Full-automatic intelligent feeding equipment for aquaculture

An aquaculture, fully automatic technology, applied in fish farming, application, climate change adaptation and other directions, can solve the problems of spreading to the outside of the feed pond, wasting feed, unable to control the range of feed spreading, etc., to avoid gathering and grabbing food , the effect of convenient management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

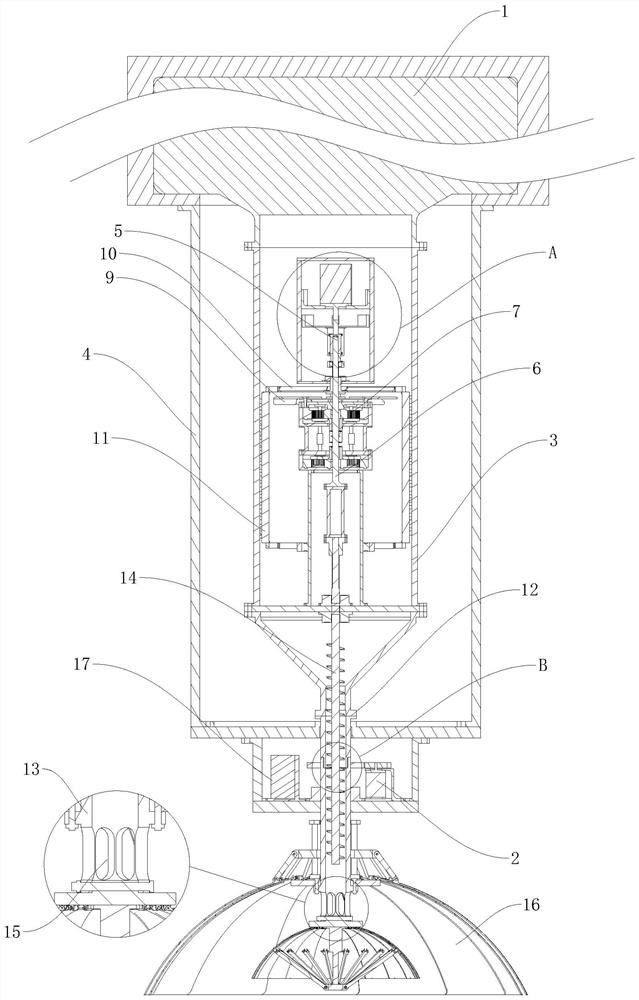

[0086] In order to further understand the features, technical means, and specific goals and functions of the present invention, the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

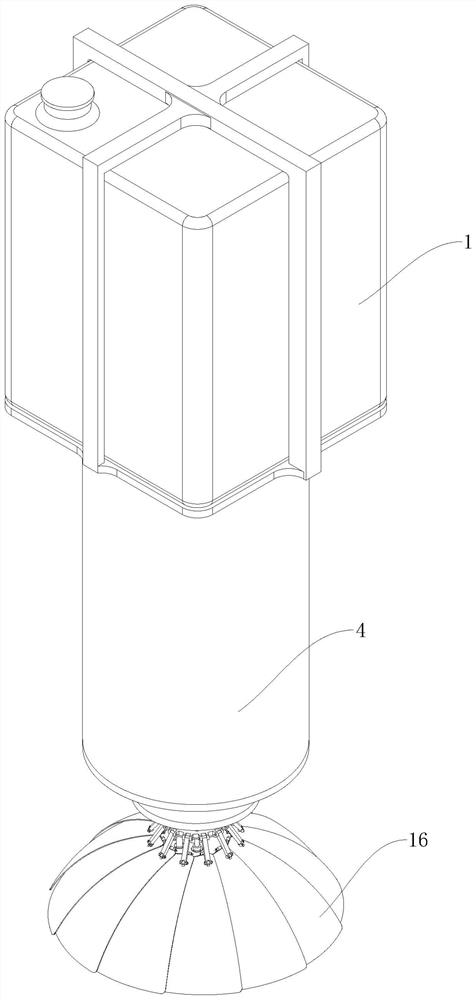

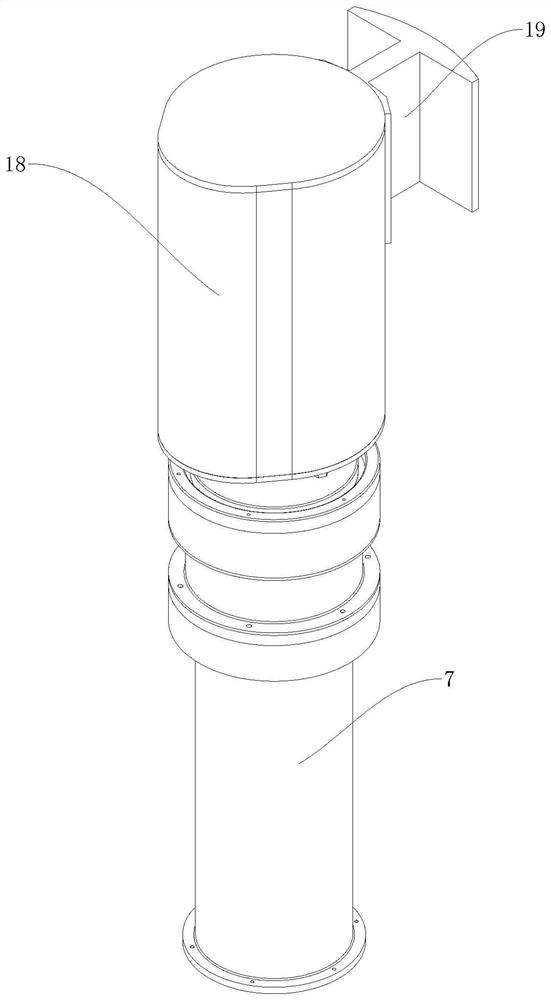

[0087] refer to Figure 1 to Figure 16 As shown, a fully automatic intelligent feeding equipment for aquaculture includes a storage box 1 and a rotating assembly 2, and also includes:

[0088] The first feeding pipe 3 is in a vertical state, and the upper end is fixedly connected with the discharge port of the storage box 1;

[0089] The upper end of the first round tube casing 4 arranged coaxially with the first feeding tube 3 is fixedly connected with the storage box 1, and the first feeding tube 3 is located in the first round tube casing 4;

[0090] The drive speed control assembly 5 is fixed on the inner side of the first feeding pipe 3. The drive speed control assembly 5 includes a vertically movable self-rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com