Automatic hooking device of freight ropeway

The technology of a hook device and a freight ropeway is applied in the field of freight ropeway, which can solve the problems of increased labor intensity of staff, low ropeway transportation efficiency, complicated operation, etc., and achieves convenient processing, production, installation and layout, reduction of labor intensity, and convenient operation and operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

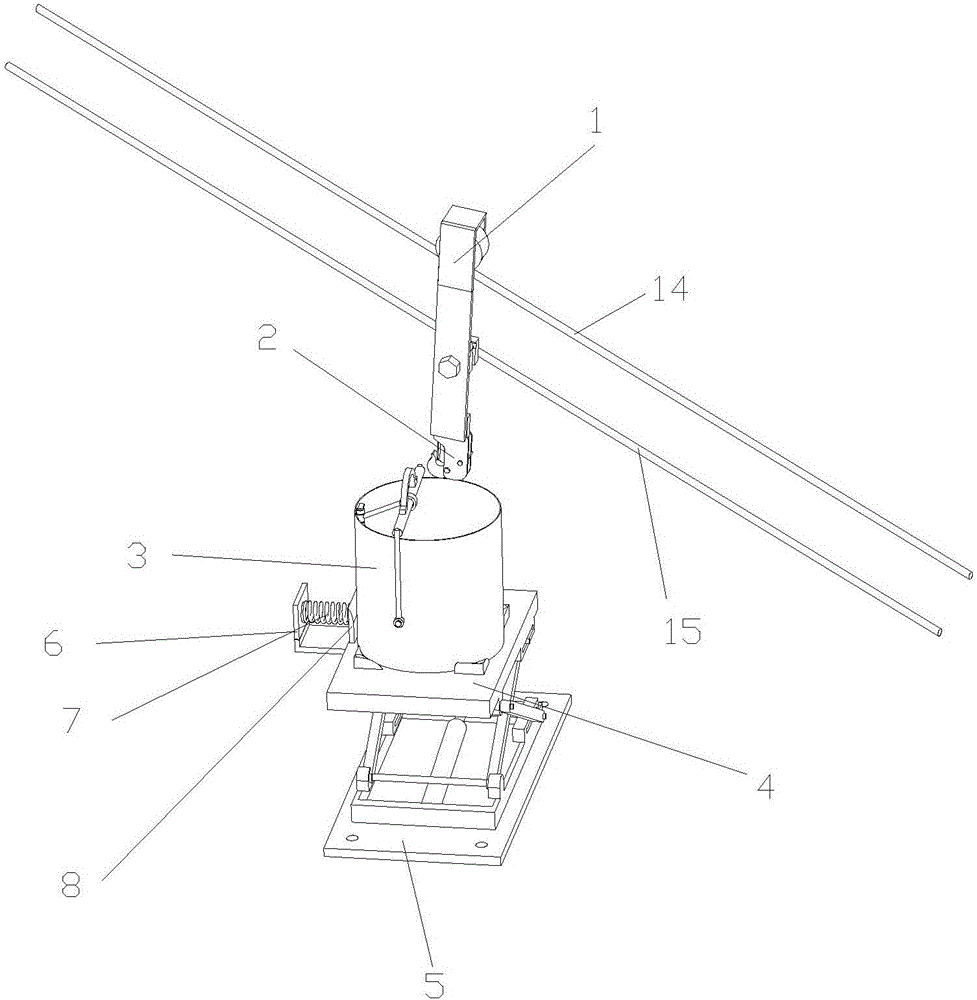

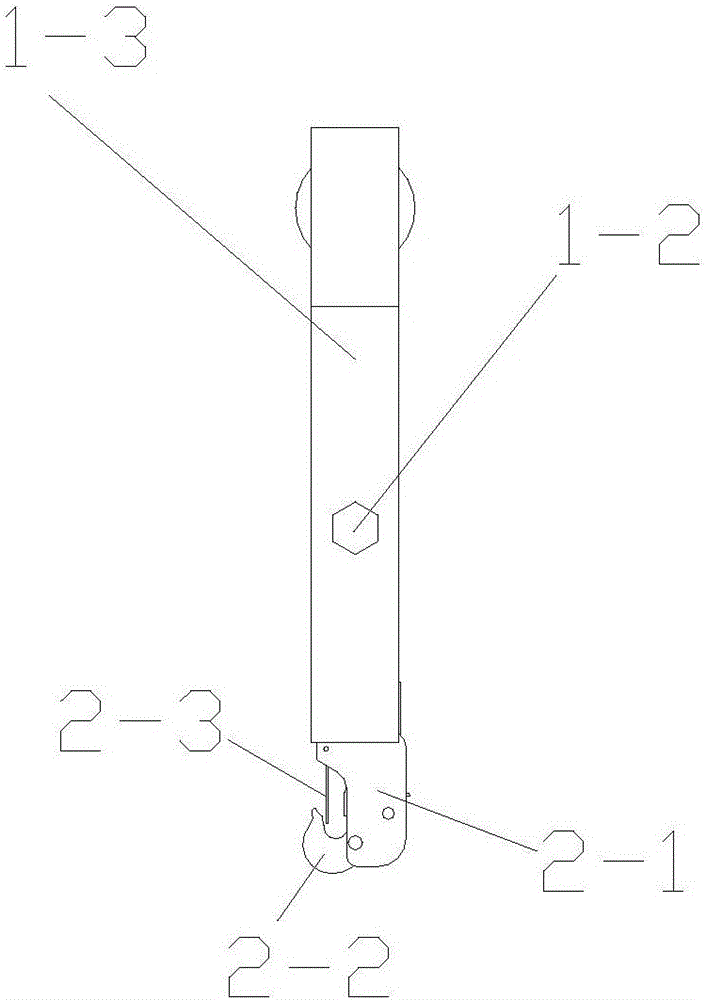

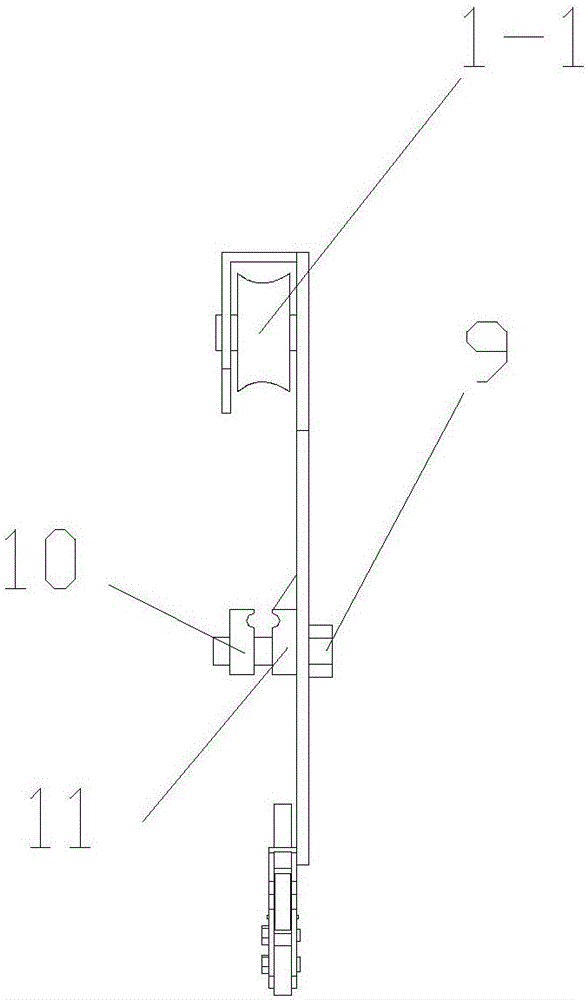

[0049] Such as figure 1 with Figure 4 As shown, the present invention includes a traveling mechanism 1, a self-locking hook mechanism 2 arranged on the traveling mechanism 1 and a barrel mechanism 3 that can be hooked on the self-locking hook mechanism 2, and a barrel mechanism 3 for holding the barrel. And the installation platform 4 that can go up and down in the vertical direction and the limit mechanism that limits the lifting height of the installation platform 4, the barrel mechanism 3 includes a barrel 3-1 for containing materials and a barrel mounted on the barrel. 3-1 and deviate from the center of the barrel 3-1, the self-locking hook mechanism 2 includes a connecting plate 2-1 installed at the bottom of the traveling mechanism 1, and a hook installed at the bottom of the connecting plate 2-1. 2-2 and a self-locking part 2-3 arranged above the connecting plate 2-1 and extending vertically into the hook 2-2, the installation platform 4 includes a horizontal The lai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com