Automatic glue spreading and veneering device and method for production of wood-plastic floorboards

A wood-plastic floor and veneer technology, which is applied in the field of automatic gluing and veneer devices, can solve problems such as lack of automation, and achieve the effects of convenient operation, high production efficiency, accurate veneer and stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

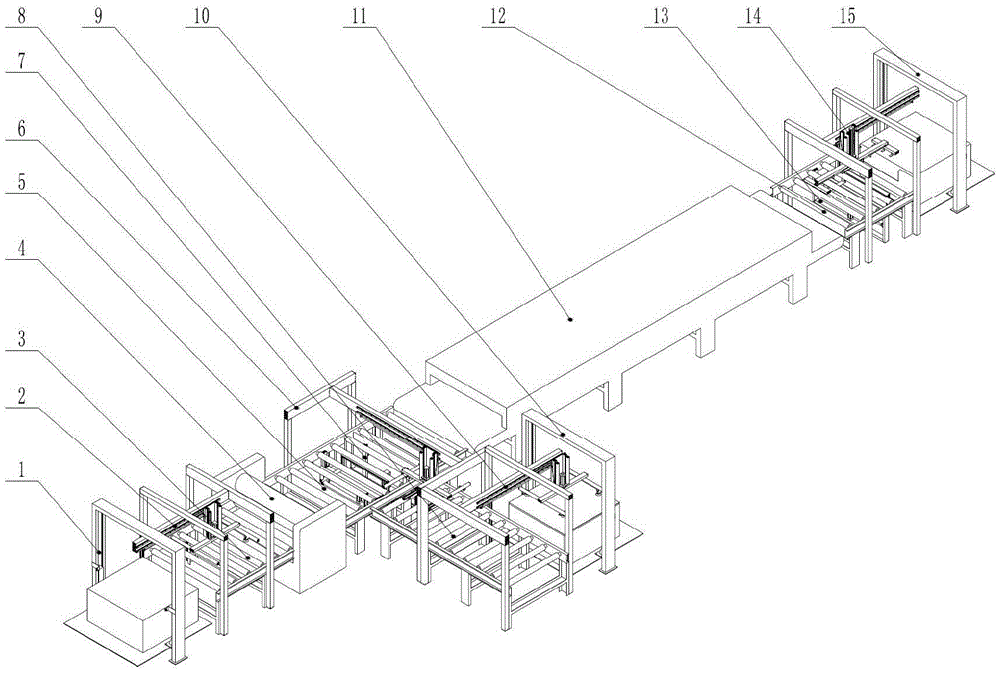

[0034] combine figure 1 , an automatic gluing and veneering device for the production of wood-plastic flooring according to the present embodiment, comprising a bottom plate feeding device, a gluing machine 4, a panel feeding device, a veneering device, a dryer 11 and a stacking device, Fully automatic work, automatic loading and unloading, automatic gluing, automatic veneering, high production efficiency, saving time and effort;

