Lithium ion battery hot-press formation clamp

A lithium-ion battery and fixture technology, applied in non-aqueous electrolyte batteries, electrolyte battery manufacturing, sustainable manufacturing/processing, etc., can solve the problems of limited number of batteries, waste, and impact on battery performance, and achieve improved automation and simplification. Manufacturing process, the effect of shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the examples and the accompanying drawings, but the implementation of the present invention is not limited thereto.

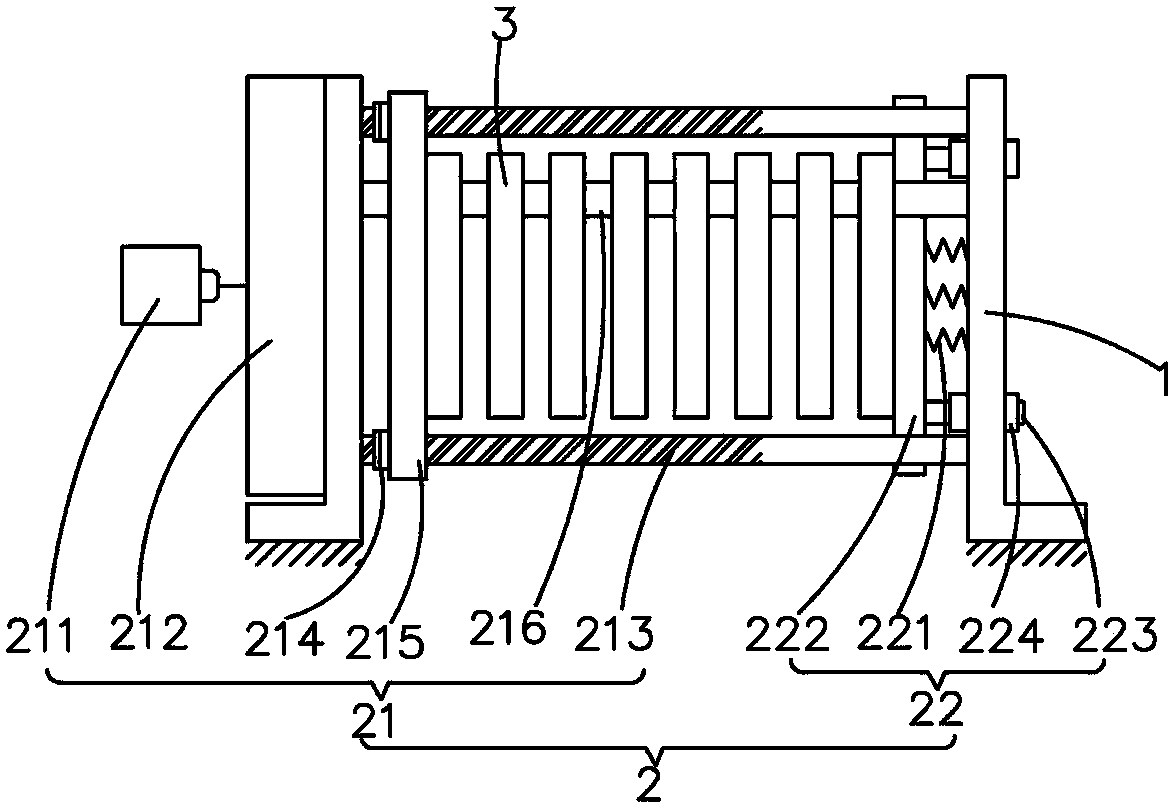

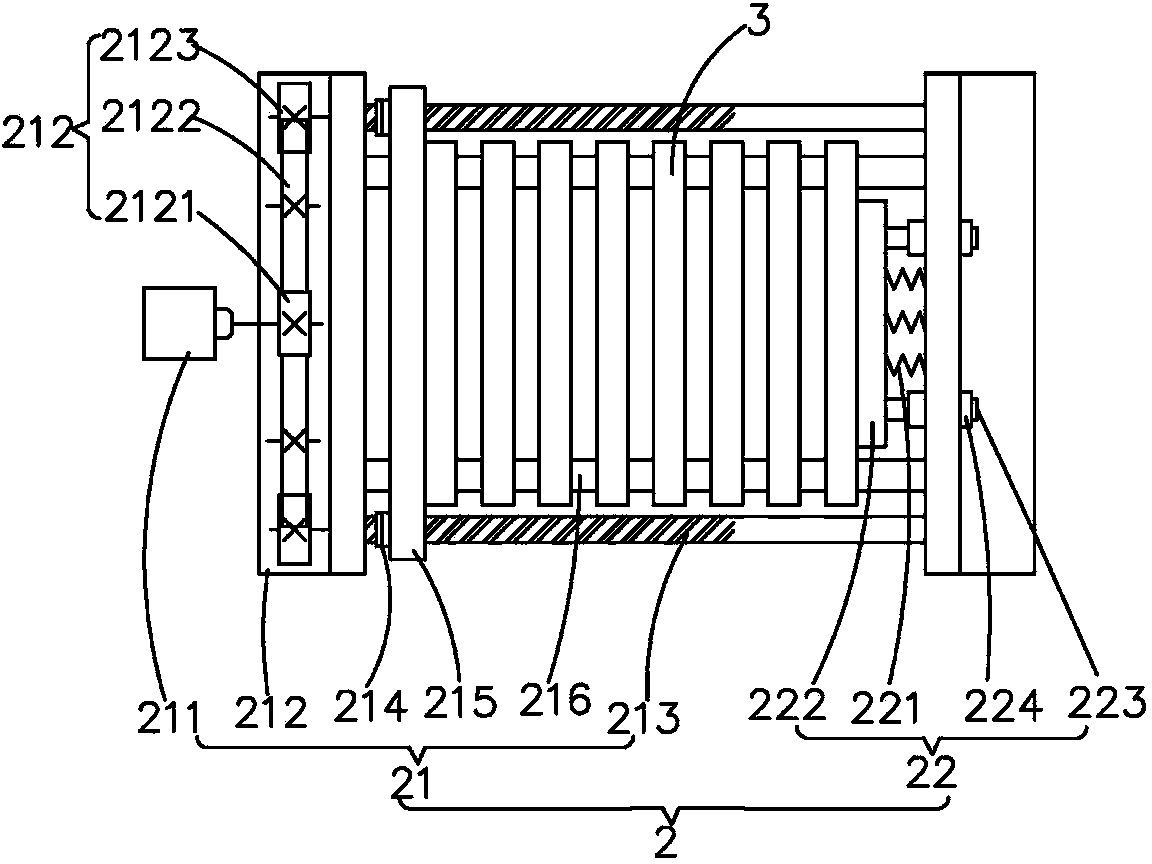

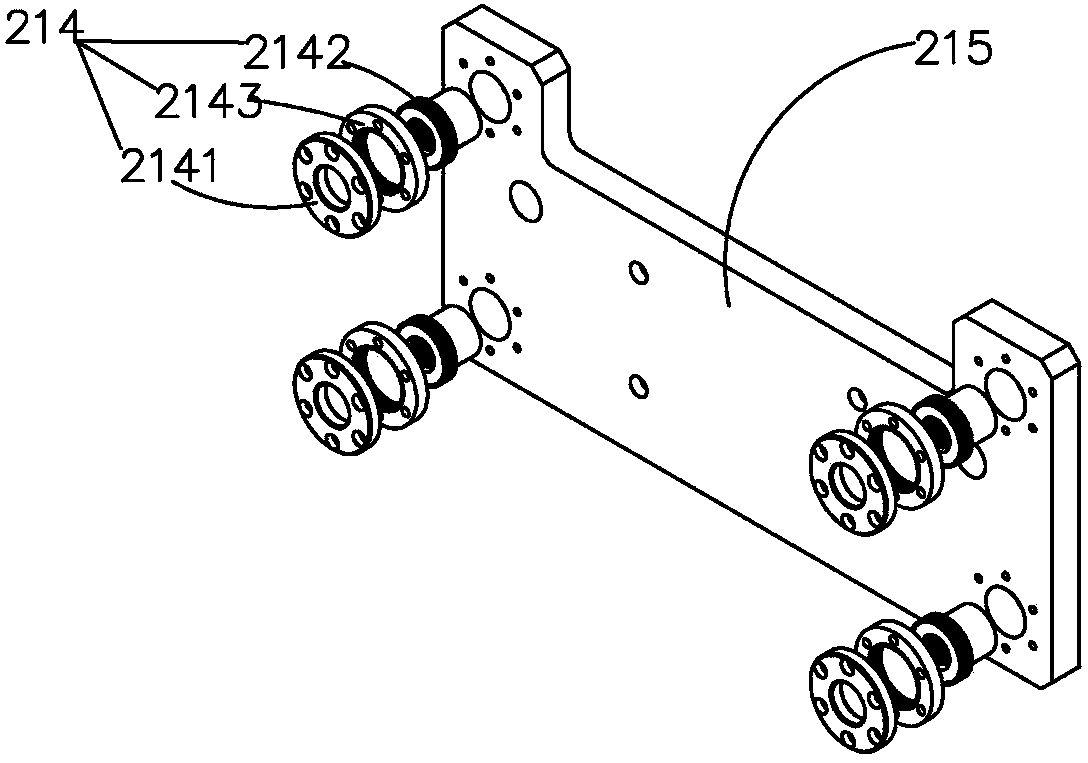

[0030] refer to Figure 1 to Figure 10 , a lithium-ion battery hot-pressing forming fixture provided by the present invention includes a fixed seat 1, a power device 2, a plurality of laminates 3, a heating device 4, a forming device 5 and a lithium-ion battery 6, and the adjacent laminates 3 are placed between The lithium ion battery 6 is inserted into the lithium ion battery 6, the heating device 4 and the formation device 5 are arranged on the laminate 3, the heating device 4 provides heat for rapidly heating the lithium ion battery 6, the formation device 5 performs formation on the lithium ion battery 6, and the power unit 2 is arranged on the on the fixed seat 1, and apply pressure to the lithium-ion battery 6 between the laminates 3, so that the gas generated by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com