Spring double-face polishing device capable of carrying out feeding automatically

A technology of automatic feeding and double-sided grinding, which is applied in the direction of grinding machine, grinding feed movement, grinding workpiece support, etc., can solve the problems affecting the efficiency, affecting the beauty of the spring and the accuracy of the installation, and the injury of the operator, so as to reduce the Work load, productivity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

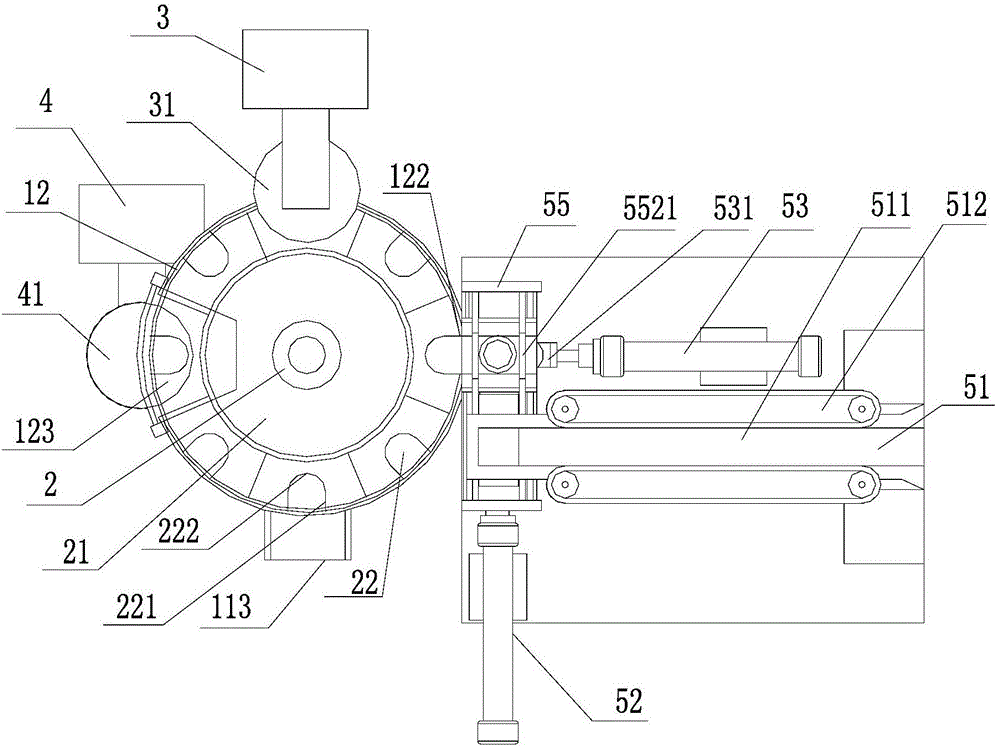

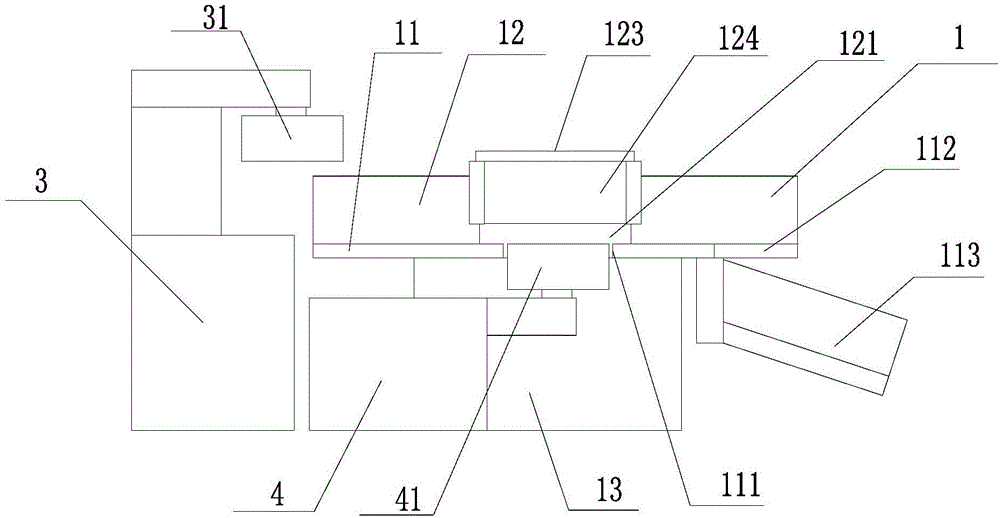

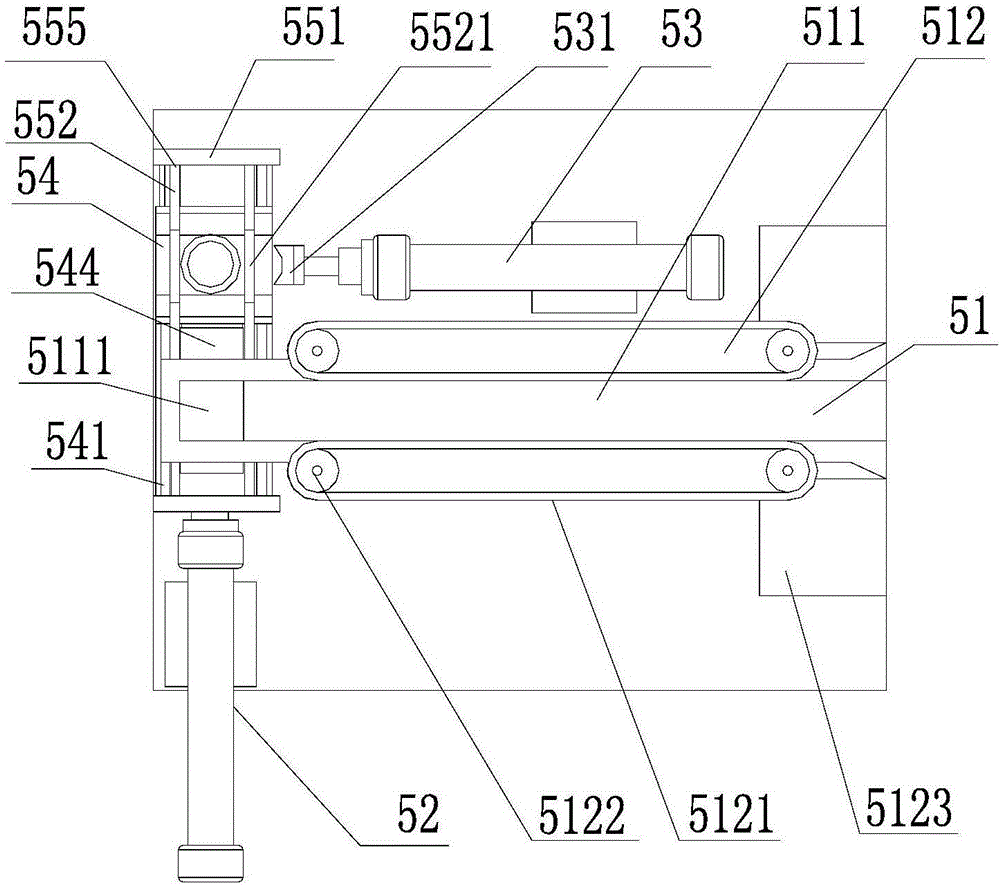

[0025] see Figure 1 to Figure 5 , the present invention is an automatic feeding spring double-sided grinding device, comprising a frame 1, a rotating feeding seat 2, an upper end surface grinding mechanism 3, a lower end surface grinding mechanism 4 and an automatic feeding device 5. A fixed chassis 11 is provided, the outer periphery of the fixed chassis 11 is provided with a blocking frame 12, a mounting cavity 114 is opened at the center of the fixed chassis 11, and a power box 13 is arranged below the fixed chassis 11, and the power box The drive shaft of 13 passes through the installation cavity 114 and is matched with the rotary feeding base 2. The rotary feeding base 2 is provided with a turntable 21, and a plurality of embedding grooves 22 are opened on the rotary table 21, and the embedding grooves 22 penetrate through the rotary table. 21. An automatic feeding device 5, an upper end surface grinding mechanism 3, a lower end surface grinding mechanism 4 and an unload...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com