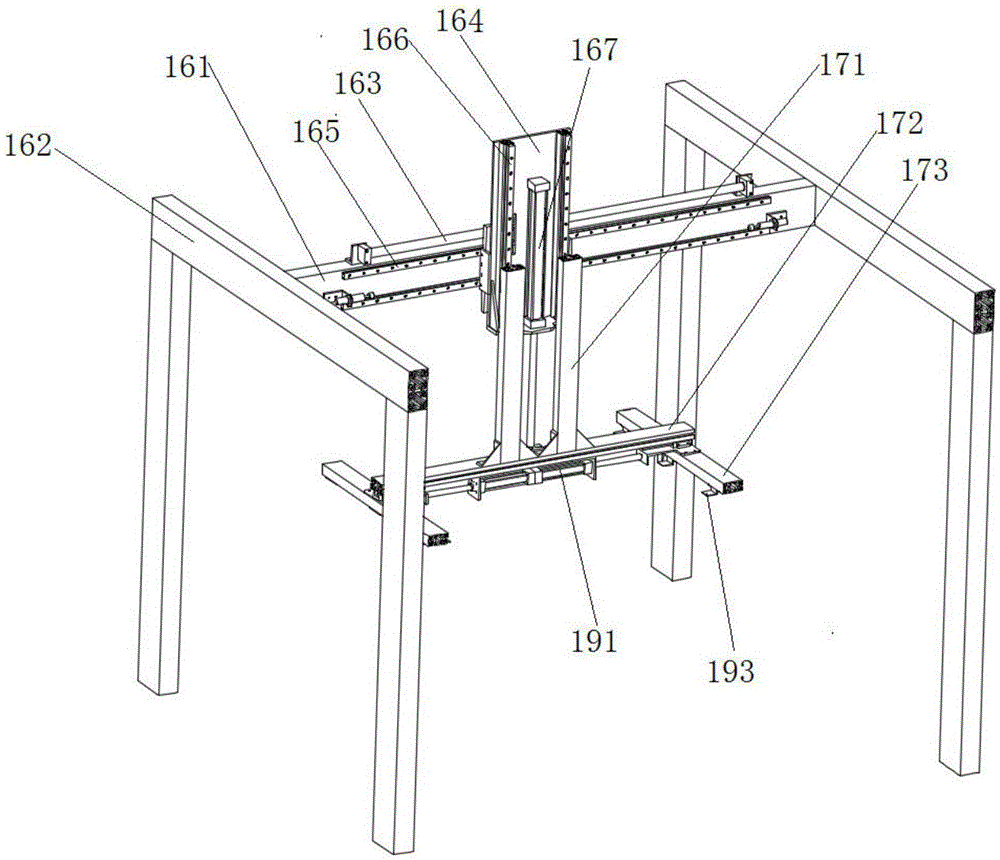

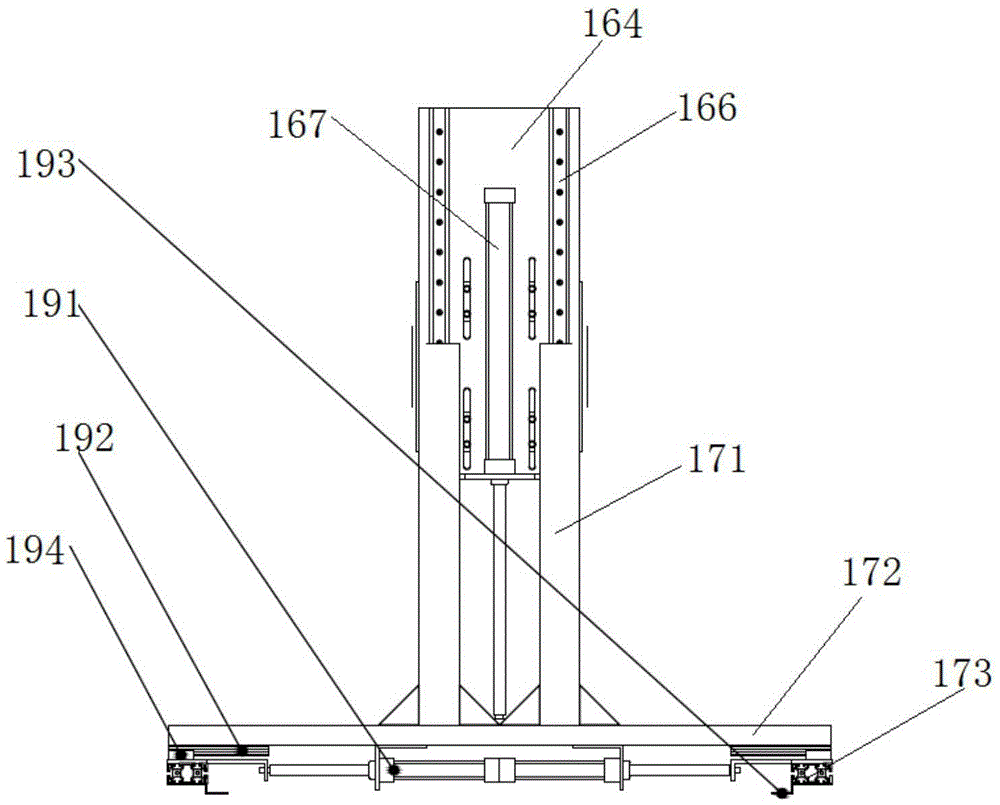

[0035]The bottom plate feeding device includes a bottom plate feeding lifting platform 1, a bottom plate feeding manipulator 3, and a bottom plate stick conveyor 2, and a bottom plate feeding manipulator 3 is arranged between the bottom plate feeding lifting platform 1 and the bottom plate stick conveyor 2; the terminal of the bottom plate stick conveyor 2 Facing the inlet of the glue applicator 4, the outlet of the glue applicator 4 is facing the veneer device; the panel feeding device includes a panel feeding lifting platform 10, a panel feeding m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com