Automobile automatic transmission liquid composition with excellent anti-wear property

A technology of automatic transmission fluid and composition, applied in lubricating compositions, petroleum industry, additives, etc., can solve the problems of undiscovered public reports and patent authorization, insufficient attention to the anti-wear performance of automobile automatic transmission fluid, etc., and achieve good economic benefits and social benefits, excellent wear resistance, wide application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

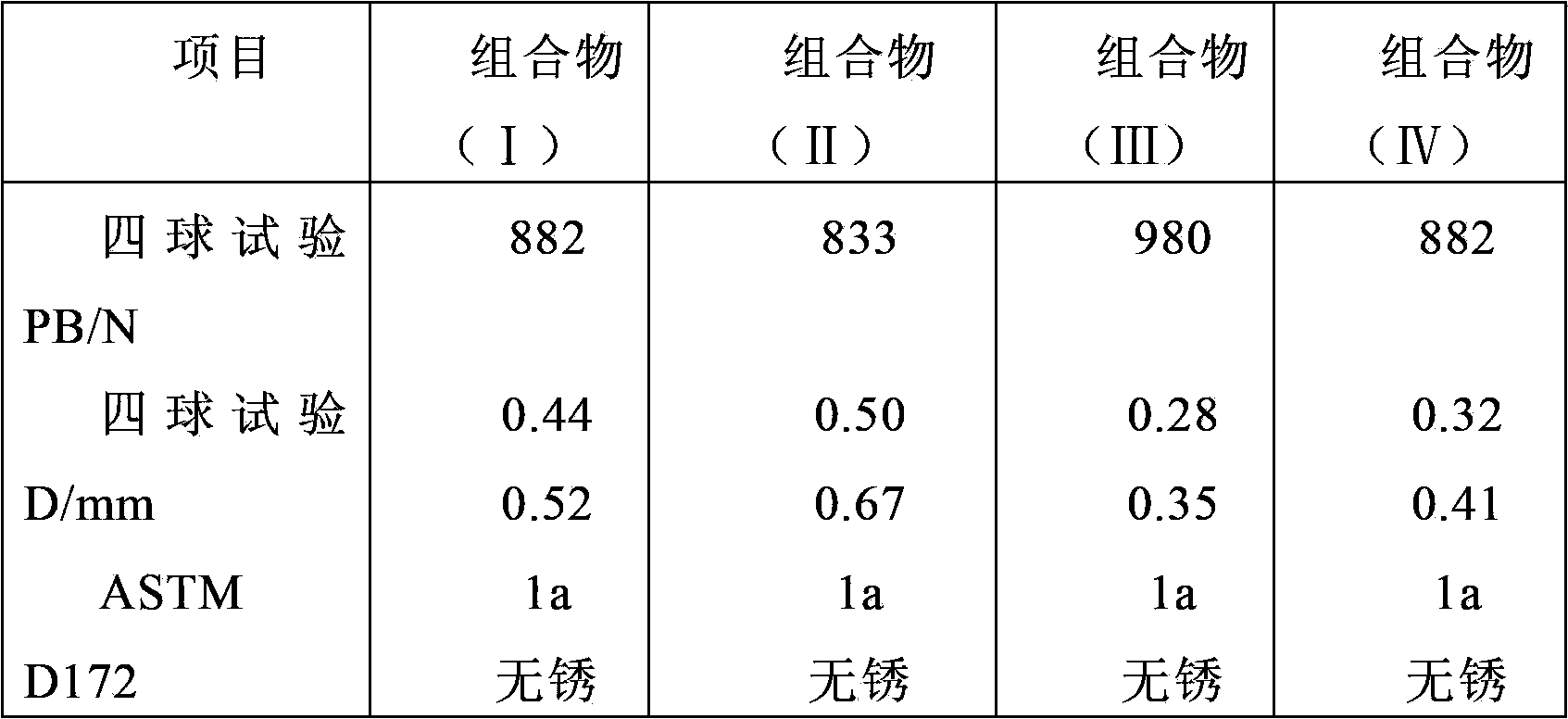

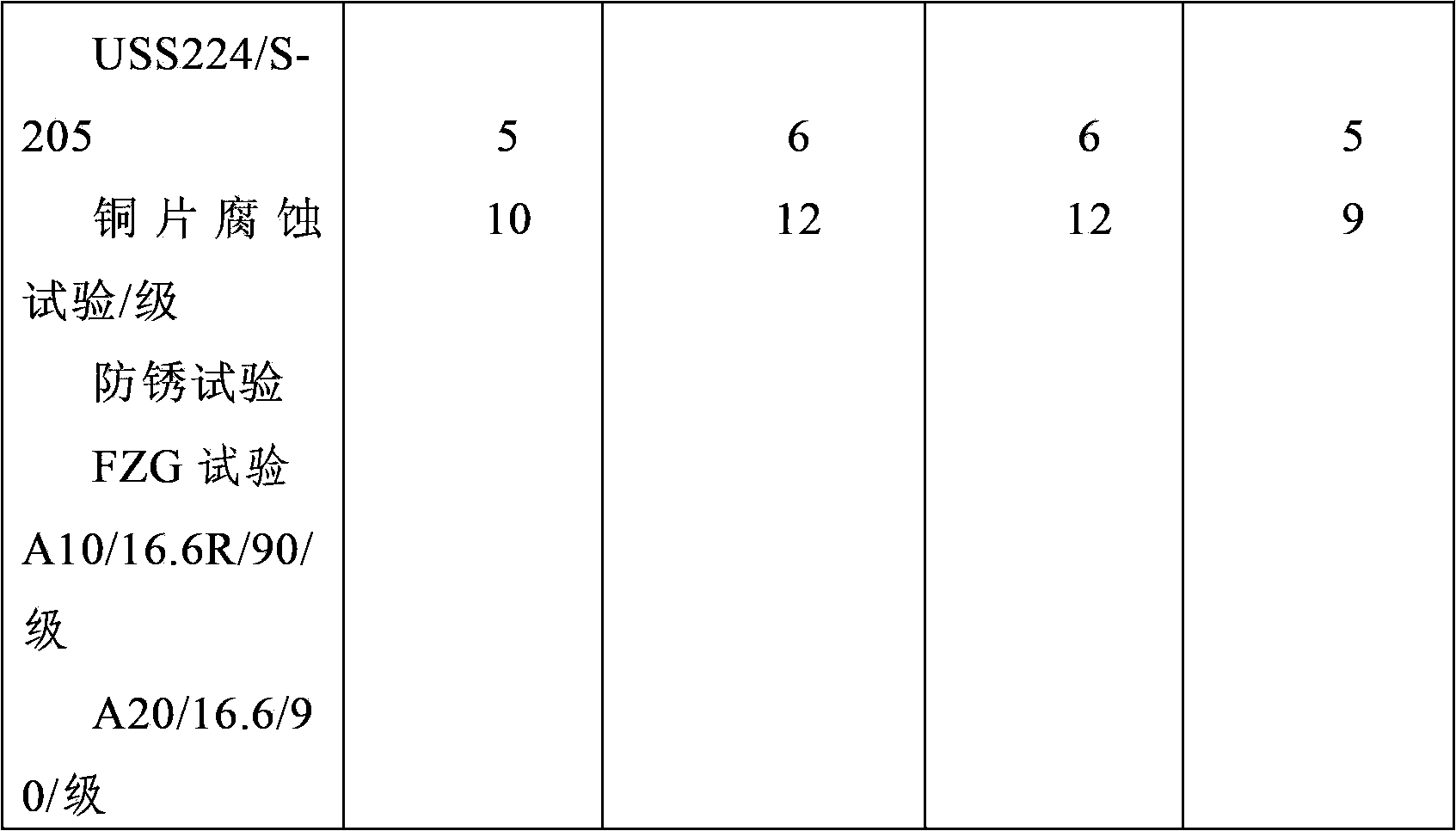

Embodiment 1

[0022] Lubricating oil composition (I), it comprises: 32.0wt% hydroisomerization dewaxing III type base oil No. 4 oil, 32.0wt% poly-olefin synthetic oil PAO4, 20.0wt% diester synthetic oil ( Component A); 8.0wt% polymethacrylate (component B) with a molecular weight of 800; 1.0wt% polya-olefin (component C); 0.8wt% tricresyl phosphate (component D); 0.50 wt% base number 300mgKOH / g calcium alkyl salicylate (component E); 4.7wt% borophosphated monopolyisobutylene succinimide (component F); 0.30wt% di-n-octyldi Thiocarbamate, 0.30 wt% dinonyl diphenylamine (component G); 0.30 wt% monooctadecyl phosphonate (component H); 0.10 wt% octadecyl thiadi Azole (Component I). Lubricating oil composition (II) is the same as composition (I) except that 0.8wt% tricresyl phosphate in component (D) is replaced by 0.8wt% tricresyl thiophosphate. Lubricating oil composition (Ⅲ) is the same as composition (Ⅰ) except that 0.8wt% tricresyl phosphate in component (D) is replaced by 0.8wt% di-n-dode...

