Patents

Literature

49results about How to "Avoid pressure deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An automatic capping machine

InactiveCN102294673AReduce labor intensityImprove work efficiencyMetal-working hand toolsTransverse planeMaster controller

The invention discloses an automatic capping machine, comprising a left wing plate, a right wing plate and a master controller, wherein a feeding belt used for conveying bottle caps under the control the master controller is arranged between the two wing plates; transverse base plates are fixed to the two wing plates; the transverse base plates are arranged above the feeding belt and close to each other; a bottle cap channel along the conveying direction of the feeding belt is arranged on the bottom of each transverse base plate; the bottle cap channel is internally provided with a detection device which is used for detecting the bottle caps and transmitting a detection signal to the master controller; and a transverse base plate is provided with a capping device which extends downward into the bottle cap channel under the control of the master controller and is used for pressing the bottle caps. The invention aims at providing an automatic capping machine with high working efficiency and high yield of extruded products.

Owner:SINO ASIA PLASTIC PACKAGE ZHONGSHAN

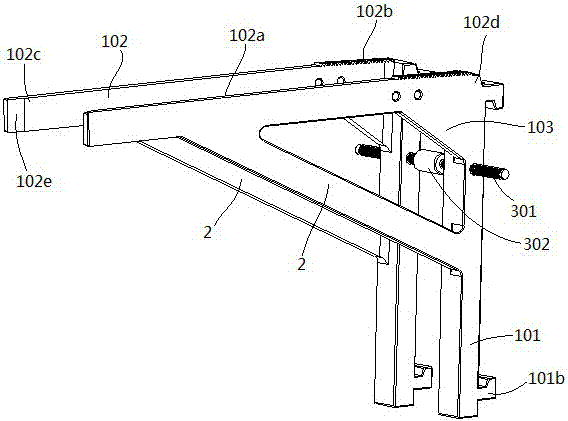

Template jacking and template bracket using same

ActiveCN103216088ASolve the inconvenienceFirmly connectedForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksSteel tubeArchitectural engineering

Owner:朱新伟

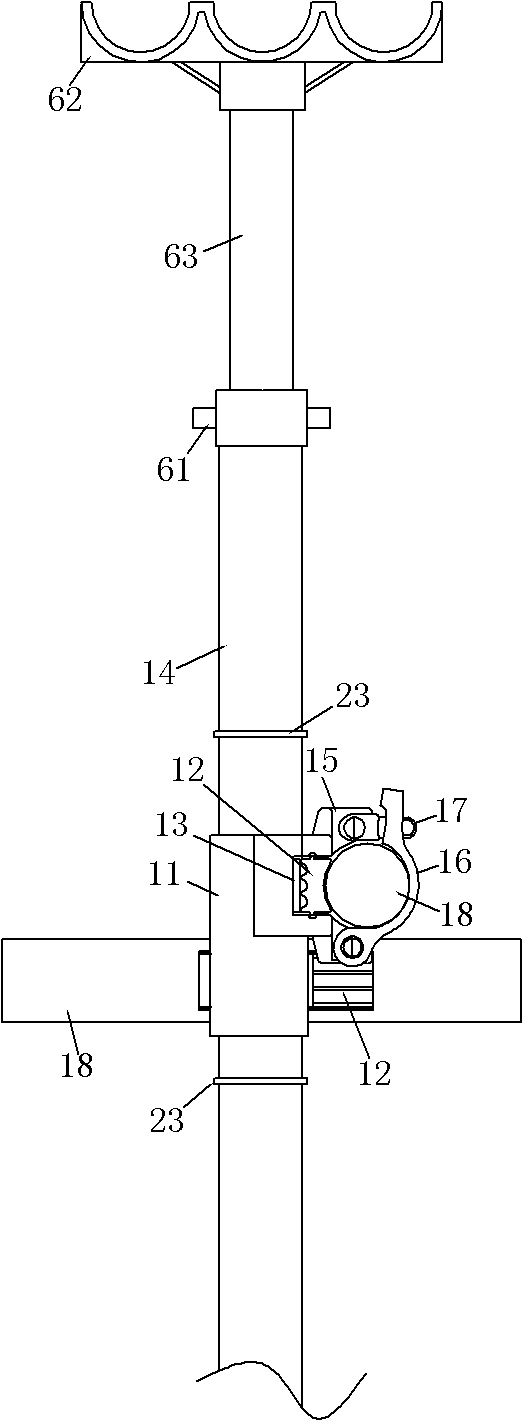

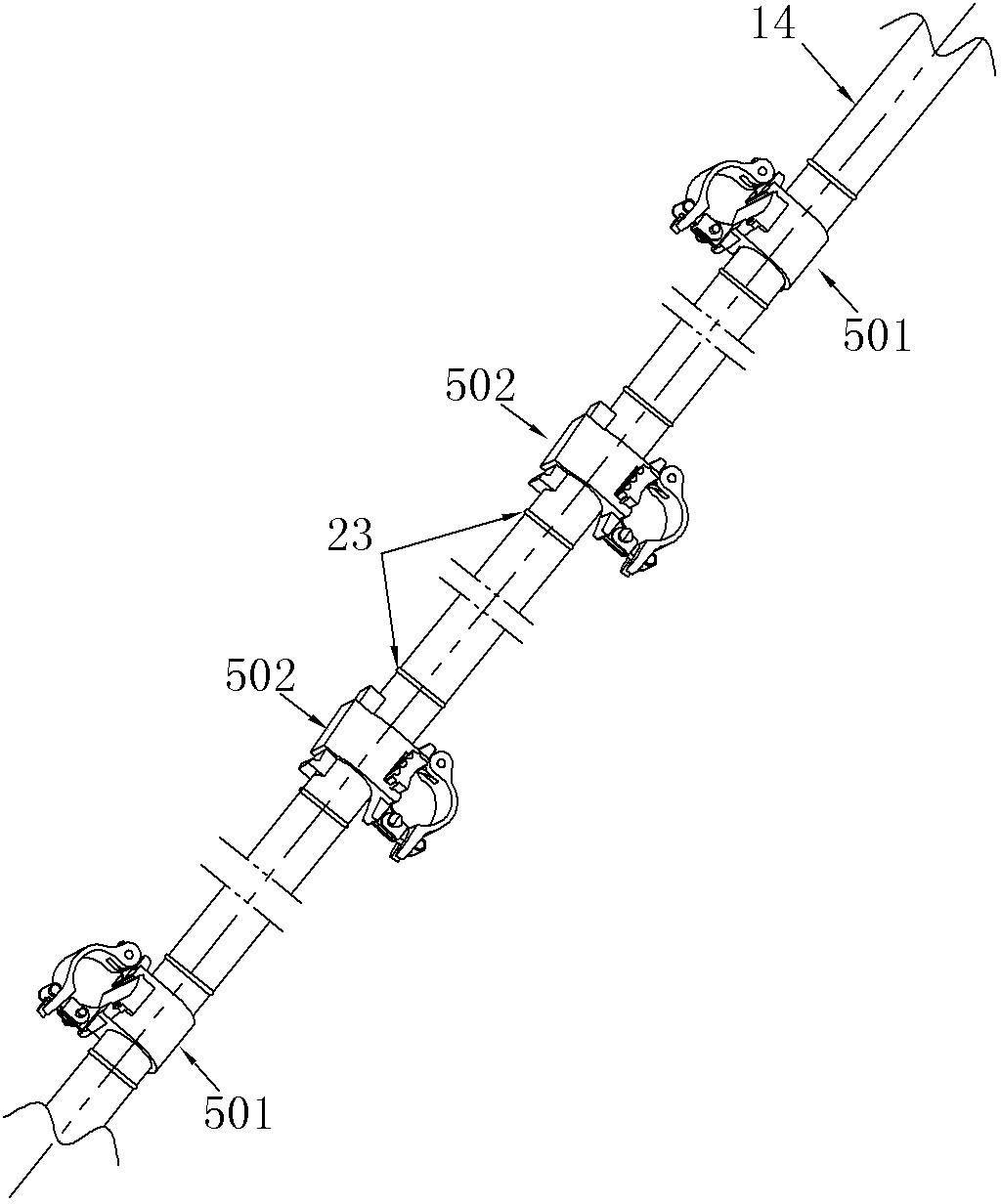

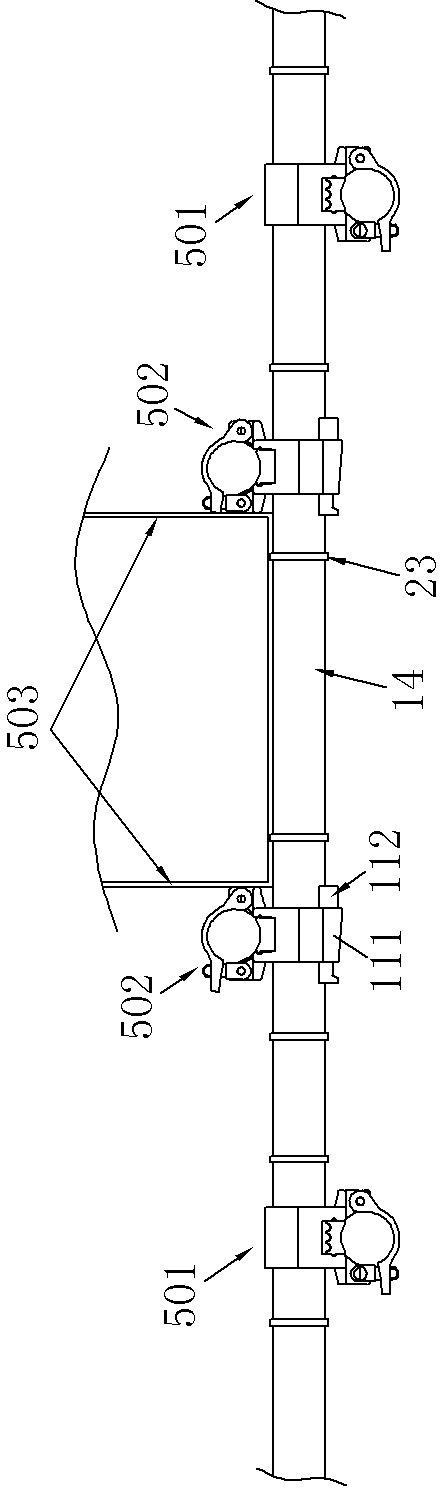

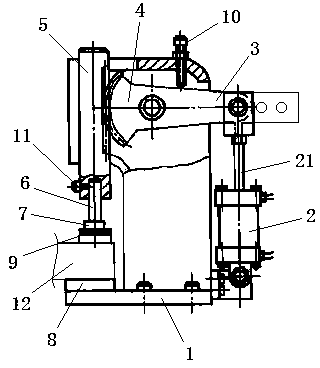

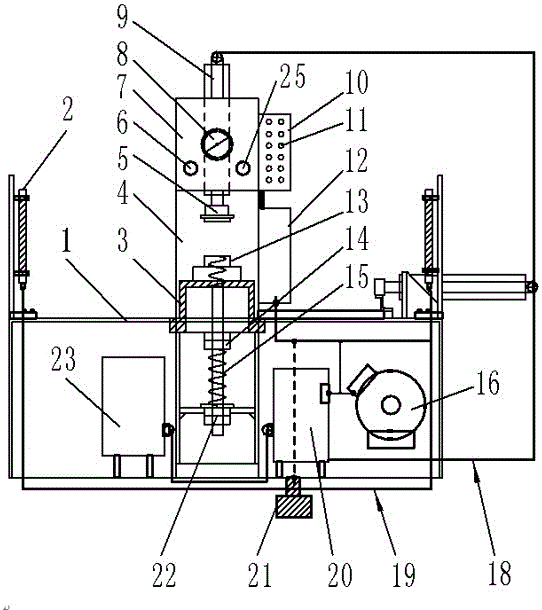

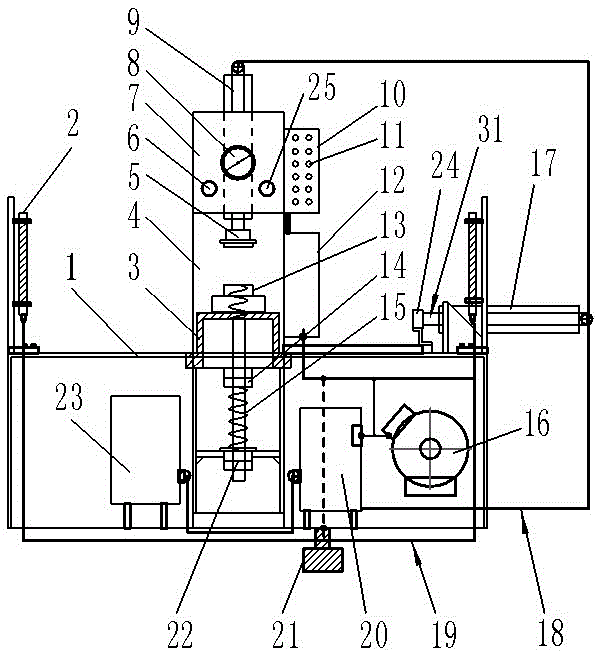

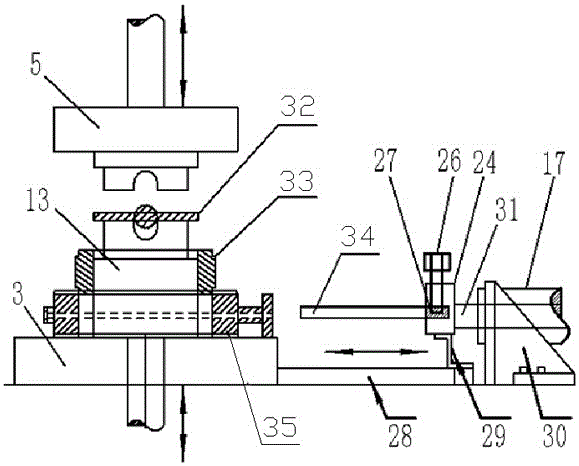

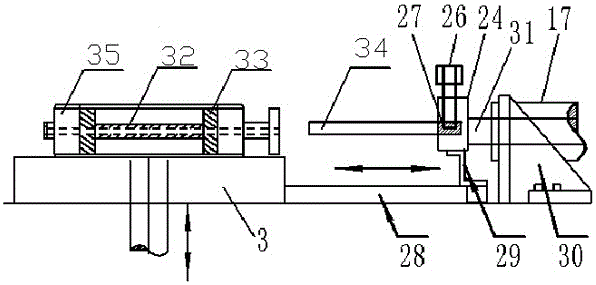

Automatic hydraulic valve rod assembly device of butterfly valve assembly machine and assembly method thereof

ActiveCN104742079AAvoid pressure deformationSimple structureMetal-working hand toolsAutomatic controlMachine

Provided are an automatic electrohydraulic control butterfly valve assembly machine and an assembly method thereof. Use is convenient, assembly procedures are less, operation is fast, and the host machine pressure can be regulated in time according to butterfly valves with different types and specifications; the working efficiency and quality are greatly improved, and the economic benefit is good; because a PLC is adopted to perform automatic control, the man-machine security coefficients are high, the assembly is accurate, a large amount of time and a large number of energy resources are saved, the maintenance cost and the production cost which are caused by wear are reduced, the engine performance is obviously improved, the service life is obviously prolonged, and popularization is convenient. The automatic electrohydraulic control butterfly valve assembly machine is composed of a butterfly assembly workbench, an infrared induction security device, a tooling base, an assembly machine stand column, a pressure head tool, a pressure regulation valve device, an upper oil cylinder support frame, a pressure gauge device, an upper hydraulic cylinder device, a PLC control box device, control buttons, an electrical box device, a butterfly valve tool, a locking nut mechanism and a pressing lead screw assembly.

Owner:BAND VALVE TECH CO LTD

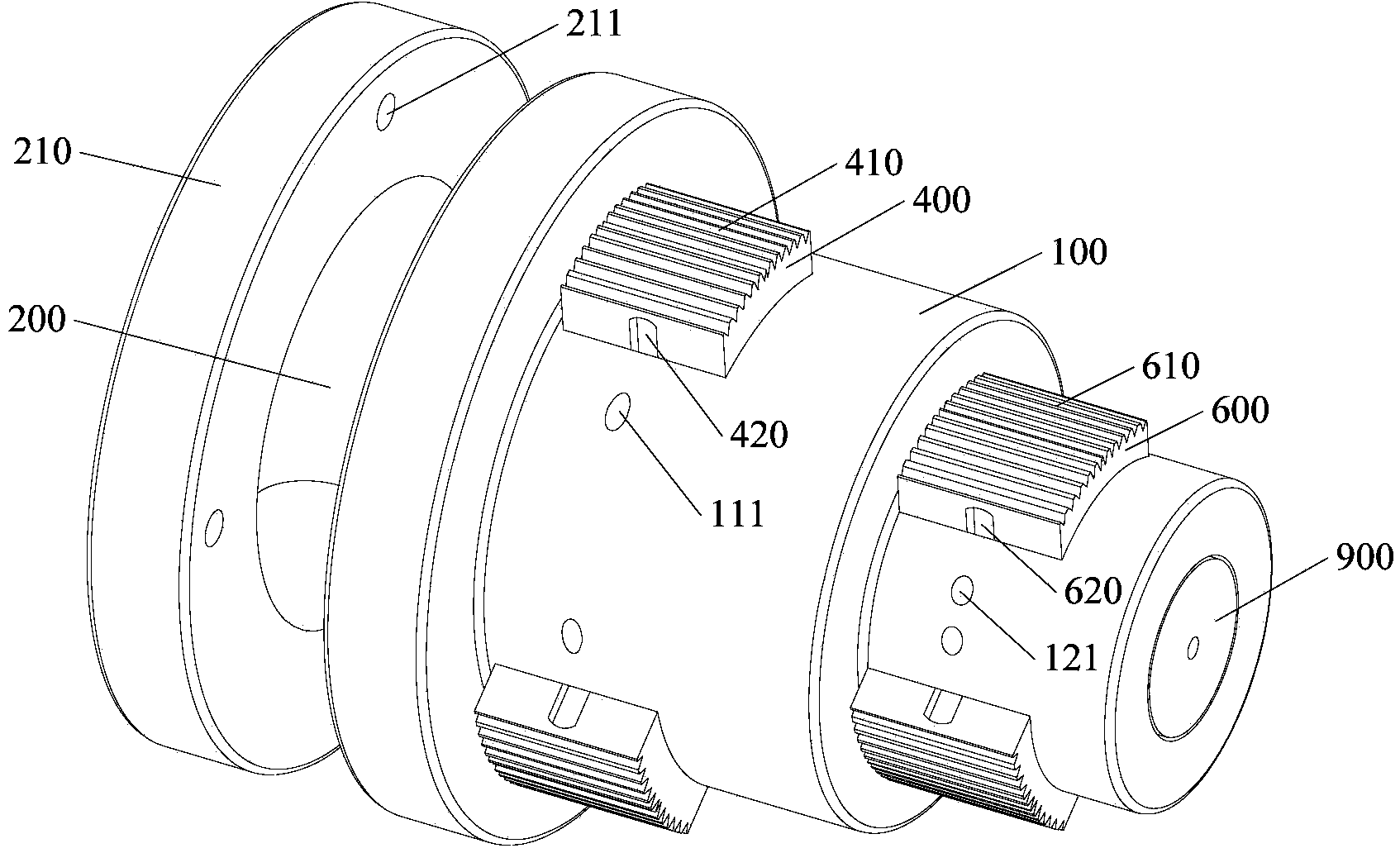

Slitter machine unrolling fixing device and high-speed slitter machine

The invention discloses a slitter machine unrolling fixing device and a high-speed slitter machine. The slitter machine unrolling fixing device comprises a cylindrical outer shell and a center shaft which is installed in the outer shell in a rotatable mode. An installation flange is arranged at one end of the center shaft, and at least one ejecting mechanism is arranged in the axial direction of the center shaft. The ejecting mechanism comprises a cam and at least three ejecting blocks. The cross section of the cam is a regular polygon. The number of sides of the regular polygon is the same as that of the ejecting blocks. The cam is arranged on the center shaft, and the center line of the cam coincides with that of the center shaft. Radial holes are evenly formed in the periphery wall of the outer shell and correspond to all the ejecting blocks. The shape of the radial holes is matched with that of the ejecting blocks. Each ejecting block is embedded into the corresponding radial hole in a sliding mode. One end, located on the inner side of the outer shell, of each ejecting block is provided with an arc surface or a plane, the ejecting blocks are matched with the cam in a sliding mode, and one end, located on the outer side of the outer shell, of each ejecting block is provided with ejecting threads. In this way, only radial clamping force is exerted on a paper tube core, the two ends of the paper tube core will not deform after pressing, and therefore service life is prolonged.

