Slitter machine unrolling fixing device and high-speed slitter machine

A technology of fixing device and slitting machine, which is applied in the direction of winding strips, transportation and packaging, thin material handling, etc. problems, to achieve the effect of reducing replacement, smooth operation and high versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

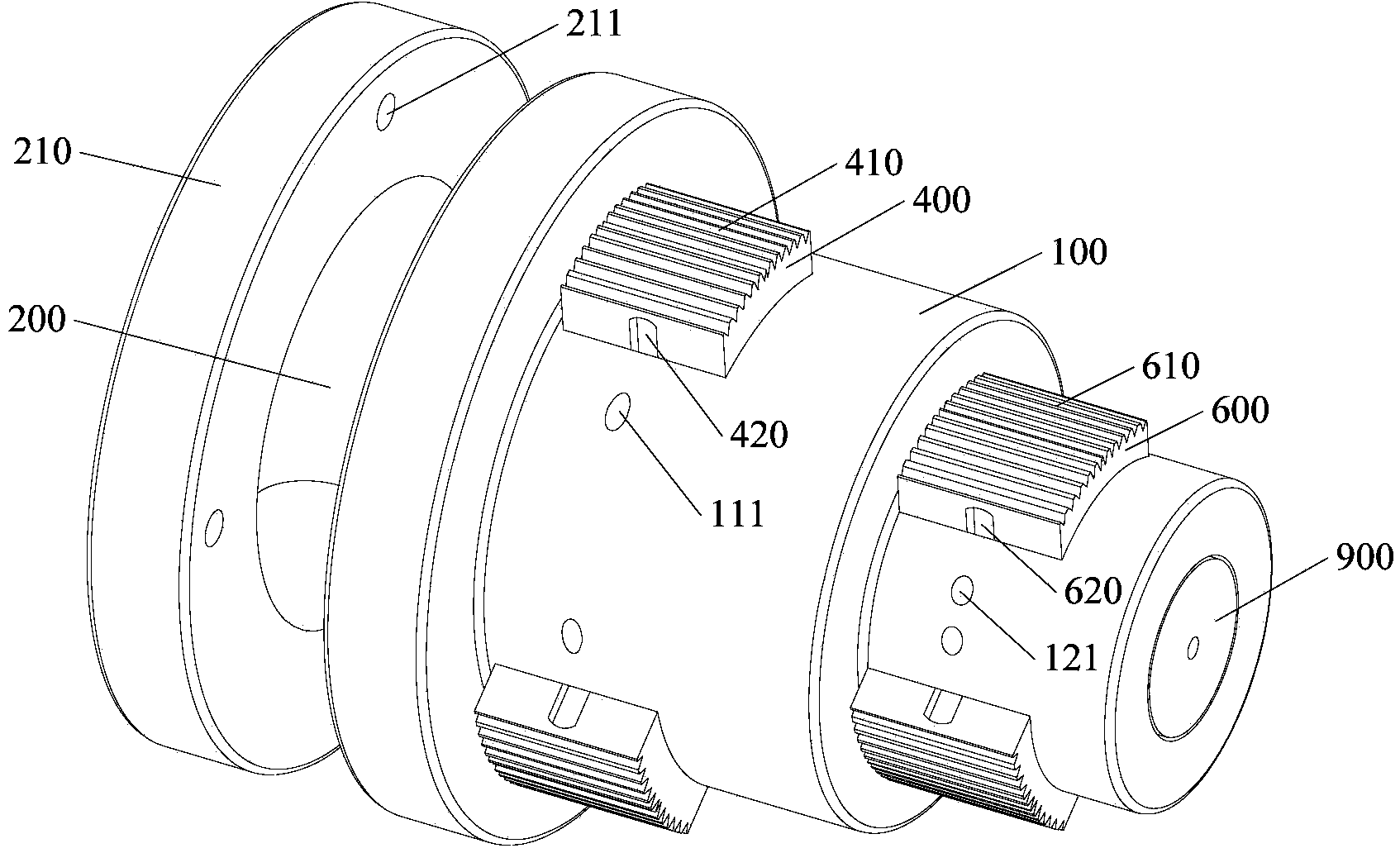

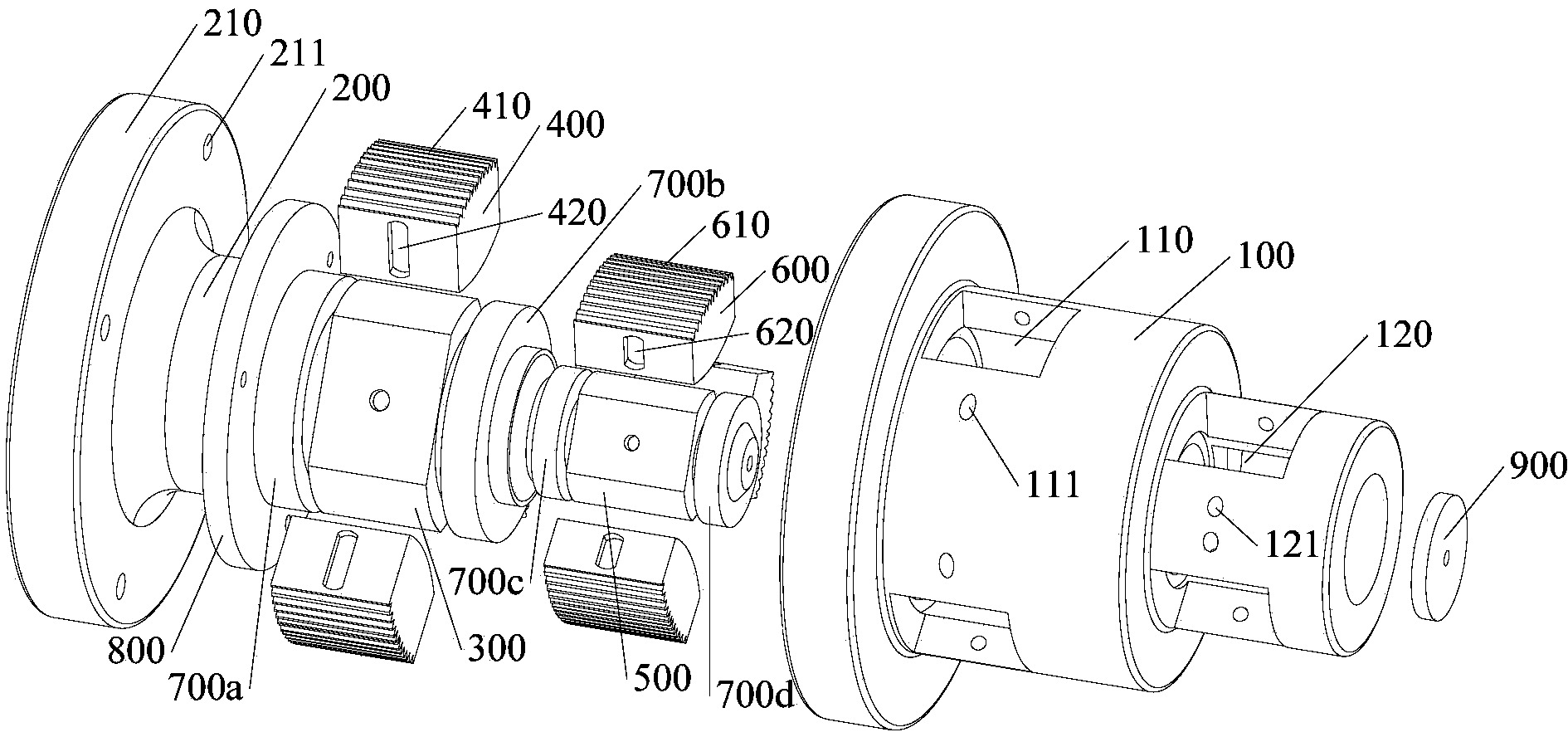