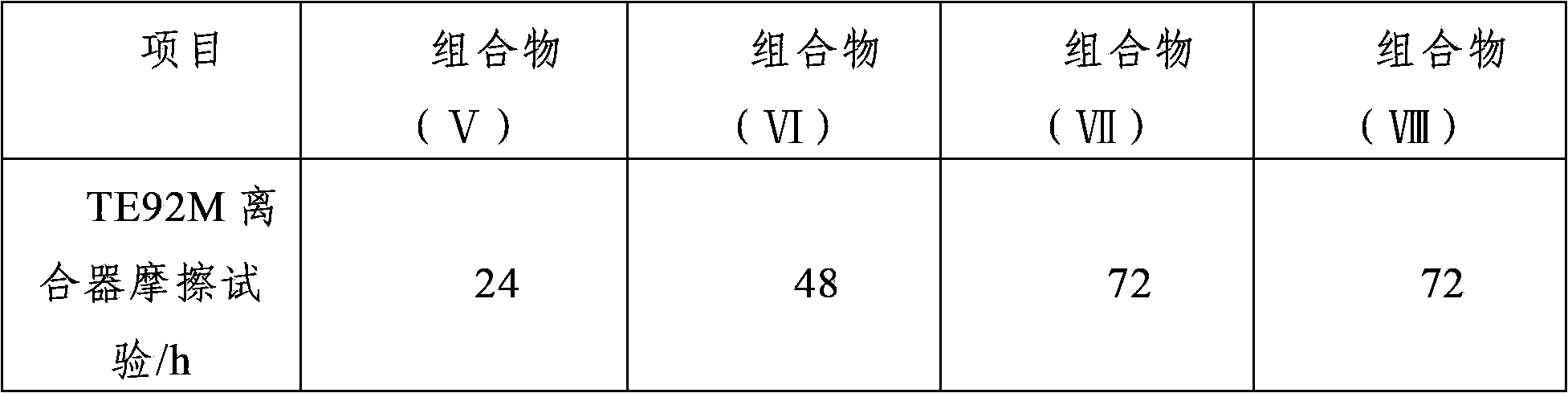

Embodiment 2

[0028] Lubricating oil composition (Ⅴ), it comprises: 84.75wt% hydroisomerization dewaxed type III base oil No. 6 oil (component A); 4.0wt% polymethacrylate (component B) of molecular weight 800 1.5wt% poly-olefin (component C); 0.5wt% di-n-butyl monothiophosphate fatty amine salt (component D); Component E); 7.0wt% of monopolyisobutylene succinimide (component F); 0.30wt% of 2,6-di-tert-butyl-p-cresol, 0.25wt% of di-n-dodecyl di Thiocarbamate, 0.25 wt% n-butyl n-octyl diphenylamine (component G); 0.30 wt% borated glycerol oleate, 0.10 wt% monooctadecyl phosphonate , 0.10wt% di(octadecyl) alkyl phosphite (component H); 0.05wt% thiadiazole dodecyl mercaptan formaldehyde condensate, 0.05wt% thiadiazole dimer, 0.05 wt% of thiadiazole stearylamine formaldehyde condensate (component I). Lubricating oil composition (VI) is the same as composition (V) except that 7.0 wt% of monopolyisobutylene succinimide in component (F) is replaced by 7.0 wt% of bispolyisobutylene succinimide. T...

Embodiment 3

[0033] Lubricating oil composition (IX), it comprises: the polyalkene synthetic oil PAO4 of 68.64wt%, the polyol ester synthetic oil (component A) of 17.16wt%; The polymethacrylate of 10.0wt% molecular weight 800 ( Component B); 0.10wt% polya-olefin (component C); 0.30wt% di-n-octyl monothiophosphate fatty amine salt (component D); 0.10wt% alkali value 40mgKOH / g alkyl Calcium sulfonate (component E); 3.0 wt% boron phosphating bispolyisobutylene succinimide (component F); 0.10 wt% 2,6-di-tert-butylphenol substituted n-butyl acrylate, 0.10 wt% 2,6-di-tert-butylphenol substituted isooctyl acrylate, 0.10wt% 2,6-di-tert-butylphenol substituted dodecyl acrylate (component G); 0.30wt% boronated Ethylene glycol oleate (component H); 0.10 wt% dodecylthiadiazole (component I). Lubricating oil composition (X) except component (H) 0.30wt% borated ethylene glycol oleate is replaced by 0.15wt% borated ethylene glycol oleate and 0.15wt% dioctadecyl Except for the replacement of phosphite, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com