Owner:SHENZHEN KUNHONG PRINTING

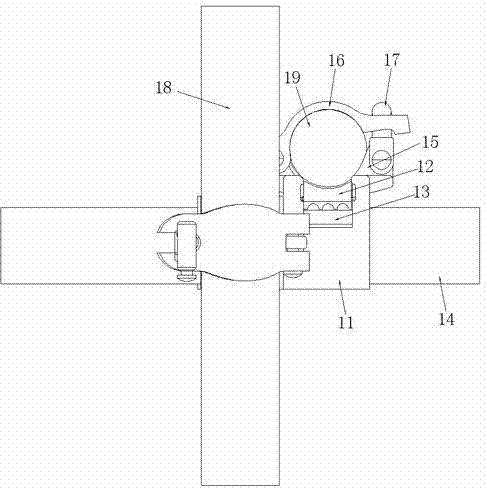

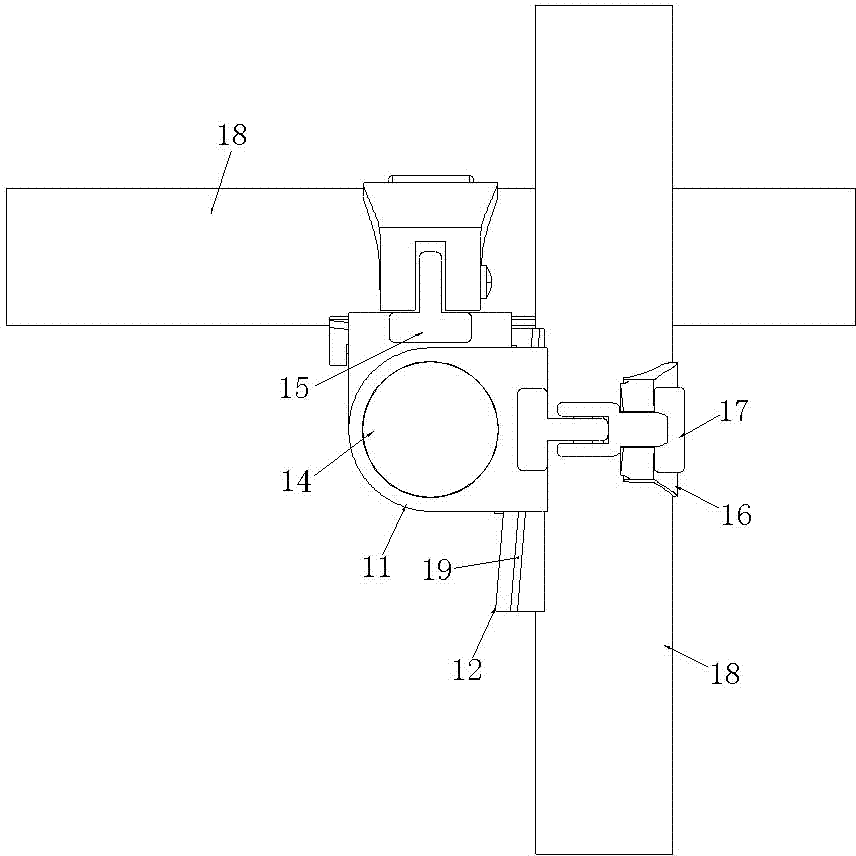

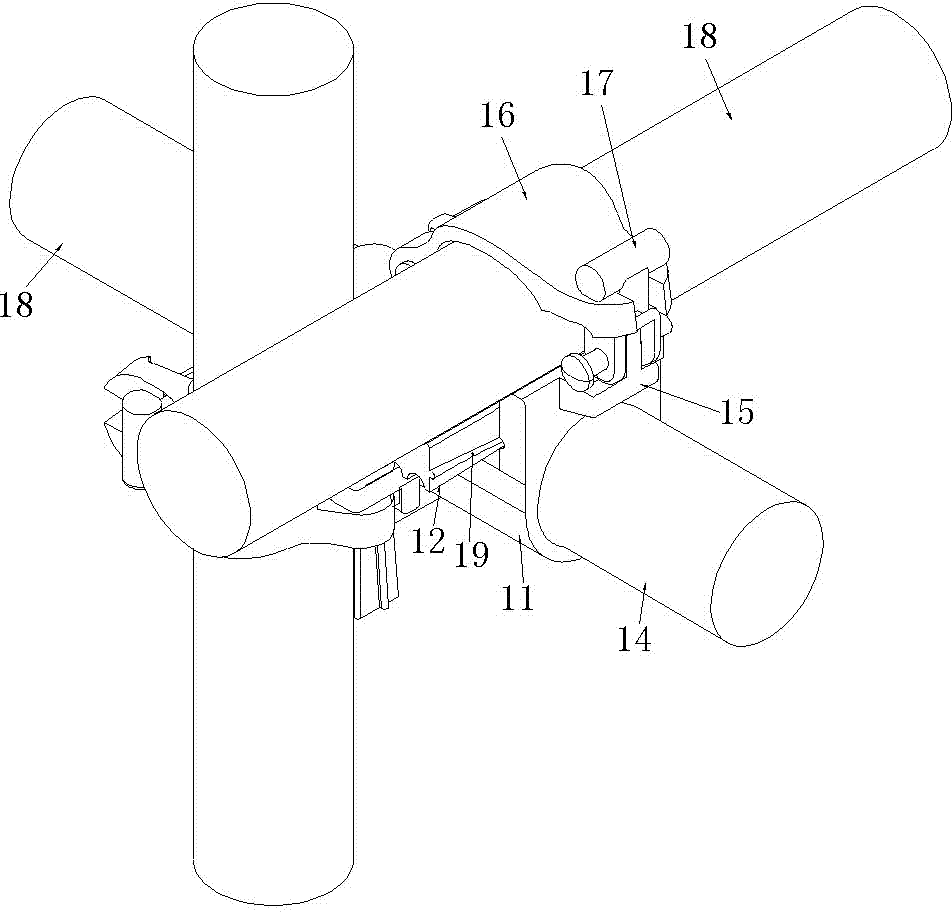

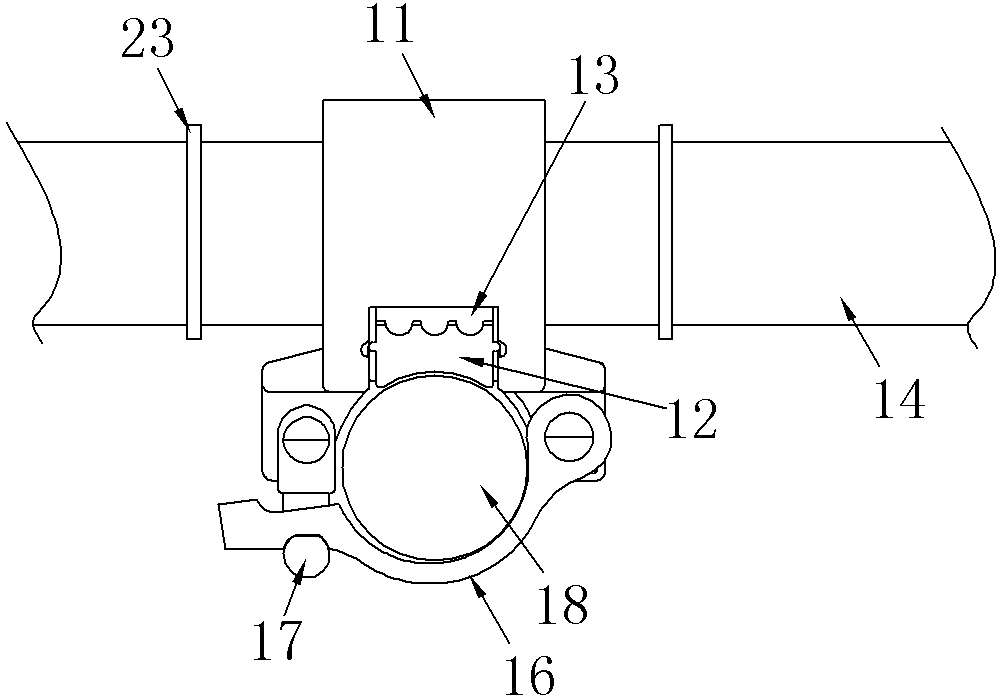

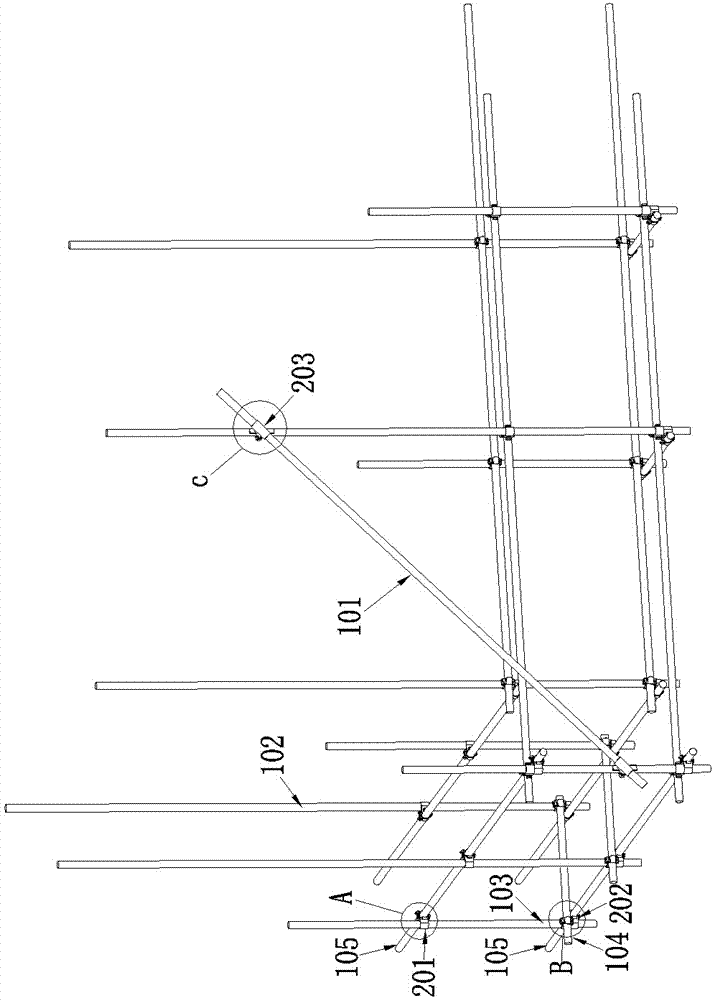

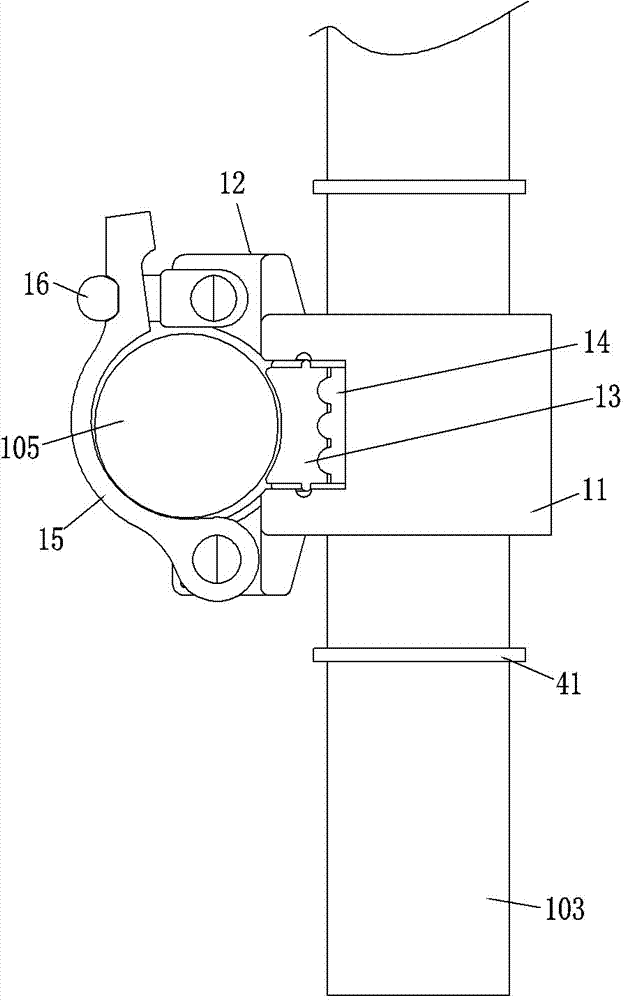

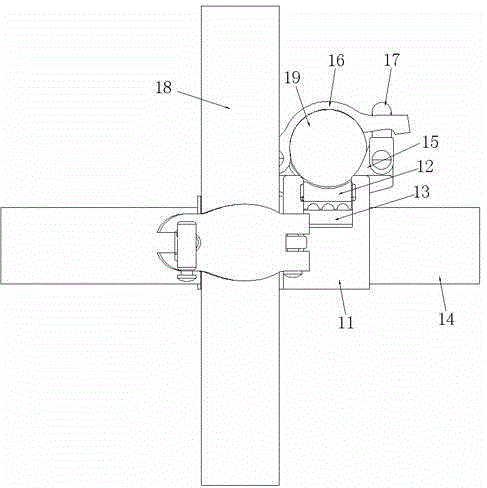

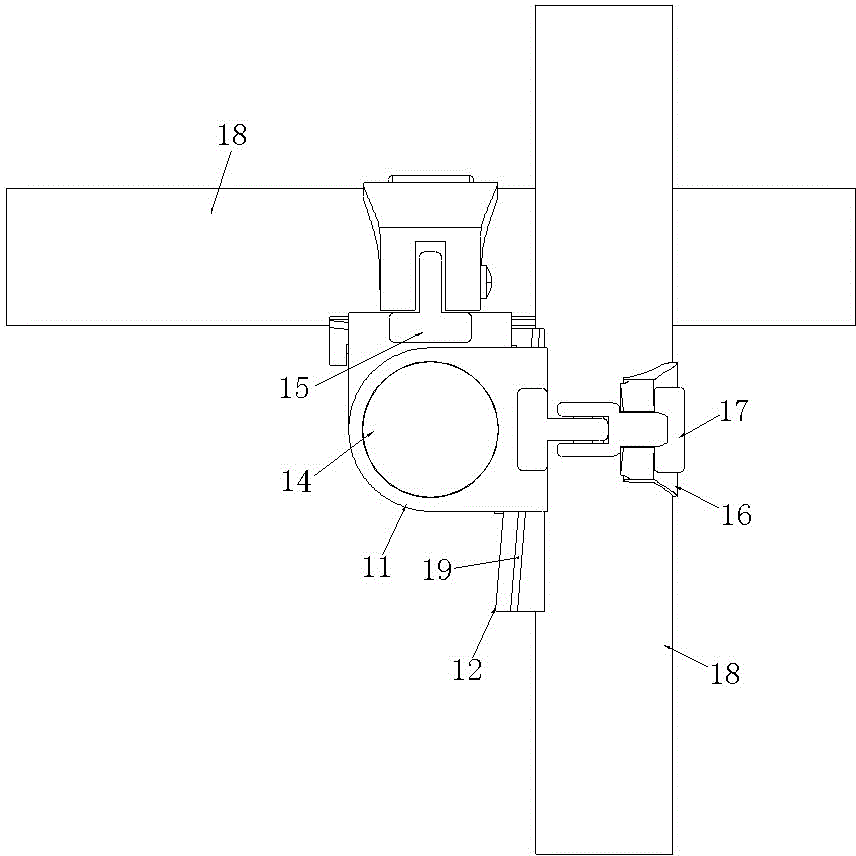

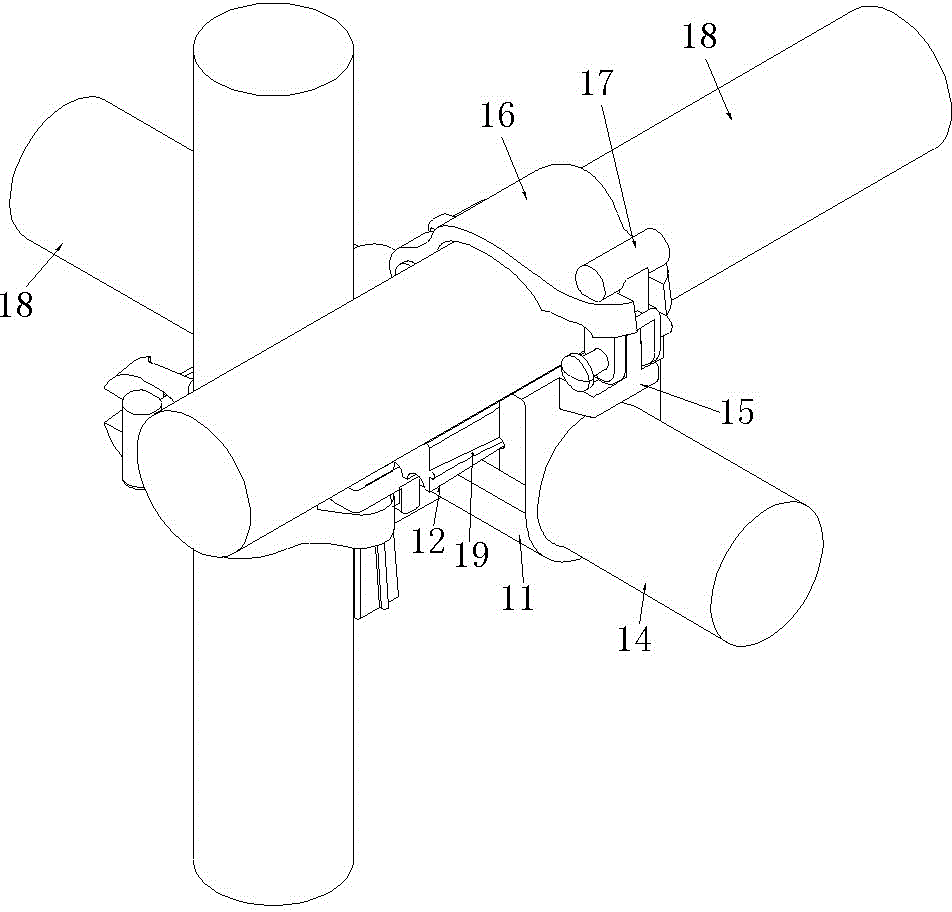

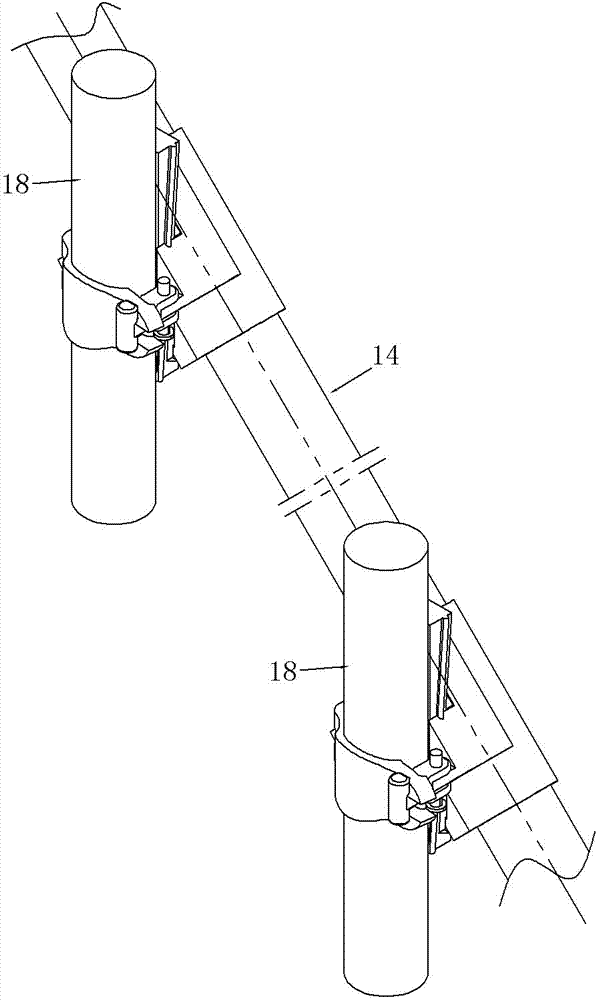

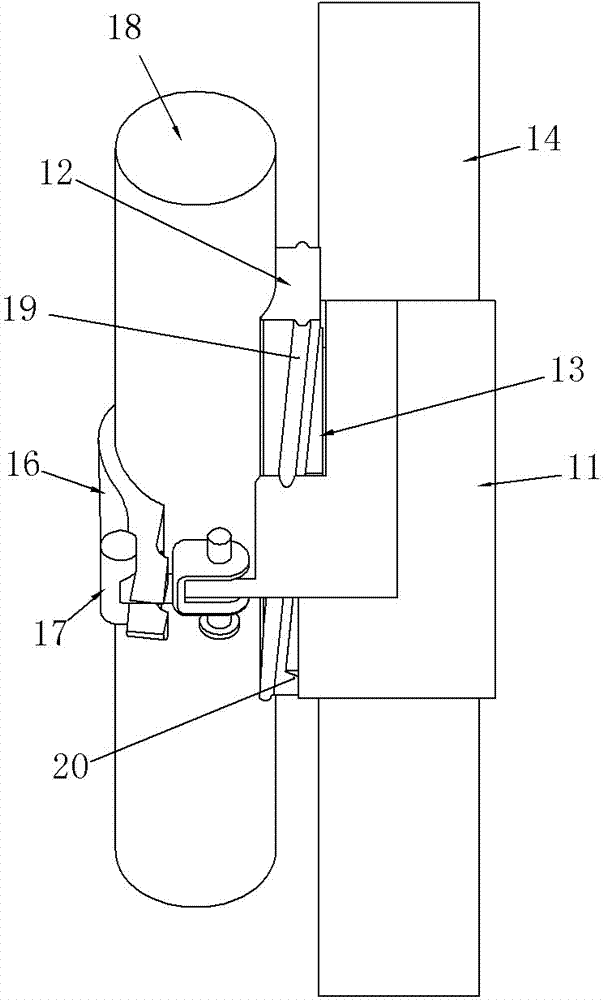

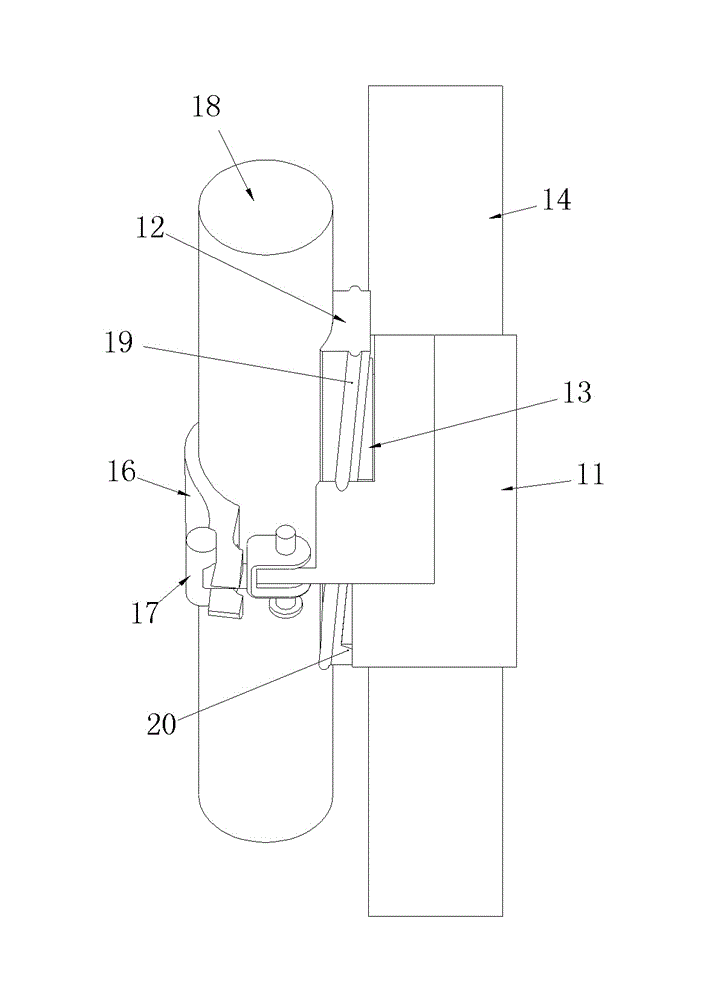

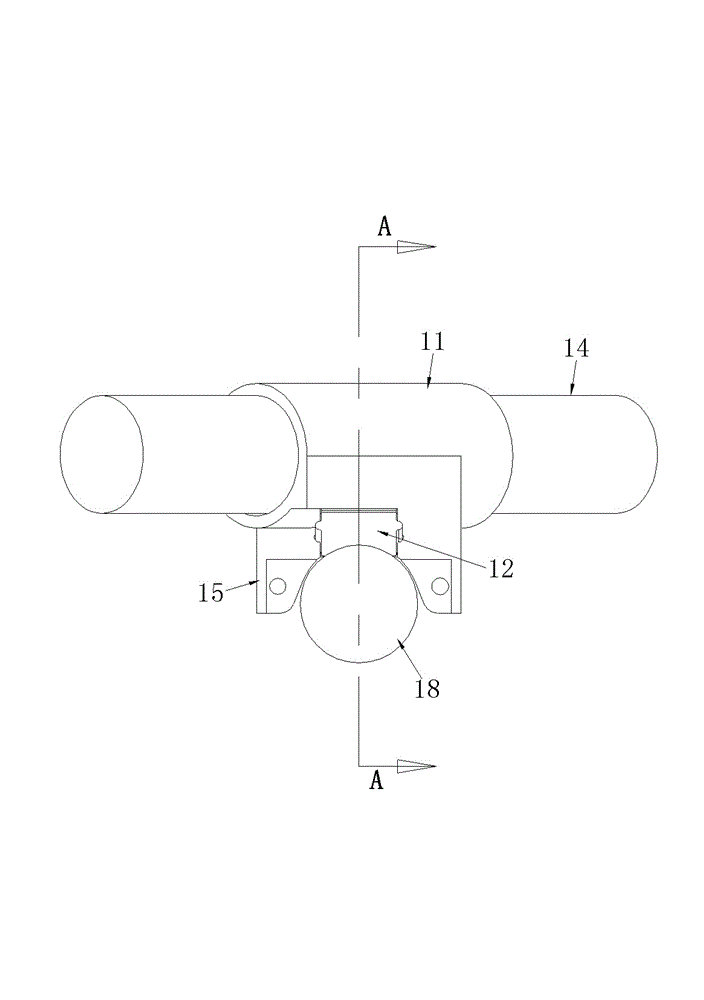

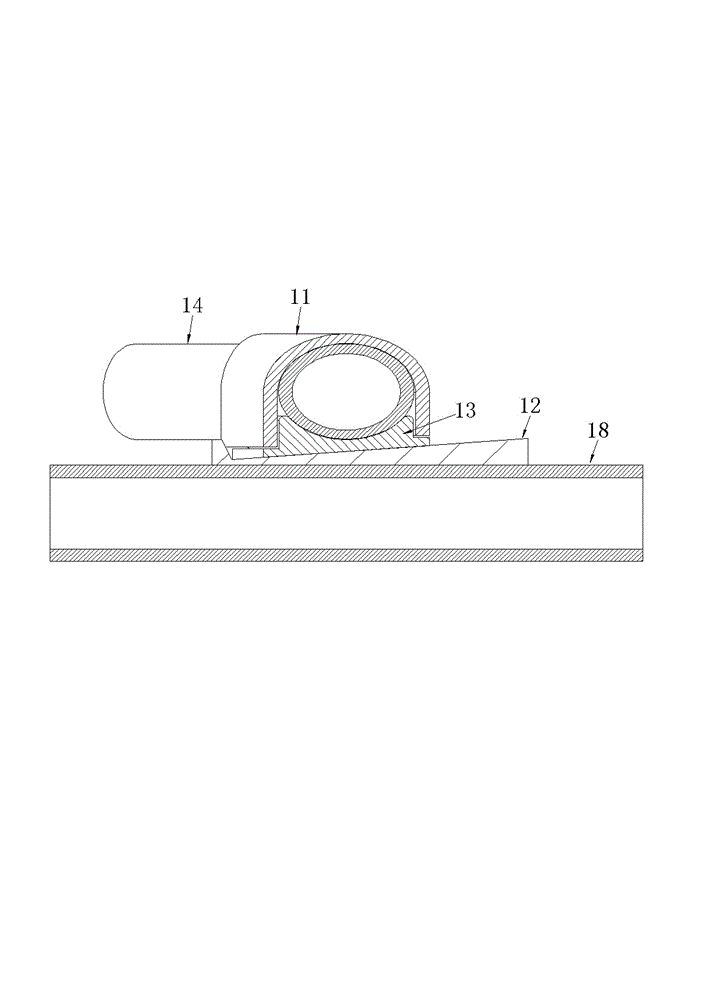

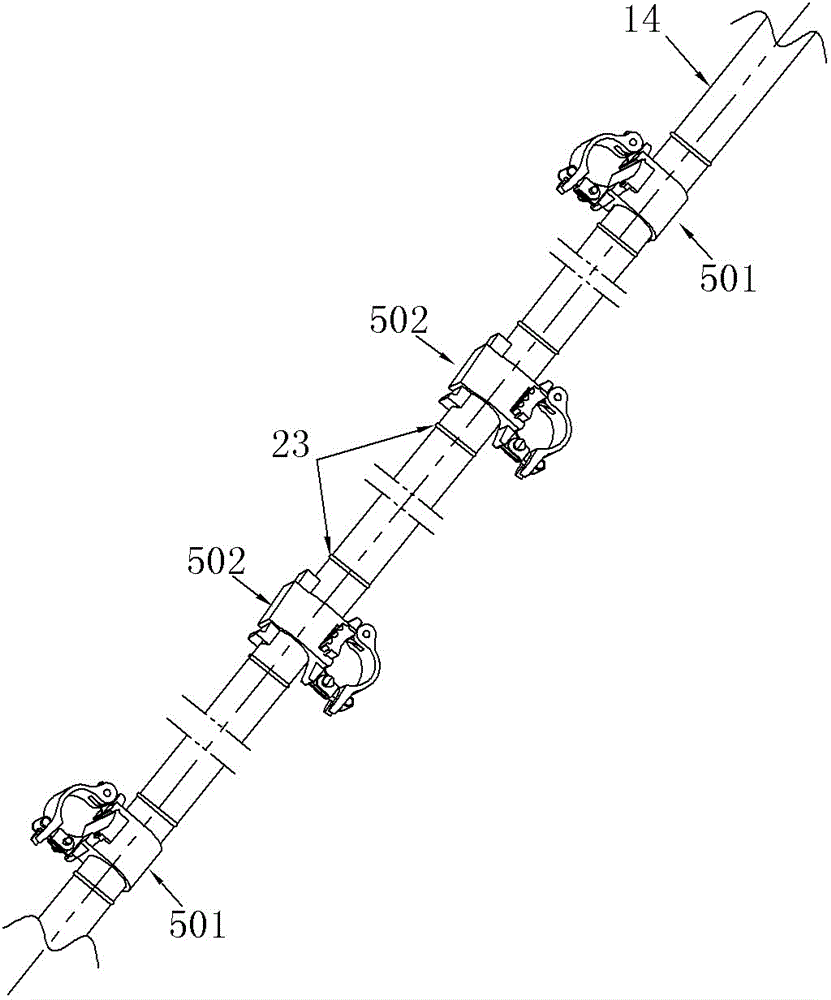

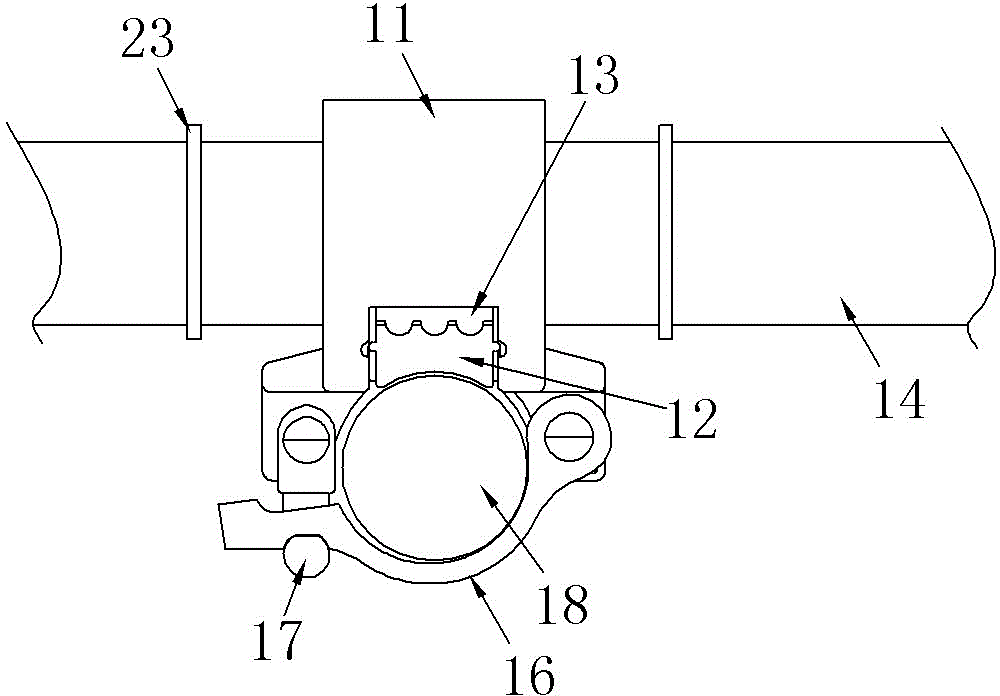

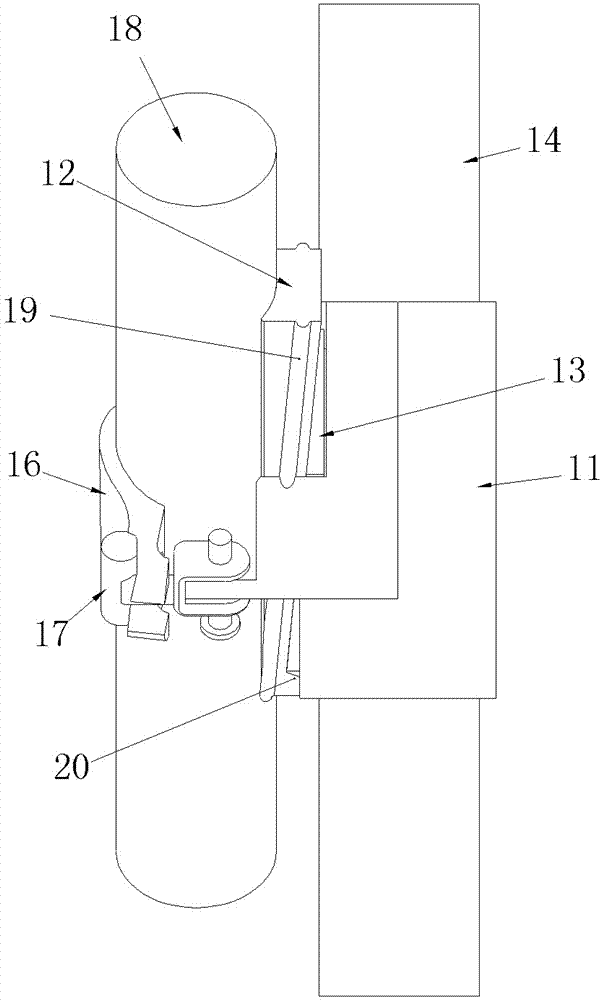

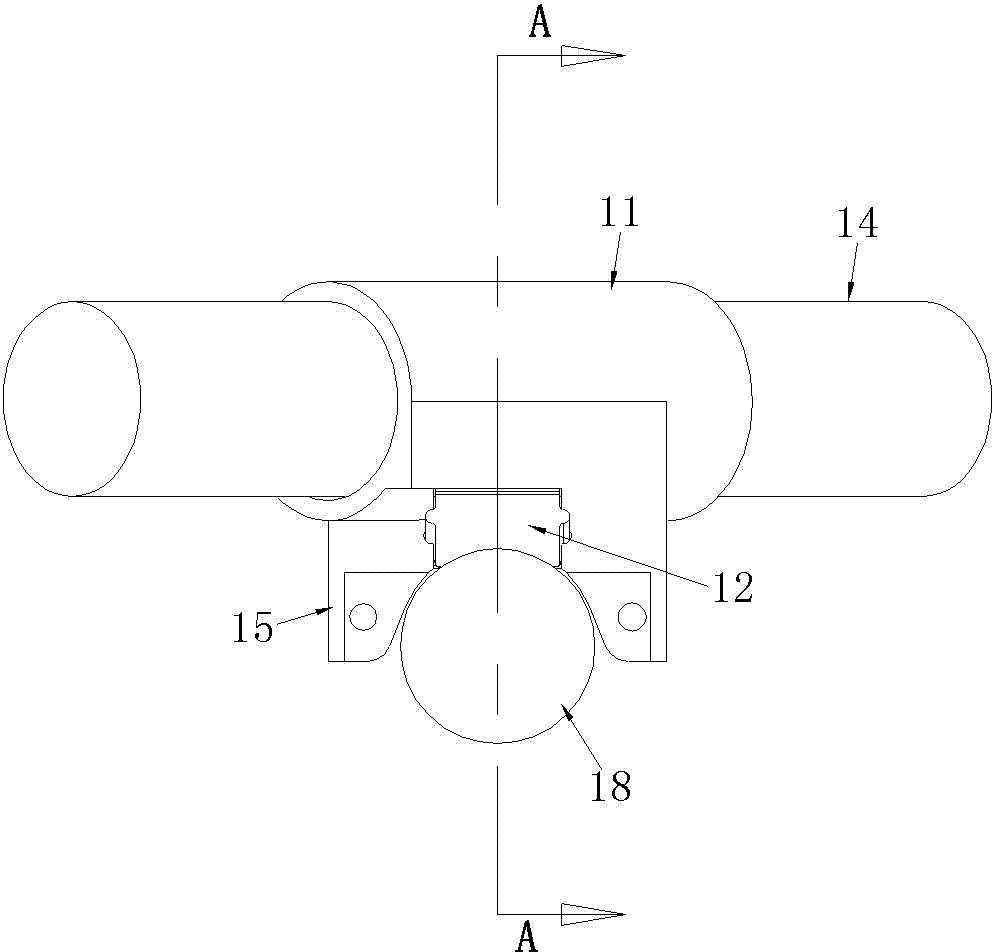

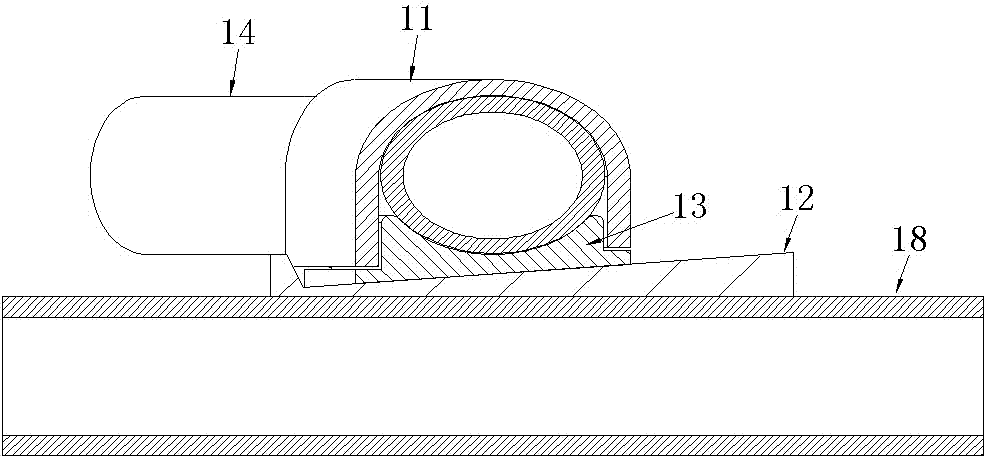

Scaffold steel tube spatial assembling fastener and sliding sleeve thereof

The invention relates to the field of scaffold fasteners and particularly relates to a scaffold steel tube spatial assembling fastener and a sliding sleeve thereof. The fastener comprises the sliding sleeve, two sets of pressing assemblies are arranged on the outer sides of the sliding sleeve, each pressing assembly comprises hinge bases oppositely distributed on the sliding sleeve along the axial direction of the sliding sleeve, the hinge axes of the two hinge bases are parallel and spatially and perpendicularly crossed with a central line of the sliding sleeve, a containing opening for containing scaffold steel tubes is enclosed between the upper portions of the two hinge bases, an expansion block installation groove is enclosed between the lower portions of the two hinge bases, an opening is arranged between the two