Unloading mechanism of bottle blowing machine

A bottle blowing machine and feeding technology, applied in the field of bottle blowing machines, can solve the problems of short service life and high cost, and achieve the effect of long service life and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

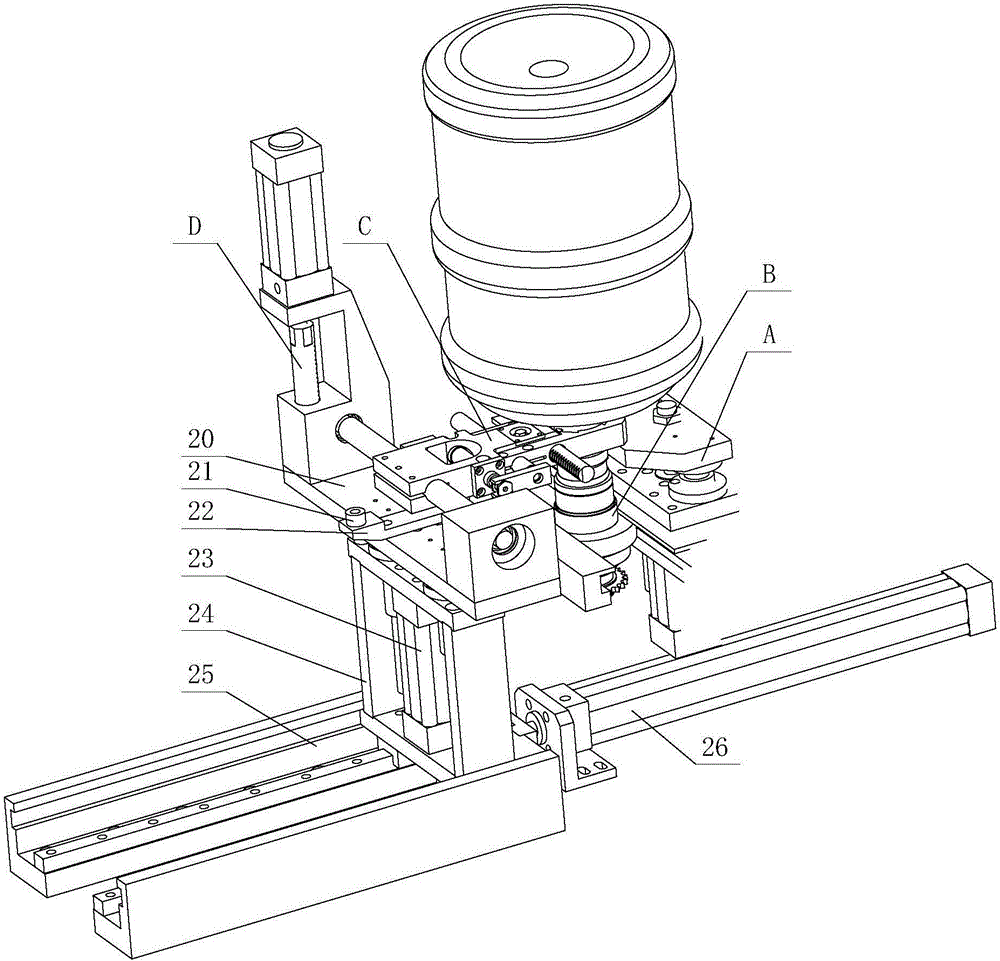

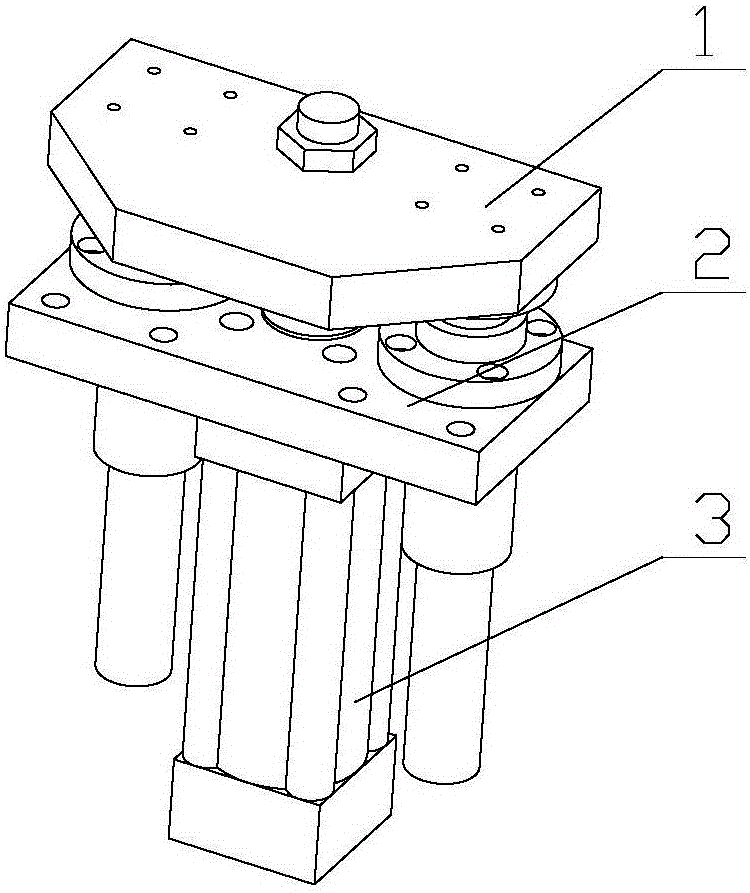

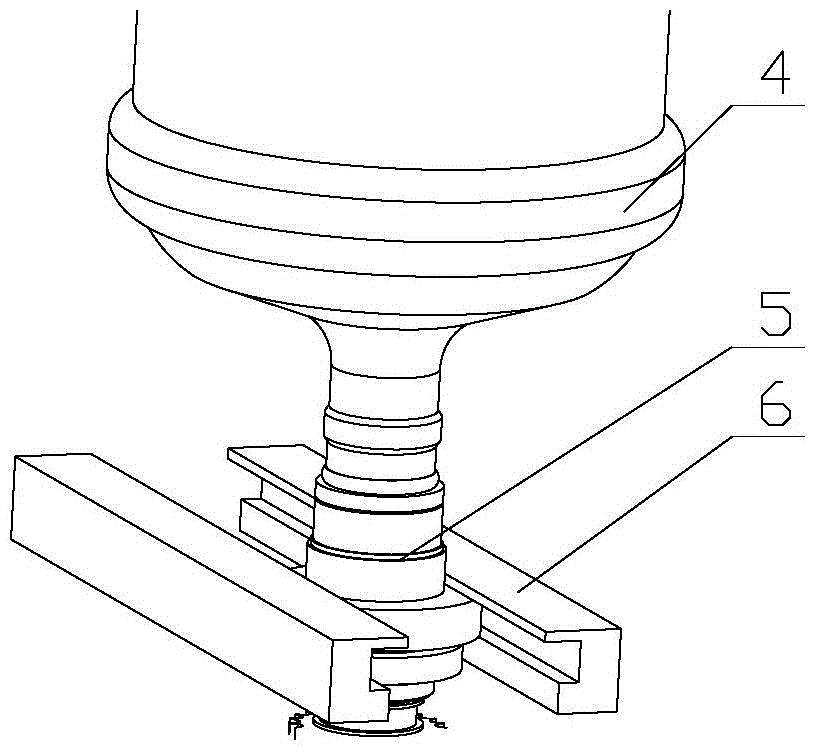

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

[0024] refer to Figure 1 to Figure 8 , a blanking mechanism of a bottle blowing machine, including a frame and a manipulator, a lifting frame 24 can be slidably installed on the frame, a platform 20 can be installed up and down on the lifting frame 24, and a platform 20 can be rotated The rotating shaft 15 is installed firmly, and the rotating shaft 15 is connected with the rotating drive assembly for driving the rotating shaft 15 to rotate. The manipulator seat 13 is fixedly installed on the rotating shaft 15, and the manipulator includes a left finger 11 and a right finger 10, so The rear parts of the left finger 11 and the right finger 10 are provided with a front mounting hole and a rear mounting hole from front to rear, and the connection line between the front mounting holes and the connection line between the rear mounting holes are respectively parallel to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com