Automatic feeding device suitable for production line of pipes

A technology of automatic feeding and production line, applied in the direction of transportation and packaging, conveyor objects, etc., can solve problems such as low production efficiency, and achieve the effect of improving production efficiency, high safety and reliability, and reducing operation steps and labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] With reference to accompanying drawing, further illustrate the present invention:

[0033] An automatic feeding device suitable for a pipe processing production line, including a bracket, and the bracket is equipped with:

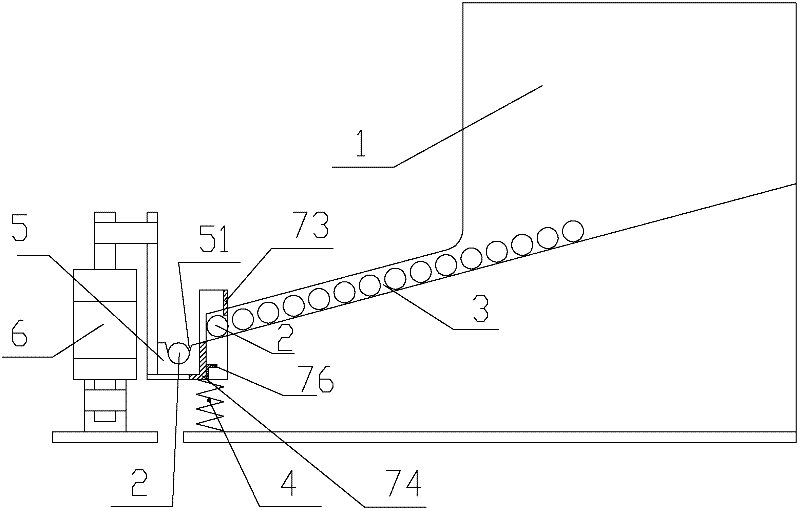

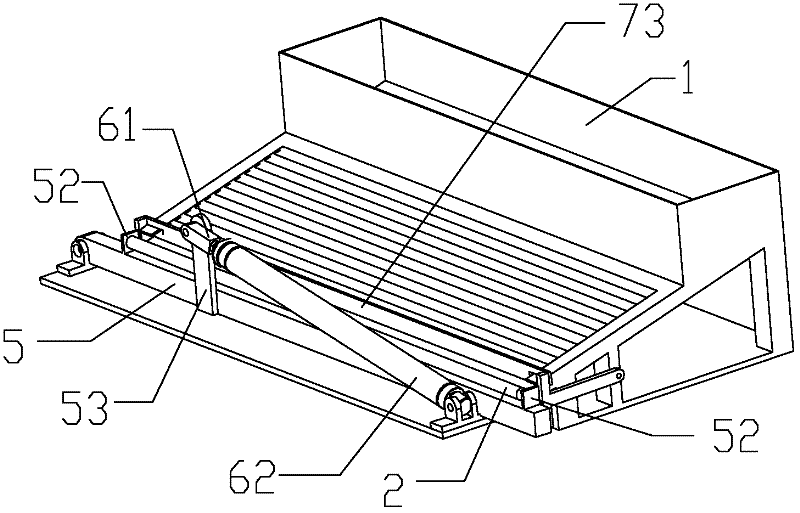

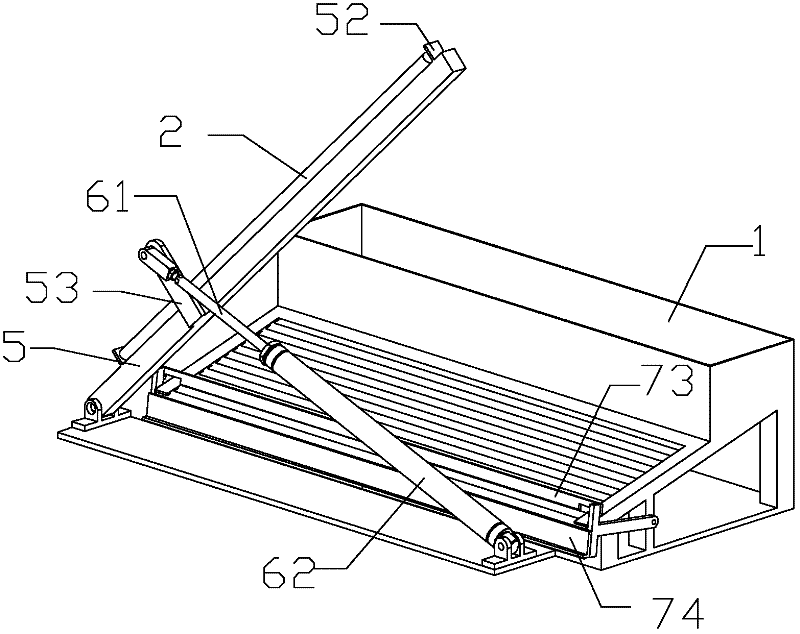

[0034] A storage bin 1 storing horizontally placed pipes,

[0035] The inclined chute 3 for discharging the pipe material 2 in the storage box 1,

[0036] A baffle mechanism that is located at the outlet of the inclined slideway 3 and only allows a single pipe to pass through. A spring 4 is arranged between the baffle mechanism and the bracket.

[0037] Undertake the feeding bracket 5 of the single pipe material 2 that has passed the baffle mechanism, one end of the feeding bracket 5 is hinged with the bracket, and the feeding bracket 5 is provided with a The accommodating tank 51 is equipped, and the clamping member 52 for clamping the pipe material 2 is arranged on the described feeding support member 5. When the described feeding support member ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com