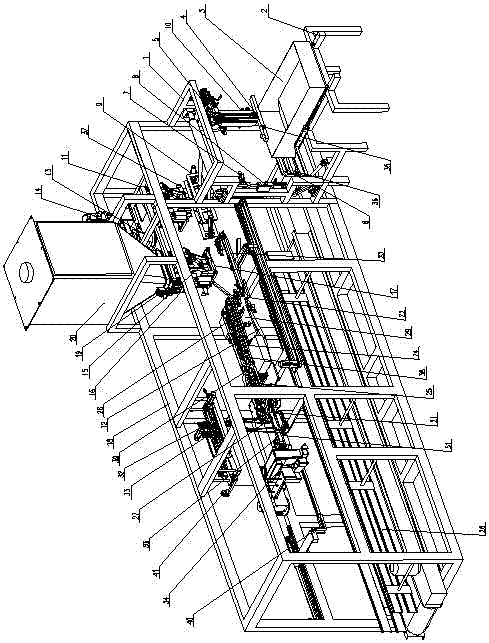

Full-automatic material packaging production line based on sleeved type inner-outer bags and packaging method of full-automatic material packaging production line

A set bag, fully automatic technology, applied in the direction of packaging automatic control, packaging, packaging machines, etc., can solve the problems of a lot of labor, food safety and hygiene, human health damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] refer to figure 1, Frame 18 is welded with rectangular tube to make vertical frame, and belt conveyor 26 is installed on the ground of frame 18 bottoms with expansion bolts. The material table is made of channel steel, angle steel, round steel and pattern plate by electric welding, and is installed on the frame 18 with bolts, and the automatic packing scale 20 is installed on the material table with bolts, and the blanking sealing device 19 is installed on the automatic packing scale 20 on the discharge port. The powdered sugar sealing device 19 of the falling hopper includes a fixed seat, a flexible expansion joint, a guide cylinder, a connecting frame and a sealing ring. The fixed seat is made of a rectangular frame with a steel plate, and is installed on the discharge port of the automatic packing scale 20 with bolts. The cylinder of guide cylinder is simply connected on the automatic packaging scale 20 with screws, and the piston rod is connected with the connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com