High-speed binding machine

A high-speed wire and tying machine technology, which is applied to the equipment for tying sausage casings, etc., can solve the problems of different lengths, large inertia, and limiting mechanism speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

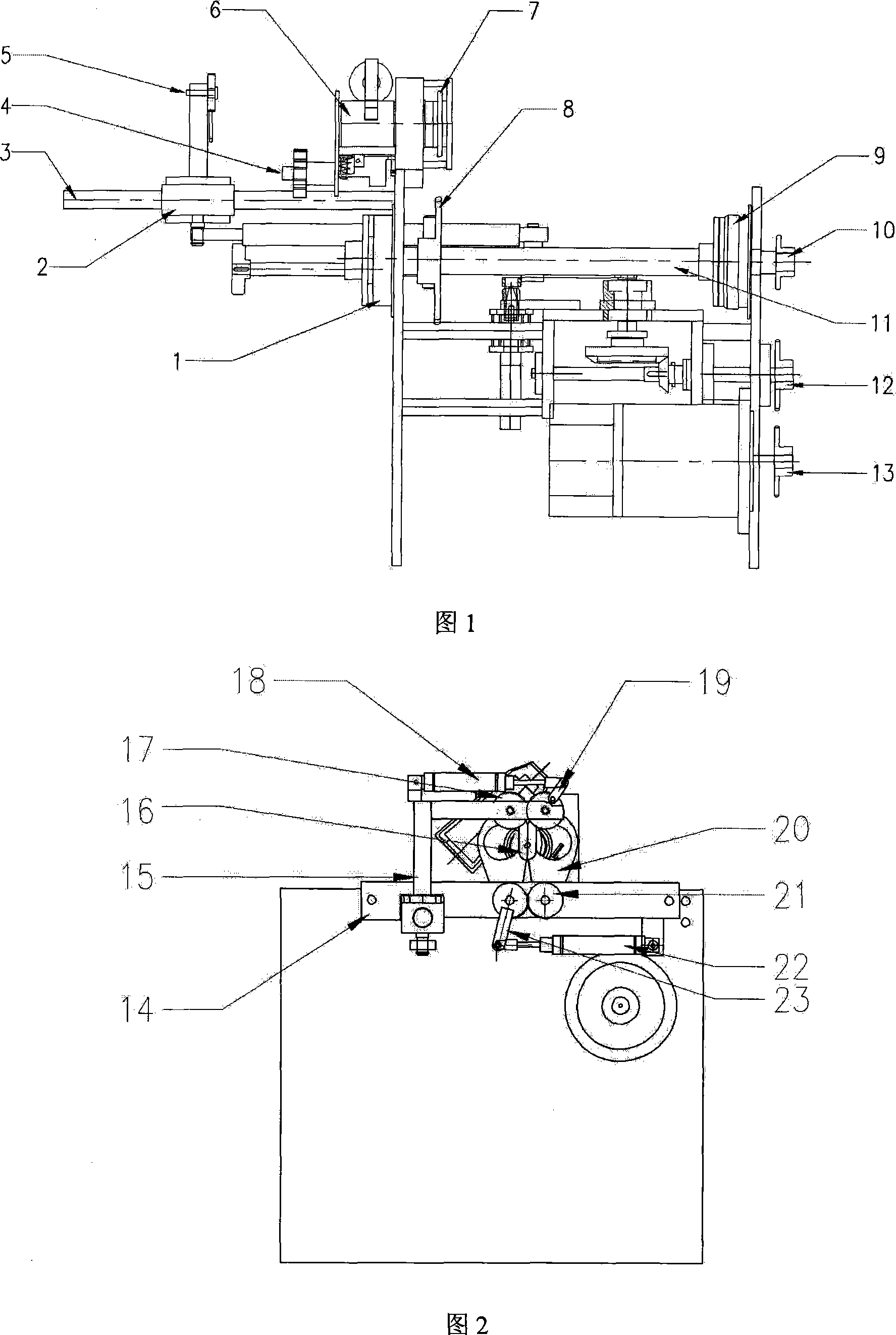

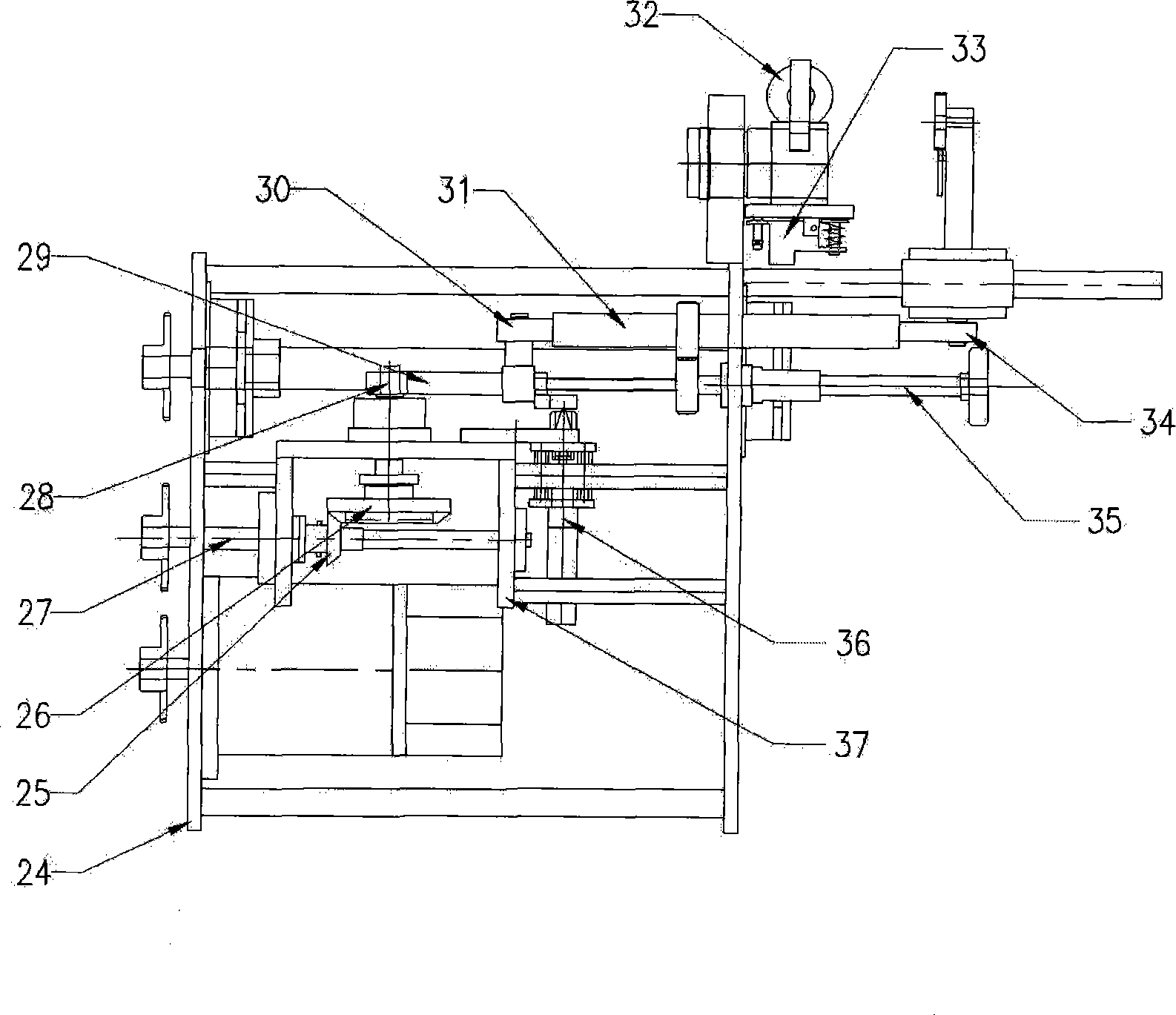

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings: As shown in the accompanying drawings, the present invention is mainly composed of a frame, a clamping mechanism, a necking mechanism, a one-way synchronous adjustment mechanism and the like. Frame is made of the support between two main boards 24 and the main board, and the two ends of winding transmission shaft 12 are fixed on the main board 24, and gear box 37 is fixed between the main board 24 by connecting rod, and motor is fixed on the main board 24. Motor sprocket 13 is fixed on the motor shaft, and it is positioned on the same plane with transmission sprocket 12, transmission sprocket 10, and tensioning sprocket, constitutes a sprocket pair.

[0016] A pinion bevel gear 25 is fixed on the drive shaft 27 in a keyed manner, and is located inside the gear box 37 . Gear box 37 both sides have through holes, power transmission shaft 27 is fixed on the through holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com