Single-roller bit with PDC (polycrystalline diamond compact) composite plates

A single-cone, composite piece technology, applied in drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of affecting the crushing efficiency, unfavorable cutting rock efficiency, not improving the cutting and crushing rock efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

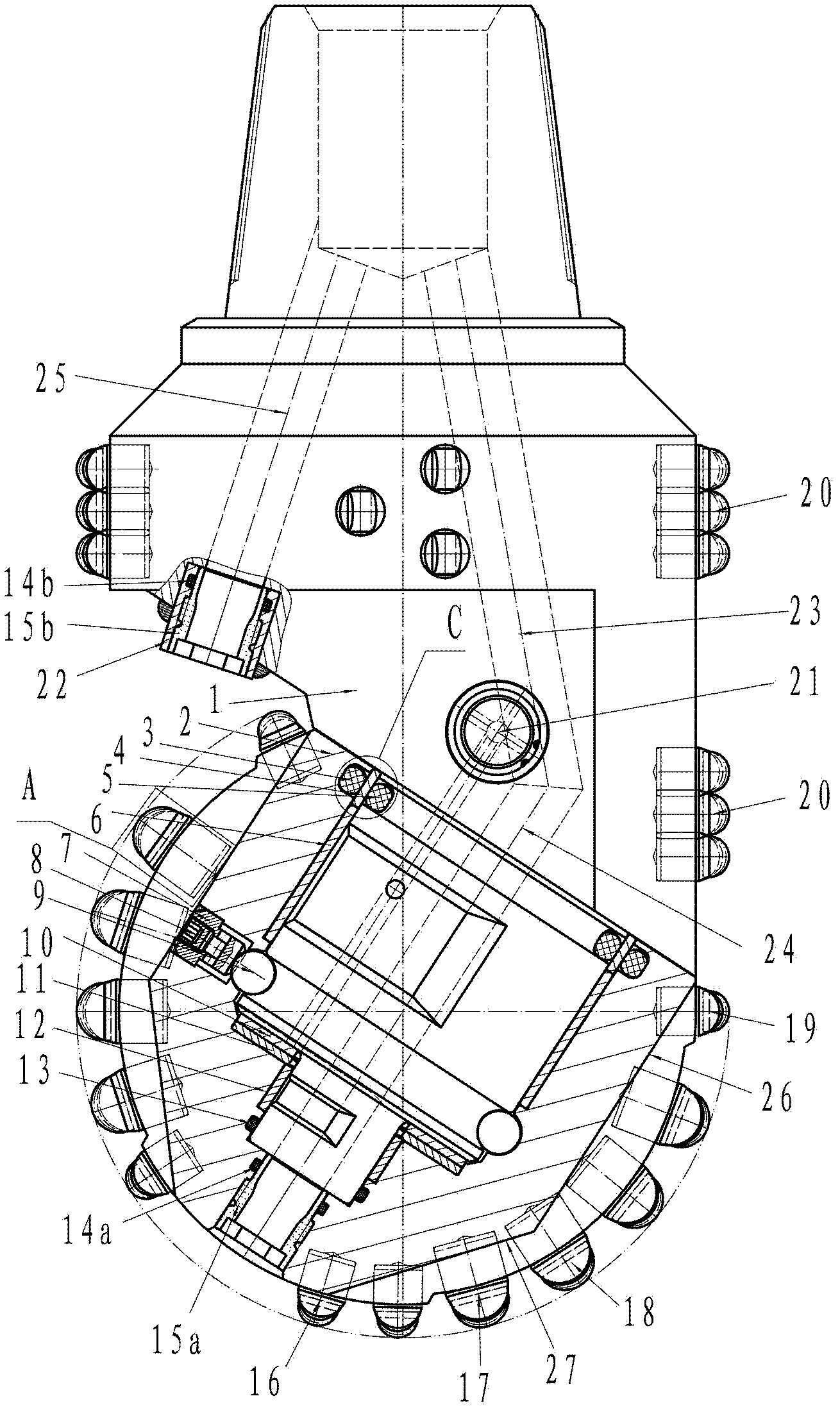

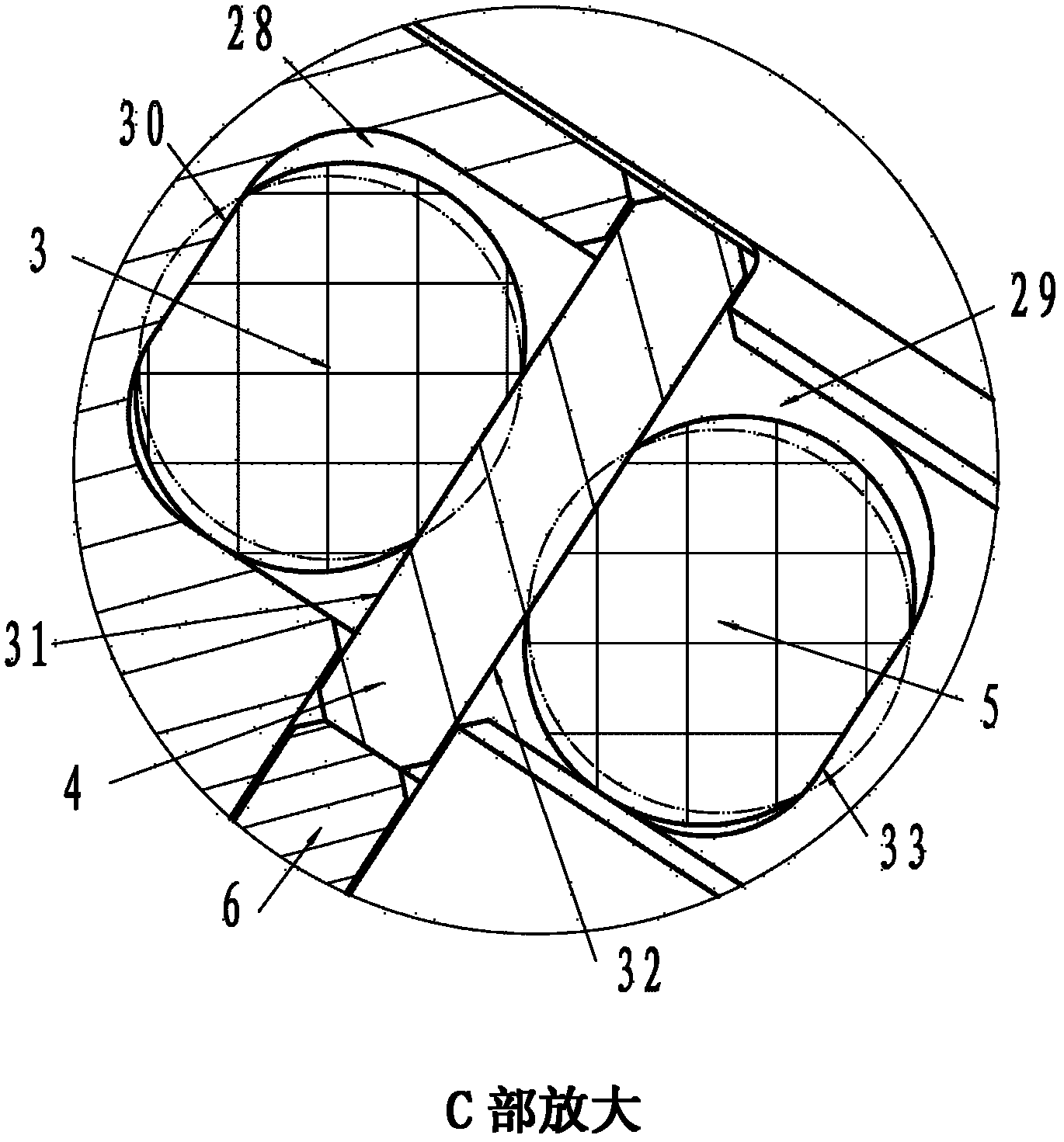

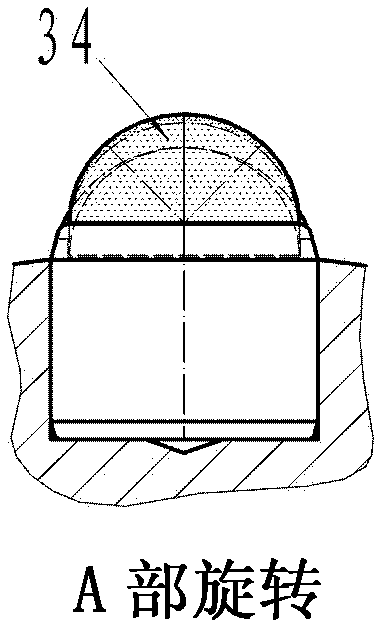

[0017] Embodiment 1: The cone (2) is installed in the upper gap of the drill body (1), the lower end of the drill body (1) is provided with a journal groove (29), and the shaft O-ring (5) is installed in the journal groove (29), There is a shaft groove diameter (33) on the minimum outer circle of the journal groove (29), and the floating ring (4) is installed with interference on the maximum outer diameter of the O-ring (5), and the outer surface of the floating ring (4) is provided with an outer ring. The diameter surface (31), the outer circular surface of the floating ring (4) is provided with the ring inner diameter surface (32), the lower end gap of the floating ring (4) is installed with the large shaft sleeve (6), and the bottom end of the drill bit body (1) is successively gapped The upper thrust pad (10), the lower thrust pad (11) and the small shaft sleeve (12) are installed, and the large end of the inner hole of the cone (2) is provided with a cone groove (28), and ...

Embodiment 2

[0018]Embodiment 2: the cone (2) is installed in the upper gap of the drill bit body (1), the lower end of the drill bit body (1) is provided with a journal groove (29), and the shaft O-ring (5) is installed in the journal groove (29), There is a shaft groove diameter (33) on the minimum outer circle of the journal groove (29), and the floating ring (4) is installed with interference on the maximum outer diameter of the O-ring (5), and the outer surface of the floating ring (4) is provided with an outer ring. The diameter surface (31), the outer circular surface of the floating ring (4) is processed with a ring inner diameter surface (32), the lower end of the floating ring (4) is equipped with a large shaft sleeve (6), and the bottom end of the drill body (1) is sequentially gapped The upper thrust pad (10), the lower thrust pad (11) and the small shaft sleeve (12) are installed, and the large end of the inner hole of the cone (2) is provided with a cone groove (28), and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com