Rotary transducer with monitoring of the bearing wear and method therefor

An automatic synchronization and transmitter technology, which is applied to bearings, bearing assembly, bearing components, etc., can solve the problem of not being able to reliably and accurately predict the mechanical failure of the detector, and achieve the effect of low design cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

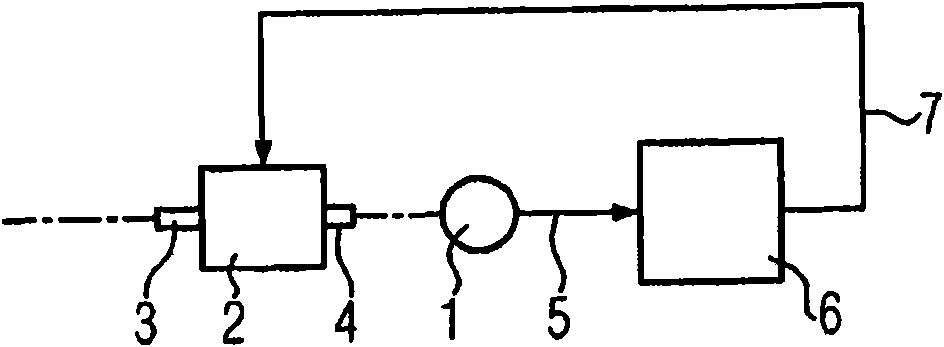

[0046] exist figure 1 A typical use of the automatic synchronization transmitter 1 is shown in . Actuator 2, such as electric motor utilizes its drive shaft 3 to drive the working machine (in figure 1 not shown). The drive machine can, for example, be built in a paper machine and run continuously at 1500 rpm and thus produce 0.78×10 9 turn / year.

[0047] The automatic synchronizing transmitter 1 is connected to the drive shaft 3, or as in figure 1 Shown in is connected to a second drive shaft 4, which is generally rotationally fixedly connected to the first drive shaft 3.

[0048] Automatic synchronization transmitter 1 converts the angular position and / or angular velocity of drive shaft 3 or 4 into electrical signals and feeds these values via line 5 to controller 6 . The regulator 6 derives a control signal from the measurement signal, which is used via a line 7 to control the actuator 2 in order to maintain a predetermined desired value. In the case of a paper machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com