Slurry moistening equipment

A kind of equipment and technology of dipping paste, applied in casting and forming equipment, metal processing equipment, tools, etc., can solve the problem of labor force and consumption of paste that cannot be evenly attached to the surface of the workpiece, save the time of loading and unloading, and improve work. Efficiency, saving labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

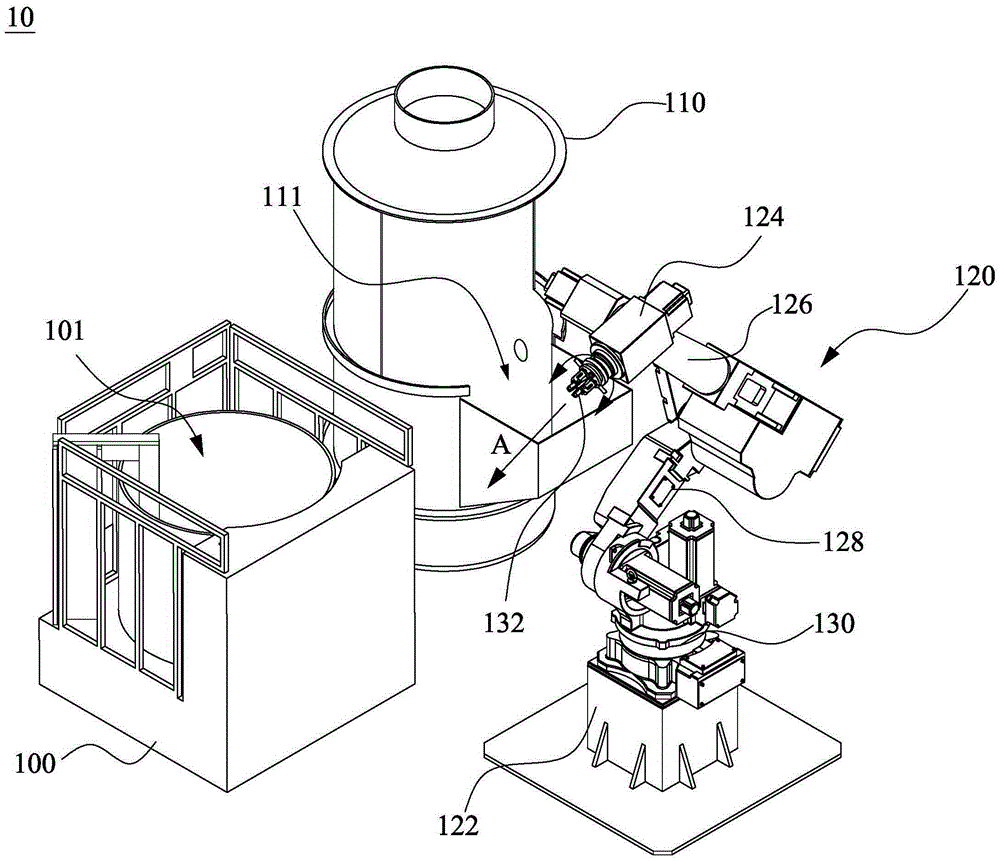

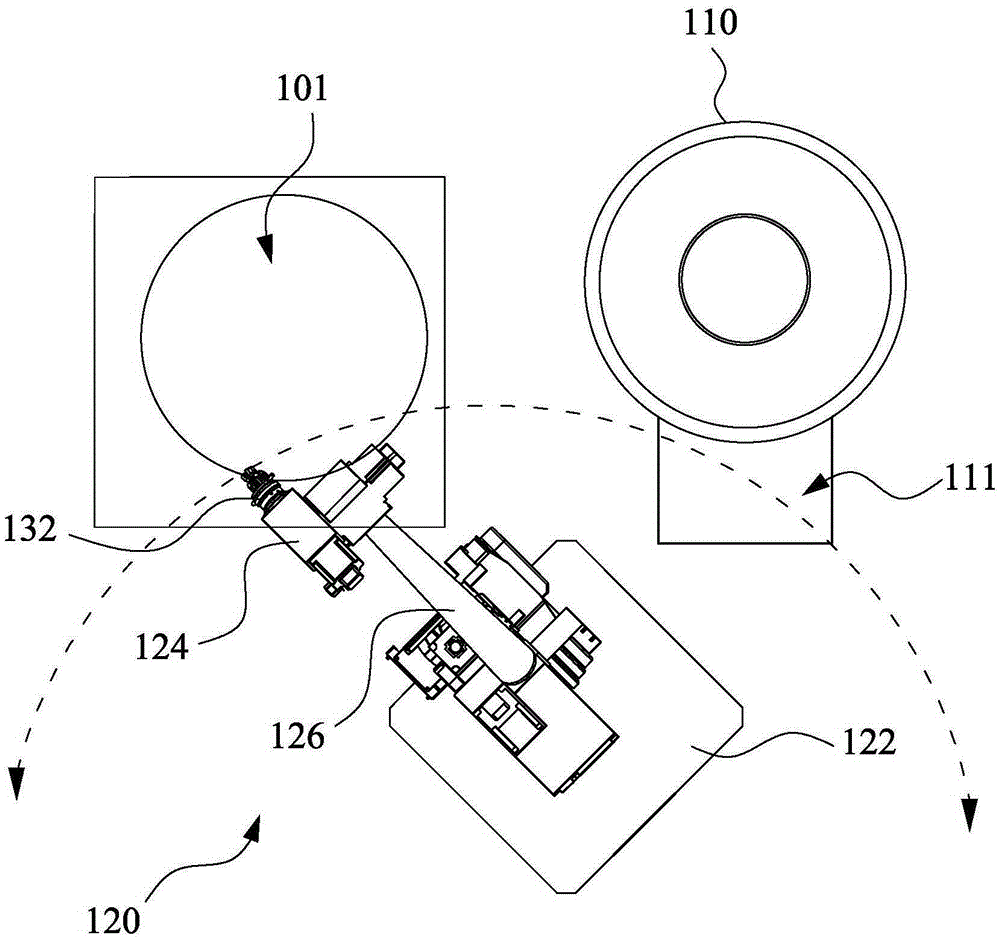

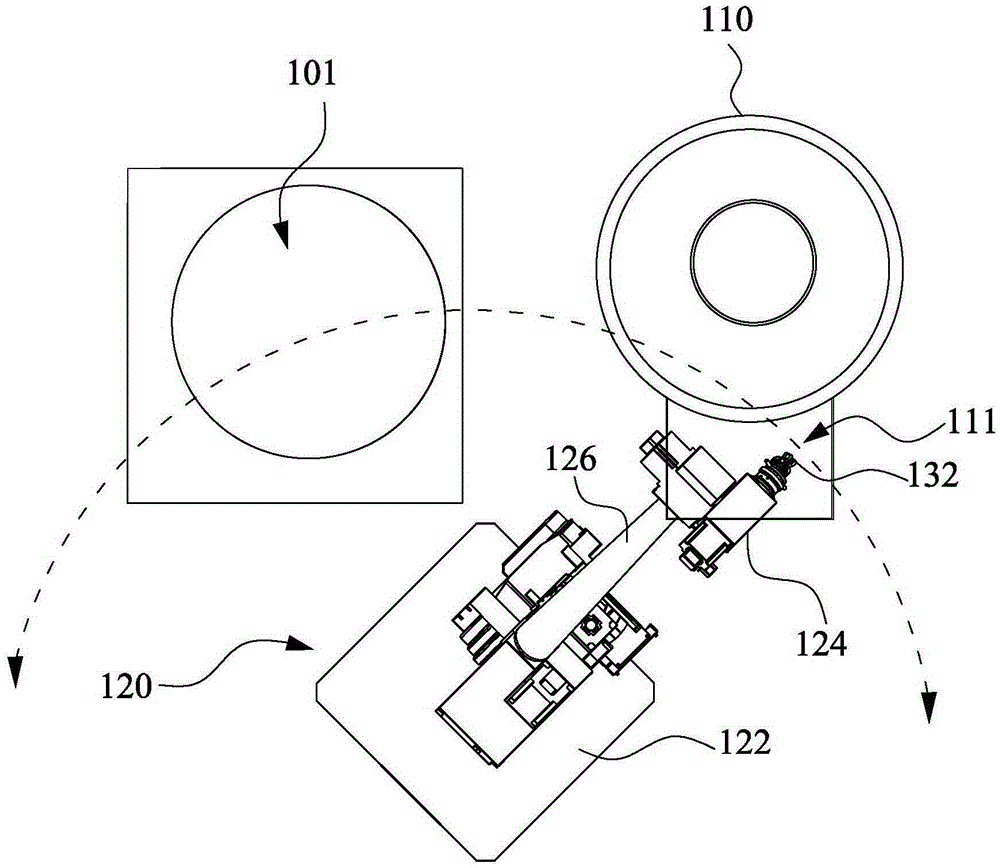

[0025] A number of embodiments of the present invention will be disclosed in the following figures. For the sake of clarity, many practical details will be described together in the following description. It should be understood, however, that these practical details should not be used to limit the invention. That is, in some embodiments of the invention, these practical details are not necessary. In addition, for the sake of simplifying the drawings, some well-known and commonly used structures and elements will be shown in a simple and schematic manner in the drawings.

[0026] In the process of lost-wax casting, a thin-shell mother mold is generally first processed by dipping slurry and sanding for many times, and then the mother mold is melted by heating and poured out from the gate of the shell mold. In this way, the clear shell mold can be used to add casting liquid to complete the casting of the casting. However. Generally, in the process of slurry dipping and sand s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com