hinge bases on the wall of the sliding sleeve, a pressing slider is assembled in the opening, an expansion slider for being firmly wedged between the scaffold steel tubes and the pressing slider in the containing opening is assembled in the expansion block installation groove, and the hinge bases of the two sets of pressing assemblies are spatially and perpendicularly crossed. The scaffold steel tube spatial assembling fastener has the advantages of being convenient to operate, reliable to fix and not apt to lose and can simultaneously fix three spatially crossed scaffold steel tubes.

Owner:朱晓龙

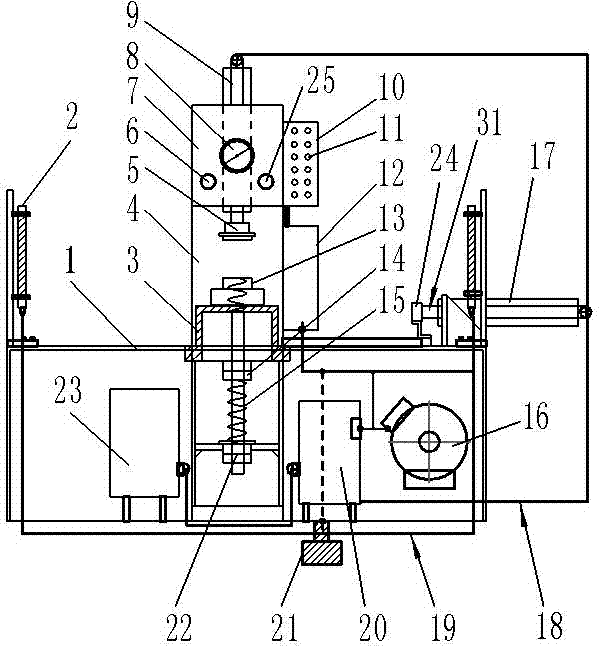

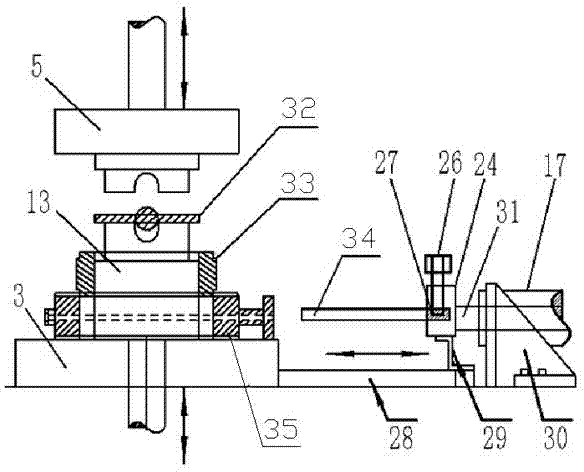

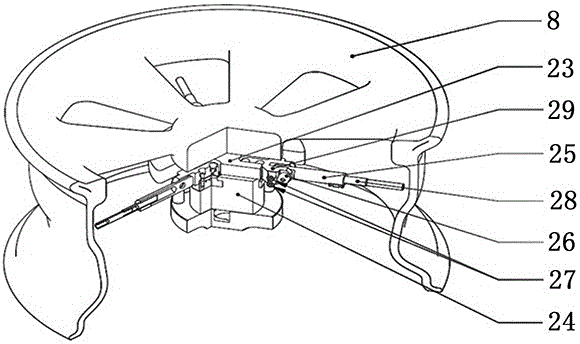

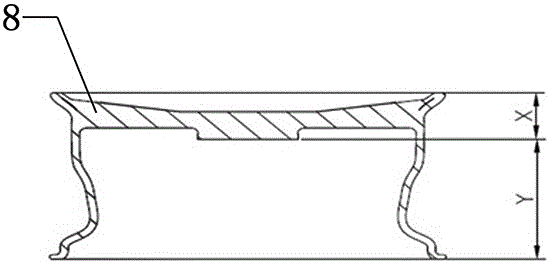

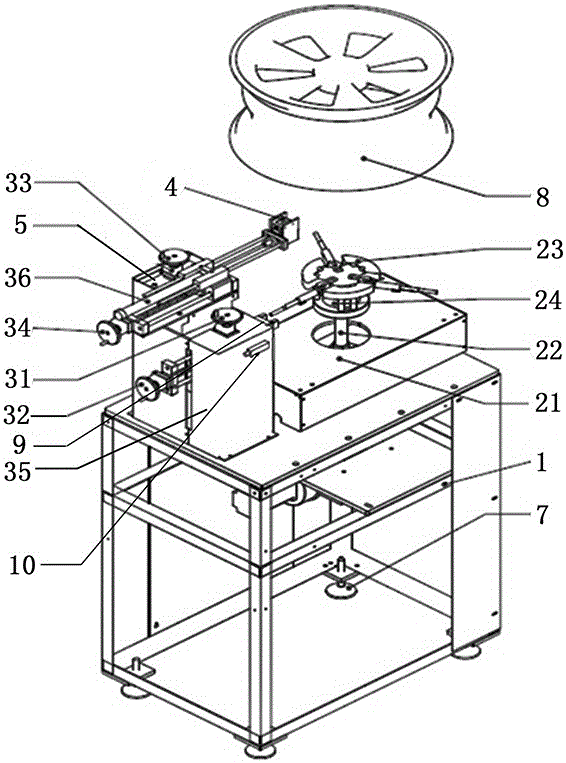

Efficient rim rotation type automatic positioning device

ActiveCN105058138ALow environmental requirementsReduce false positive rateMeasurement/indication equipmentsMetal working apparatusLaser rangingEngineering

The invention discloses an efficient rim rotation type automatic positioning device. The efficient rim rotation type automatic positioning device comprises a rack, a positioning mechanism and an adjusting mechanism. The positioning mechanism and the adjusting mechanism are arranged on the rack, and the adjusting mechanism is further provided with a laser range finder. The efficient rim rotation type automatic positioning device is reasonable in structure, reliable in performance, capable of being used for detecting various rims in different specifications, preventing materials from being mixed and detecting whether materials exist, and high in automation degree, and efficiency is greatly improved.

