Material delivery-based automobile chassis blanking workshop scheduling method

A car chassis and workshop scheduling technology, applied in the direction of genetic models, genetic rules, instruments, etc., can solve the problems of affecting processing tasks, difficult to grasp the crane, and occupying a large space, so as to reduce the waiting time of processing equipment and maintain population diversity , the effect of the full crossover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

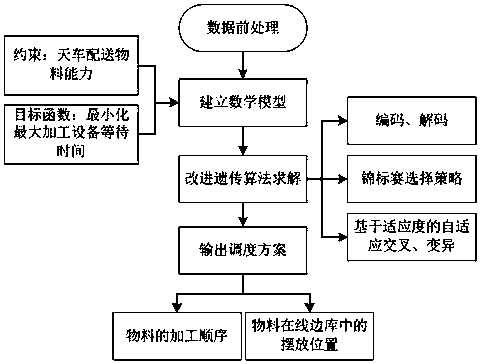

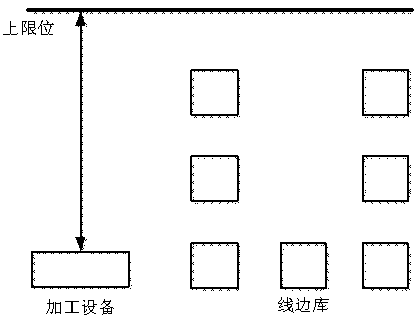

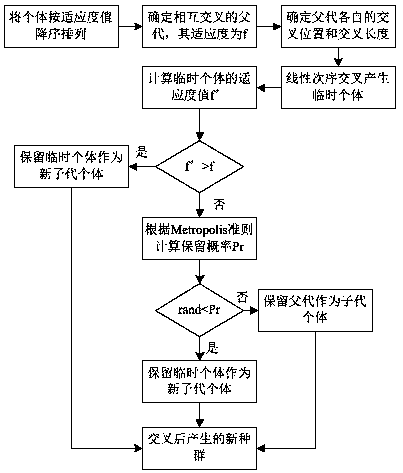

[0034] In this embodiment, a scheduling method for the automobile chassis blanking workshop based on material distribution is to model the scheduling problem of the automobile chassis blanking workshop with limited material distribution capacity and a line side warehouse next to the processing equipment, and then improve the genetic Solve the algorithm to obtain the optimal scheduling plan of the automobile chassis blanking workshop, and optimize the placement of materials in the online side warehouse according to the scheduling plan, so as to shorten the waiting time of processing equipment, improve production efficiency, and achieve continuous and stable production. . Specifically, proceed as follows:

[0035] Step 1. Data preprocessing, counting the types of materials required, and calculating the processing time of each material according to the type, number and processing time of the workpieces to be processed for each material. The processing time of the materials is cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com