Telescopic-swivel hydraulic cylinder

A technology of telescopic rotation and hydraulic cylinders, which is applied in the field of hydraulic cylinders, can solve the problems of complex structure and high cost of the overall hydraulic system, and achieve the effects of simple structure, reduced costs, and improved economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

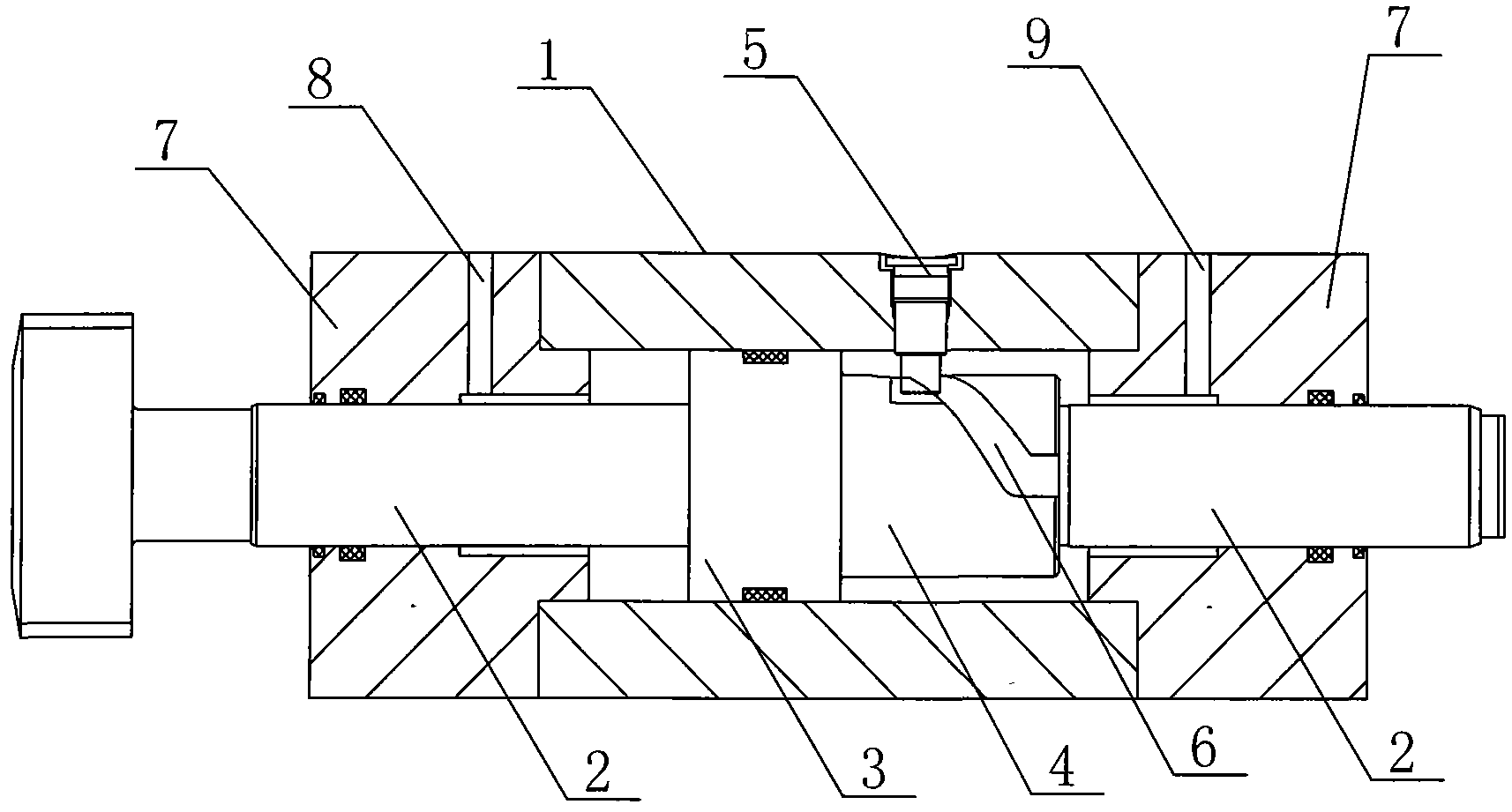

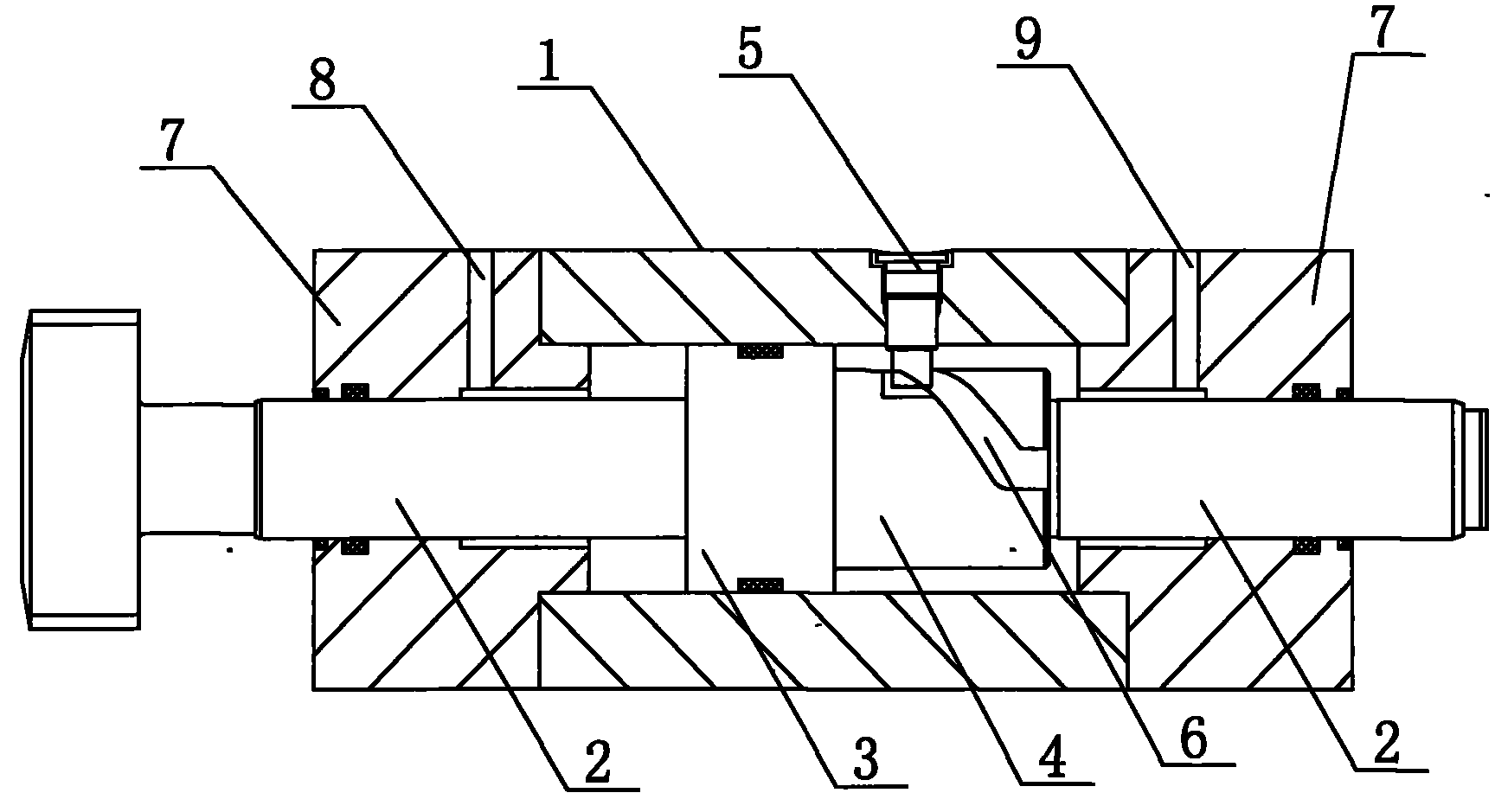

[0014] Please refer to figure 1 as shown, figure 1 It is a structural schematic diagram of the telescopic rotary hydraulic cylinder of the present invention. In this embodiment, the telescopic rotary hydraulic cylinder includes a piston 3, a piston rod 2, a cylinder body 1, and a first oil port 8 and a second oil port 9 communicating with the inner cavity of the cylinder body 1. The cylinder body 1 is fixed with a cylinder head 7 at both ends, the piston rod 2 passes through the piston 3 and runs through the entire cylinder body 1, and a spiral guide groove 6 is opened on the piston rod 2 on one side of the piston 3, and the spiral guide groove 6 is matched with the One end of the limit screw plug 5 is fixed on the inner wall of the cylinder body 1, and the other end of the limit screw plug 5 is clamped in the spiral guide groove 6. When the piston rod 2 moves linearly, it is guided by the limit screw plug 5 and the screw. The effect of the groove 6 can drive the piston rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com