Owner:铁王数控机床(苏州)有限公司

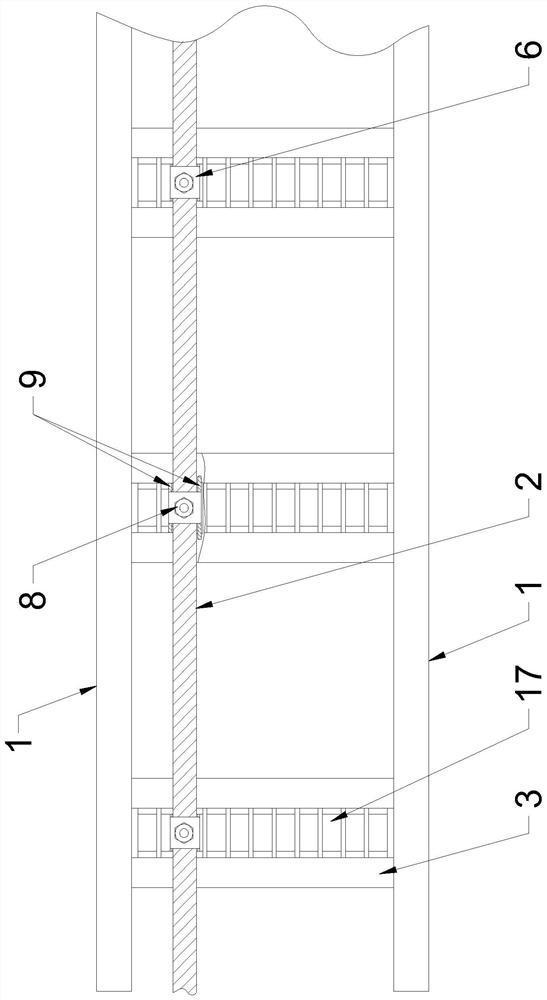

Scaffold cross-bar used for supporting girder formwork

InactiveCN103233576ARealize top supportImprove building construction efficiencyForms/shuttering/falseworksFalseworkSteel tube

The invention relates to the field of scaffolds for buildings, and particularly to a scaffold cross-bar used for supporting a girder formwork. The scaffold cross-bar comprises a transverse steel pipe which is provided with at least a pair of tightly supported fasteners; each tightly supported fastener comprises a top sleeve sleeved on the transverse steel pipe in a sliding manner; each top sleeve is provided with a tight support part used for tightly supporting a side vertical surface formwork of a girder; in addition, a wedge block which is fixed on the transverse steel pipe in the expansion manner is also inserted in each top sleeve. When the scaffold cross-bar is used, the transverse steel pipe can be arranged below the girder, so that the two corresponding tightly supported fasteners are respectively located at two sides of the girder, and the positions of the top sleeves are adjusted by enabling the top sleeves to slide on the transverse steel pipe; and when the tight support part of each top sleeve tightly presses the side vertical surface formwork of the girder, each top sleeve is fixed in the expansion manner by knocking each wedge block, so that the tight support of the side vertical surface formwork of the girder is realized. After the scaffold cross-bar is adopted, step-to-step fasteners adopted in the prior art can be abandoned completely, and efficiency of building construction can be improved greatly.

Owner:朱新伟

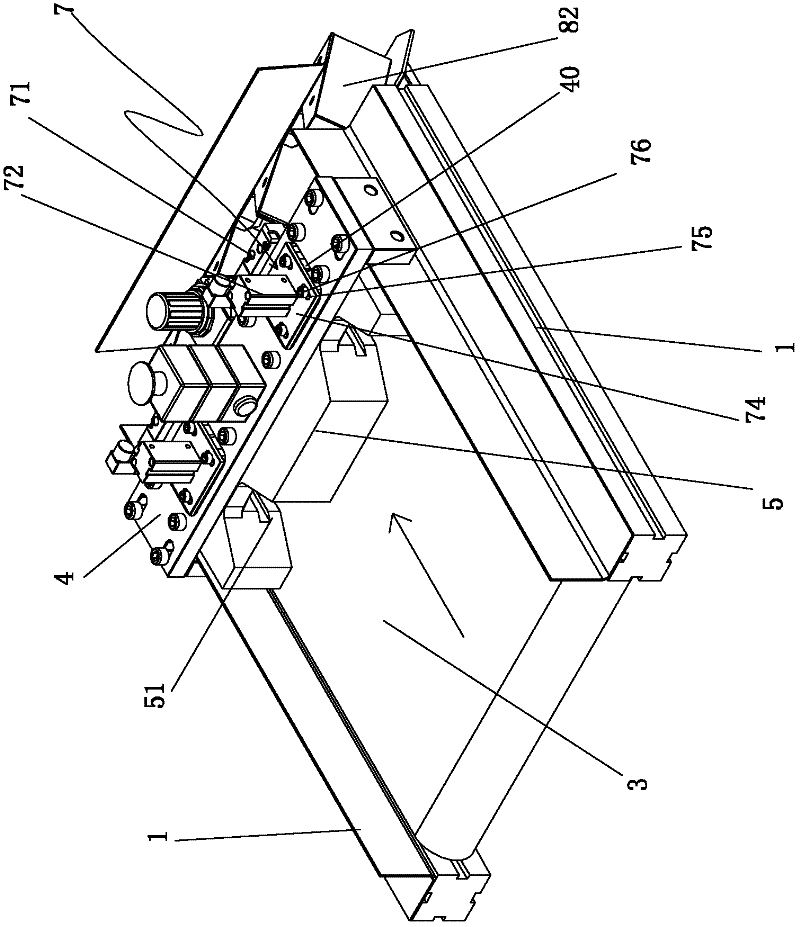

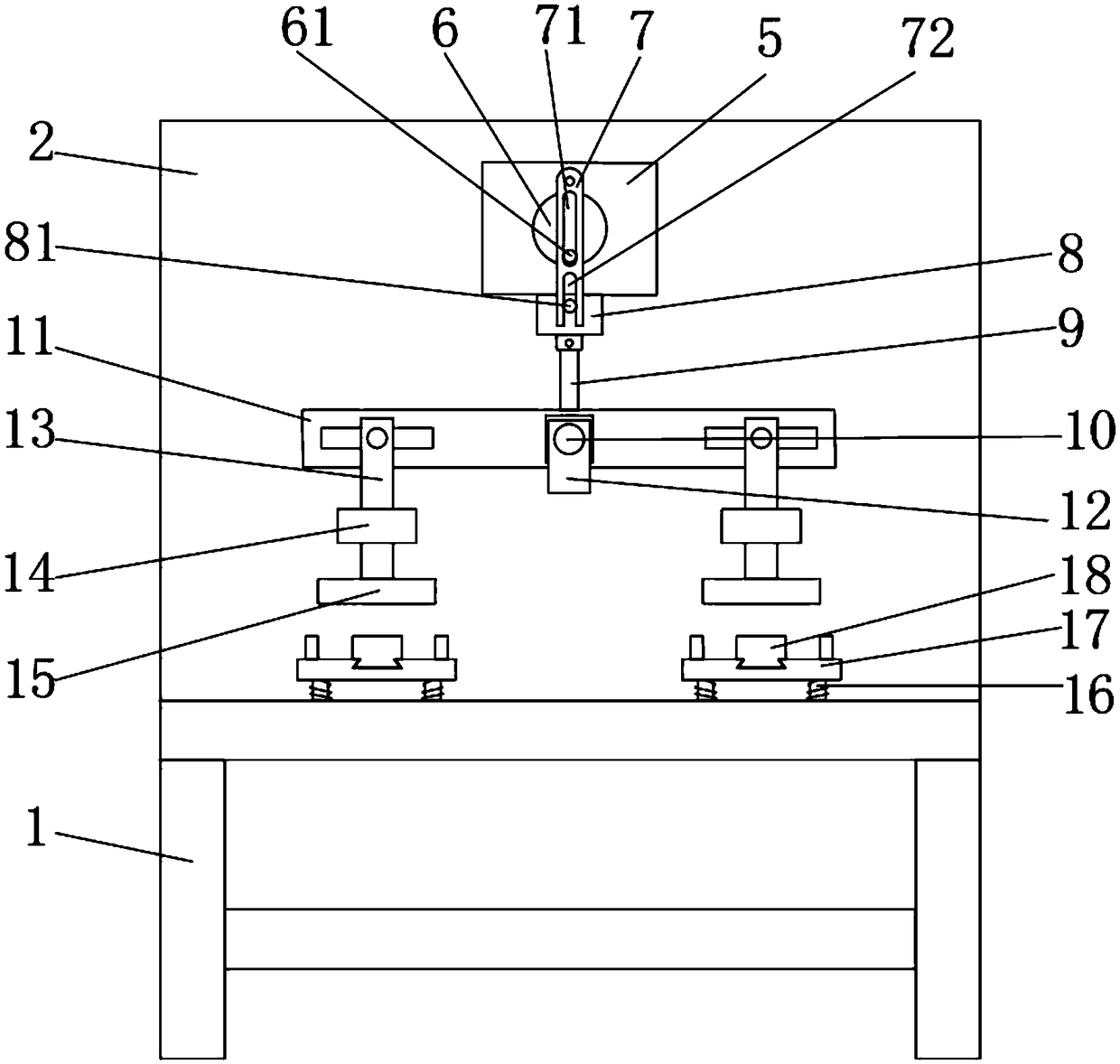

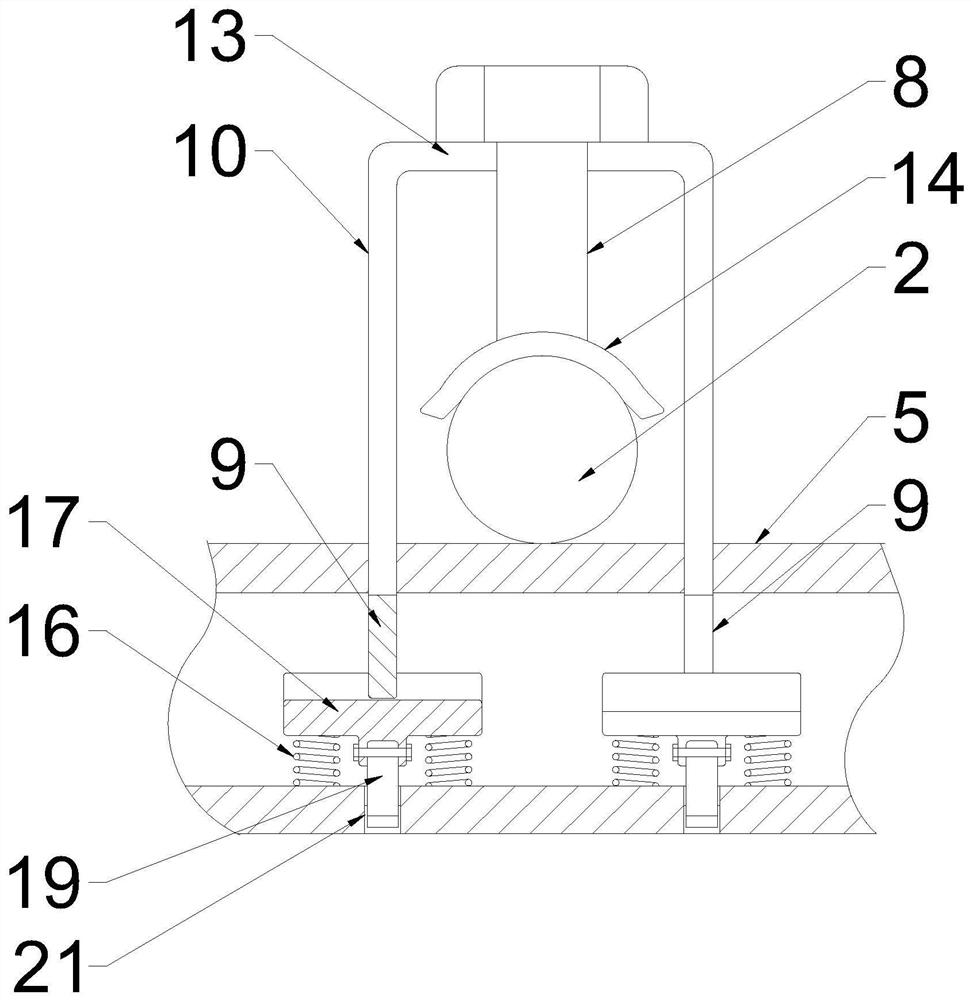

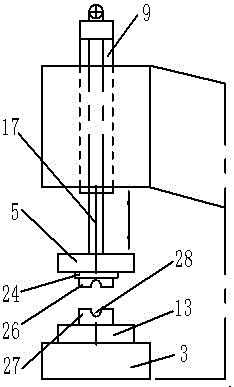

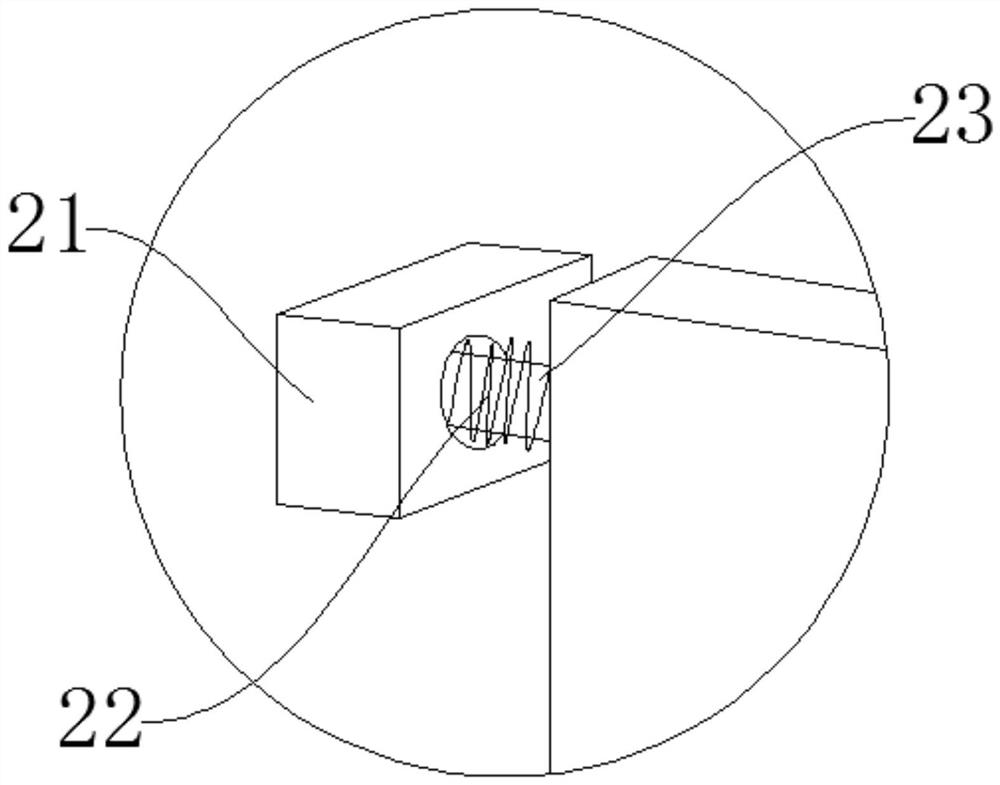

Workpiece pressing mechanism

InactiveCN104369034ALimit the maximum displacementAvoid pressure deformationWork clamping meansPositioning apparatusMechanical engineeringPiston rod

The invention discloses a workpiece pressing mechanism which comprises a machine base and a rack and is further provided with a conical gear with a strength increasing handle, an oscillating air cylinder and a pressing head with a connection rod. The machine base is provided with a sliding groove, and the rack is located in the sliding groove. The circle center position of the conical gear is connected with the machine base in a rotating mode, and the conical gear is meshed with the rack. A piston rod of the oscillating air cylinder is hinged to the strength increasing handle. The end, away from the piston rod, of the oscillating air cylinder is connected with the machine base in an oscillating mode. The position, opposite to one end of the rack, of the machine base is provided with a supporting base. The connection rod of the pressing head is connected with the end, close to the supporting base, of the rack. The workpiece pressing mechanism is large in clamping force, and workpieces can be stably clamped.

Owner:重庆川茂建材有限公司

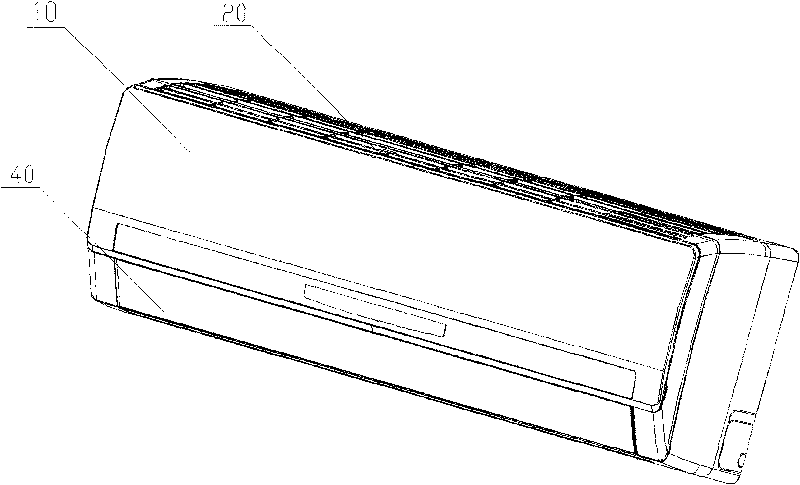

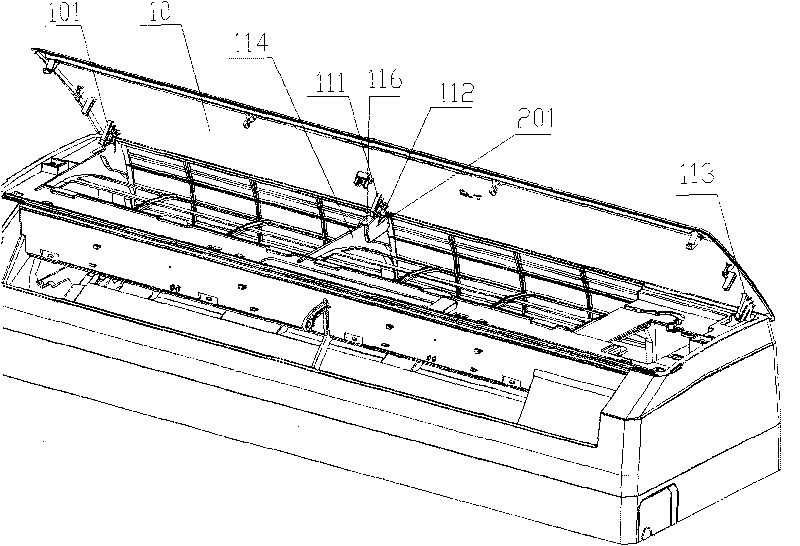

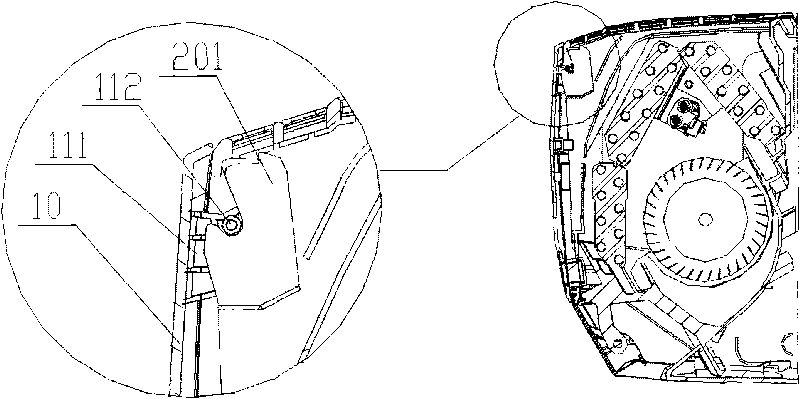

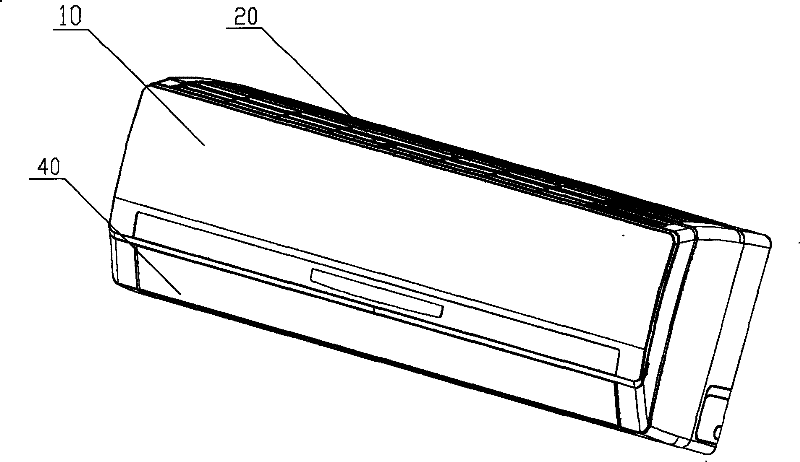

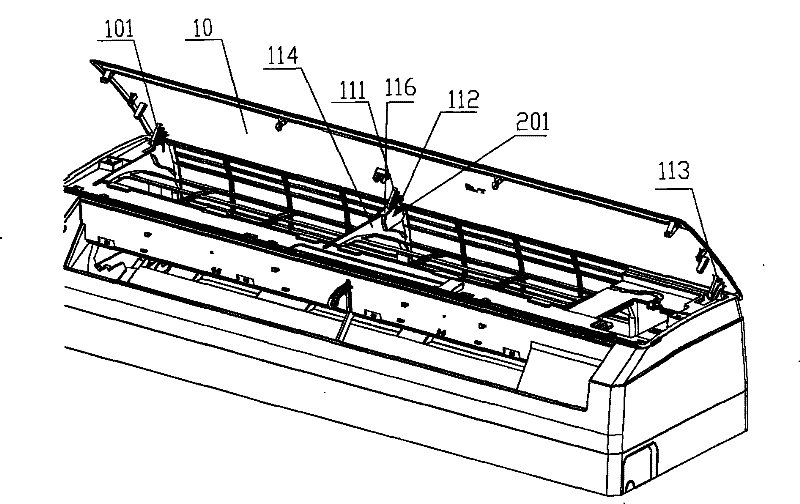

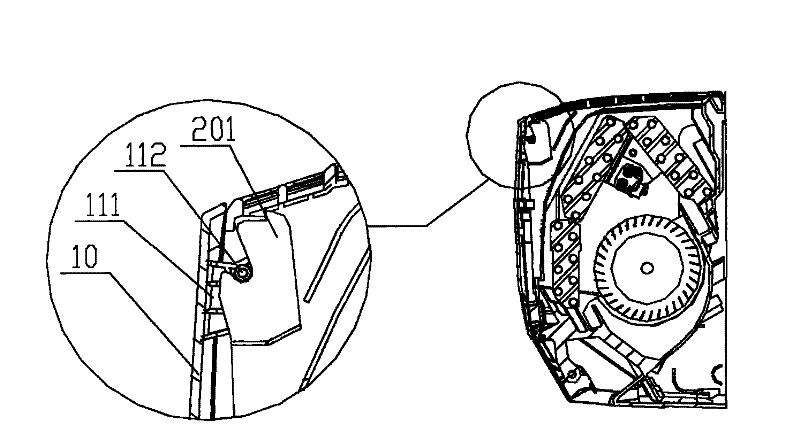

Air conditioner

ActiveCN101749796AAvoid pressure deformationEasy to disassembleLighting and heating apparatusAir conditioning systemsEngineeringElectrical and Electronics engineering

Owner:GREE ELECTRIC APPLIANCES INC

Double-pole scaffold system

ActiveCN103206079AImprove securitySolve efficiency problemsScaffold connectionsMechanical engineeringHinge angle

The invention relates to the field of building scaffolds, and in particular relates to a double-pole scaffold system. The system comprises vertical rods and horizontal rods, wherein cross-shaped buckling parts are arranged at positions of the corresponding cross-shaped joints on the vertical rods; the cross-shaped buckling parts comprise sliding sleeves sleeved on the vertical rods and pressing assemblies arranged on the sliding sleeves; each pressing assembly comprises two hinge seats; one of the two hinge seats is hinged with a pressing cover, the other one of the two hinge seats is hinged with a hasp; hinging axial lines of the two hinge seats are parallel to each other and are vertically crossed with a space of central lines of the sliding sleeves; and in addition, a containing opening for containing the corresponding horizontal rods is encircled between the upper parts of the two hinge seats; an expansion block mounting groove is encircled between the lower parts of the two hinge seats; openings, of which the inner parts and the outer parts penetrate through each other, are formed between the two hinge seats of each set of pressing assembly on the walls of the sliding sleeves; an expanding sliding block which is used for preventing falling and wedged between the vertical rods and the corresponding horizontal rods is arranged in the expanding block mounting groove; and the double-pole scaffold system has the characteristic of convenience in application, and the security performance of a scaffold is improved.

