Cutting knife, device and method for manufacturing dumbbell sample for cable detection

A dumbbell sample and manufacturing device technology, which is applied in the preparation of test samples, measuring devices, sampling, etc., can solve problems such as pressure deformation, and achieve the effects of improving efficiency, avoiding deformation, and reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

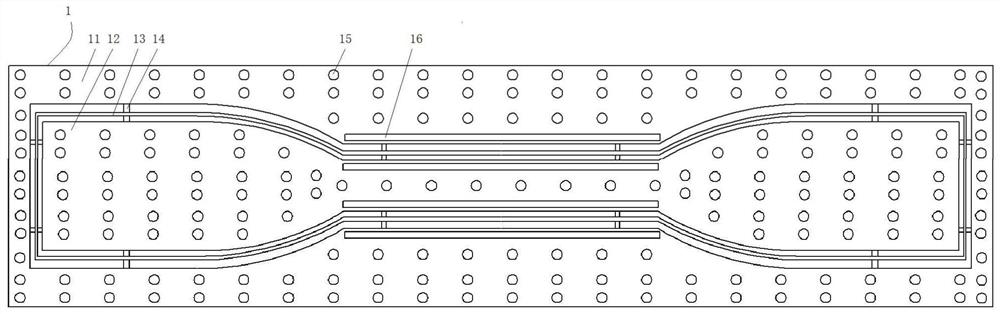

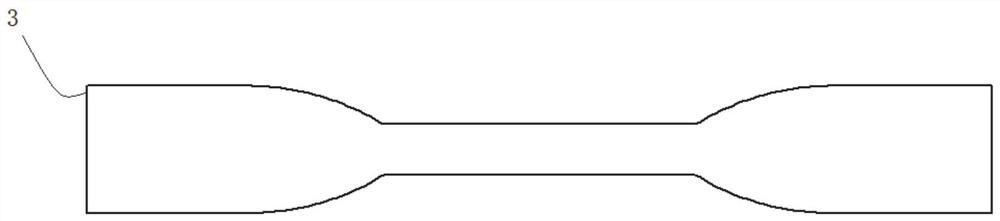

[0041] Such as figure 1 As shown, the present disclosure provides a dumbbell sample making cutter for cable detection, which adopts the following technical solution:

[0042] A dumbbell sample making cutter for cable detection, comprising a first pressing device 11, a second pressing device 12 and a blade 13;

[0043] A dumbbell-shaped space is formed between the first pressing device 11 and the second pressing device 12; The pressing device 11 is connected with the second pressing device 12 through a sliding mechanism 14 .

[0044] Specifically, the overall structure of the first pressing device 11 is a rectangular metal block, and a through hole with a dumbbell-shaped cross-section is provided in the middle of the rectangular block, and the 12-bit metal block with a dumbbell-shaped cross-section in the second pressing and pressing device; The second compression compression device 12 is arranged in the through hole of the dumbbell shape; when working, the first compression ...

Embodiment 2

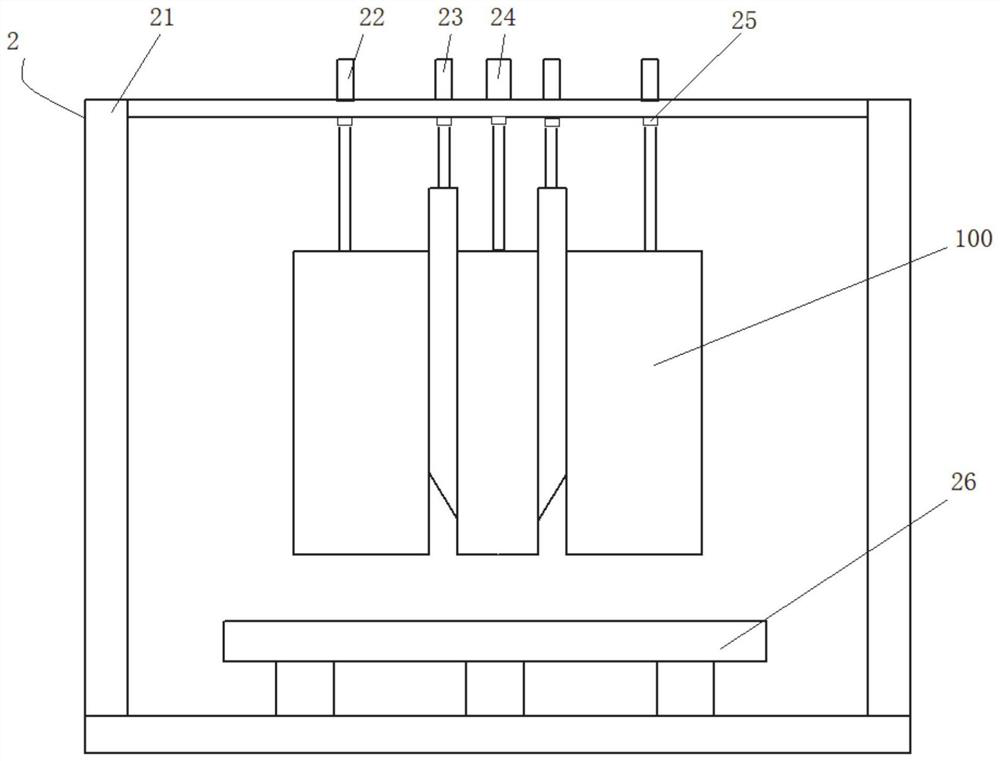

[0050] Such as image 3 As shown, the present embodiment provides a dumbbell sample making device for cable detection, including a frame 21, a backing plate 26, a first power unit 22, a second power unit 24, a third power unit 23 and as in the embodiment cutter 1 as described in 1;

[0051] The backing plate 26 is arranged at the lower end of the frame 21, and the first pressing device 11, the second pressing device 12 and the blade 13 pass through the first power device 22 and the second pressing device 22 respectively. The power unit 24 and the third power unit 23 are arranged on the upper end of the frame 1 .

[0052] Specifically, when working, firstly, the first pressing device 11 and the second pressing device 12 compress the cable sheath on the backing plate 26 under the action of the power device, and then the blade 13 Under the action of the power device, the charging action is realized.

[0053] In this embodiment, a dumbbell-shaped groove 2601 corresponding to th...

Embodiment 3

[0058] This embodiment provides a method for making a dumbbell sample for cable detection, using the dumbbell sample making device 2 as described in Example 2; the main contents include:

[0059] Measure the thickness of the sample of the cable sheath to be cut to ensure that the thickness is equal in each area;

[0060] Specifically, the measurement of the thickness of the sample of the cable sheath adopts the existing technology, for example, it can be obtained by measuring at different positions with a vernier caliper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com