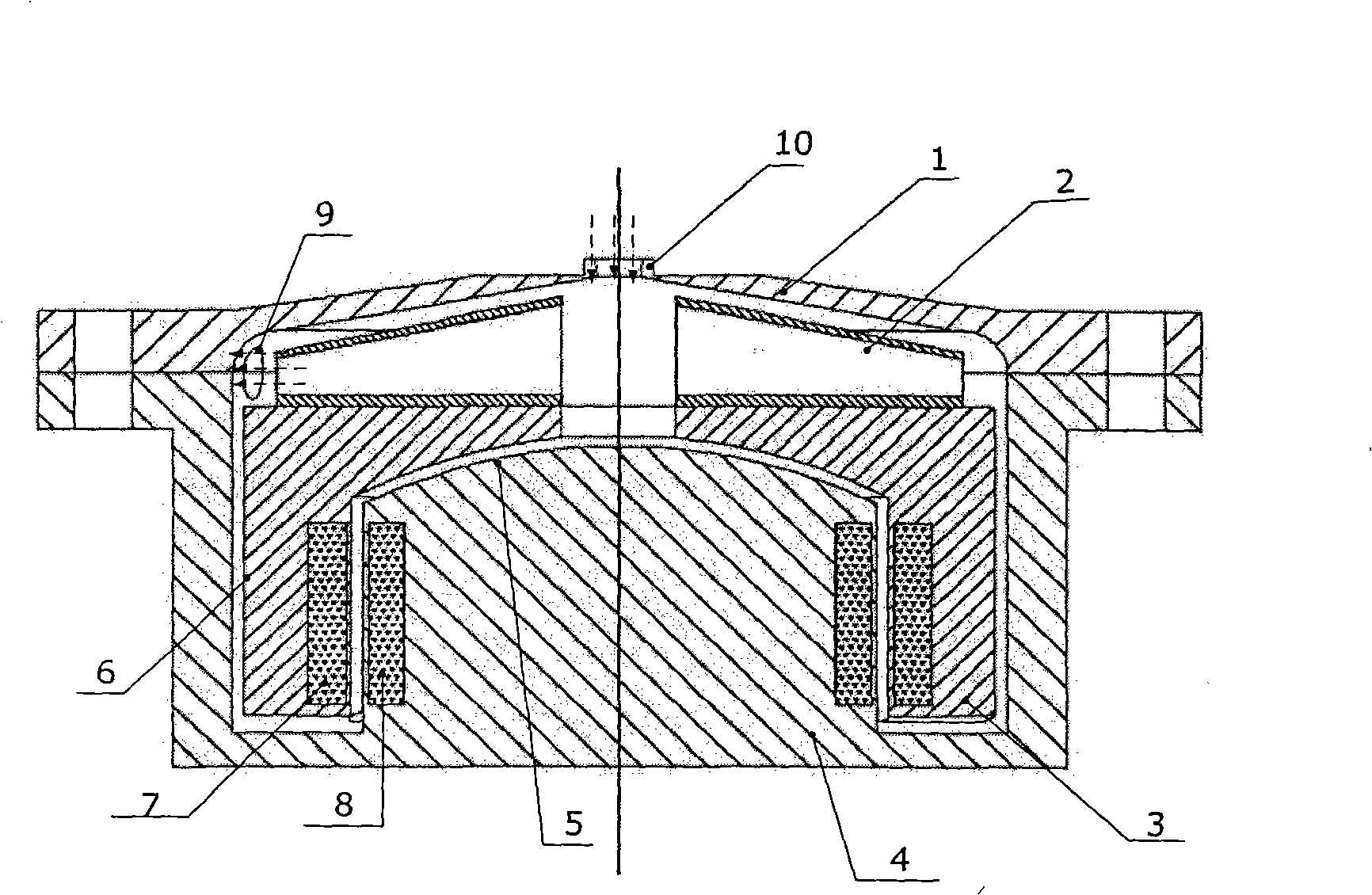

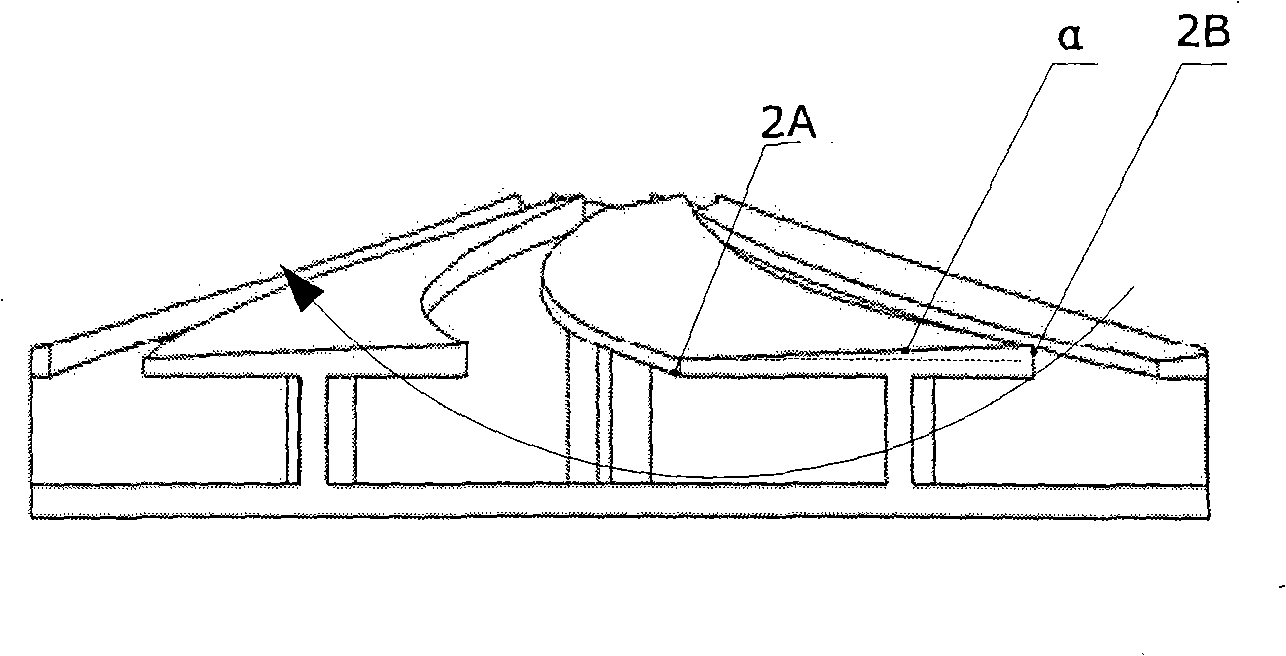

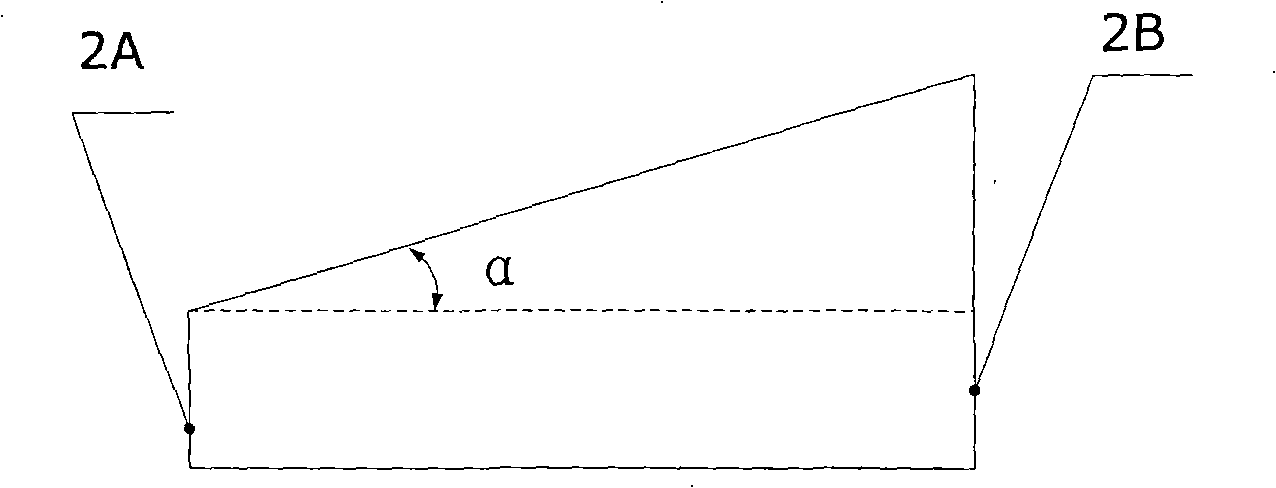

[0020] Such as figure 1 As shown, the present invention includes a pump casing 1 and an impeller 2, a rotor 3, a stator 4, a permanent magnetic steel 7 and an electromagnetic coil 8; the rotor 3 whose inner top surface is arc-shaped is embedded in the stator 4 whose top is arc-shaped. In the groove, the ring-shaped permanent magnetic steel 7 is installed on the inner ring of the rotor 3, the electromagnetic coil 8 is fixed on the outer ring of the stator 4, the top of the stator 4 has a variable pitch helical groove 5, and the outer ring of the rotor 3 has an equal pitch Spiral groove 6, impeller 2 is installed on the top surface of rotor 3, impeller 2 is installed in pump casing 1, pump casing 1 and stator 4 are connected as one; blood flows in from pump casing inlet 10, and most of the blood flows from The outlet 9 of the pump casing flows out, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com