Owner:朱新伟

Shell embossing device of electronic product production

InactiveCN109049658AEmbossing operation continuousShorten the timeDomestic articlesEmbossing decorationsDrive motorEngineering

The invention discloses a shell embossing device of electronic product production in the technical field of shell embossing. The device comprises a bottom supporting table. The top of the bottom supporting table is provided with a vertical plate. The rear end of the vertical plate is provided with a motor mounting plate. The top of the motor mounting plate is provided with a driving motor. The front end of the vertical plate is provided with a fixing block. A clamping rod is located in a shifting groove. The bottom of the left and right sides of an upper and lower swing rod is connected with pressing rods. The middles of the outer walls of the pressing rods are sleeved with pressing rod sleeves. The bottoms of the pressing rods are provided with pressing heads. Four sets of movable rods are movably inserted into the left side and the right side of the top front side of the bottom supporting table. The outer walls of the movable rods are covered with compression springs. Electronic product placement seats are arranged at the tops of the movable rods. Elastic clamping blocks are arranged on four sides of the top of the electronic product placement seats. According to the shell embossing device of electronic product production, shell embossing of left and right two groups of electronic products can be rapidly conducted according to the lever principle, and the embossing operationis quick and efficient.

Owner:扬州华青电子有限公司

Scaffold steel tube spatial assembling fastener and sliding sleeve thereof

The invention relates to the field of scaffold fasteners and particularly relates to a scaffold steel tube spatial assembling fastener and a sliding sleeve thereof. The fastener comprises the sliding sleeve, two sets of pressing assemblies are arranged on the outer sides of the sliding sleeve, each pressing assembly comprises hinge bases oppositely distributed on the sliding sleeve along the axial direction of the sliding sleeve, the hinge axes of the two hinge bases are parallel and spatially and perpendicularly crossed with a central line of the sliding sleeve, a containing opening for containing scaffold steel tubes is enclosed between the upper portions of the two hinge bases, an expansion block installation groove is enclosed between the lower portions of the two hinge bases, an opening is arranged between the two hinge bases on the wall of the sliding sleeve, a pressing slider is assembled in the opening, an expansion slider for being firmly wedged between the scaffold steel tubes and the pressing slider in the containing opening is assembled in the expansion block installation groove, and the hinge bases of the two sets of pressing assemblies are spatially and perpendicularly crossed. The scaffold steel tube spatial assembling fastener has the advantages of being convenient to operate, reliable to fix and not apt to lose and can simultaneously fix three spatially crossed scaffold steel tubes.

Owner:朱晓龙

Anti-seismic ladder-type cable bridge for nuclear island of nuclear power station

ActiveCN112398060AImprove assembly efficiencyReduced risk of bolt looseningElectrical apparatusVibration suppression adjustmentsCable trayEarthquake resistant

The invention provides an anti-seismic ladder-type cable bridge for a nuclear island of a nuclear power station. The anti-seismic ladder-type cable bridge comprises two side frames and a plurality ofladder plates which are arranged on the side frames and are used for supporting a cable, wherein each ladder plate is formed by cutting C-shaped steel, a pressing piece is installed on each ladder plate, the cable is pressed on each ladder plate through the pressing piece, each pressing piece comprises a pressing plate, a locking bolt and an ejecting piece, two pressing legs of each pressing plateare erected on the front side and the rear side of the cable, the two ejecting pieces are connected to the bottoms of the two pressing legs respectively, and the ejecting pieces stretch into a steelgroove of each ladder plate. Each ejecting piece comprises a horizontally-arranged force application ejecting face and an arc-shaped side wall converging towards the inner side. The force applicationejecting face is located below top turnups of each ladder plate, and the left side and the right side of the force application ejecting face can abut against the two top turnups respectively. The locking bolts are installed on transverse ribs on the top of the pressing plates, and the cable can be pressed by screwing the locking bolts downwards. According to the cable bridge, the problems of longmounting time, low construction efficiency and hidden danger of connection looseness after long-term use of the ladder type bridge frame are solved.

Owner:JIANGSU HAIWEI ELECTRIC

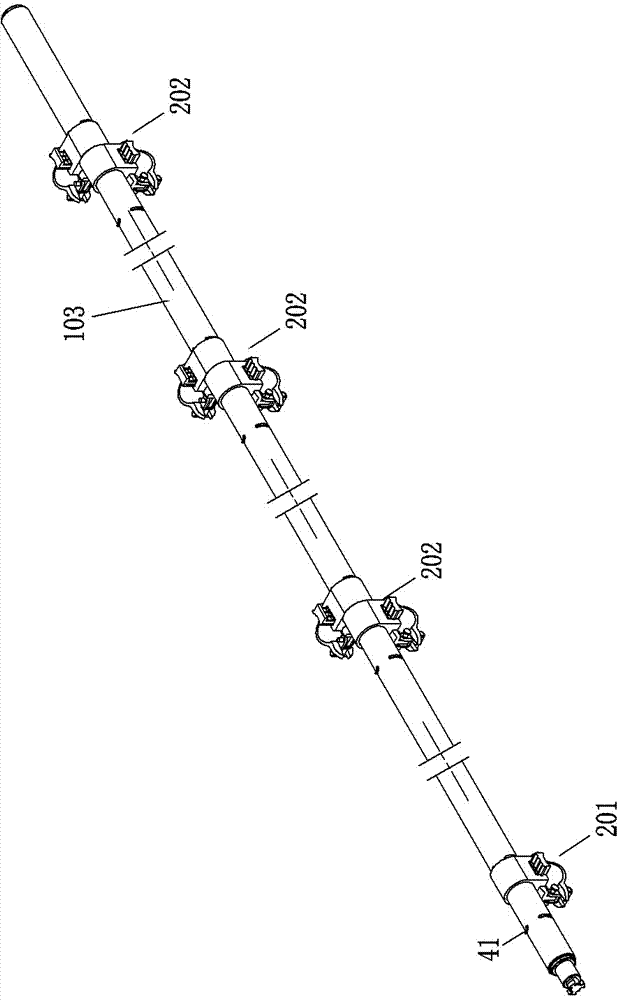

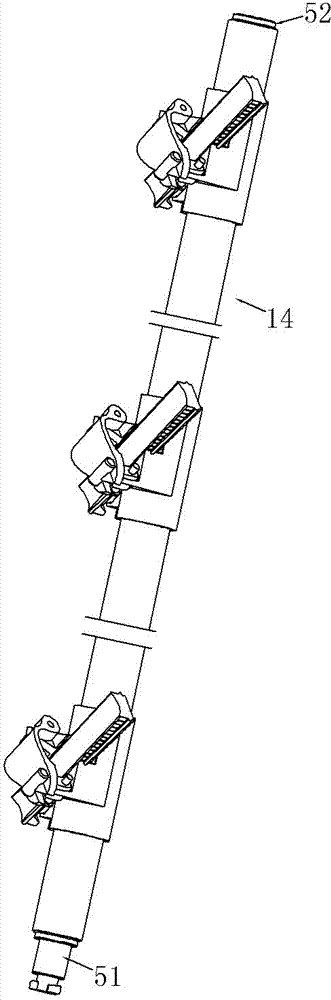

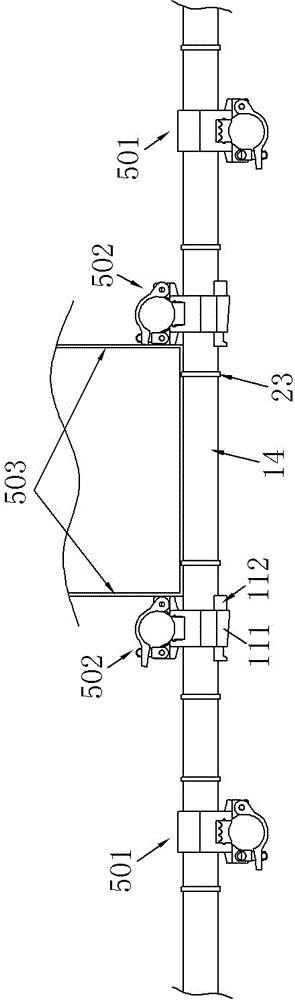

Scaffold diagonal bar

InactiveCN103206080APrevent accidental looseningImprove securityScaffold connectionsFalseworkEngineering

The invention relates to the field of scaffolds for buildings, and particularly relates to a scaffold diagonal bar. The scaffold diagonal bar comprises a diagonal steel pipe and a fastener assembled on the diagonal steel pipe, wherein the fastener comprises a sliding sleeve which is sleeved on the diagonal steel pipe in a sliding manner; two hinged supports are oppositely arranged on the outer side of the sliding sleeve; the hinged axles of the hinged supports are parallel to each other and in spatial crossing with the center line of the sliding sleeve; a set included angle of 30-60 degrees is formed between the center line of the sliding sleeve and the hinged axis of each hinged support; the upper parts of the two hinged supports define a containing opening for containing a basic steel pipe of a scaffold, and the lower parts of the hinged supports define an expanding block mounting groove; the wall of the sliding sleeve is provided with an opening through inside and outside between the two hinged supports; the expanding block mounting groove is internally provided with an expanding slider wedged between the diagonal steel pipe and the basic steel pipe in the containing opening; and the diagonal steel pipe is provided with corresponding limit structures at both ends of the sliding sleeve. The scaffold diagonal bar is convenient to use and high in safety.

Owner:朱新伟

Assembling method for aluminum frame door leaf

The invention provides an assembling method for an aluminum frame door leaf. The assembling method includes the following steps that according to door sheet gluing, a front door sheet and a rear door sheet are glued together to form a door leaf semi-finished product, and closure sheets are installed on the front door sheet and the rear door sheet; according to aluminum frame assembling, an aluminum frame adheres to the closure sheets of the door leaf semi-finished product through adhesive, and therefore the aluminum frame door leaf is formed. The assembling method further includes the step of spraying treatment on the door leaf semi-finished product and the aluminum frame, wherein the step is executed between the step of door sheet gluing and the step of aluminum frame assembling. The assembling method has the advantages of being simple, easy to implement by one person and high in firmness, lowering the labor intensity, improving the production efficiency, saving labor, lowering the rejection rate of the product, improving the appearance attractiveness of the product and the like.

