UV light and heat dual-curing high-airtightness polyisobutene glue and preparation method thereof

A polyisobutylene adhesive and dual-curing technology, used in adhesives, epoxy resin adhesives, non-polymer adhesive additives, etc., can solve the problems of reduced gas barrier performance, oxygen inhibition, low curing temperature, etc. The effect of variable performance, strong gas barrier performance and simplified process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3 and comparative example 1-2

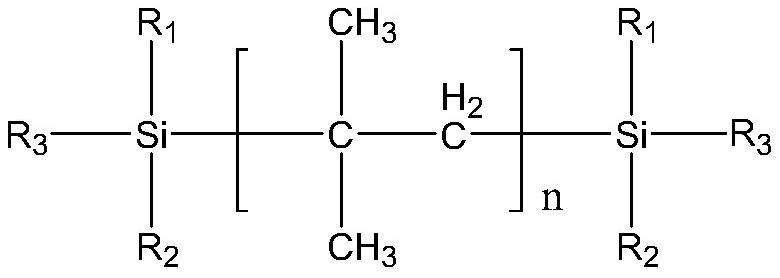

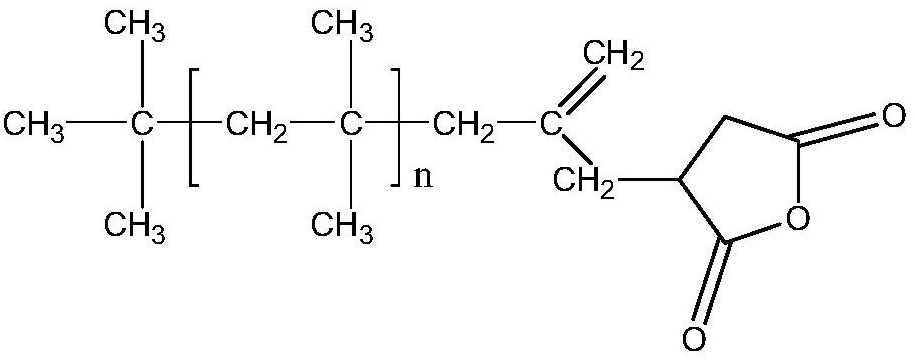

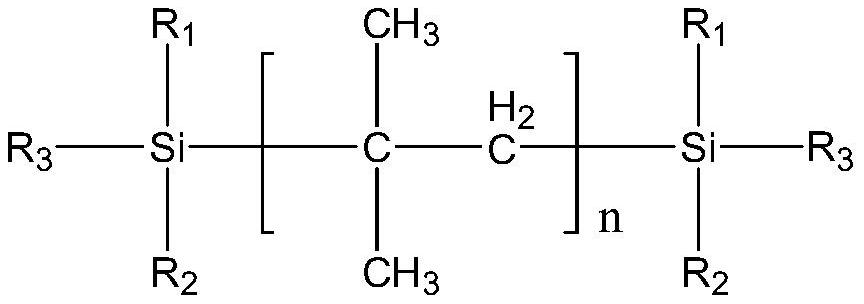

[0032] A preparation method of UV light and heat dual curing high airtight polyisobutylene glue, comprising the following steps:

[0033] (1) Select raw materials for batching according to Table 1

[0034] (2) Under the condition of eliminating ultraviolet light or in a yellow light chamber, vinyl-terminated polyisobutylene polymer, maleic anhydride-terminated polyisobutylene polymer, epoxy resin, inorganic filler, polyα-olefin plasticizer , silane coupling agent, anti-aging agent, hydrogen-containing silicone oil, ultraviolet photoinitiator, catalyst, and maleate inhibitors are put into the planetary mixer in turn for 1 hour of vacuum stirring, and then 0.5 hour of vacuum stirring to obtain a viscous adhesive , filled into a silicone cartridge for storage.

[0035] (3) Determination of viscosity:

[0036] The viscosity (Pa·s) of the adhesive was measured under predetermined measurement conditions using a cone-plate viscometer (manufactured by Brookfield). Considering the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com