Double-pole scaffold system

A technology of scaffolding and poles, applied in the field of construction scaffolding, which can solve the problems of reducing the efficiency of building and dismantling double-row scaffolding, loss of wedges, and poor working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

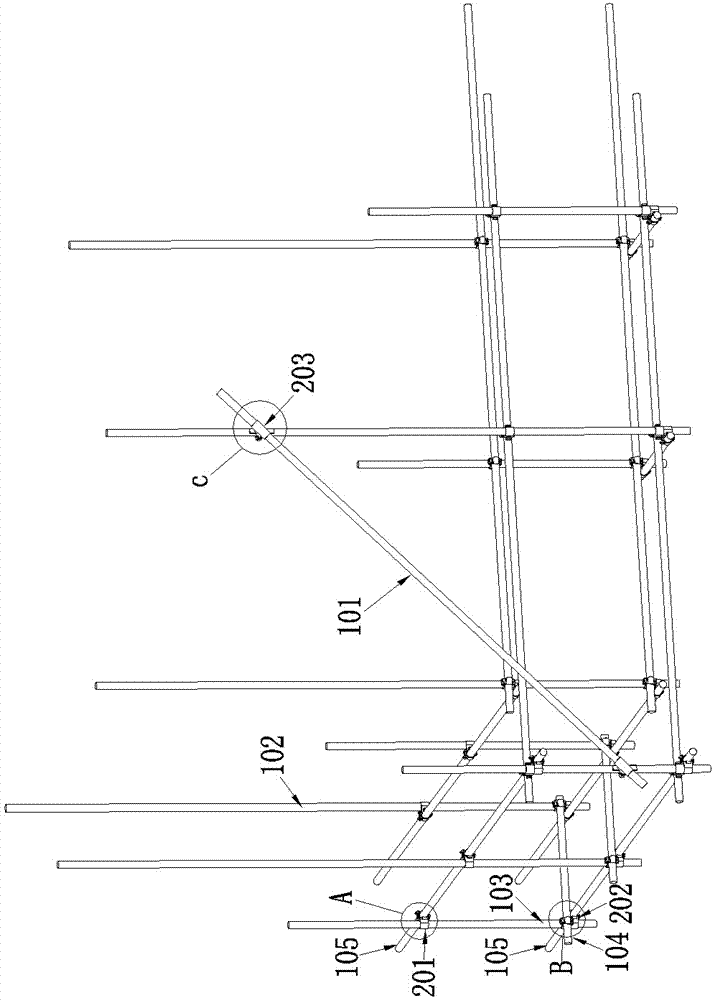

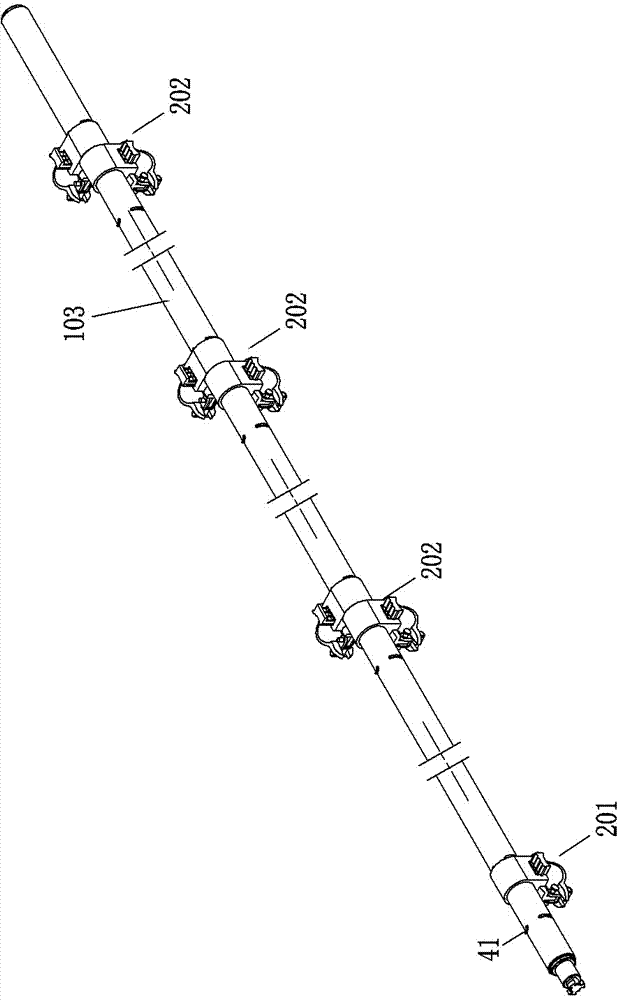

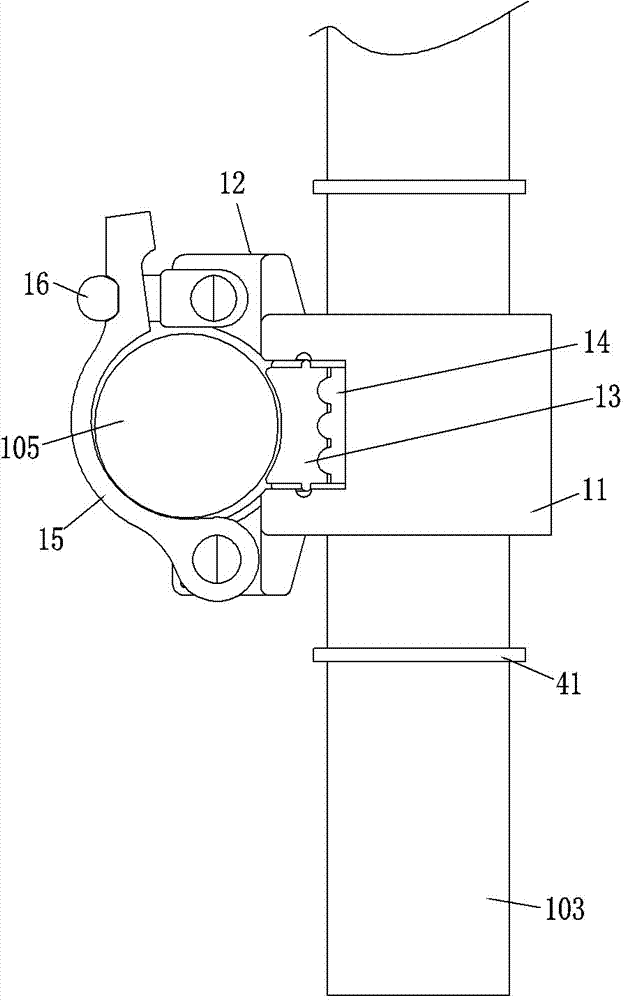

[0047] Examples of double-row scaffolding systems, such as Figure 1-24 As shown, it includes diagonal struts 101, vertical rods and horizontal rods, the vertical rods are divided into inner row vertical rods 102 and outer row vertical rods 103, and the horizontal rods are divided into longitudinal horizontal rods 104 and horizontal horizontal rods 105, wherein the inner row vertical rods 102 intersects with the corresponding vertical and horizontal horizontal bars, and the outer row of vertical bars and the corresponding vertical and horizontal horizontal bars intersect each other to form a cross-shaped node (the vertical bar only intersects vertically with one horizontal bar at the same position) or Spatial nodes (vertical intersections between the vertical bars and the horizontal horizontal bars and vertical horizontal bars at the same position, and the horizontal horizontal bars and longitudinal horizontal bars here are also vertically intersected. The arrangement of vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com