Owner:ZHUMADIAN ZHAYASHAN DOOR IND

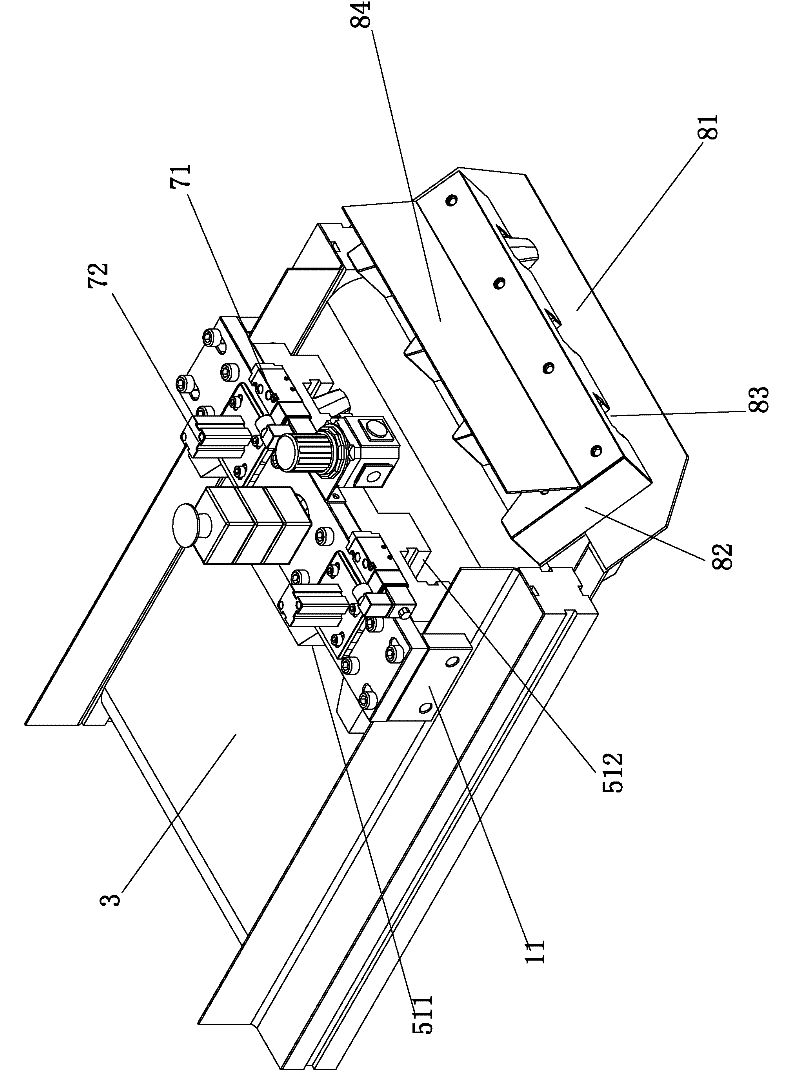

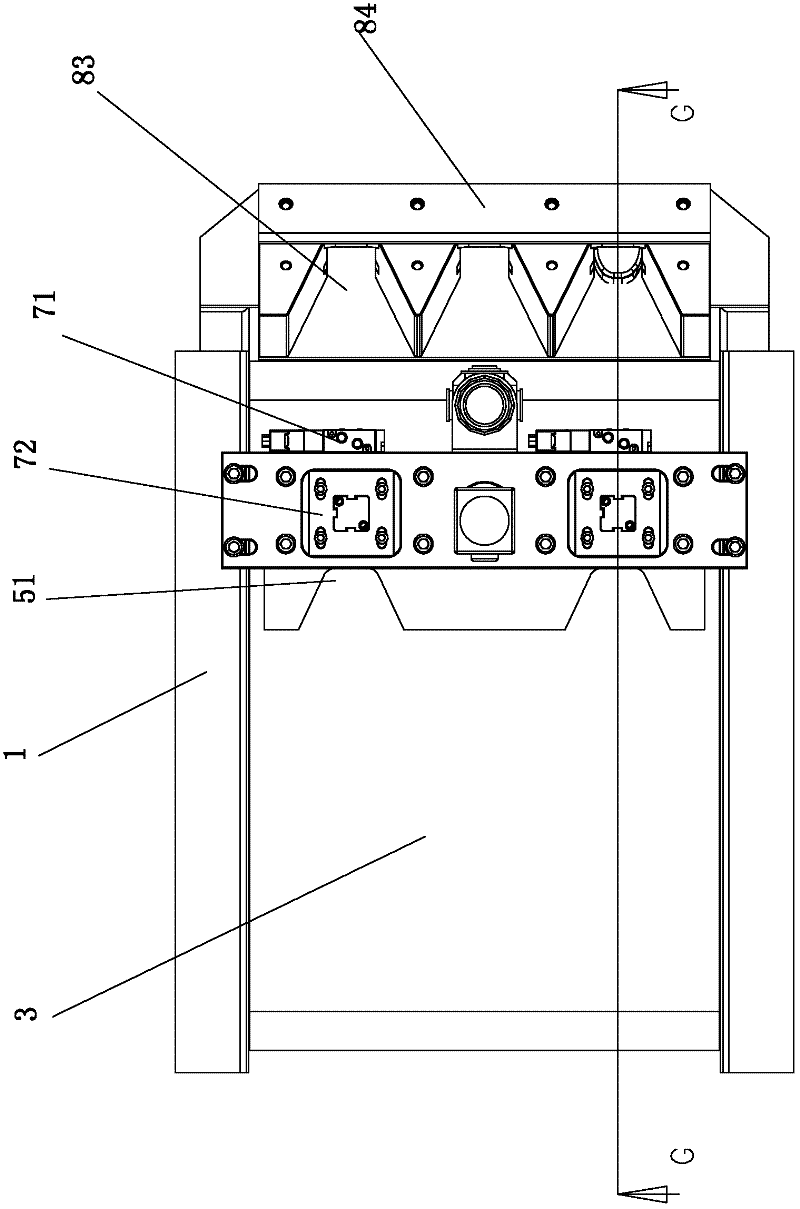

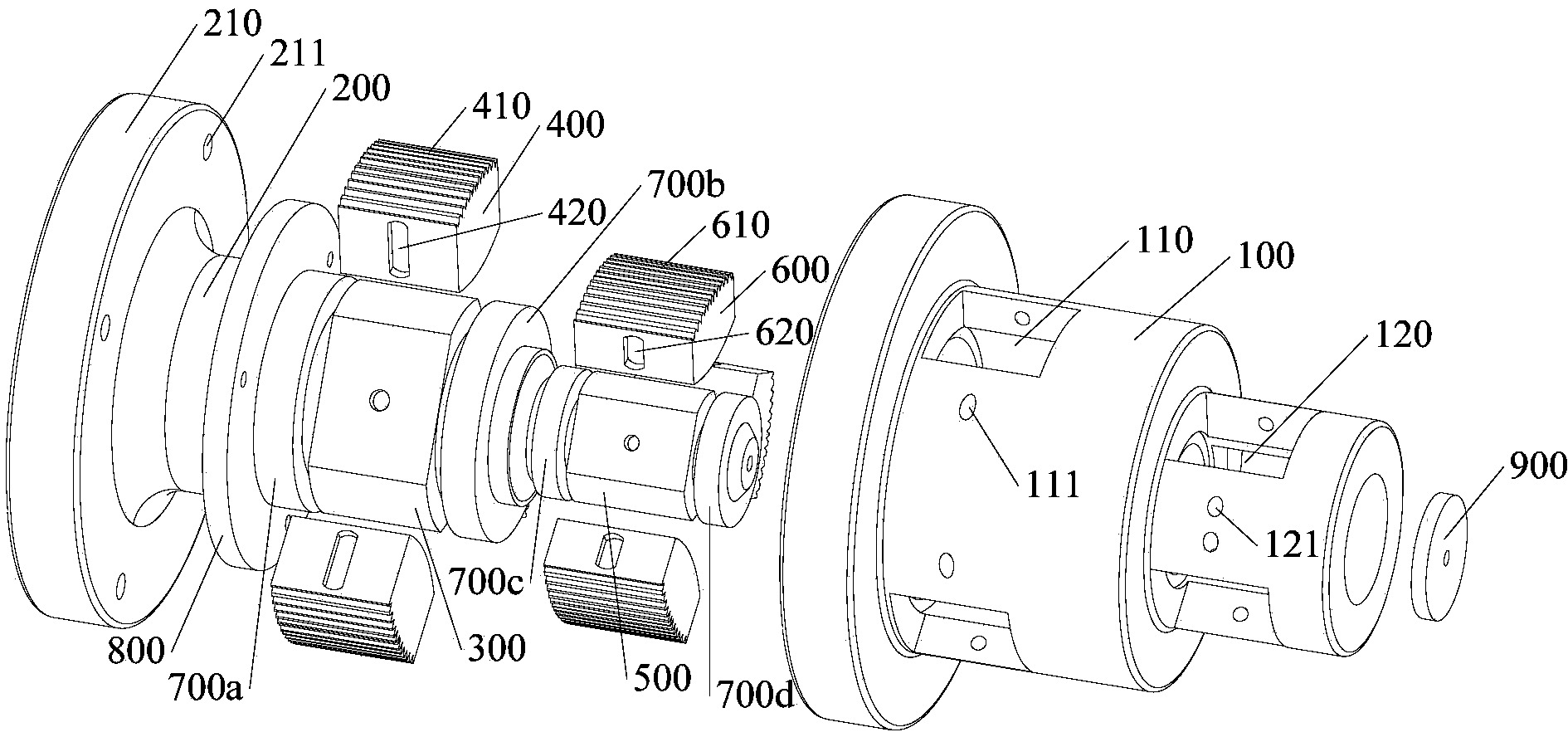

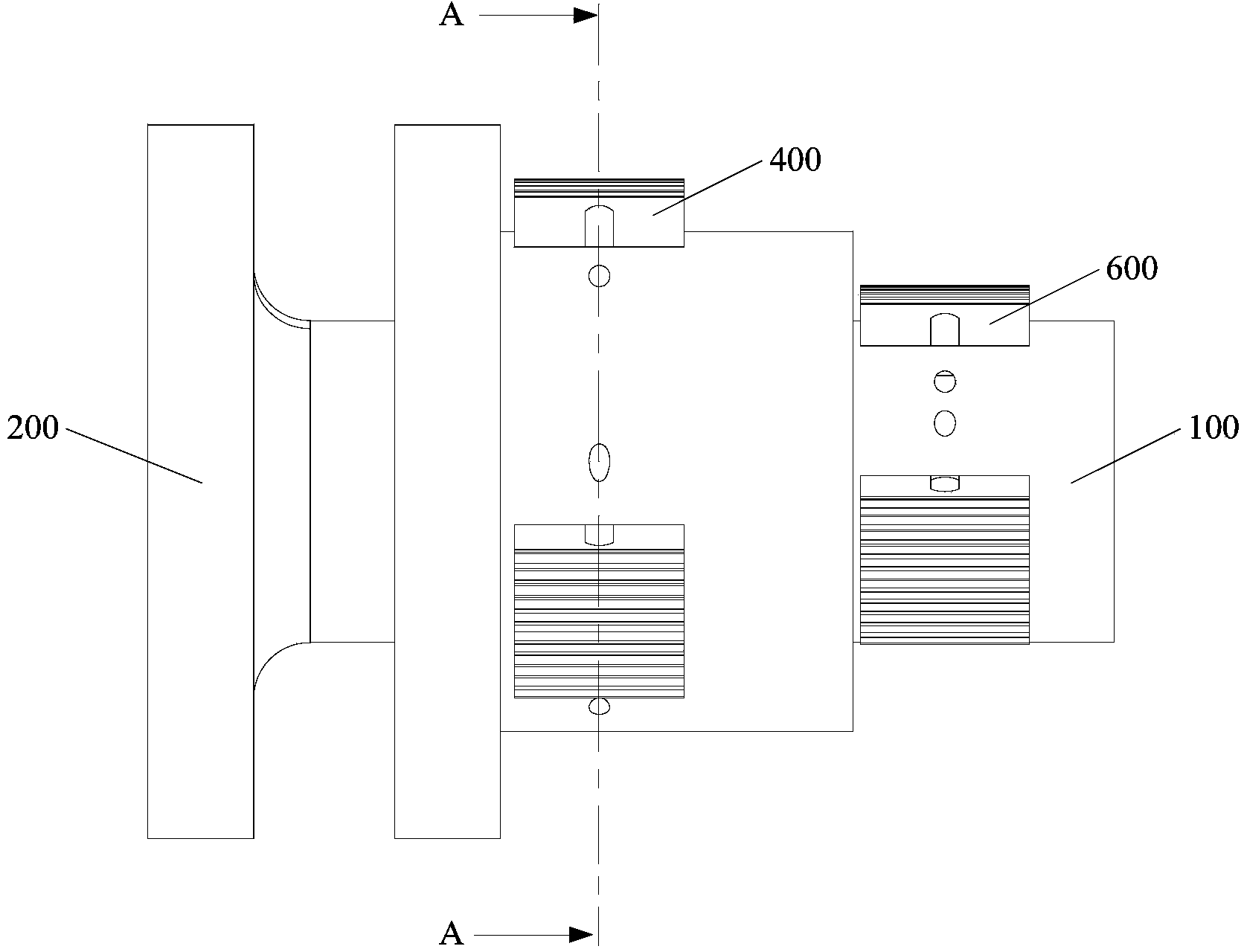

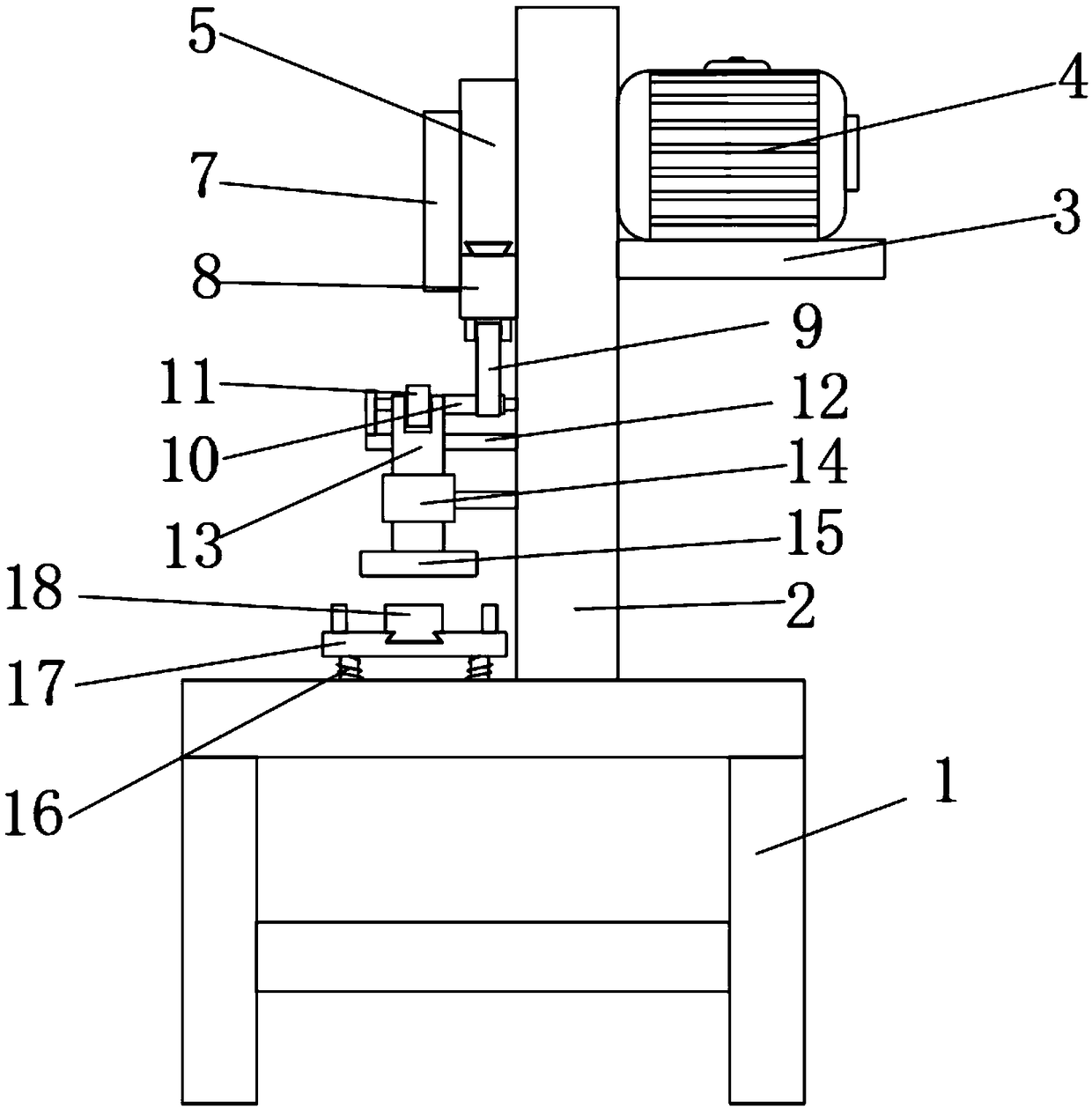

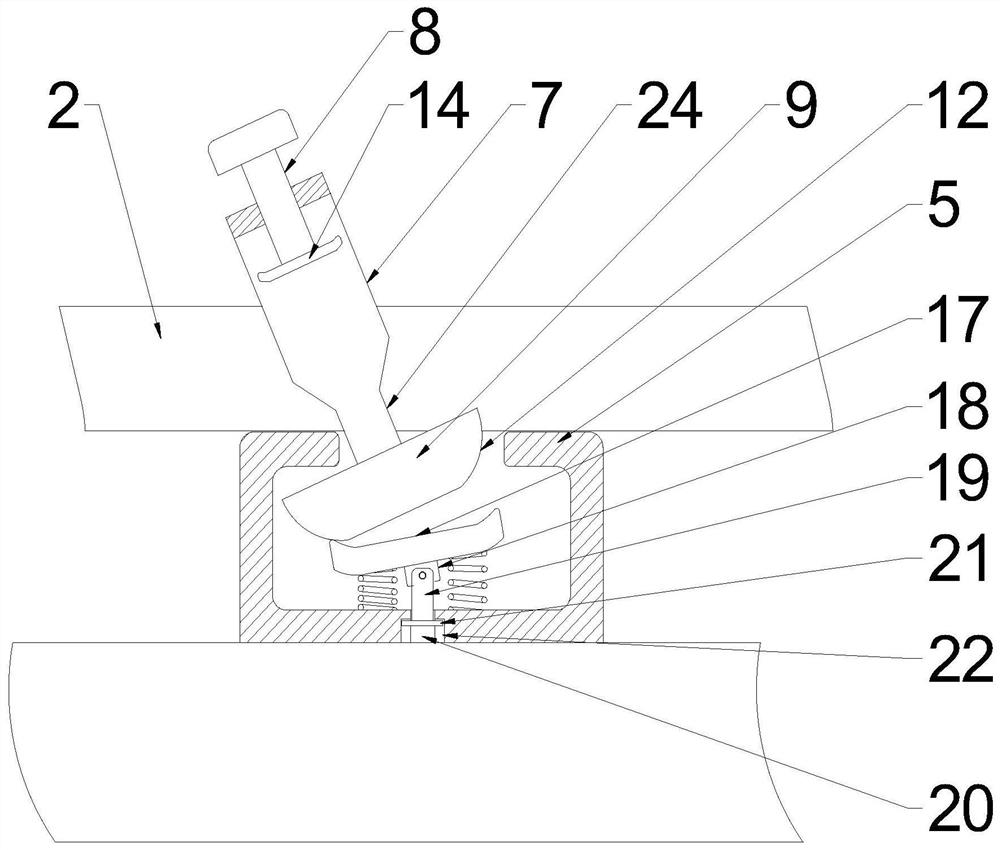

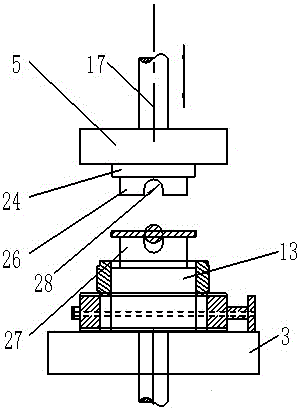

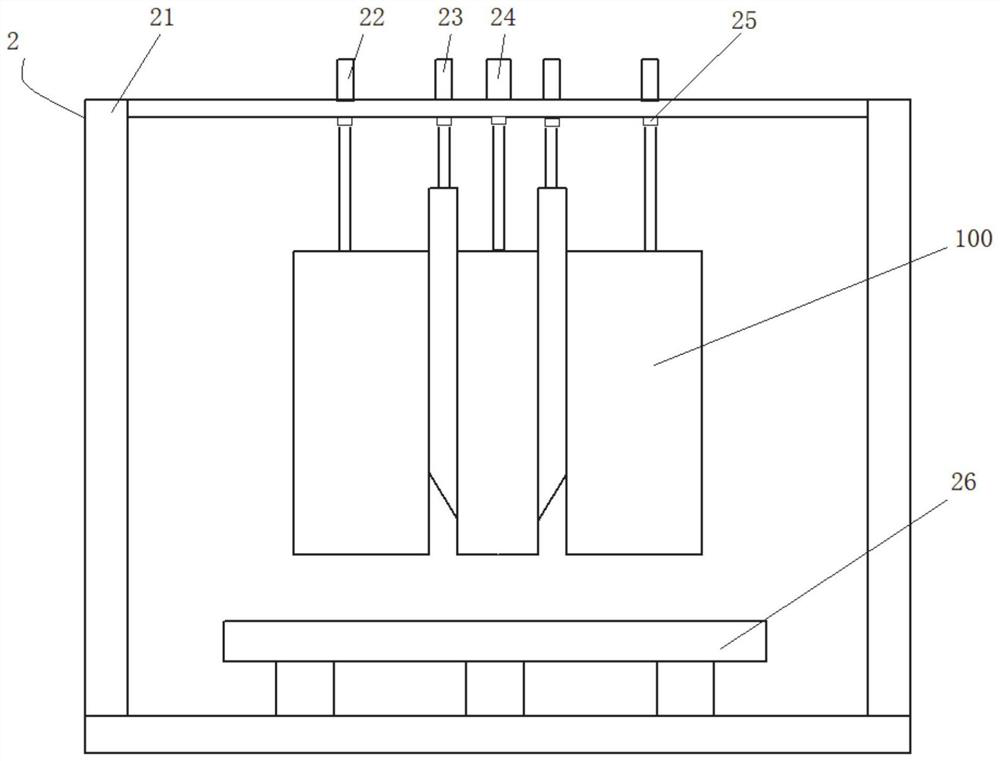

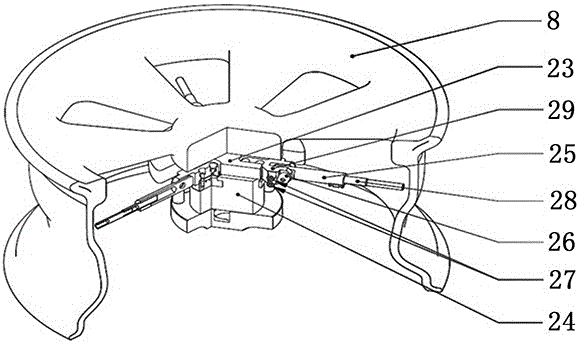

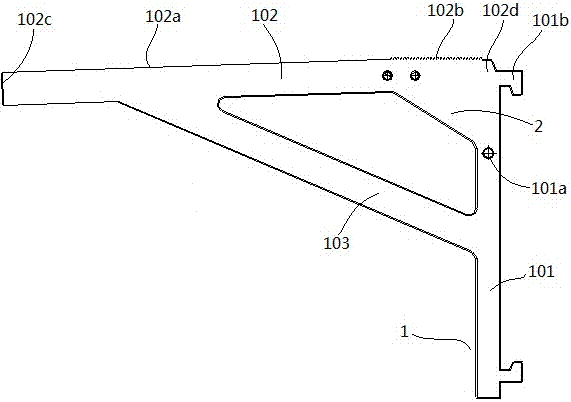

A butterfly plate hydraulic automatic combination device of a butterfly valve assembly machine and its combination method

ActiveCN104589033BAvoid pressure deformationHigh man-machine safety factorMetal working apparatusHydraulic cylinderControl system

The invention relates to an assembly machine and a combination method thereof, in particular to a butterfly plate hydraulic automatic combination device for a butterfly valve assembly machine and the combination method thereof. The butterfly plate hydraulic automatic combination device consists of a butterfly valve assembly workbench, infrared sensing safety devices, a tool base, an assembly machine upright post, a pressure head tool, a pressure regulating valve device, an upper hydraulic oil cylinder support frame, a pressure meter, an upper hydraulic cylinder device, a PLC (Programmable Logic Controller) control box device, control buttons, an electrical cabinet device, a butterfly valve tool, a locking nut mechanism and the like. The butterfly plate hydraulic automatic combination device is convenient and safe to use and is rapid to operate, the pressure of a host machine can be adjusted in time according to butterfly valve rubber sleeves and butterfly plates of different models and specifications; working efficiency and quality are greatly improved, the yield is over 99 percent, machining can be finished within 1 minute, and the economic benefit is good; a PLC is adopted in a main control system, so that the control accuracy is increased, the human-machine safety coefficient is high, a large amount of time and energy sources are saved greatly, wear is reduced, compression deformation of the butterfly plate is avoided, the maintenance cost and production cost are saved, and the overall machine performance and service life are improved and prolonged respectively.

Owner:BAND VALVE TECH CO LTD

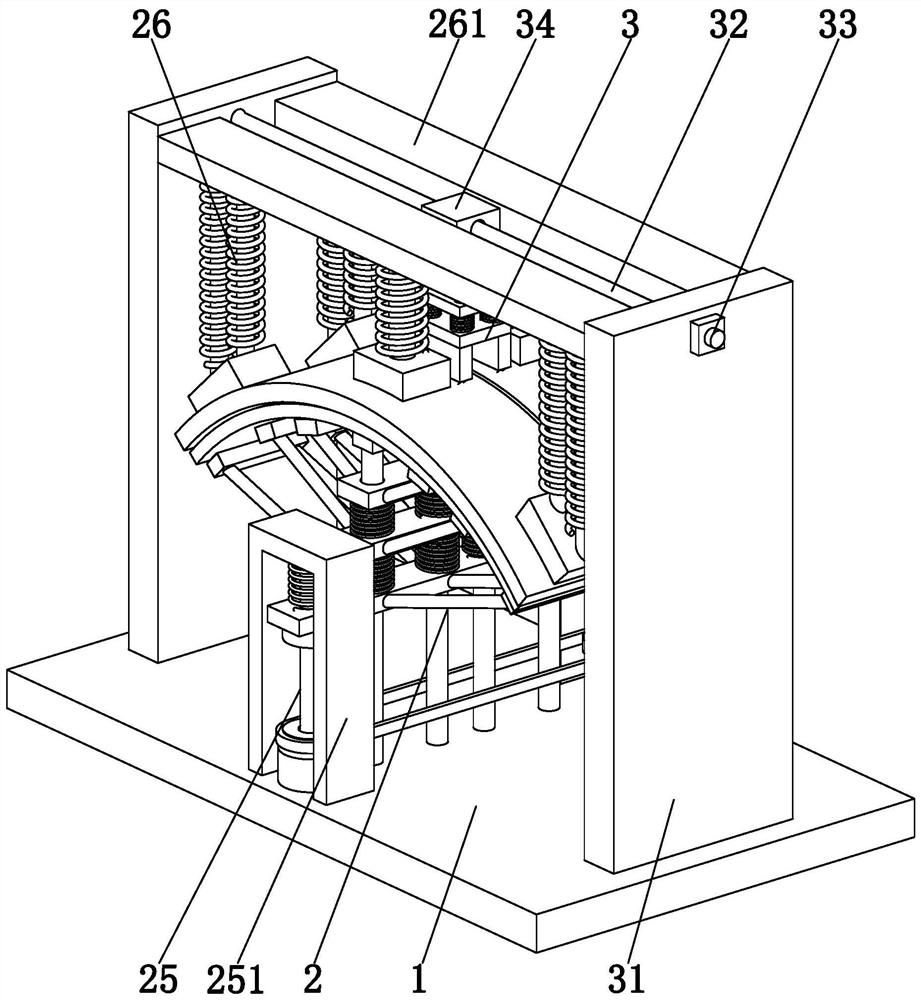

Intelligent welding robot

InactiveCN112975251AHas limitationsNo deformationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding torch

The invention provides an intelligent welding robot. The intelligent welding robot comprises a base, a clamping and fixing mechanism and a mobile welding mechanism. The intelligent welding robot can solve the following problems in the welding process: (a) according to a traditional welding method, in one case, due to the fact that welding is achieved by fixing a welding torch and enabling clamped weldments to move, the weldments may deviate when moving, resulting in welding misalignment, false welding and other problems; and in the other case, due to the fact that welding is achieved by fixing the clamped weldments and enabling the welding torch to move, the different weldments require different clamping devices, and the purpose that the same clamping device is applicable to the weldments of various specifications can not be achieved, resulting in certain limitations; and (b) during traditional welding of weldments with arc-shaped surfaces, due to the fact that the weldments are clamped and fixed through the clamping devices, the weldments are prone to be deformed and the surfaces of the weldments are prone to be scratched when the clamping force is too large; and in addition, the clamping devices for the weldments with the arc-shaped surfaces are relatively simplistic, and incapable of achieving the clamping of the weldments with different arcs.