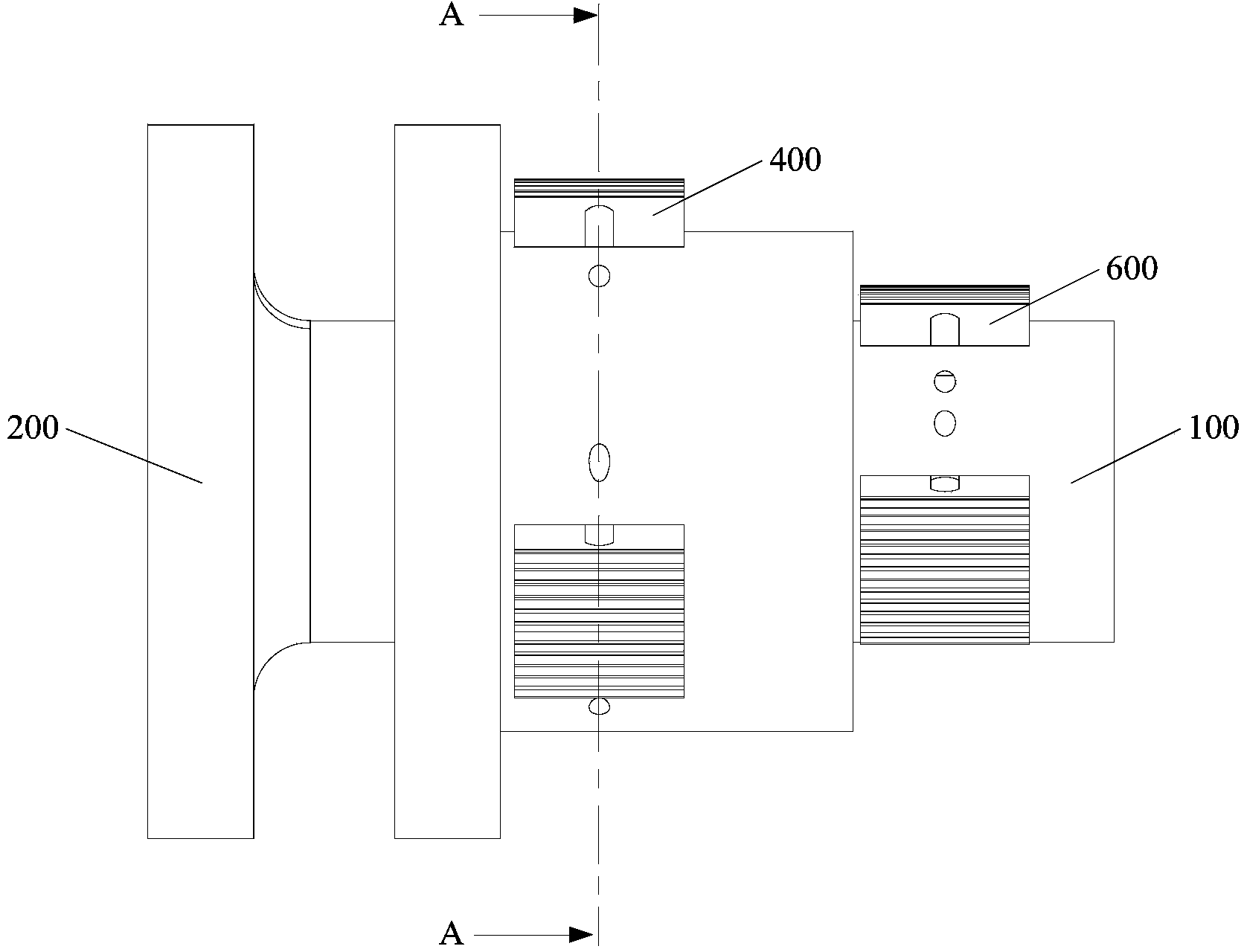

[0022] The invention provides a slitting machine unwinding and fixing device, see figure 1 and figure 2 , in one embodiment, the slitter unwinding fixture includes a cylindrical shell 100 and a central shaft 200 rotatably installed in the shell 100, considering the durability of the slitter unwinding fixture The problem is that both the shell 100 and the central shaft 200 are made of metal materials, such as carbon steel, stainless steel, etc., and one end of the central shaft 200 is provided with a mounting flange 210, through which the slitting machine can be unwound and fixed. Installed on the supporting slitting machine (for example, a high-speed slitting machine), in order to facilitate installation and disassembly, the mounting flange 210 is fastened on the corresponding parts of the slitting machine by bolts,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com