Owner:NANJING FORESTRY UNIV

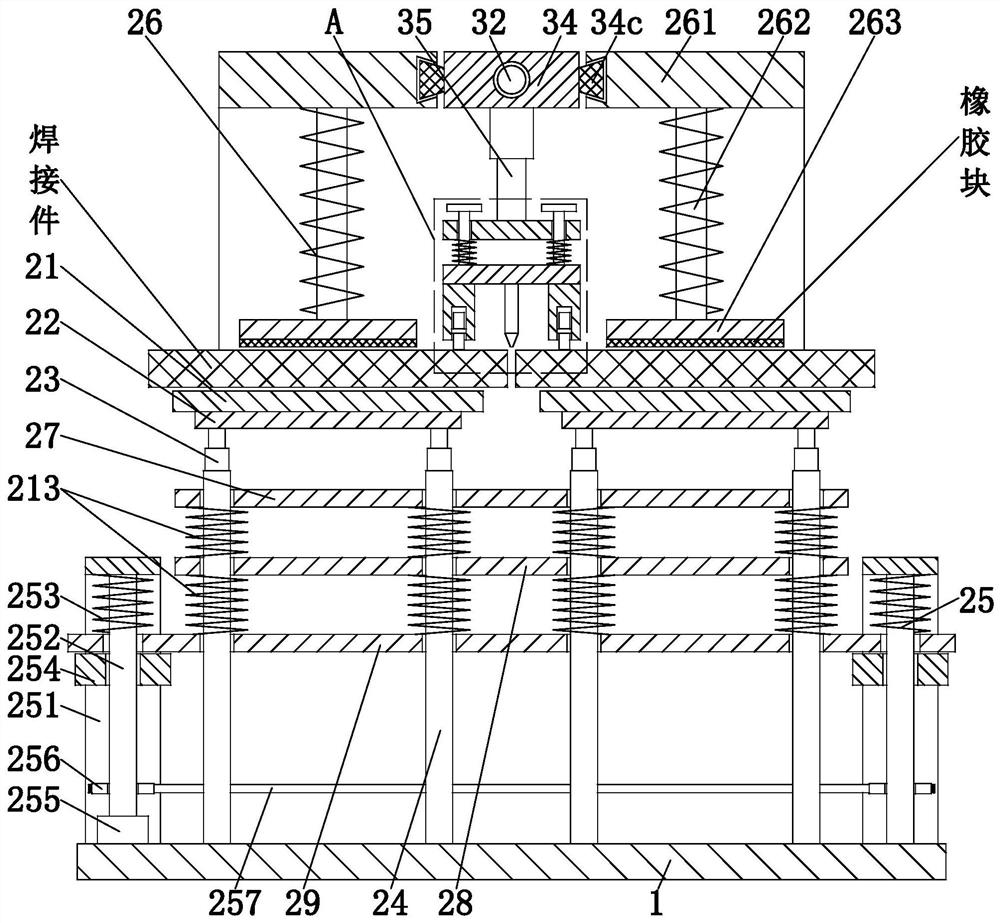

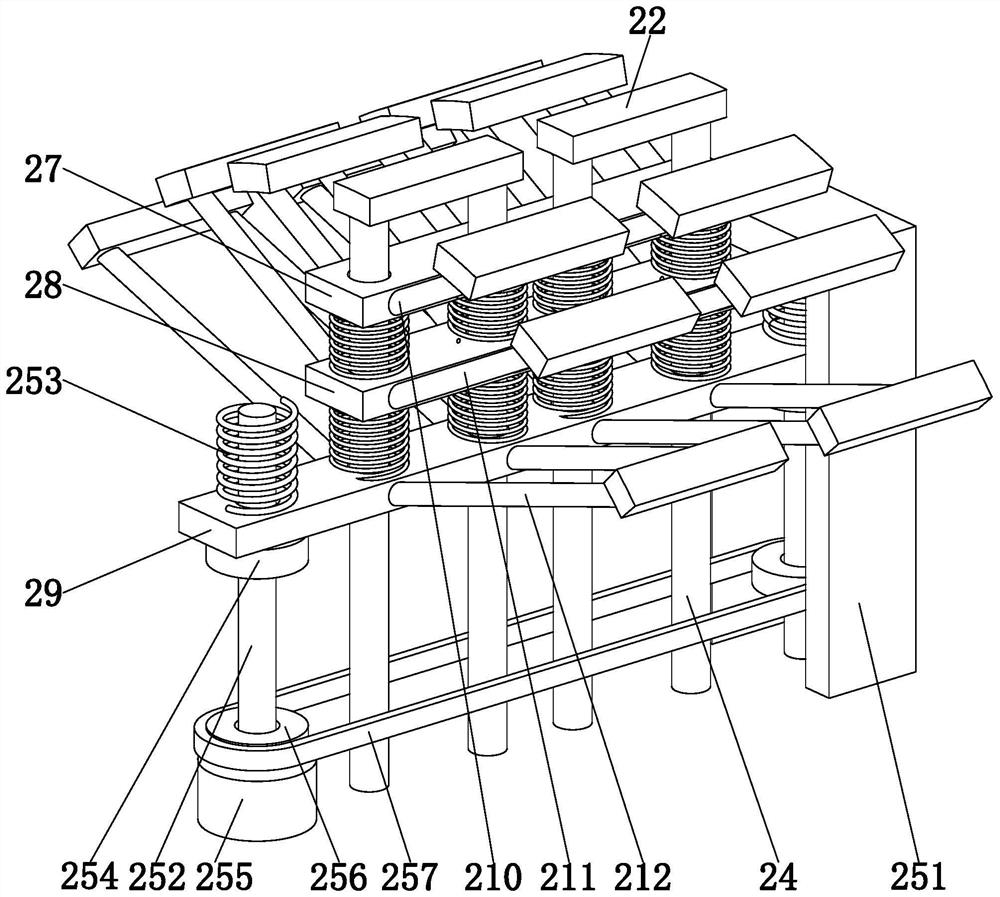

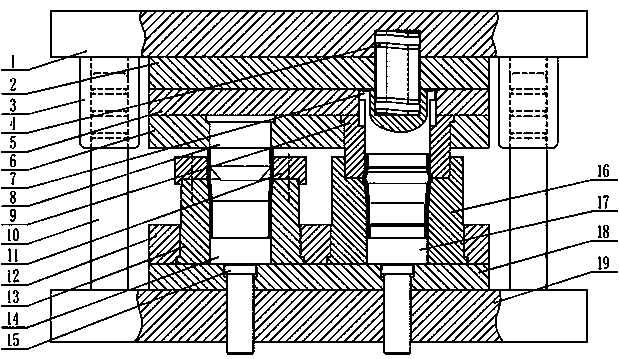

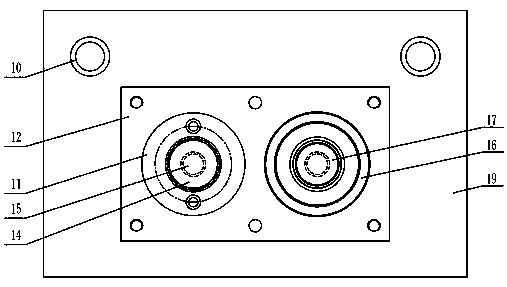

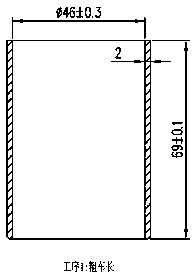

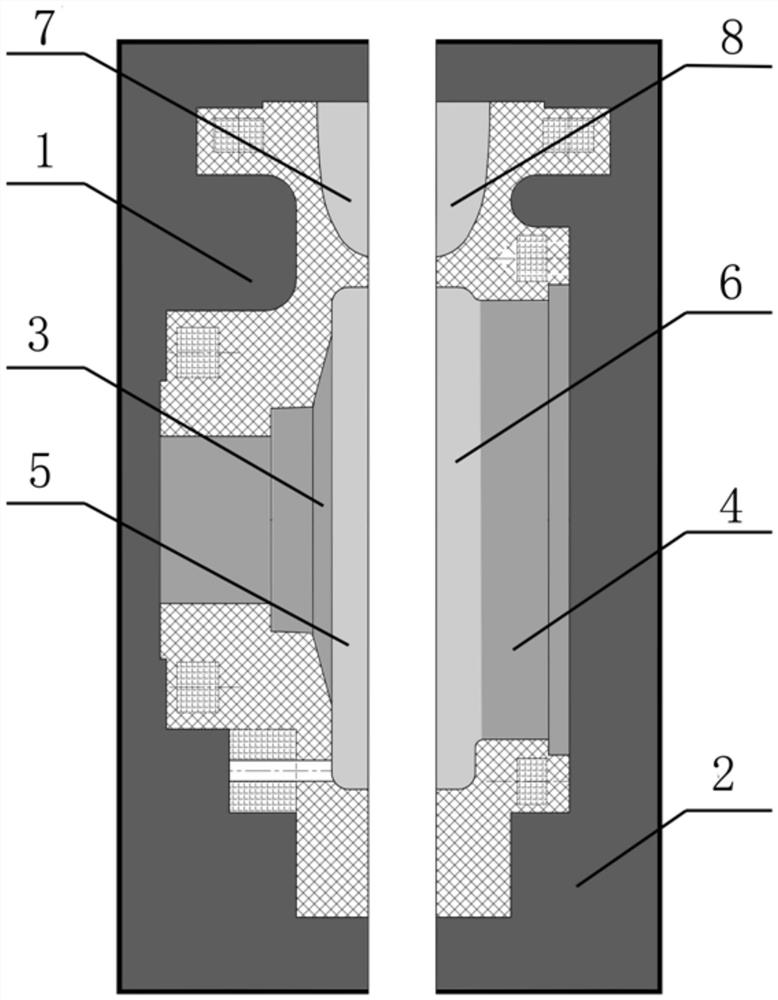

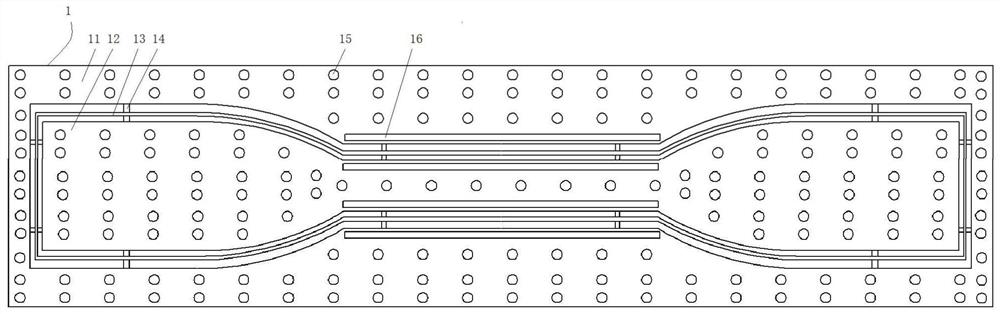

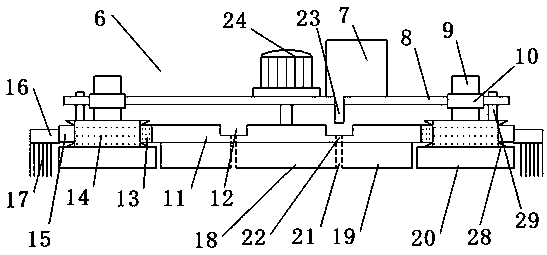

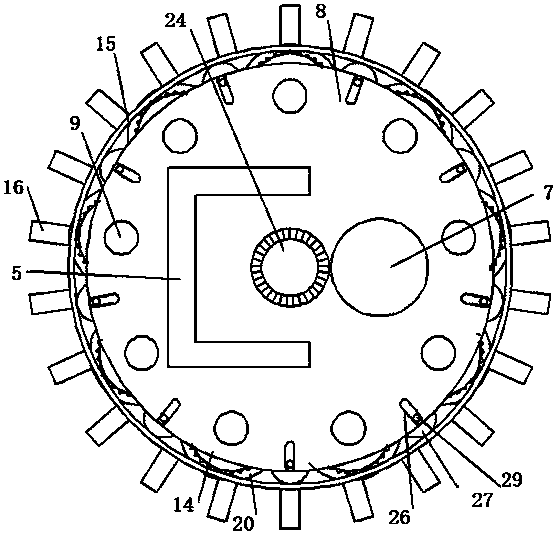

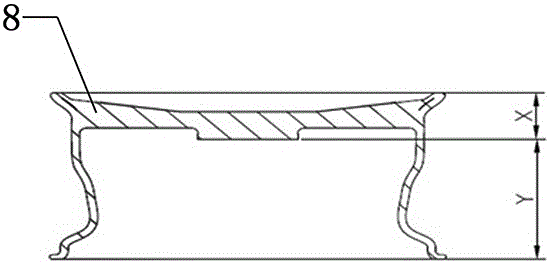

Multi-station assembling mold and process for necking and bulging elastic spacer of rear driving axle of automobile

InactiveCN110814169AExtend your lifeIncrease productivityShaping toolsVehicle componentsStructural engineeringWasher

The present invention relates to a multi-station assembling mold and process for necking and bulging an elastic spacer of a rear driving axle of an automobile. The mold is divided into an upper half part and a lower half part; the upper half part includes an upper template, a washer, a guide sleeve, a discharging spring, an upper backing plate, an upper fixing plate, a bulging upper limit block, anecking guide core and a bulging upper mold; and the lower half part includes a guide post, a necking positioning plate, a lower fixing plate, a necking die, a necking lower top plate, an ejector rod, a bulging lower die, a bulging lower limit block, a lower backing plate and a lower template. In the mold of the present invention, a mold calibration spigot that automatically calibrates the mold bulging gap is used, and the upper mold is provided with a discharging spring, so that the bulged workpiece is not adhered to the bulging upper mold and the like; and a traditional two-step process iscombined into a multi-station combination process, the production efficiency is improved by 47%, the service life of the mold is increased by 2.6 times, and the product quality is stable.

Owner:JIANGXI JIANGLING CHASSIS CO LTD

Scaffold diagonal-bracing fastener and sliding sleeve thereof

The invention relates to the field of scaffold fasteners, in particular to a scaffold diagonal-bracing fastener and a sliding sleeve thereof. The fastener comprises the sliding sleeve which can be sleeved on a scaffold steel tube in a sliding manner, wherein two hinged supports, which are assembled with pressure covers and hasps in a hinged way respectively, are oppositely arranged at the outer side of the sliding sleeve; the hinged axes of the hinged supports are parallel to each other and spatially crossed with the central line of the sliding sleeve; a set included angle of 30 degrees to 60 degrees is formed between the central line of the sliding sleeve and each of the hinged axes of the two hinged supports; a containing port for containing the scaffold steel tube is enclosed by the upper parts of the two hinged supports; an expansion block installation slot is enclosed by the lower parts of the two hinged supports; an opening is formed in the sleeve wall of the sliding sleeve at a position between the two hinged supports; a pressing slide block for pressing the scaffold steel tube in the sliding sleeve is assembled in the opening; and an expanding slide block which is wedged between the scaffold steel tube in the containing port and the pressing slide block is assembled in the expansion block installation slot. The scaffold diagonal-bracing fastener simultaneously has the characteristics of being convenient to operate, reliable in fixation and unlikely to lose.

Owner:朱新伟

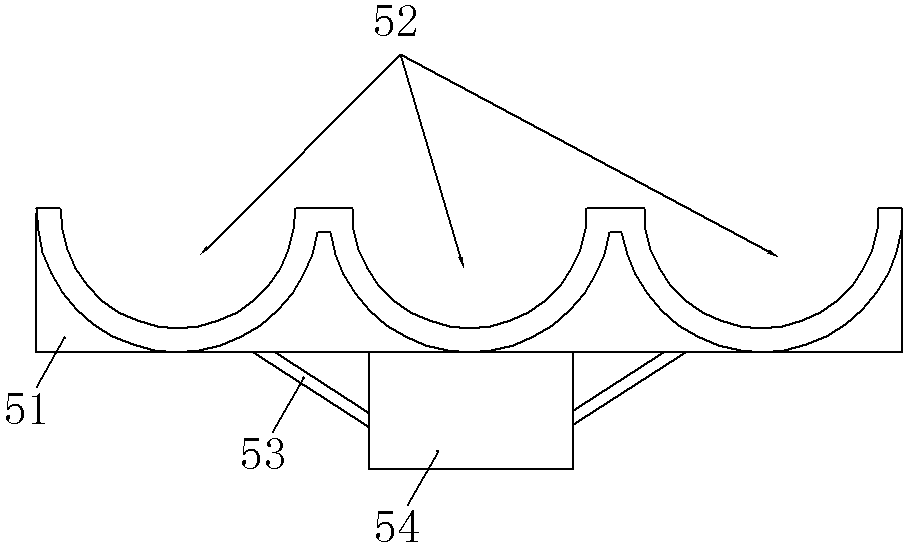

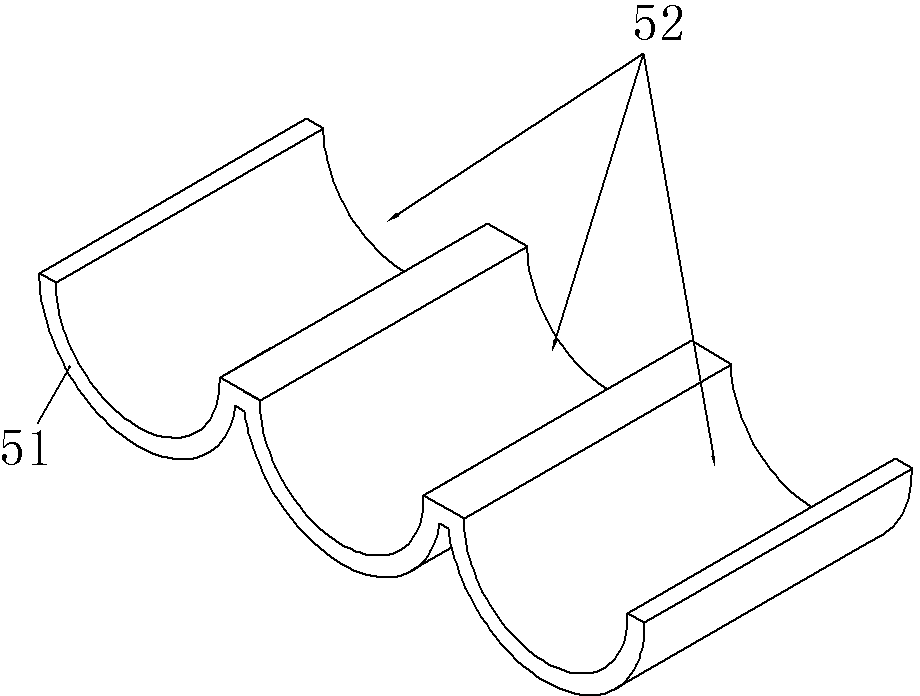

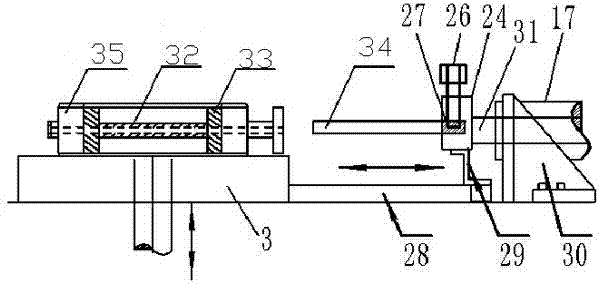

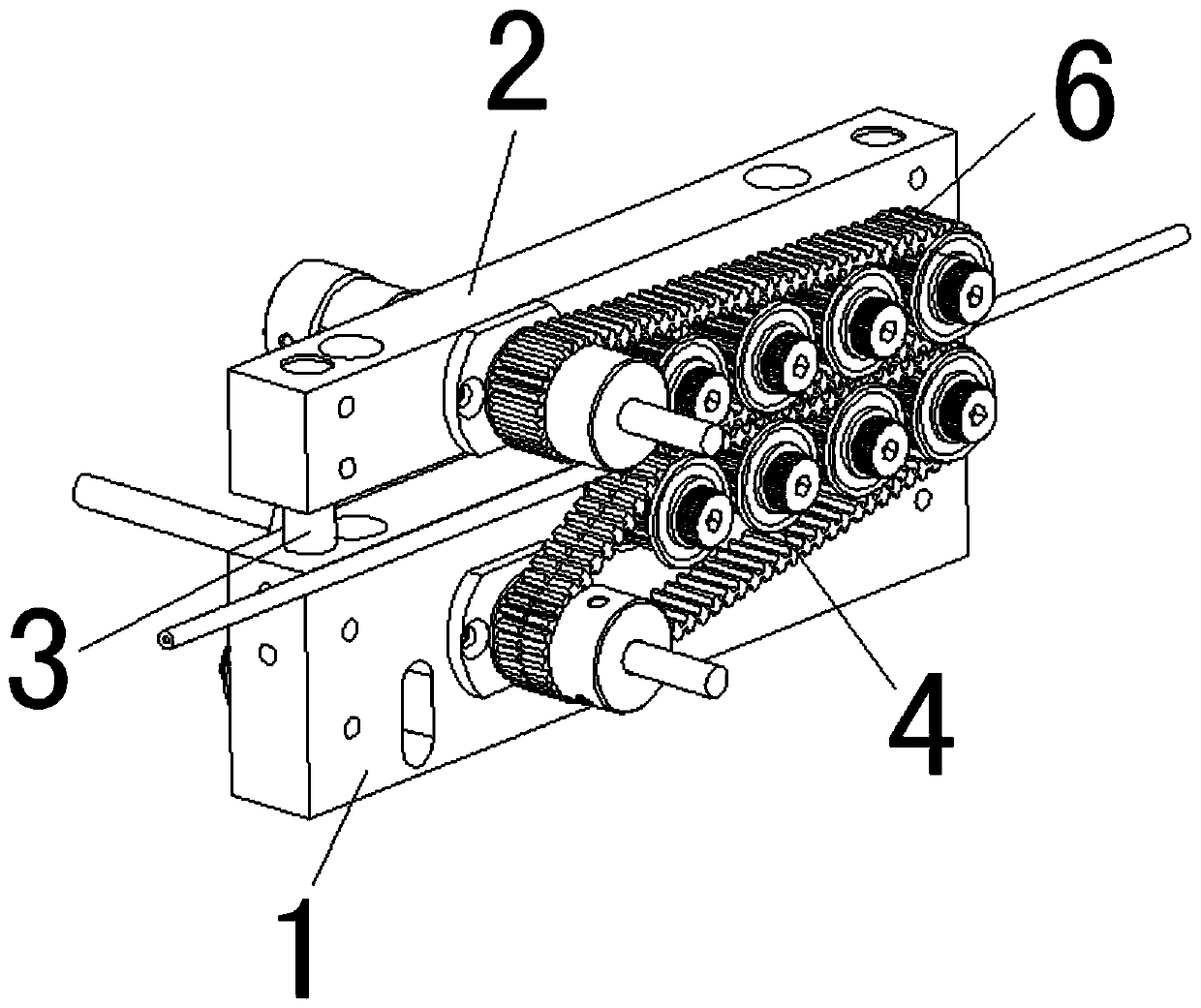

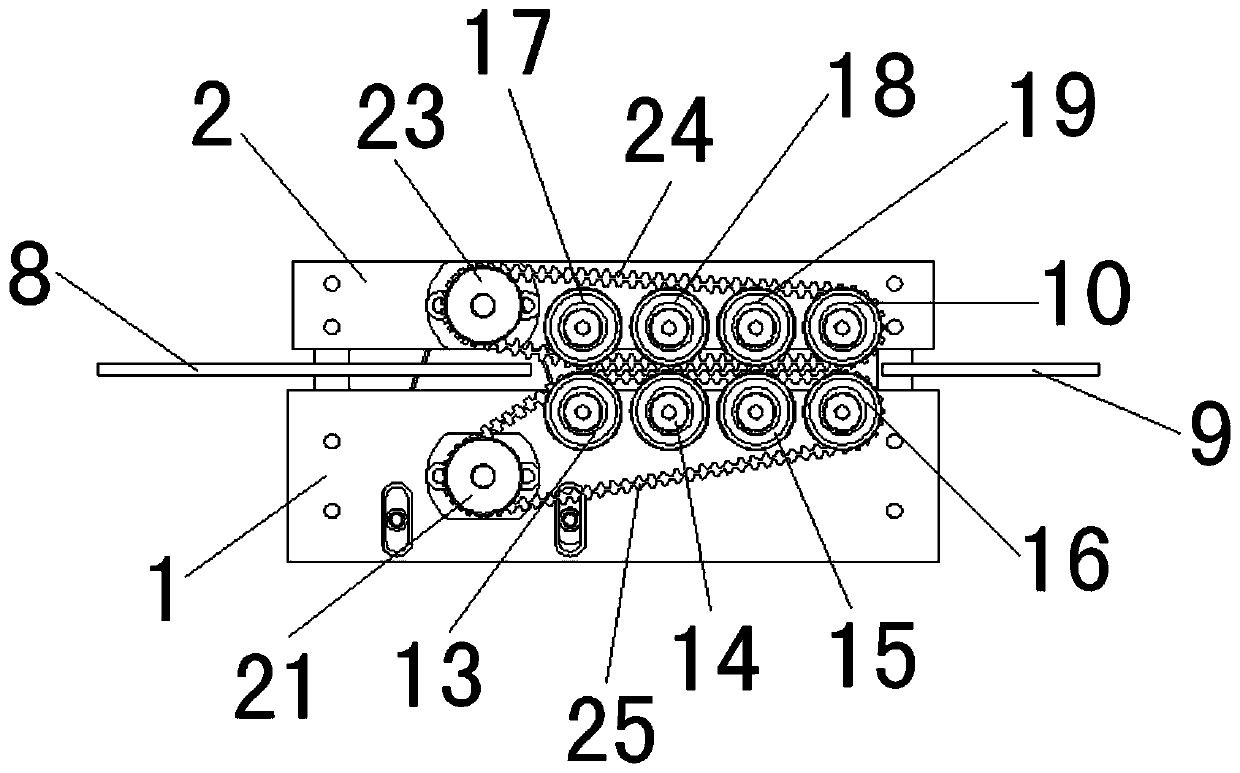

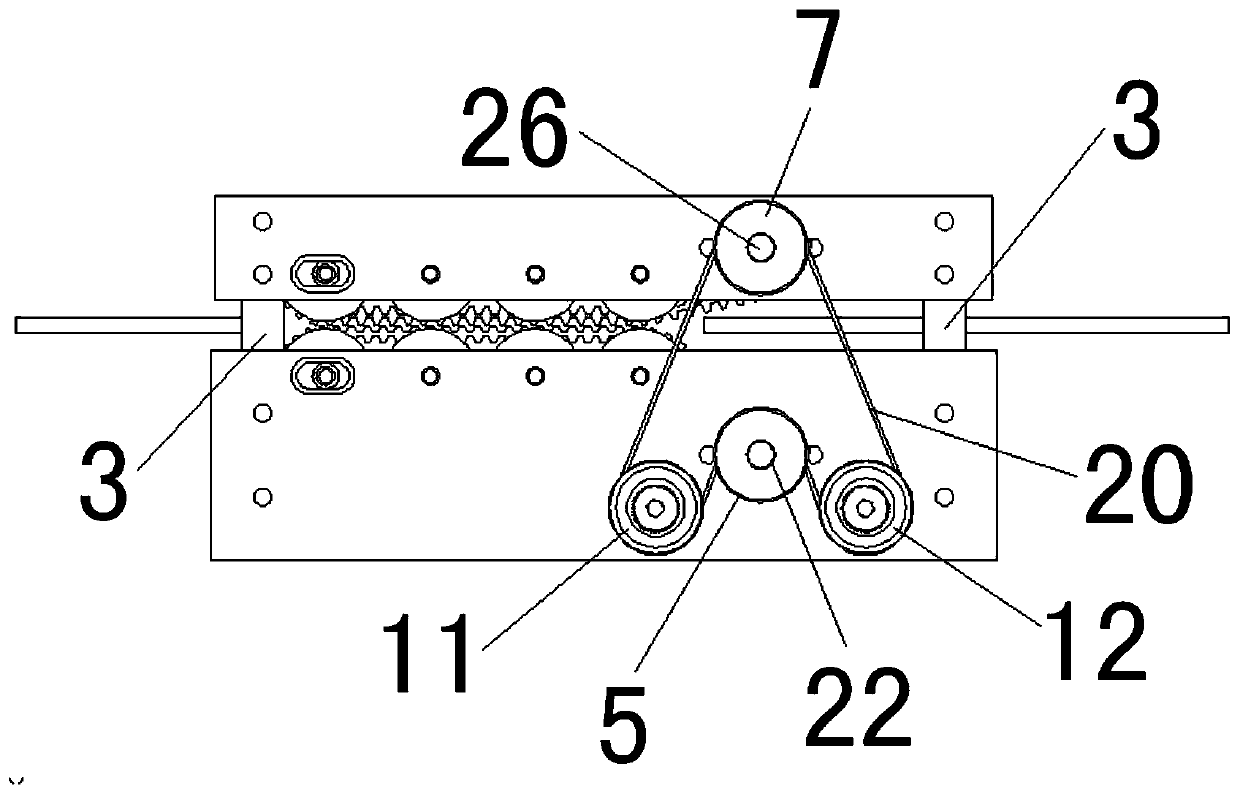

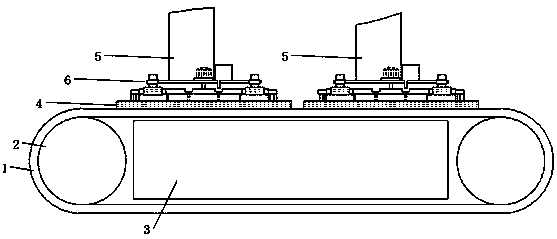

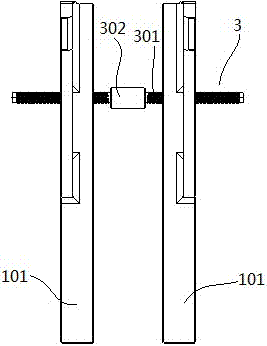

Belt wheel type pipe conveying structure

PendingCN111361924AAvoid squishingAvoid pressure deformationConveyorsConveyor partsDrive wheelElectric machinery

The invention discloses a belt wheel type pipe conveying structure. The belt wheel type pipe conveying structure comprises a lower installation block, an upper installation block, an installation column, a first transmission wheel assembly, a motor driving wheel, a second transmission wheel assembly, a pipe pressing driving wheel, a casing pipe input guide pin, a casing pipe output guide pin, a first transmission wheel, a second transmission wheel and transmission belts. By means of the overall structural design, enough frictional force still can be provided for smoothly conveying and pushingout casing pipes on the premise of keeping the shape of the casing pipes and preventing the casing pipes from extrusion deformation, and besides, the belt wheel type pipe conveying structure is suitable for conveying various casing pipes with different diameters and different specifications while achieving automatic pipe conveying; the whole pipe conveying process does not require workers to participate in operation, and the belt wheel type pipe conveying structure has the advantages that the pipe conveying efficiency is high, the pipe conveying effect is good, the pipe conveying process is smooth, and it can be ensured that the casing pipes are prevented from extrusion deformation; and moreover, the belt wheel type pipe conveying structure solves the problems of low pipe conveying efficiency and high labor intensity of workers of a traditional manual pipe conveying mode, and also solves the problem that the casing pipes are often flattened in a present pipe conveying mechanism.

Owner:苏州创易技研股份有限公司

Manufacturing method for integrally forming carbon fiber composite material pump body and impeller for pump

The invention provides a manufacturing method for integrally forming a carbon fiber composite material pump body and an impeller for a pump. The manufacturing method comprises the following steps that1, the carbon fiber material with a proper specification is prepared; 2, MgO, a curing agent, a low-shrinkage agent and a wetting dispersant are added into an epoxy vinyl resin raw material, and themixture is stirred for 2-4 h at the normal temperature and fully mixed; 3, the carbon fiber material is mixed with the mixture; 4, the temperature of a molding press is raised to a preset temperature,and a mold is preheated; 5, a mixing material is put into a preheated pump body mould pressing mold or ab impeller mould pressing mold, and mold closing is performed; and 6, the mixing material is pressurized and heated to a preset temperature, the temperature is kept, and after cooling, demolding is performed. According to the method, the complexity of the forming process of the carbon fiber composite material pump body and the impeller for the pump is greatly reduced, integral forming is achieved, the problems of gluing and bolt fastening connection are solved, the structural strength of the pump body and the impeller is enhanced, the problems of low structural strength, pressure-bearing deformation, cracking, leakage and the like are solved, the manufacturing process is simple, the cost is low, and the application prospect is wide.

Owner:殷艾伯特

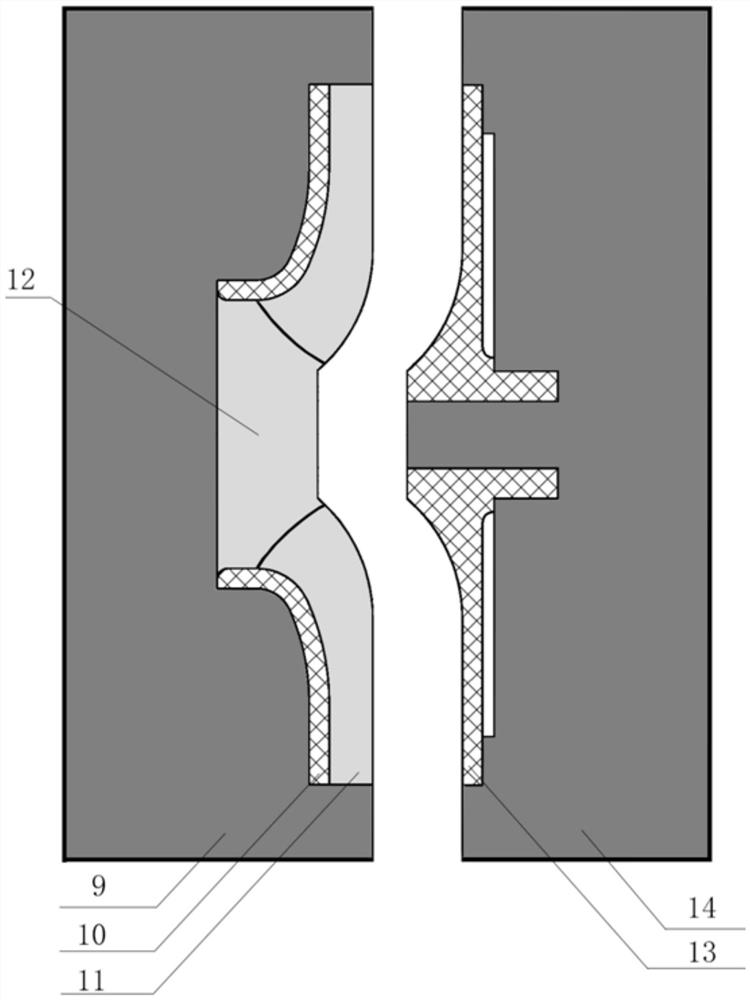

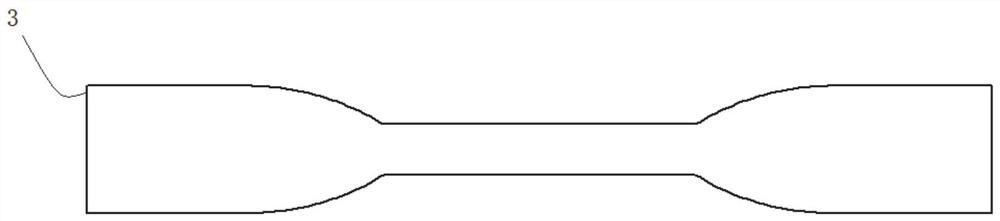

Cutting knife, device and method for manufacturing dumbbell sample for cable detection

PendingCN113829435ARealize automated manufacturingAvoid pressure deformationPreparing sample for investigationMetal working apparatusKnife bladesStructural engineering

The invention provides a cutting knife, device and method for manufacturing a dumbbell sample for cable detection. The cutting knife comprises a first pressing device, a second pressing device and a blade. A dumbbell-shaped space is formed between the first pressing device and the second pressing device. The blade is arranged in the dumbbell-shaped space, and the two sides of the blade are connected with the first pressing device and the second pressing device through sliding mechanisms respectively. Automatic manufacturing of the dumbbell sample of a cable insulating layer can be achieved, and the problem of pressurization deformation happening during cutting of the cable insulating layer is avoided through the pressing devices.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

Glaze polishing grinding tool for processing ceramic tiles

ActiveCN108972277AAchieve a polished effectAvoid defectsPolishing machinesGrinding machinesMechanical engineeringCeramic tiles

The invention discloses a glaze polishing grinding tool for processing ceramic tiles. The glaze polishing grinding tool comprises a first support, a transmission shaft, a transmission belt and a polishing portion. The polishing portion comprises a round support plate. A motor is connected to the center of the top of the support plate. A rotating disc is connected to a shaft of the motor. A round first grinding head is fixedly connected to the middle of the lower portion of the rotating disc. A ringlike second grinding head is fixedly connected to the outer side of the lower portion of the rotating disc. A ringlike annular tooth portion is connected to the outer side of the rotating disc. Multiple bearing seats are connected to the support plate, wherein the bearing seats are arranged in the annular form. A rotating shaft is movably arranged on each bearing seat in an inserted manner. A first gear is connected to each rotating shaft. The first gears are engaged with the annular tooth portion. A round third grinding head is fixedly connected to the bottom of each rotating shaft. A chain is arranged at the outer sides of the multiple first gears in a sleeving manner. Multiple connecting blocks are connected to the outer side of the chain, wherein the connecting blocks are uniformly arranged. A brush is connected to the lower portion of each connecting block. By means of the glazepolishing grinding tool, defects of the prior art can be overcome, and the problem that surface defects of the ceramic tiles are caused due to the singular grinding action is avoided.

Owner:重庆众越装修工程有限公司

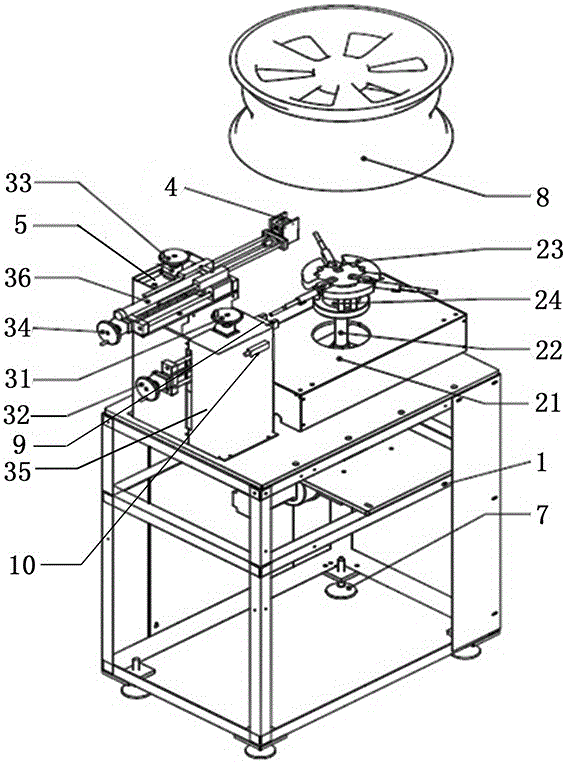

A high-efficiency rim rotary automatic positioning device

ActiveCN105058138BLow environmental requirementsReduce false positive rateMeasurement/indication equipmentsMetal working apparatusLaser rangingEngineering

The invention discloses an efficient rim rotation type automatic positioning device. The efficient rim rotation type automatic positioning device comprises a rack, a positioning mechanism and an adjusting mechanism. The positioning mechanism and the adjusting mechanism are arranged on the rack, and the adjusting mechanism is further provided with a laser range finder. The efficient rim rotation type automatic positioning device is reasonable in structure, reliable in performance, capable of being used for detecting various rims in different specifications, preventing materials from being mixed and detecting whether materials exist, and high in automation degree, and efficiency is greatly improved.

Owner:铁王数控机床(苏州)有限公司

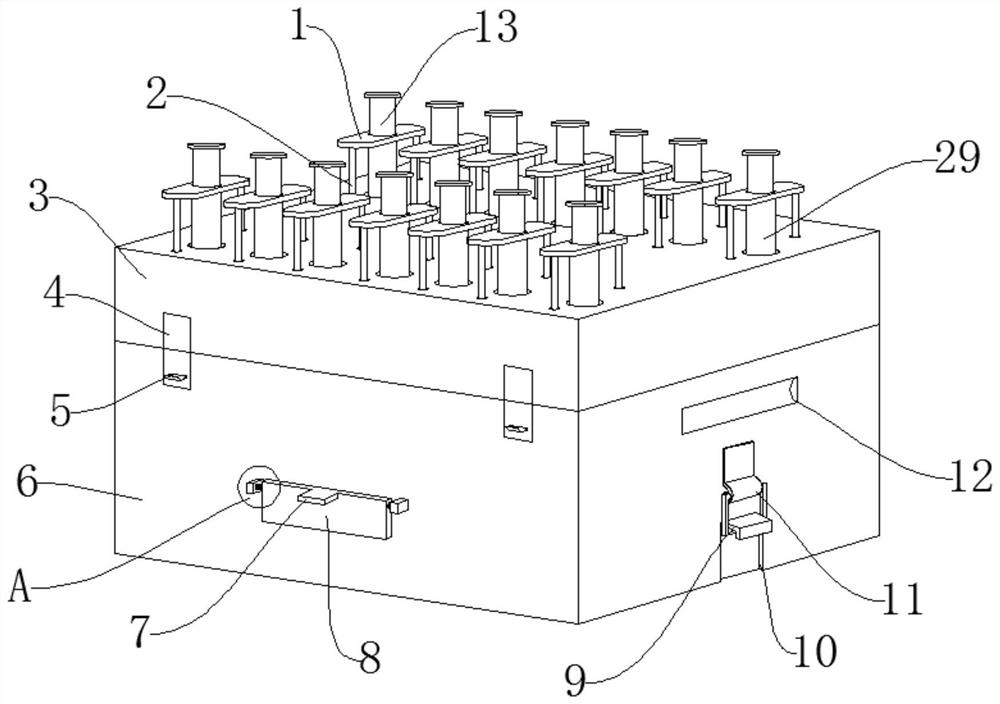

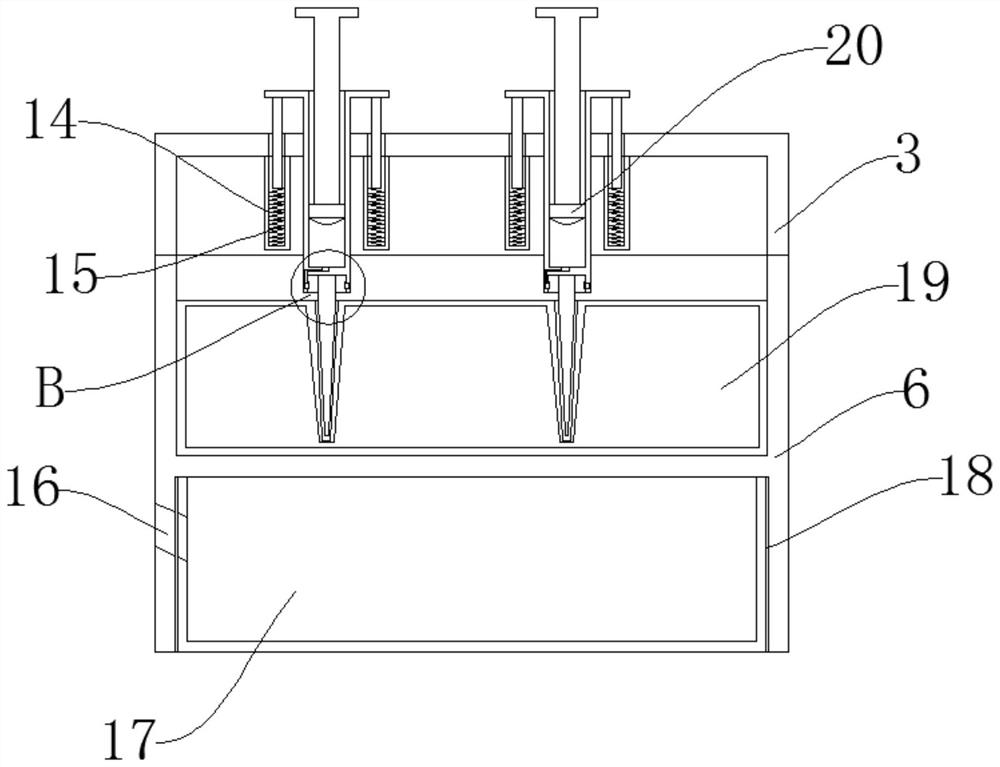

A quick storage box for pipette tips and its usage method

ActiveCN112169857BQuick grip and takeGuaranteed accuracySupporting apparatusAirbagIndustrial engineering

The invention discloses a storage box for quickly sorting the tip of a pipette gun and a method for using it, which includes a box body, a clamping table, an elastic air bag and a collection box. The collection box is provided. The beneficial effect is that: by setting the cylinder body, the pinch table, the telescopic rod, the spring, the sleeve rod, the clamping table and the elastic bag pad, the quick clamping and taking of the pipette tips one by one can be realized, and at the same time, the pipette tips are effectively Avoiding the exposure of other unused tips, thereby effectively avoiding the risk of contamination of other unused tips and ensuring the accuracy of the subsequent use of the tips; by setting the design of the support column, elastic air bag and installation groove, not only can pass through all The elastic action of the elastic airbag realizes the clamping of different types of gun heads, and through the function of the support column, the pressurized deformation of the gun heads during storage is effectively avoided, ensuring the storage quality of the gun heads.

Owner:SOUTHWEST MEDICAL UNIVERISTY

Air conditioner

ActiveCN101749796BAvoid pressure deformationEasy to disassembleLighting and heating apparatusAir conditioning systemsEngineeringElectrical and Electronics engineering

Owner:GREE ELECTRIC APPLIANCES INC

A butterfly valve assembly machine stem hydraulic automatic combination device and its combination method

ActiveCN104742079BAvoid pressure deformationSimple structureMetal-working hand toolsHydraulic cylinderAutomatic control

Provided are an automatic electrohydraulic control butterfly valve assembly machine and an assembly method thereof. Use is convenient, assembly procedures are less, operation is fast, and the host machine pressure can be regulated in time according to butterfly valves with different types and specifications; the working efficiency and quality are greatly improved, and the economic benefit is good; because a PLC is adopted to perform automatic control, the man-machine security coefficients are high, the assembly is accurate, a large amount of time and a large number of energy resources are saved, the maintenance cost and the production cost which are caused by wear are reduced, the engine performance is obviously improved, the service life is obviously prolonged, and popularization is convenient. The automatic electrohydraulic control butterfly valve assembly machine is composed of a butterfly assembly workbench, an infrared induction security device, a tooling base, an assembly machine stand column, a pressure head tool, a pressure regulation valve device, an upper oil cylinder support frame, a pressure gauge device, an upper hydraulic cylinder device, a PLC control box device, control buttons, an electrical box device, a butterfly valve tool, a locking nut mechanism and a pressing lead screw assembly.

Owner:BAND VALVE TECH CO LTD

A device for unpacking

Owner:WUHAN WUYAO SAFETY GLASS CO LTD

Scaffold cross-bar used for supporting girder formwork

InactiveCN103233576BRealize top supportImprove building construction efficiencyForms/shuttering/falseworksFalseworkEngineering

Owner:朱新伟

Scaffold diagonal-bracing fastener and sliding sleeve thereof

The invention relates to the field of scaffold fasteners, in particular to a scaffold diagonal-bracing fastener and a sliding sleeve thereof. The fastener comprises the sliding sleeve which can be sleeved on a scaffold steel tube in a sliding manner, wherein two hinged supports, which are assembled with pressure covers and hasps in a hinged way respectively, are oppositely arranged at the outer side of the sliding sleeve; the hinged axes of the hinged supports are parallel to each other and spatially crossed with the central line of the sliding sleeve; a set included angle of 30 degrees to 60 degrees is formed between the central line of the sliding sleeve and each of the hinged axes of the two hinged supports; a containing port for containing the scaffold steel tube is enclosed by the upper parts of the two hinged supports; an expansion block installation slot is enclosed by the lower parts of the two hinged supports; an opening is formed in the sleeve wall of the sliding sleeve at a position between the two hinged supports; a pressing slide block for pressing the scaffold steel tube in the sliding sleeve is assembled in the opening; and an expanding slide block which is wedged between the scaffold steel tube in the containing port and the pressing slide block is assembled in the expansion block installation slot. The scaffold diagonal-bracing fastener simultaneously has the characteristics of being convenient to operate, reliable in fixation and unlikely to lose.

Owner:朱新伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com